Version 1.0 for distribution to SE Coastal Group for feedback

Southeast Coastal Group R&D proposal: The use of geo-bags on shingle beaches

Uwe Dornbusch, 11-11-2015

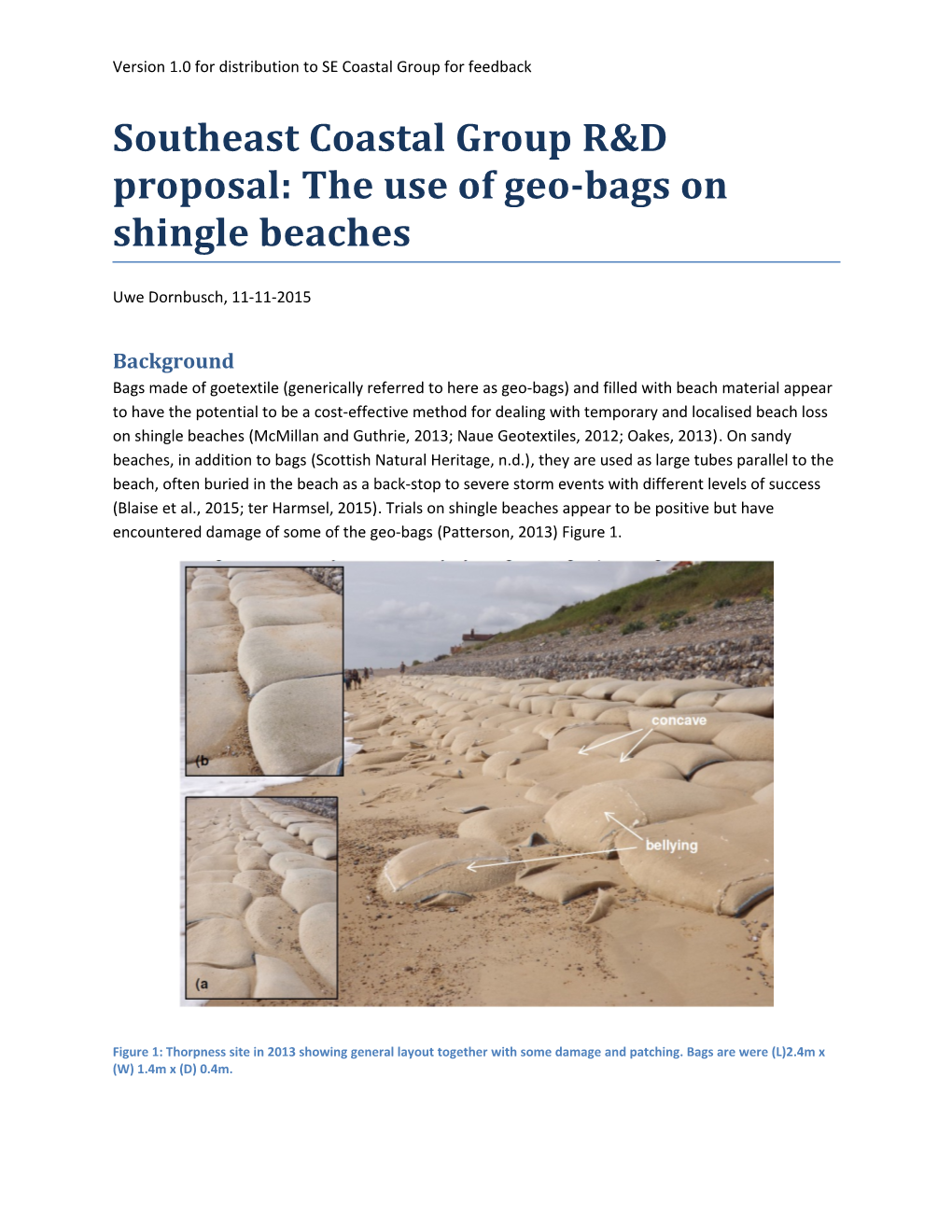

Background Bags made of goetextile (generically referred to here as geo-bags) and filled with beach material appear to have the potential to be a cost-effective method for dealing with temporary and localised beach loss on shingle beaches (McMillan and Guthrie, 2013; Naue Geotextiles, 2012; Oakes, 2013). On sandy beaches, in addition to bags (Scottish Natural Heritage, n.d.), they are used as large tubes parallel to the beach, often buried in the beach as a back-stop to severe storm events with different levels of success (Blaise et al., 2015; ter Harmsel, 2015). Trials on shingle beaches appear to be positive but have encountered damage of some of the geo-bags (Patterson, 2013) Figure 1.

Figure 1: Thorpness site in 2013 showing general layout together with some damage and patching. Bags are were (L)2.4m x (W) 1.4m x (D) 0.4m. Version 1.0 for distribution to SE Coastal Group for feedback

Fundamentally, areas of shingle loss are often repaired through beach recycling, however, the newly placed material can disappear within a matter of days. Confining that same sediment into bags inhibits long- or crosshore movement; additionally it makes it possible to generate much steeper slopes than the natural angle of repose (Figure 2) so that a revetment-type construction is possible.

At Thorpness, following a first phase of geo-bags, a trial was undertaken with bags of 3 different types of geo textile over a period of a couple of months, leading to the selection of bags with a “double polypropylene filter layer (mass per unit area, 600g/m2) and protection layer (mass per unit area, 300g/m2) of approximately 8mm thickness” (McMillan and Guthrie, 2013 p.8).

