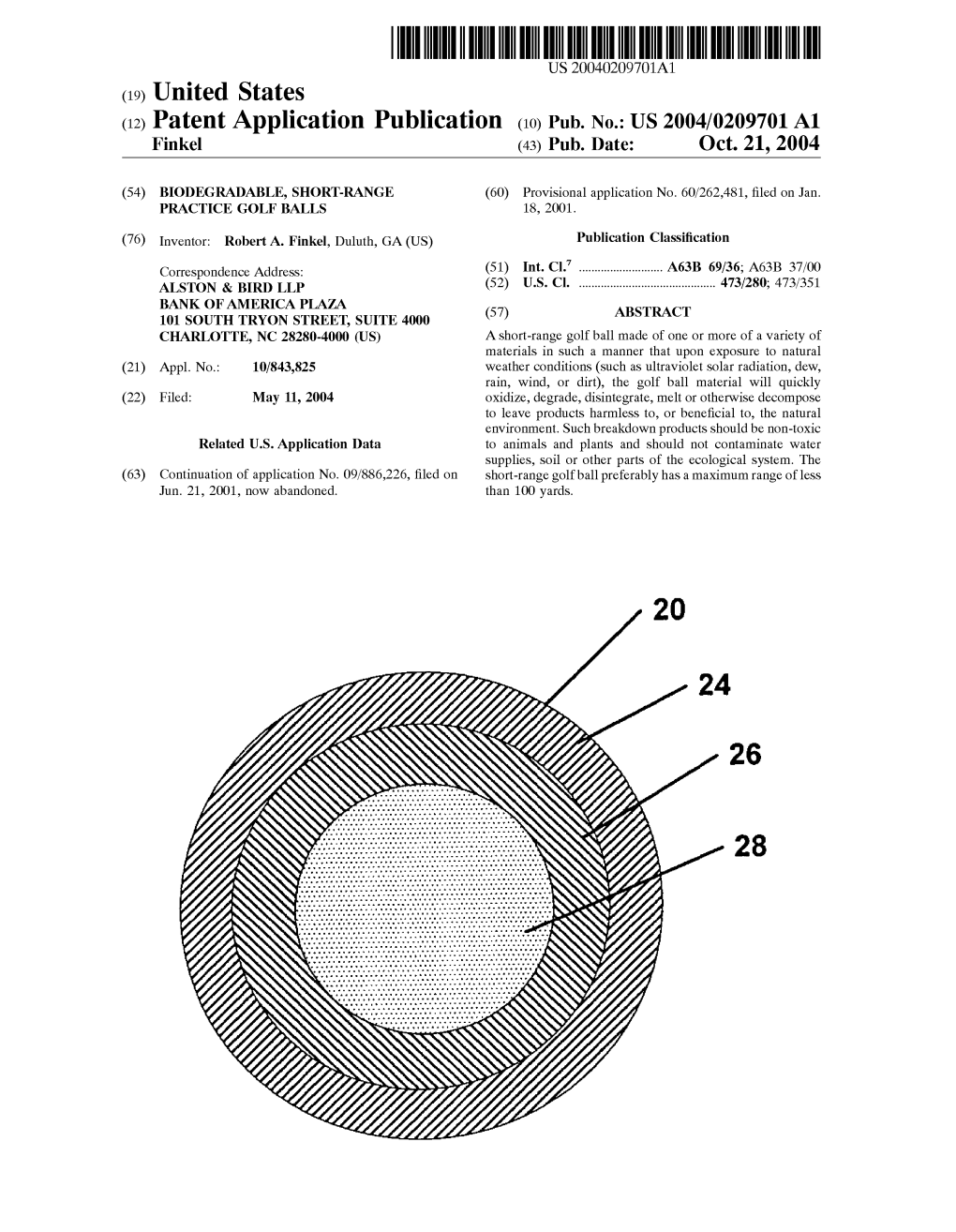

(12) Patent Application Publication (10) Pub. No.: US 2004/0209701 A1 Finkel (43) Pub

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Recreation Group Dynamics and Outdoor Skills Leadership

