SAMPLE 1 CEE REVIEW

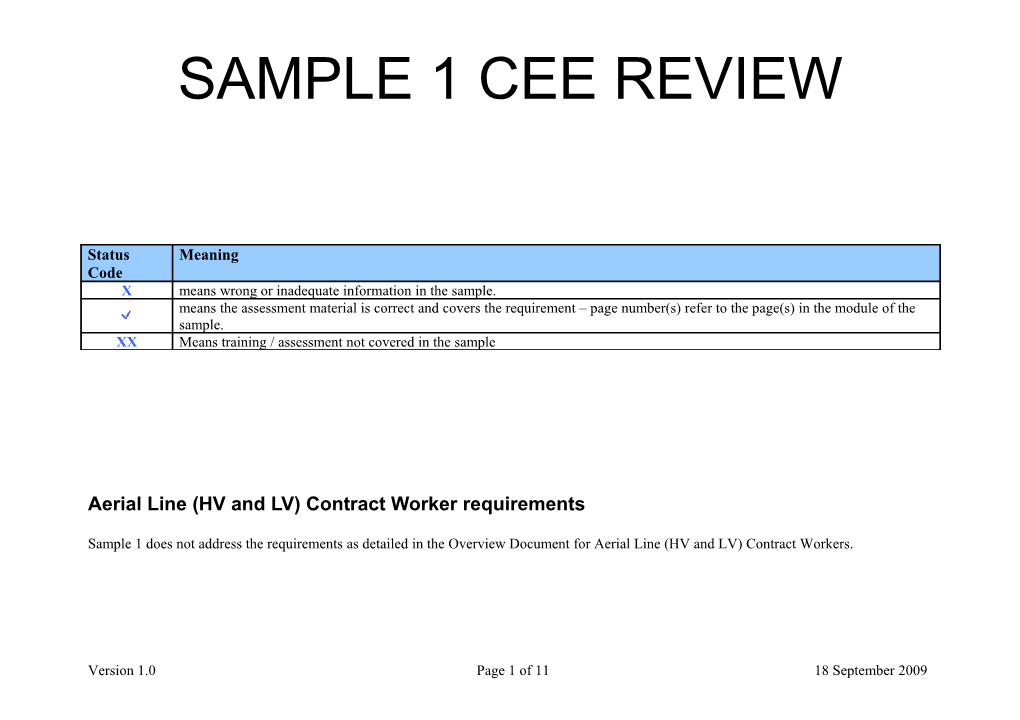

Status Meaning Code X means wrong or inadequate information in the sample. means the assessment material is correct and covers the requirement – page number(s) refer to the page(s) in the module of the sample. XX Means training / assessment not covered in the sample

Aerial Line (HV and LV) Contract Worker requirements

Sample 1 does not address the requirements as detailed in the Overview Document for Aerial Line (HV and LV) Contract Workers.

