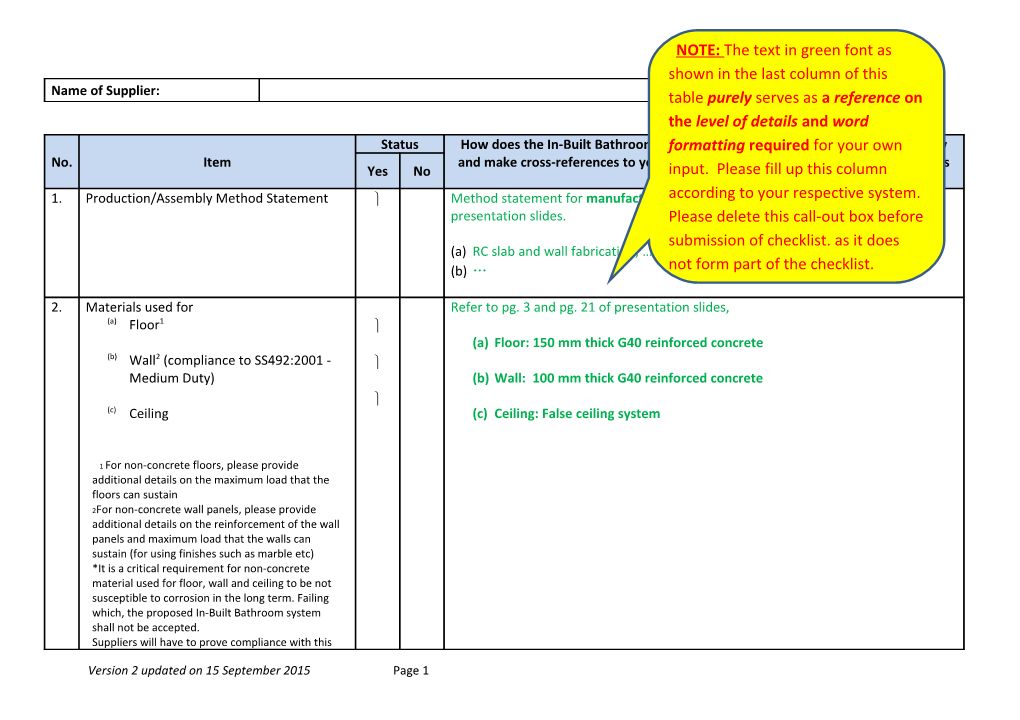

NOTE: The text in green font as shown in the last column of this Name of Supplier: table purely serves as a reference on the level of details and word Status How does the In-Built Bathroom systemformatting fulfil the required criteria? Pleasefor your describe own briefly No. Item and make cross-references to your presentation slides and supporting documents Yes No input. Please fill up this column submitted. 1. Production/Assembly Method Statement Method statement for manufacturingaccording process is toshown your on respective slide no. XX system. of presentation slides. Please delete this call-out box before submission of checklist. as it does (a) RC slab and wall fabrication; … (b) … not form part of the checklist.

2. Materials used for Refer to pg. 3 and pg. 21 of presentation slides, (a) Floor1 (a) Floor: 150 mm thick G40 reinforced concrete (b) Wall2 (compliance to SS492:2001 - Medium Duty) (b) Wall: 100 mm thick G40 reinforced concrete (c) Ceiling (c) Ceiling: False ceiling system

1 For non-concrete floors, please provide additional details on the maximum load that the floors can sustain 2For non-concrete wall panels, please provide additional details on the reinforcement of the wall panels and maximum load that the walls can sustain (for using finishes such as marble etc) *It is a critical requirement for non-concrete material used for floor, wall and ceiling to be not susceptible to corrosion in the long term. Failing which, the proposed In-Built Bathroom system shall not be accepted. Suppliers will have to prove compliance with this

Version 2 updated on 15 September 2015 Page 1 Status critical requirement with standards, test certificates and other supporting documents that could substantiate how the floor, wall and ceiling How does the In-Built Bathroom system fulfil the criteria? Please describe briefly No. perform and withstandItem the environment where In- and make cross-references to your presentation slides and supporting documents Built Bathrooms are used over a long period of submitted. time (please refer to Appendix B below).

3. Type of Refer to pg. XX of presentation slides (a) Floor Trap (a) Type of floor trap: (i) Conventional S-trap or P-trap if floor height is below 3m (ii) Shallow floor trap complying with BS EN 1253 (b) Tiles (b) Type of floor tiles: No restriction in the tiles that can be installed

4. General Layout of the In-Built Bathroom, General layout of In-Built Bathroom is provided in presentation slides pg XX including (a) Locations of Concealed Services (a) Locations of Concealed Services: pipework below bathroom floor and within (b) Location of Vertical Stack drywall system, and accessible from outside the bathroom but within the building (c) Location of Maintenance Panel (b) Location of Vertical Stack: Accessible from outside the bathroom and within the (d) Location of Manufacturer’s Label dwelling unit (e) Possible options of bathroom (c) Location of Maintenance Panel: on the wall next to the bathroom entrance (also locations in building/PPVC layout refer to pg. 29 of presentation slides) (d) Location of Manufacturer’s Label: On the wall panel within the bathroom

5. Typical Details (shop drawing to be The following typical details are provided:- provided) (a) Cross-section of bathroom floor and structural floor – (i) When conventional S-trap and P-trap are used: (Refer to slide no. XX of presentation.) (ii) When shallow floor trap is used: Localised increased floor thickness by 100 mm to house shallow floor trap (Refer to pg. 13 of presentation slides.)