Recreation Group Dynamics and Outdoor Skills Leadership Workbook compiled by Sid Stevenson, Ph.D., CPRP 12th edition, 2006 -1- ii TABLE OF CONTENTS CHAPTER I LEADERSHIP PHILOSOPHY AND THEORY -1- What is Leadership? -1- How does a leader assume this role -2- RECREATION REVIEW -5- Needs likely satisfied by recreation experiences -10- WHY DO WE ENGAGE IN RECREATION EXPERIENCES? -11- THEORIES .............................................................................. -11- LEADERSHIP STYLES -14- COMPARISON OF FOUR CONTEMPORARY LEADERSHIP/COMMUNICATION STYLES -15- APPROPRIATENESS OF LEADERSHIP STYLE -18- Determining Your Predominant Leadership Style A checklist approach DETERMINING YOUR LEADERSHIP STYLE (DPST. MODEL) -25- Principles of Recreation Leadership -26- Recreation leaders should possess the following qualities: -27- Career Settings for Recreation Leaders -28- Levels of Leadership in Recreation -30- PROFESSIONALISM -33- Accreditation ............................................................................. -33- CHAPTER II GROUP DYNAMICS -35- Elements of Groups -36- Comparison of effective and ineffective groups -37- Correcting problems in group effectiveness -37- Stages of Group Growth -38- IDENTIFYING THE ROLES PLAYED IN GROUPS -39- CHAPTER III TEACHING METHODS AND TYPES OF LEARNING -40- TYPES OF LEARNING -40- TEACHING STRATEGIES -41- Writing Performance Objectives* -42- DRILL and PRACTICE -47- A SAMPLE PLAN FOR A YOUTH BASEBALL PRACTICE ...................................... -47- Evaluating a Practice Plan -48- COACHING YOUNG -

Wilderness House Literary Review 6/4 Dewitt Henry on GOLF Golf

Wilderness House Literary Review 6/4 DeWitt Henry ON GOLF Golf was as central to my childhood’s family in the 1950’s as swim- ming, writing, drawing and painting, or the candy factory that my grand- father had started and that my father now ran. There were always golf clubs, golf bags, golf balls, putters, wiffle golf balls, rubber targets for putting on rugs, golf shoes with cleats, fingerless golf gloves, and green sun visors around our house, mostly in the down- stairs closet (a huge closet, where umbrellas, overcoats, dad’s felt hats, and mom’s special silver fox stole and its fox-head clasp hung). There were also trophies from past tournaments, a crystal dish for cigarettes with a silver lid; three or four crystal ashtrays with silver rims; a silver cup with winged handles; a golden figurine of a golfer on a wooden base, with a little plaque. Mom, Chuck (my second oldest brother), and Dad would practice their swings outside. Dad and Chuck would practice chip shots in the side yard, careful not to make divots. Jack (my oldest brother) and Judy (my sister, older than me, younger than Chuck) never played. Jack was absorbed by his cars and by hunting, Judy by swimming and reading. Chuck had been Junior Club Champion, and several of the ashtrays were his. He had his own set of clubs, his own golf shoes. My mother’s financier father, Jerome Thralls, had played on Long Island, and when my mother was a teenager she had walked the course with him. -

Player Core Lesson # 1 Welcome & Showing Respect

PLAYer Core Lesson # 1 Welcome & Showing Respect Coach Name: Lundy Chapter: Indiana Facility: Gongaware Date: 4/14/15 # of Coaches/Volunteers: 1 Coach # Participants: 4 Age Range: 7-11 Skill Level: 3 Player 1 Par PLAYer-to-Coach ratio:4 to 1 X 3-hole 6-hole 9-hole # of Stations/# of Holes: 1 X On-course Off-course Duration (mins.): 60 Equipment and supplies needed: Cones, Range Baskets, Various types of balls, Putters & Irons Additional Notes: Just used putting green and area next to putting green to make swings with club. Warm-up Time Allotted: 15 Minutes Location(s): Putting Green Welcome Parents and tour facility for bathrooms Name and Fruits: Introduce yourself and give favorite fruit. Go in a circle and listen to others and remember what they say so later in the game you can say person next to you their name and favorite fruit. Physically engage PLAYers in a fitness circuit (Recommend one activity from each Category): Strength Flexibility/Mobility Agility/Coordination Balance Object Control Bowling swing Toe to knee touches Walk to pick up balls Flamingo bends to pick up Different weighted balls balls Safety – Healthy habit is safety and explain where to start, where to stand, when to move forward. At first without clubs, rolling the balls and next with clubs after they have the idea of energy needed to make the ball go a certain distance. Used very few golf balls for first lesson Life Skills Experience—The Nine Core Values Time Allotted: 40 minutes PLAY LEARN (Games/Activities (Behaviors reflective of The First Tee APPRECIATE YOUR GAME PLAYers will experience) Code of Conduct and Nine Core Values) Activity: Life Skill—Objective & Behaviors: Game of Golf: Parts of the course Get the ball in the areas by rolling Welcome and Showing Respect. -