Version 1.0 Page 1 of 11 18 September 2009 Overhead Wiring (Traction) Contract Worker Level 2 requirements On the Job assessment for Overhead Wiring (Traction) Contract Workers- Status Module Xref See Activities Description pages Note # (a) Erection of OHW components (fittings) understands and correctly uses cantilever data sheets pp. 7- 10 10 understands RailCorp OHW fitting numbers and correctly selects fittings required to complete a task from the RailCorp drawing (b) Registering Wire, including attachment of arms Standing on wrong side 2 p.3 Attaching slings Correcting twist 9 pp. 6-7 Checking for Correct length of arm XX 1 Split pins 9 p. 7 Mechanical wear on span wires XX 2 What is thin contact wire (is it suitable for safe rigging) XX 3 Vertical alignment of catenary and contact insulators Checking Correct stagger of contact wire Checking Clearance between live equipment and rail or earth ( c) Clipping up catenary Correct orientation of envelope 9 pp. 3-4 Knows the correct angle the cantilever should be to the mast dependent on the position in pp. 3-4 X 9 4 the tension length and the temperature of the day (d) Installing Droppers and Feeders Droppers 7 pp. 3-10 Feeders 6 pp. 1-5 Has demonstrated the ability to correctly position and install droppers and feeders (correctly installed onto contact groove) correct orientation cleanness of contact wire and catenary Correct nut tension Different size dropper clips and how to identify them XX 5 (e) Removing Kinks XX 6 (f) Removing Wire at reduced tension with particular emphasis on risk of contact wire Version 1.0 Page 2 of 11 18 September 2009 On the Job assessment for Overhead Wiring (Traction) Contract Workers- Status Module Xref See Activities Description pages Note # handling (g) Installation of bridge / structure bonding arrangements as per design XX 7 (h) Appropriate use of SWMS and SWI’s and pre work briefs XX 8 (j) (k) Adjusting height, stagger, heel heights, clearances to design 4 p. 11 (m) Works in the vicinity of running lines safely XX 9 Valid Rail Industry Safety Induction card (n) Works around electrical equipment safely Appropriate use of mobile plant and equipment around RailCorp’s Electrical System XX 10 Compliance with Safe Approach Distances XX 11 Complies with requirements of Electrical Permits numerous pages mentioned but no specific assessment Construction earthing / rail connecting XX 12 (o) Works aloft safely appropriate use of harness XX 13 appropriate attached climbing (when approved) and fall arrest systems XX 13 appropriate EWP usage XX 13 appropriate ladder usage XX 13 inspects safety equipment before use XX 13 displays the appropriate attitude to his duties to his co-workers and Himself XX 14 (p) Wears appropriate safety equipment and PPE XX 13 Min 185 gm clothing Safety glasses Hard Hat (q) Follows the instructions of supervisors XX 14

Version 1.0 Page 3 of 11 18 September 2009 On the Job assessment for Overhead Wiring (Traction) Contract Workers- Status Module Xref See Activities Description pages Note # (r) Running of Wire – elements of a risk assessment – right equipment, right plant and XX 15 right material Identification of cad copper from tinned copper from hard drawn bare copper XX 16 Silly side issue 2 p. 7 Swivel for polymeric insulator 1 p. 10 Positioning of machinery in correct order XX 15 Live wire in vicinity XX 17 Running roads in vicinity XX 9 Clearance to redundant structures XX 19 Mid point anchor installation X 20 (s) Tensioning Wire XX 21 Working in fixed rather than regulated – recognition and memory XX 22 Unloaded tension / loaded tension / over tensioned / use of tensioning charts / temperature XX 23 reading ( t) Terminating Wire (fixed and regulated) Full splices Half splices 8 p. 6 Wedges 8 p. 7 Shims XX 24 Snail clamps for 510mm2 catenary XX 25 Use of pfisterer clamps 1 p. 12 Application of preformed terminations 1 p. 7 26 Application of preformed splices on catenary XX (u) Installing Section Insulators XX 27 Demonstrate knowledge of the use of the proforma Use of tension wrench Adjustment for running and its importance

Version 1.0 Page 4 of 11 18 September 2009 On the Job assessment for Overhead Wiring (Traction) Contract Workers- Status Module Xref Notes Activities Description pages (v) Installing Pennant Insulators Clearances – between pans and OHW arrangements XX 28 Clearances – electrical clearances 4 p. 12 Clearances - between pans and drop verticals 4 p. 12 Bonding issues – floating sections XX 29 Vertical alignment of insulators in catenary and contact 8 p. 10 Cutting in rigging process for catenary pennant insulator 8 p. 10 Cutting in rigging process for contact pennant insulator 8 p. 11 (w) Deals appropriately with unexpected situations like the design doesn’t work XX 30 Ask someone with design authority for advice XX 31 (x) Correcting twisted wire (y) Installation of aerial Feeding arrangements at Overlaps and Section Insulators as per X 32 design (z) Removal of Wire Order of dropping 2 pp. 3-4 Stripping fittings from catenary and contact wires 2 pp. 3-4 Rigging up 2 pp. 4-6 Lowering conductors 2 p. 5 Cutting up conductors 2 p. 6 (aa) Testing required under RailCorp’s SMS Structure to rail tests XX 33 (bb) Switches XX 34 (cc) Demonstrated knowledge of their own QA system and the Overhead Wiring (Traction) Contract worker’s workers role in this system What are the important issues to consider for runability and safety 4 p. 5 Checklist 4 p. 3 Sectionability

