Project Readiness Package Rev 5/16/13

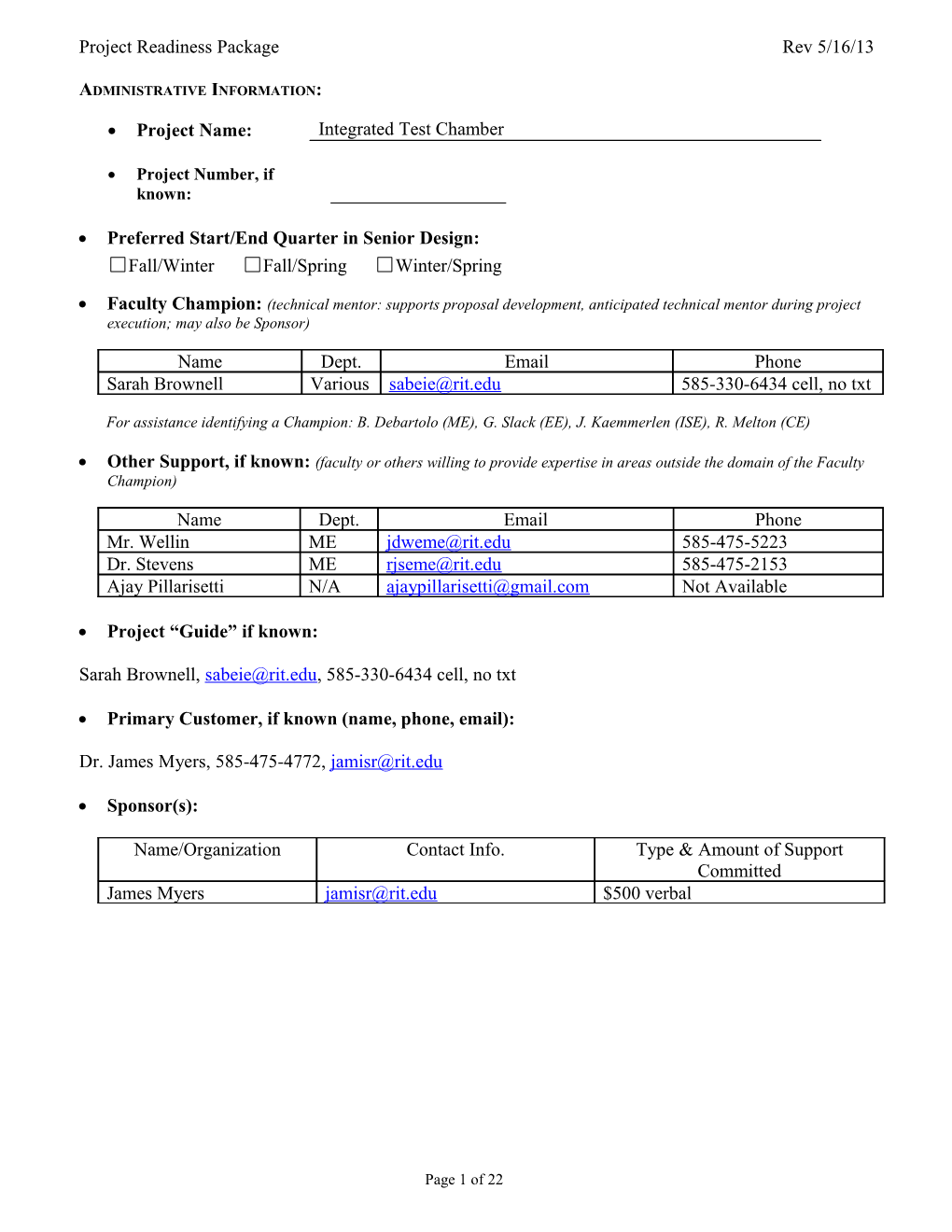

ADMINISTRATIVE INFORMATION:

Project Name: Integrated Test Chamber

Project Number, if known:

Preferred Start/End Quarter in Senior Design: Fall/Winter Fall/Spring Winter/Spring

Faculty Champion: (technical mentor: supports proposal development, anticipated technical mentor during project execution; may also be Sponsor)

Name Dept. Email Phone Sarah Brownell Various [email protected] 585-330-6434 cell, no txt

For assistance identifying a Champion: B. Debartolo (ME), G. Slack (EE), J. Kaemmerlen (ISE), R. Melton (CE)

Other Support, if known: (faculty or others willing to provide expertise in areas outside the domain of the Faculty Champion)

Name Dept. Email Phone Mr. Wellin ME [email protected] 585-475-5223 Dr. Stevens ME [email protected] 585-475-2153 Ajay Pillarisetti N/A [email protected] Not Available