Figure 2: Geobags at the western end of Pagham rock revetment stacked at slope of ~ 1 in 1.

Anecdotal observations suggest that bags rip from gradual thinning due to shingle beach abrasion on the beach face or from impact puncture where pebbles and cobbles thrown against the bag by waves hit a pebble or cobble inside the bag.

Research proposal While experience so far (Suffolk, Pagham) indicates that using geo-bags reduces beach loss, the durability of the bags is uncertain. There are now several suppliers of geotextiles and geo-bags including those below (non-exhaustive):

TenCate http://www.tencate.com/apac/geosynthetics/product/hydraulic-marine/tencate- geotube-geocontainment-unit.aspx

Naue http://www.naue.com/en-ie/applications/hydraulic-engineering/coastal-protection.html

Huesker http://www.huesker.co.uk/uploads/tx_itmdownload/PB_SoilTain_Bags_engl_.pdf Version 1.0 for distribution to SE Coastal Group for feedback

GTM http://gtmgeotextile.com/nonwoven-geotextile-bag/

Geofabrics http://www.geofabrics.com/

The proposal would be to

invite suppliers to provide a small number of bags that they think are best in providing abrasion and puncture resistance (as well as chemical stability when exposed to seawater and sun light) either at cost or as free trial samples; size needs to be specified so that they are all the same

install these on an open beach along the SECG frontage at short distance from each other so that they do not influence each other but are exposed to the same hydrodynamic conditions. Installation should include a filling frame to be used on the beach that might be able to accommodate slightly different sizes. 1

monitor shape (laser scanner would be useful) and surface of the geobags

write a report of findings

It is anticipated that monitoring is carried out over 2 to 3 winter seasons assuming this is the length of time the bags need to be functional to provide an intended temporary protection.

Potential design To test abrasion and impact resistance, geo-bags could be just placed on the surface of the beach or dug in so they are level. This would also allow to monitor any movement they may show.

Alternatively, they could be placed

1. alongside the western side of a timber groyne to that they do not interfere with the beach any more than the groyne does

2. in small shore parallel structure around MHW to capture the most energetic waves, however, this would have a significant impact on the beach so may not be desirable on a satisfactorily functioning beach

3. as a temporary shore parallel structure at a location that is under threat at the moment (e.g. Pagham)

It is possible that the present size of 2.4x1.2x0.4 is deemed to be too small (~1m3 which would result in a weight of ~1.5t) to be just placed on the beach or next to groynes in which case larger bags would be required.

1 It could be tried to sieve beach sediment on filling so as to exclude pebbles above a certain size. This would double the required number of bags to make this an equitable trial. Version 1.0 for distribution to SE Coastal Group for feedback

Costs Cost for the bags, filling and placement at Thorpness are given in the scheme proposal with £95 per bag. Arun DC purchased bags only at £36.30 per bag delivered (100 in packs of 25). It is also reported that 5 bags could be filled and placed per hour involving a 21t digger plus 2 people. This would add ~£30 to each bag, though this may increase in relation to length of construction time plus welfare facilities. All in all, the £95 per bag for Thorpness can be seen as good upper estimate as the number bags per hour could quite possibly be improved.

Figure 3: Two pack of 25 bags each at Pagham

For a test, 25 bags of each variant would seem sufficient.

Assuming £50 and £100 per bag all inclusive (this range is from bags received for free from suppliers to paying for bags that might also be more expensive than those used so far) and 5 to 10 different types of bags (assuming the supplier will provide one or two of their most suitable / there are more than 5 suppliers), the cost for 25 bags each would range then from £6,250 to £25,000. In addition a filling frame would have to be commissioned or may already be available given that the bags are marketed.

References Blaise, E., Suanez, S., Stéphan, P., Fichaut, B., David, L., Cuq, V., Autret, R., Houron, J., Rouan, M., Floc’h, F., Ardhuin, F., Cancouët, R., Davidson, R., Costa, S., Delacourt, C., 2015. Bilan des tempêtes de l’hiver 2013-2014 sur la dynamique de recul du trait de côte en Bretagne. Géomorphologie Relief Process. Environ. 267–292. McMillan, A., Guthrie, G., 2013. Bag to the Future – Meeting the Challenges of Coastal Erosion and Affordability, in: Coasts, Marine Structures and Breakwaters 2013 Proceedings. Presented at the ICE Coasts, Marine Structures and Breakwaters 2013, ICE, Edinburgh. Naue Geotextiles, 2012. Coastal erosion rectified - shingle filled geotextile bags at Thorpeness (Case study No. CS042-Thormeness Erosion Works). Naue Geotextiles. Version 1.0 for distribution to SE Coastal Group for feedback

Oakes, T., 2013. Dunwich coastal defence demonstration project (No. SC050071/R). Environment Agency. Patterson, P., 2013. Thorpness Site inspection report June 2013 (Internal report No. /N1s/301164/PBor). Royal Haskoning DHV. Scottish Natural Heritage, n.d. A guide to managing coastal erosion in beach/dune systems [WWW Document]. URL http://www.snh.org.uk/publications/on- line/heritagemanagement/erosion/appendix_1.6.shtml (accessed 11.10.15). ter Harmsel, M., 2015. Engineered shoreline protection - case study from the Jersey Shore on material selection process, sustainability and impacts from superstorm Sandy. Presented at the ICE Coastal Management, ICE, Amsterdam, pp. 1–10.