XX 35

Version 1.0 Page 5 of 11 18 September 2009 On the Job assessment for Overhead Wiring (Traction) Contract Workers- Status Module Xref Notes Activities Description pages (dd) Installation of tension regulators XX 36 Distance between pulley wheels is correct for the temperature and tension length Existence of objects under the weight system Distance between thimble on top of weight system and first pulley wheel is correct for the temperature and tension length Position of the weight guide eye bolt is correct with respect to the top and bottom of the weight guide rod for the range of movement of the eye bolt over the required temperature extremes and for that tension length That pulley wheel bearing protectors are installed

Note 1 The tool needs to specifically show that the candidate has been assessed on his/her understanding of the different types of pull off arm and how they are identified and used and checked as to the correct length and application

Note 2 The tool needs to specifically show that the candidate has been assessed on his/her awareness of the issue of mechanical wear due to wires (spans and main catenarys etc) rubbing and wearing and how this is prevented).

Note 3 The tool needs to specifically show that the candidate has been assessed on his/her awareness of the issue of thin contact wire and tasks where this needs to be considered before being performed such as re-tensioning fixed anchored contact wire

Note 4 The tool needs to specifically show that the candidate has been assessed on his/her awareness of the issue of which way the cantilever should be displaced relative to the structure at a particular temperature and location in the tension length

Note 5 The tool needs to specifically show that the candidate has been assessed on his/her awareness of the existence of different size dropper clips for different size contact wires

Version 1.0 Page 6 of 11 18 September 2009 Note 6 The tool needs to specifically show that the candidate has been assessed on his/her awareness of the methodology and tools used for removing kinks and the ability to perform this work

Note 7 The tool needs to specifically show that the candidate has been assessed on his/her use and understanding of design drawings and fittings associated with tunnel and overbridge OHW arrangements (including bonding arrangements) and has demonstrated competency of installation

Note 8 The tool needs to specifically show that the candidate has been assessed on his/her awareness of the use and compliance with SWM’s and SWI’s for OHW installation tasks for which the candidate has been certified to perform.

Note 9 The tool needs to specifically show that the candidate has been assessed on his/her awareness of the SWMS directly dealing with installing OHW around running lines

Note 10 The tool needs to specifically show that the candidate has been assessed on his/her awareness of the requirements of Appendix A of RailCorp’s Guide SMS-06-GD-0268 “Working around electrical equipment” and complies with these requirements

Note 11 The tool needs to specifically show that the candidate has been assessed on his/her awareness of the requirements of RailCorp’s Guide SMS-06- GD-0268 “Working around electrical equipment” and complies with these requirements

Note 12 The tool needs to specifically show that the candidate has been assessed on his/her awareness of the requirements of Clause 12.2 of RailCorp’s Guide SMS-06-GD-0268 “Working around electrical equipment” and complies with these requirements

Note 13 The tool needs to specifically show that the candidate has been observed as complying on-the-job with the practices as assessed in the 12 monthly re-accreditation’s covering Rescue from a pole or structure Rescue from an EWP

Version 1.0 Page 7 of 11 18 September 2009 Note 14 The tool needs to specifically show that the candidate has been observed as exhibiting on-the-job attitudes of care and diligence with respect to his responsibilities to his co-workers and supervisors

Note 15 The tool needs to specifically show that the candidate has been observed as being able to identify, position and use The right equipment The right plant The right material to carry out OHW installation tasks which he is required to perform

Note 16 The tool needs to specifically show that the candidate is able to differentiate different size and types of conductor utilised on RailCorp’s OHW system and understands any conductor marking systems associated with these conductors

Note 17 The tool needs to specifically show that the candidate has been assessed on his/her awareness of the SWMS directly dealing with installing OHW around live equipment the requirements of RailCorp ETN 08/11 entitled “Overhead Line Contract Workers – additional requirements for installing 1500 volt overhead wiring and has been observed on the job to comply with these requirements

Note 19 The tool needs to specifically show that the candidate has been assessed on his/her awareness of the fact that OHW re-builds often involve the temporary existence of redundant OHW support structures and of the need to maintain electrical and mechanical clearance between the rebuilt OHW and these structures.