Project “Guide” if known:

Sarah Brownell, [email protected], 585-330-6434 cell, no txt

Primary Customer, if known (name, phone, email):

Dr. James Myers, 585-475-4772, [email protected]

Sponsor(s):

Name/Organization Contact Info. Type & Amount of Support Committed James Myers [email protected] $500 verbal

Page 1 of 22 Project Readiness Package Rev 5/16/13

PROJECT OVERVIEW:

BACKGROUND The Test Chamber Project was inspired by the Indoor Air Quality Monitor Project that was started during fall quarter of the 2012-2013 academic year. The goal of the air quality monitor project was to meet the needs of researchers who quantify the health impacts of inefficient burning fires for both cooking and heating in developing countries. The project though was unable to correctly calibrate the monitor properly due to insufficient facilities. Thus a need for a test chamber occurred. The current funding for this project is being provided by Dr. James Myers who has verbally agreed to provide $500 to fund this project.

Context The context of this project will be to work alongside the air quality monitor team with an end goal of this project line being the creation of test chamber that can properly calibrate the air quality monitor by controlling and understanding the environment inside the chamber.

The first iteration of this project was two projects working in parallel. One concentrated on developing the chamber and the other concentrated on analyzing varieties of sensors in order to determine the best ones. This project is to combine these projects and concentrate on improving the interface of the chamber so it can be more easily manipulated and controlled. This will allow for more efficient testing and calibrating of the air quality monitor.

Motivation Currently in the realm of air quality monitoring in developing countries there are two different monitors in use: the UCB-PATS and the Aprovecho Indoor Air Pollution Meter. In addition to these two well- established sources, during the fall quarter of 2012 RIT began a senior design project to develop their own monitor.

The creation of these monitors came from the need to be able to record what people are exposed to in homes in developing countries; however, many researchers are not receiving the data that they truly want from either of these devices and would like something that can marry the two. By creating a monitor that can take more data (PM, CO, temperature, and humidity) at a high sample rate, the researchers using this device can gain a clearer picture of how the atmosphere inside of homes is changed by cooking and heating stoves. This data can then in turn be used to help drive the needs of these countries in terms of both education on what and how to burn and technology that will burn fuels more efficiently. The air quality monitor, however, cannot be developed properly without the use of a test chamber to calibrate it. The test chamber will be able to produce environments similar to that of which the air quality monitor will be exposed to, thus effectively testing the device and enabling the team to fabricate an accurate monitor for use in the field. In the end the data collected by the monitor will be used to help save lives as well as assist countries such as Haiti and Kosovo to develop more quickly and sustainably.

This test chamber will aid in the creation of a monitor that should be able to bridge the gaps left between the other two monitors and give a clearer picture to researchers as to the exposure levels of individuals within a home.

Page 2 of 22 Project Readiness Package Rev 5/16/13

DETAILED PROJECT DESCRIPTION:

Customer Needs and Objectives: The customer needs for this project were developed through interviews with both Dr. James Myers and Sarah Brownell. Dr. Myers would be the customer for this project and Sarah would likely return as a guide due to her experience with both the previous project (P13625) as well as the knowledge that she accumulated while living in Haiti.

Customer Importance Description Need # CN1 9 Tests the performance of air quality monitors CN2 9 Exposes monitor to varying CO concentrations Exposes monitor to varying quantities of particulate matter 2.5 CN3 9 (PM2.5) CN4 9 Exposes monitor to varying temperature levels CN5 9 Exposes monitor to varying humidity levels CN6 9 Capable of measuring CO concentrations CN7 9 Capable of measuring PM2.5 CN8 9 Capable of measuring temperature levels CN9 9 Capable of measuring humidity levels Capable of safely evacuating any gasses or particulates from within CN10 9 the chamber Records information about the environment within the chamber for CN11 9 comparison to monitors being tested Test levels should be able to be varied by the user with the use of an CN12 9 interface system CN13 9 The interface system provides live data during testing CN14 9 The interface system provides a report of the test after completion CN15 3 Variation of concentration levels within the test chamber are minimal CN16 3 The test chamber can be moved and stored CN17 3 Maintains cost affordability for the public and researchers

NOTE: The importance scale for the customer needs shows 9 as most important and 1 as least important.

Page 3 of 22 Project Readiness Package Rev 5/16/13

Functional Decomposition:

Potential Concepts: In the process of preparing for this project a Pugh Selection Matrix was also to compare a few of the possible solutions that the team may come up with; this can be viewed in the Appendix. The concepts considered in order to input and supply data included a computer attached to a newly developed chamber, a USB import to the previous teams chamber, and transfer data from the previous teams chamber to a computer.