The Walking Golfer Apr

The Walking Golfers Society is dedicated to providing information about the many benefits of walking when you golf, which is how the game was intended to be played. If you are a passionate walking golfer then please join our growing Society and help us advocate for the enjoyment of golf as a walking game. Q&A with Golf Course Architect Drew Rogers Posted by Ben Cowan - April 2018 Drew, considering you have lived in my hometown, the “Glass City” for over 20 years now, it’s extra special to be able to do this interview. I am excited to ask you a few questions about the Sylvania CC restoration/renovation. I started caddying there at the age of 12 and it enabled me to get my first car at 16 (Freedom)! Drew has been traveling all over the globe the last 20+ years working outside the US as far as Portugal. Currently he works frequently in the Midwest and Florida. In 2010, Drew formed his solo design business by the name of JDR (www.jdrewrogers.com). Prior to that, Drew spent 19 years working for Arthur Hills, collaborating on 30 new designs and 20 renovations. I have played two courses that Drew has renovated (Old Elm & Sylvania). What has impressed me, is his ability to prioritize what’s most important depending on the budget he is given. Drew’s work seems practical from a maintenance perspective while using different textures such as grass types in his presentation to achieve a pleasant artistic finish to his work. I suppose it’s time Old Elm #4 to hear from Drew… Thank you, Ben. -

Player Core Lesson # 1 Welcome & Showing

PLAYer Core Lesson # 1 Welcome & Showing Respect Coach Name: Lundy Chapter: Indiana Facility: Gongaware Date: 4/14/15 # of Coaches/Volunteers: 1 Coach # Participants: 4 Age Range: 7-11 Skill Level: 3 Player 1 Par PLAYer-to-Coach ratio:4 to 1 X 3-hole 6-hole 9-hole # of Stations/# of Holes: 1 X On-course Off-course Duration (mins.): 60 Equipment and supplies needed: Cones, Range Baskets, Various types of balls, Putters & Irons Additional Notes: Just used putting green and area next to putting green to make swings with club. Warm-up Time Allotted: 15 Minutes Location(s): Putting Green Welcome Parents and tour facility for bathrooms Name and Fruits: Introduce yourself and give favorite fruit. Go in a circle and listen to others and remember what they say so later in the game you can say person next to you their name and favorite fruit. Physically engage PLAYers in a fitness circuit (Recommend one activity from each Category): Strength Flexibility/Mobility Agility/Coordination Balance Object Control Bowling swing Toe to knee touches Walk to pick up balls Flamingo bends to pick up Different weighted balls balls Safety – Healthy habit is safety and explain where to start, where to stand, when to move forward. At first without clubs, rolling the balls and next with clubs after they have the idea of energy needed to make the ball go a certain distance. Used very few golf balls for first lesson Life Skills Experience—The Nine Core Values Time Allotted: 40 minutes PLAY LEARN (Games/Activities (Behaviors reflective of The First Tee APPRECIATE YOUR GAME PLAYers will experience) Code of Conduct and Nine Core Values) Activity: Life Skill—Objective & Behaviors: Game of Golf: Parts of the course Get the ball in the areas by rolling Welcome and Showing Respect. -

15 Easy Ways to Improve Your Golf Game

Contents Introduction .............................................................................................................................................. 3 How to Focus on the Driving Range ................................................................................................ 3 How to Improve Your Mental Game ................................................................................................ 4 How to Compress a Golf Ball ............................................................................................................. 7 How to Stop Hitting Shots Fat ........................................................................................................... 8 How to Stop Slicing The Ball ............................................................................................................ 10 How to Tune Up Your Game During the Off-Season .............................................................. 12 How to Gain Consistency With Your Driver ................................................................................ 13 How to Read the Green Like a Pro ................................................................................................ 15 How to Eliminate 3 Putts ................................................................................................................... 18 How to Escape the Sand .................................................................................................................... 20 How to Hit from the Thick Rough ..................................................................................................