Note 20 The tool needs to require candidates to demonstrate understanding of and ability to install mid-point anchor arrangements that comply with RailCorp’s design and construction practices

Version 1.0 Page 8 of 11 18 September 2009 Note 21 The tool needs to specifically show that the candidate has been assessed on his/her awareness of RailCorp’s “super-tensioning” policy and of the controls to be implemented in relation to the risks associated with implementing this policy such as overloading of fittings and structures attached to the wire being super-tensioned

Note 22 The tool needs to specifically show that the candidate has been assessed on his/her ability to understand and use temperature-tension charts relevant to tensioning fixed OHW and of the need to consult the Construction Engineer when worn contact wire is involved.

Note 23 The tool needs to specifically show that the candidate has been assessed re understanding and use of unloaded / loaded temperature-tension charts relevant to tensioning fixed ended catenary wires

Note 24 The tool needs to specifically show that the candidate has been assessed re understanding and use of shims in relation to the installation of contact wire full splices

Note 25 The tool needs to specifically show that the candidate has been assessed re understanding and correct use of snail clamps on 510mm squared catenary

Note 26 The tool needs to specifically show that the candidate has been assessed and observed to be competent re correct installation of pre-formed catenary splices

Note 27 The tool needs to specifically show that the candidate has been assessed and observed to be competent in the installation and adjustment of OHW Section Insulators

Note 28 The tool needs to specifically show that the candidate has been assessed as being aware of the issue of clearance between running pantographs and OHW fittings such as pennant insulators and live verticals / dead verticals

Version 1.0 Page 9 of 11 18 September 2009 Note 29 The tool needs to specifically show that the candidate has been assessed in understanding of the use of potential jumpers to ensure that floating sections do not exist on RailCorp’s OHW system unless specifically called up in the design.

Note 30 The tool needs to specifically show that the candidate has been observed as exhibiting on-the-job attitudes of care and diligence with respect to his responsibilities to seek guidance where needed and deal with unexpected / emergency situations

Note 31 The tool needs to specifically show that the candidate has been observed as exhibiting understanding that designs are not to be modified without the approval of persons holding design authority.

Note 32 The tool needs to specifically show that the candidate has been observed as exhibiting understanding of how wires move in feeding overlaps with the potential to reduce clearances/short out airgaps under extremes of temperature

Note 33 The tool needs to specifically show that the candidate has been assessed on his/her awareness of the requirements of RailCorp’s Document SMS- 06-EN-0571 “Overhead Wiring Structure to Rail Voltage Test” and has been observed to comply with these requirements

Note 34 The tool needs to specifically show that the candidate has been assessed on his/her ability to install OHW switch arrangements in accordance with design including bare conductor / cable connections, operating mechanisms, operators platforms, bonding arrangements and signage

Note 35 The tool needs to specifically show that the candidate has been assessed on his/her understanding of electrical sectioning and has demonstrated the ability to assess that the electrical sectioning required by a design has been achieved

Note 36 The tool needs to specifically show that the candidate has been assessed on his/her ability to verify that an OHW tension regulator weight system will correctly operate on the tension length for which it has been installed and, in particular, of the need to check the Distance between pulley wheels is correct for the temperature and tension length Existence of objects under the weight system that would impede the free movement of the weights Distance between thimble on top of weight system and first pulley wheel is correct for the temperature and tension length Version 1.0 Page 10 of 11 18 September 2009 Position of the weight guide eye bolt is correct with respect to the top and bottom of the weight guide rod for the range of movement of the eye bolt over the required temperature extremes and for that tension length pulley wheel bearing protectors are installed

Version 1.0 Page 11 of 11 18 September 2009