Page 4 of 22 Project Readiness Package Rev 5/16/13

Specifications: The following specifications were developed from the customer needs and have all been confirmed as being feasible. The specs which do not map back directly to customer needs are things which the team may need to test or measure to be successful.

TEST CHAMBER: METRICS AND SPECIFICATIONS Unit of Spec # Source (CN) Area Specification (Metric) Marginal Value Ideal Value Comments Measure Based off of PEMS benchmark S1 2, 12 Chamber Range of CO levels measured ppm 0 - 1000 0 - 2000 Marginal Value is from PEMS benchmark Based off of PEMS benchmark S2 1, 6 Sensors Accuracy of CO levels measured ppm 1 1 Marginal Value is from PEMS benchmark Determined by the level of accuracy available in the sensors S3 1, 6 Sensors Precision of CO levels measured Sig Figs 2 4 and at what point data becomes unnecessarily exact

S4 15 Chamber Consistency of CO levels within chamber ppm 0.5 < 0.5 Based off of flow rate analysis

Feasible number of total PM2.5 S5 3, 12 Chamber Range of PM2.5 density achievable by chamber μg/m³ 0 - 60,000 25,000 Marginal Value is from PEMS benchmark Based on available technologies S6 1, 7 Sensors Accuracy of PM2.5 levels measured μg/m³ 15 0.1 Marginal Value is from PEMS benchmark Determined by the level of accuracy available in the sensors S7 1, 7 Sensors Precision of PM2.5 levels measured Sig Figs 2 4 and at what point data becomes unnecessarily exact

S8 15 Chamber Consistency of PM2.5 levels within chamber μg/m³ 0.5 < 0.5 Based off of flow rate analysis

Room temperature to above max Haiti temperature S9 4, 12 Chamber Range of temperature levels in chamber °C 20 20 - 38 Marginal Value is room temperature Capable of measuring any possible temperature in chamber S10 8 Sensors Range of temperature levels measured °C -40 - 123.8 0 - 45 Marginal Value base off of SHT1x Sensor

S11 8 Sensors Accuracy of the temperature levels measured °C 1 0.1 Based off of SHT1x Sensor

Determined by the level of accuracy available in the sensors S12 8 Sensors Precision of temperature levels measured Sig FIgs 2 4 and at what point data becomes unnecessarily exact

S13 5, 12 Chamber Range of humidity levels in chamber % RH 0 - 100 0 - 100 Humidity levels affects PM, needs to reach max humidity

S14 9 Sensors Range of humidity levels measured % RH 0 - 100 0 - 100 Based off of SHT1x Sensor

S15 9 Sensors Accuracy of humidity levels measured % RH 4.5 2 Based off of SHT1x Sensor

Determined by the level of accuracy available in the sensors S16 9 Sensors Precision of humidity levels measured Sig Figs 2 4 and at what point data becomes unnecessarily exact Response time of Aprovecho's sensors S17 11, 13, 14 Interface Rate of sampling data seconds 120 30 Marginal Value based off of Aprovecho's sensors

S18 16 Chamber Size (Volume) gal 55 < 30 Estimate based on UCB benchmark

S19 16 Chamber Weight kg 20 < 20 Estimate based on UCB benchmark

Recommended value from customer S20 17 Chamber Time between maintenance of mechanical parts Tests 1 1 Marginal Value based off of UCB benchmark Minimum number of desired tests S21 17 Chamber Lifetime of test chamber Tests 20000 1000 Marginal Value based off of lifetime of sensors Minimum number of desired tests S22 17 Chamber Lifetime of the sensors Tests 20000 1000 Marginal Value based off Aerosol Sensor Estimate based on UCB benchmark S23 10 Chamber Time to exhaust chamber contents min 45 45 Marginal Value is recommended time before next test of MaxUCB powerchamber available from wall outlet S24 17 Chamber Power input W 157 < 2400 Marginal Value is power requirement of Aprovecho's PEMS Available money from donations S25 17 System Development Cost $ 500 500 Marginal Value is the cost of UCB's chamber

Constraints: See the Functional Decomposition for all constraints.

Page 5 of 22 Project Readiness Package Rev 5/16/13

Project Deliverables: The deliverables for this project include a working test chamber with computer integration as well as all of the supporting documentation and software. This means that the team should, by the end of the project, have built a test chamber and completed accurate and meaningful testing to prove that the test chamber will operate as desired. In addition to this the team will complete a user manual and operating instructions with prints so that test chamber can be used to calibrate air quality monitors. Lastly the team will have a finished software user interface that allows the test chamber to connect with a PC to enable a PC to manipulate the environment of the test chamber and enable PC to retrieve data on the environment inside the chamber.

o Working and tested test chamber o Completed and debugged user interface for PC o User Manual with maintenance instructions o Assembly instruction with detailed prints o Detailed BOM with vendors o Detailed test procedures with test results (proof that specs have been met) . Testing to ensure the chamber can vary all levels as desired using the computer interface. . Sensor testing to prove sensors’ ability to respond and record changing environmental metrics from lower testing to upper testing levels. . Testing to ensure all contents in the chamber can be safely removed and the chamber can return to original settings.

Budget Estimate: The cost of the production of a new test chamber with an integrated interface would greatly exceed the budget of $500. However if the team simply uses the test chamber developed in the previous project and concentrate on integrating the computer then the only cost would be that computer integration which would fall under budget.

Unit Total Component Quantity Cost Cost

Stainless Steel for Test Chamber and Combustion Chamber 1 $375.00 $375.00 Lid for Chamber 1 $20.00 $20.00 Mixing Fan 1 $35.00 $35.00 Material for Burning - $45.00 $45.00 Power Supply 1 $30.00 $30.00 CO Sensor 1 $10.00 $10.00 Particulate Matter Sensor 1 $50.00 $50.00 Temperature and Humidity Sensor 1 $45.00 $45.00 Miscellaneous Electrical Components - $20.00 $20.00 Miscellaneous Connecting Components - $20.00 $20.00 Computer Integration - $400.00 $400.00 Total $1,050.00

NOTE: All sensor data sheets can be found in Appendix B.

Page 6 of 22 Project Readiness Package Rev 5/16/13

Intellectual Property (IP) considerations: This project is meant to test the air quality monitor project which is a humanitarian type of work and it would be best to leave it out for anyone who may make the product better to help more researchers in order to make it more beneficial.

Other Information: Potential benefits of this project include assisting in the sustainable growth of developing countries through education on the health effects of burning refuse and other materials.

Continuation Project Information, if appropriate: This project is a continuation of two other projects that concentrated on developing a test chamber and determining the best sensors. The focus of this project is to further improve upon those projects by creating an integrated interface system.

STUDENT STAFFING:

Skills Checklist: See the attached PRP Skills Checklist in the Appendix for skills needed by major.

Anticipated Staffing Levels by Discipline: How Discipline Anticipated Skills Needed (concise descriptions) Many? 2 EE students will be concerned with device programing, EE power management, data transfer, computer interface, etc. 2 ME students will be concerned with integrating the monitor and computer ME into the chamber 2 CE students are to develop the computer software interface and CE communication between the chamber and computer. ISE 0-1 Project Management Skills Other

Page 7 of 22 Project Readiness Package Rev 5/16/13

OTHER RESOURCES ANTICIPATED:

Resource Category Description Available?

Faculty

Environment

Equipment Machining equipment

Materials

Other

Prepared by: Arielle Mizov Date:

Page 8 of 22 Project Readiness Package Rev 5/16/13

Appendix:

Concept Selection:

While this Pugh selection is purposed to give a good idea of what a team may choose to do, it by no means provides a best or the best solution to this problem. It is in reality most probable that the team will pick something which encompasses the better qualities of each of the concepts listed here.

Page 9 of 22 Project Readiness Package Rev 5/16/13

House of Quality: Range of CO levels measured Correlation Codes Accuracy of CO levels measured + + + + Very Positive Precision of CO levels measured + + + + + Positive Consistency of CO level within chamber + + + + + + Range of PM2.5 density achievable by chamber ------NO INPUT IN THIS AREA Accuracy of PM2.5 levels measured ------+ + - Negative Precision of PM2.5 levels measured ------+ + + + - - Very Negative Consistency of PM2.5 levels within chamber ------+ + + + + + Range of temperature levels in chamber ------Range of temperature levels measured ------+ + Accuracy of the temperature levels measured ------+ + + + Precision of temperature levels measured ------+ + + + + + Range of humidity levels in chamber ------+ ------+ + + + + + + + Range of humidity levels measured ------+ + + + + + + + Accuracy of humidity levels measured ------+ ------+ + + + Precision of humidity levels measured ------+ ------+ + + + + + Rate of sampling data ------Size (Volume) + + + + + + + + + + + + + + + + + + + Weight ------+ + Time between maintenance for test chamber + ------+ ------+ ------+ ------+ + + Lifetime of test chamber + ------+ ------+ ------+ ------+ + + + Lifetime of the sensors - - + + + + - - - + + + + - - - + + + + + + - - + + + + + + + + ------Time to exhaust chamber contents + ------+ ------+ + - + + - Power input + + + + + + + + + + + + + + + + + ------+ + + Development Cost + + + + + + + + + + + + + + + + + + + + + + + + + + + + Preferred Engineering Metrics Customer Perception r e b r d r e e m e r b a b u h d s r m m r e c a a e

r a e e h b d y d d u h b c e r e e s b c m m r r r e d a m d n t a e d u s u u e b e i e a l s l s s h e s s r r t h h b e e r a c a a m m t u d u t d c n a i v u e e s e a s e e s e r n v s e r a r a n l h t i w l m e a m o i m

e d u e e c u n h i f e s s t e s e s s s s v o h l i l m r n l r m l l e a a e c e c i m e e e e u l

u e c e w s s a v t r v s l s s v v v l n r r e l e a l l e m e a m e e e e e a y e l r e r

e l l e e l l t s b e

v v s n b s e u b i v r S v v l 5 l t a e e y e e y e s . p e m m l e e t o l t e t t m e r r a m

l l l n i M 2 i s a a s r

v n a a s v u u m 5 e 5 t d y d i n h t l t t e d E . e . y y e h h e i O i M d s e l t t a e c h e l a a t p 2 2 c P l

i i g r r s C o C P g v t m

m 5 e t e m d d i e e n m O . s t o e O M f M f i i u e C i u s k ) h e l p p e s

2 l u h n r C o P o t h e h C t e P h t e

m m t t a c p e e m m n f f f f t O f f f f W y y M T e u u h m e f f

e e e B o o o o u o o m o o c c v

C t t e P h h x u r r o o e w a p l

n n s o e m e e y y t y y B f n f n f f n f f n v s

e e n r r t e o e

c c e c c p o o o o o o o o o o i o t t t t o C f o p

m i i t i i a a a a b t o s V s e m m h r

e r s e r s e e r s e e r s o l i i o ( S i i U A

i i i i e W B g e t t e t s s e g u g g u g u g g u

e i c c c c e s e e c n c n c c v n n n t n n n w

e e e e e m f f m z

u c c c c e a o a o a a a a a i i i i r r r r i o

Customer Requirements C R A P C R A P C R R A P R R A P R S W T L L T P D 1 2 3 4 5 Tests the performance of air quality monitors 9 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 3 3 1 5 4 3

Exposes monitor to varying CO concentrations 9 5 3 3 5 5 3 3 1 3 3 3 4 4 2 Exposes monitor to varying quantities of particulate matter 2.5 (PM2.5) 9 5 3 3 5 5 3 3 1 3 3 3 4 4 2 Exposes monitor to varying temperatures 9 5 3 3 5 5 3 3 1 3 3 3 4 4 Exposes monitor to varying humidity levels 9 5 3 3 5 5 3 3 1 3 3 3 4 4

Capable of measuring CO concentrations 9 5 5 5 5 5 3 5 3 3 Capable of measuring PM2.5 9 5 5 5 5 1 5 3 5 4 4 Capable of measuring temperature levels 9 5 5 5 5 5 3 5 4 4 Capable of measuring humidity levels 9 5 5 5 5 5 5 4 4 Capable of safely evacuating any gasses or particulates from within the chamber 9 5 5 5 3 3 3 Records information about the environment within the chamber for comparison to monitors being tested 9 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 3 5 3 3 3 3 Test levels should be able to be varied by the user with the use of an interface system 9 5 5 3 3 5 3 3 3 5 3 3 3 5 3 3 3 1 3 1 3 5 3 3

The interface system provides live data during testing 9 5 5 5 5 5 5 5 5 1 1 1 1 1 1 1 1 5 1 3 5 4 4 The interface system provides a report of the test after completion 9 5 5 5 5 5 5 5 5 1 1 1 1 1 1 1 1 5 1 3 5 4 4 Variation of concentration levels within the test chamber are minimal 3 3 5 5 5 3 5 5 5 3 3 5 5 3 3 3 3 The test chamber can be moved and stored 3 5 5 3 1 3 4 3 Maintains cost affordability for the public and researchers 3 1 5 5 1 1 5 5 1 1 1 5 5 1 1 5 5 3 5 3 5 5 5 3 3 5 3 4

Technical Targets (Specifications) 3 ^ m 3 m H H s s s / s s s s ^ t t p d R R g m m s s g g g g p n W C l i i m i i

e e p p µ / ° % % o a C

0 F F F F n p g 0 p H T T t g ° c g i 0 C 0 8 0 0 k s 0 m e g g g g R 5 5 ° 0 µ 0 0 0 0 3 5 0 0 e i . i 0 . i i 4 p s m 0 - 0 0 0 0 2 4 1 1 0 3 0 2 p S 1 S T 1 S % S 2 - 5 . 0 - . - - 0 0 0 5 5 0 1 4 < 2 0 4 < 2 0 0 4 0 0 2 4 3 < < 1 1 1 4 < $ Better 5 Stove Test Chamber 4 4 4 3 4 4 3 4 3 UCB - Berkeley 3 3 3 3 3 2 4 3 3 3 3 4 1 3 3 1 3 Aprovecho PEMS 2 2 2 2 3 2 4 3 3 4 2 3 3 3 3 4 Worse 1 Raw 7 7 9 5 5 0 2 0 3 5 8 5 7 9 9 5 0 2 0 8 0 4 4 5 2 2 0 1 2 0 0 1 5 1 2 4 5 1 2 4 1 2 4 6 5 3 7 2 5

score 3 3 3 3 3 3 3 3 2 2 2 2 2 2 2 2 2 2 2 1 2 3 1 3 5 Relati ve Weig % % % % % % % % % % % % % % % % % % % % % % % % %

ht 5 5 5 5 5 5 5 5 4 3 3 4 4 3 3 4 3 3 0 3 4 5 3 5 8

Page 10 of 22 Project Readiness Package Rev 5/16/13

Feasibility Analysis: A feasibility analysis was conducted to ensure that the project was capable of being completed by a team of 5th year KGCOE students. This included looking at the cost, weight, volume, and power consumption test chamber along with combustion rate of the materials burned and diffusion time of the gasses in the test chamber.

o Determine the Cost of a Chamber

. Assumptions: We would like a test chamber that is made of stainless steel. We would like the stainless steel to have the following qualities: High temperature and corrosion resistance with low maintenance requirements. Nonmagnetic, with good weldability and formability. Also, something that is frequently used in heat treating, moisture barriers, chemical tanks, heat exchangers, fin stock, chemical equipment, metal stampings, and shim stock.

. Alloy 34 seems to be the best type of stainless steel to use. The reason why is because is it 100% recyclable. Alloy 304 is the most widely used stainless alloy. Alloy 309 has better temperature resistance at higher temperatures. Alloy 321 has titanium added for superior corrosion resistance and weldability.

. Specifications: Foil Roll, High Temp Foil, Stainless Steel, 309, Thickness 0.002 In, Width 24 In, Length 50 ft, Finish Plain, Temper Soft, Thickness Tolerance +/-0.0002 In, Width Tolerance +/-.010, Length Tolerance +/-1 Linear Foot, Typical Tensile Strength 75, 000 min PSI, Typical Yield Strength 30, 000 min PSI, Standards A240

. Incorporating these specifications, it is approximately $375 and the weight of the stainless steel is about 10 lbs. We were looking for a test that weighs approximately 10-15 lbs and is under $500 so this seems feasible.

o Compute a Simplified Power Summation

. Most modern United States circuits are 15 – 20 amps with 120 V being the standard number of volts acquired from a power. We are content with anything lower than 2400 W. Power = Current * Voltage (P=IV): Range is 1800 W to 2400 W

. Note: For continuous loads (on for more than three hours), the limit is 20% lower: therefore, there will be 12 – 16 amps with 120 V when there is a load on for more than three hours. The range is then 1440 W to 1920.

. Laptop (Lenovo Thinkcentre m91 w/ Lenovo LCD (purchased early 2012)):

Basic specifications: Core i7, 8.0 gb ram, windows 7 professional (clean) Off (plugged in): 1 W Boot (peak): 88 W Moderate use (range): 50 – 68 W Quiescent (5 minutes of no activity): 40W Sleep: 1 W

. Mixing Fan: Axial Fan, 115VAC, 4-11/16in H, 4-11/16in W: 18 W

. The summation of this power analysis is only 106 W for these items at may power which is well under 2400 W.

Page 11 of 22 Project Readiness Package Rev 5/16/13

o Determine how much combustion is required to create a certain concentration of PM and CO. Analyze the amount of CO and PM produced after x amount of combustion. Assume wood is being burned.

. In order to address how much combustion is needed we take into account the amount of mass of fuel required to create certain amount of products for which we are going to employ stoichiometric analysis.

Wood + oxygen + heat = CO2 + H2O + heat + Ashes (Complete combustion)

. Wood (fuel): There is no chemical formula for this component since the molecules are not identical.

Nonetheless, it contains cellulose, lignite, glucose residues for which we may assume C6H12O6 (Cx2xOx). The other approach indicates that wood is mostly cellulose for which its chemical formula tend to be C6H10O5.

. A/F = 6.1 Therefore, 6.1 kg of air is required per 1kg of wood. Therefore, we assume 1kg of wood is being burned and the chemical process is incomplete combustion:

aC6H12O6 + b (O2 + 3.76 N2) d CO2 + e H2O +f CO + gO2 + hN2 a=1kmol wood, b=6.1kmol of air

Table 2.1 Stoichiometric air-fuel ratios of common fuels

http://wiki.gekgasifier.com/w/page/6123822/Stoichi metric

Page 12 of 22 Project Readiness Package Rev 5/16/13

o Determine how long this combustion process would take to create a certain concentration of PM and CO. Determine the time it takes for the chemical reactions to occur

. We want to obtain a concentration of 25000 ug/m^3 of particulate matter and from 0-2000 ppm of CO. In the case of CO concentrations we might base the analysis in the EPA standards which yield a total of 100ppm in 16 min. Concentrations differ as the times varies. The table below shows the different times for which a common CO detector works.

Table 2.2: Air quality index at certain time

Source: http://www.usa829.org/Portals/0/Documents/Health-and-Safety/Safety- Library/Carbon-Monoxide-and-CO-Detectors.pdf

. In the case of Particulate matter we might consider the following tables that show an estimate of how much particle matter is created in certain time. The table ind icates the data of PM that has been reported daily concentrations which is on 25 ug/m^3.

Table 2.3: Air quality targets on particulate matter

Source: http://www.ieabcc.nl/publications/Nussbaumer_et_al_IEA_Report_PM10_Jan_2008.pdf

Page 13 of 22 Project Readiness Package Rev 5/16/13

o Determine when incomplete combustion will occur. Assume the size and shape of the combustion chamber. Determine how much oxygen is in the chamber and if that is sufficient for the amount of combustion that is required.

. Incomplete combustion occurs as a consequence of time, temperature and turbulence factors in the reaction. Practically for our analysis we have an incomplete combustion since we have different temperature, humidity and air conditions. A common excess of air shown in table 3.1, indicates that wood commonly the range from 20-25% in excess of air by weight.

. In terms of the amount of oxygen sufficient for the combustion required we are going to take a look back on the balanced chemical equation for wood combustion taking into account 20% of excess in air: (Amount of Oxygen required) The size of the test chamber: Volume assumption = 40 gallons = 151L = 151 000cm^3, 20 kg.

. We assume a height of 76cm*(1/2.54) = 30in H

. d= 50.3 cm*(1/2.54)in = 19.8in

. Therefore, the size of the chamber is: 30’’ H; d=20’

o Determine how long it would take CO and PM to diffuse in the chamber

. Assume the chamber is a box with dimensions of 20” W x 20” L x 25” H and the gasses are entering from the center of the chamber at the top.

. To make the analysis simple, the flow of the gas is traveling straight down, then spreading out to the rest of the chamber, then traveling back up to fill the rest of the chamber. This means the flow is traveling 25’’ down, then spreading out the 10’’ to the side, and then traveling back up the 25’’. This means the flow is traveling a total length of 60’’ in order to fill the chamber. We will then assume this gas is traveling in a box that has a height of 60’’ and a length and width of 10’’. We will also assume the velocity of the gas is 2’’/s as a result from the fan.

. Using the flow rate equation: Q = vA

. The area the gas is traveling through is 100 inches2 which means the flow rate is 200 inches3/sec

. The volume of this new box is 6000 inches3 which means it would take less than a minute to fill the entire container which is a reasonable time.

Page 14 of 22 Project Readiness Package Rev 5/16/13

PRP Skills Checklist:

Project Name (tentative): Integrated Test Chamber

Checklist Completed by: Arielle Mizov

For each discipline, the skills or knowledge that will be needed by students working on the associated project are indicated below and are ranked in order of importance (1=highest priority).

Mechanical Engineering

1 3D CAD Aerodynamics MATLAB programming CFD 1 Machining (basic) Biomaterials Stress analysis (2D) Vibrations 3 Statics/dynamic analysis (2D) Combustion engines 3 Thermodynamics GD&T (geometic dimensioning & tolerancing) 2 Fluid dynamics (CV) Linear controls 1 LabView (data acquisition, etc.) Composites Statistics DFM Robotics (motion control) FEA Composites 2 Heat transfer Other: Modeling of electromechanical & fluid systems Other: Fatigue & static failure criteria (DME) Other: 3 Specifying machine elements

Reviewed by (ME faculty):

Industrial & Systems Engineering

Statistical analysis of data – regression Shop floor IE – methods, time study Materials science Programming (C++) Materials processing – machining lab Facilities planning – layout, material handling DOE 2 Production systems design – lean, process Systems design – product/process design improvement Ergonomics – interface of people & equipment Data analysis, data mining (procedures, training, maintenance) Math modeling – linear programming), simulation Manufacturing engr. 1 Project management DFx -- Manuf., environment, sustainability Engineering economy – ROI Other: Quality tools – SPC Other: 1 Production control – scheduling Other:

Reviewed by (ISE faculty):

Electrical Engineering

Page 15 of 22 Project Readiness Package Rev 5/16/13

1 Circuit design: AC/DC converters, regulators, Digital filter design and implementation, amplifier ckts, analog filter design, FPGA Logic DSP design, sensor bias/support circuitry Power systems: selection, analysis, power budget Microcontroller selection/application determination System analysis: frequency analysis (Fourier, Wireless protocol, component selection Laplace), stability, PID controllers, modulation schemes, VCO’s & mixers, ADC selection 1 Circuit build, test, debug (scopes, DMM, function Antenna selection (simple design) generators) Board layout 2 Communication system front end design MATLAB Algorithm design/simulation PSpice 1 Embedded software design/ implementation Programming: C, Assembly Other: Electromagnetics (shielding, interference) Other: Other:

Reviewed by (EE faculty):

Computer Engineering

Digital design (including HDL and FPGA) Wireless networks Software for microcontrollers (including Linux and Robotics (guidance, navigation, vision, Windows) machine learning, and control) 1 Device programming: Assembly language, C 1 Concurrent and embedded software 3 Programming: Java, C++ 2 Embedded and real-time systems Analog design 3 Digital image processing Networking and network protocols 4 Computer vision Scientific computing (including C and MATLAB) Network security 2 Signal processing Other: Interfacing transducers and actuators to Other: microcontrollers Other:

Reviewed by (CE faculty):

Page 16 of 22 Project Readiness Package Rev 5/16/13

Data Sheets:

Page 17 of 22 Project Readiness Package Rev 5/16/13

Page 18 of 22 Project Readiness Package Rev 5/16/13

Page 19 of 22 Project Readiness Package Rev 5/16/13

PEMS Technical Specifications Sheet By Aprovecho Research Center www.aprovecho.org (541) 767-0287

Function: portable equipment designed for collecting and measuring real-time cookstove emissions.

Records: 1. CO Concentration 2. CO2 Concentration 3. PM Concentration 4. Flow Rate in Exhaust Duct 5. Exhaust Gas Temperature 6. Water Temperature of Pot

Emissions Sensors 1. Carbon Monoxide: Type: Electrochemical cell Range: 0 – 1000 ppm Repeatability: 2% Resolution: 1 ppm Response time: T90 = 30 seconds 2. Carbon Dioxide: Type: NDIR (Non-Dispersive Infrared) Range: 0 – 10,000 ppm Accuracy: 75 ppm or 10% (whichever is greater) Resolution: 2 ppm Response time: T90 = 2 minutes 3. Particulate Matter: Type: Red laser scattering photometer Range: 0 – 60,000 ug/m3 Resolution: 15 ug/m3 Response time: 1 second

Data Acquisition System Waltech 21 channel configurable DAQ Delta Sigma ADC (exceptional noise filtration) Sample frequency: 1 hz Terminals for additional inputs RS-232 Serial Port Output (USB adapter included)

Page 20 of 22 Project Readiness Package Rev 5/16/13

Power Requirement Sensor Box: 7 Watts (12V DC, 110V AC, or 220V input) Blower Fan: 150 Watts (110V AC input)

*Power adapter for 200 – 240 V AC available upon request

Sensor Box Size: 33 x 42 x 18 cm Weight: 6.6 kg

Collection System Size: Fits in suitcase for airline travel Weight: Under 50 lbs (23 kg) Hood: Fire-resistant Nomex fabric with fiberglass pole frame Exhaust Duct: 6 inch (12 cm) steel conduit Blower: 250 CFM Isokinetic sample inlet

Software Included Microsoft Excel Compatible Data Processing Software Outputs include: Total Emissions Specific Emissions Emission Factors Fuel Consumption and Efficiency LiveGraph for graphing the output in real time Terreterm serial port communication software

Add-ons Available Two channel SD card data logger Tedlar bag sampling for additional gas measurements Filter system for OCEC particle analysis Dilution cap for collecting emissions from chimney stoves

Page 21 of 22 Project Readiness Package Rev 5/16/13

Faculty Sign off:

Page 22 of 22