Version 2 updated on 15 September 2015 Page 2 Status How does the In-Built Bathroom system fulfil the criteria? Please describe briefly No. Item and make cross-references to your presentation slides and supporting documents (b) Interfacing between bathroomsubmitted. wall and external structural wall for window opening – window is installed in the structural wall. Perimeter of gap between the two walls is sealed with sealant. (Refer to slide no. 17 of presentation slides.)

6. Provision for Barrier-Free Accessibility (a) Steel backing to be installed at the back of drywall as reinforcement to Requirements support installation of grab bars (Refer to pg. 27 of presentation slides) (b) Locations of grab bars are provided in pg. 9 of presentation slides 7. Quality Control (QC) Checklist/Standard, Refer to … including (a) Watertightness Test Method (a) Watertightness test – Waterponding test Statement3 (i) Carried out in 2 stages, i.e. Stage 1 - before application of waterproofing membrane and Stage 2 - after application of waterproofing but before 3Should comply to CONQUAS standard of 24 hours & finishing works at minimum of 25mm of water as measured from the (ii) Method of statement for watertightness test requiring 24 hours of water- highest point of the area for both stages ponding in the bathroom structure at both stages followed by detection of leakage and rectification if leakages are found (b) Method Statements for all other (iii) Water spray test - …. relevant QC Tests Refer to slide no. XX of presentation. (b) Other quality checks include: (i) Pipe pressure test (ii) Tiles pull-off test

8. Provision for Training of Provision for training is by … Installers/Renovators 9. Method Statement for Method statement for the following are provided on pg. 44 to 47 of presentation Maintenance/Replacement/Renovation slides: (including tile replacement)

Version 2 updated on 15 September 2015 Page 3 Status How does the In-Built Bathroom system fulfil the criteria? Please describe briefly No. Item and(a) makeReplacement cross-references of tiles –to cut your the presentation tile into smaller slides pieces and andsupporting chisel out… documents (b) Repair and replacement of pipeworksubmitted. - locate pipes based on drawings in homeowner user manual, and hack the tiles and concrete to replace pipe (c) Unclogging choke in floor trap and floor waste – … 10. Provision for Homeowner User Manual Outline of homeowner user manual is provided. Refer to slide no. XX of presentation slides. 11. Any other supporting document (for list of (a) Test report A….tested in accordance with

Additional Frequently-Asked Questions:

Please answer each of the following questions by entering a new line below the respective question. If the question is not applicable to your In-Built Bathroom system, please state “N.A.”

In-Built Bathroom Details

1. What is the net storey height, thickness of the In-Built Bathroom’s floor slab and its false ceiling?

2. What is the minimum height provided between the In-Built Bathroom’s ceiling and structural ceiling for housing M&E services?

3. Please provide joint details at bathroom’s wall/floor, wall/wall boards, and wall/external wall (at window opening)

4. For non-concrete In-Built Bathrooms, please show the drainage system to address potential water leakages.

5. Please show details of the additional reinforcement, if applicable, for supporting grab bars.

Maintenance

1. Please provide the method statement for replacing tiles on the In-Built Bathroom’s wall and floor.

Version 2 updated on 15 September 2015 Page 4 2. Please provide the method statement for repairing or replacing embedded/hidden pipes.

Corrosion

1. Please provide details on corrosion protection and life span of the metal components used for the In-Built Bathroom.

2. Has the In-Built Bathroom been used in areas with higher risk of corrosion e.g. coastal areas? What preventive measures are to be taken if the In-Built Bathrooms are installed in projects near coastal areas?

Version 2 updated on 15 September 2015 Page 5 Version 2 updated on 15 September 2015 Page 6 Appendix A

Conventional Bathroom In-Built Bathroom Activity Description Construction Fabrication/Installation

Output (area, vol etc)

Slab Casting & Wall Erection Time (manhours)

Productivity (e.g. m2/manhour)

Output (area, vol etc)

Piping Installation Time (manhours)

Productivity (e.g. m2/manhour)

Output (area, vol etc)

M&E Installation Time (manhours)

Productivity (e.g. m2/manhour)

Output (area, vol etc)

Finishing (Wall, Floor and Ceiling) Time (manhours)

Productivity (e.g. m2/manhour)

Output (area, vol etc) Internal Fittings (e.g. Sanitary Time (manhours) Wares, Cabinets etc) Productivity (e.g. m2/manhour)

Output (area, vol etc)

Site Installation Time (manhours)

Productivity (e.g. m2/manhour)

Output (area, vol etc)

Window/Door Installation Time (manhours)

Productivity (e.g. m2/manhour)

Total Output

Overall Productivity Total Time

Overall Productivity

Page 7 Appendix B

Test Reports for Panel Boards Used as Wall and Floor

Product Name : Type of Board : Density (kg/m3) :

Instructions

1. Unless otherwise stated, please conduct and submit test reports according to the test standards listed below. 2. All test reports shall be the original or certified true copies from local or overseas laboratories accredited to ISO/IEC 17025, SAC-SINGLAS and SAC-MRA1. 3. The manufacturer of the panel boards used in the In-Built Bathroom system shall establish a Quality Management System certified according to EN ISO 9001.

S/N Test Standard Criteria/Remarks

A Strength Performance

1. SS492:2001 To achieve a grade of Medium Duty (MD) and above Specification for performance requirements for strength and robustness (including methods of test) for partition walls

B Thermal Properties

2. BS 476 Part 21: 1987* *Only applicable for single-slab bathroom system Fire tests on building materials and structures. Methods for determination of the fire resistance of loadbearing elements of construction

3. BS 476 Part 22: 1987* *Only applicable for bathroom wall system which is also used as Fire tests on building materials and structures. Method for party wall or compartment wall determination of the fire resistance of non-loadbearing elements of construction

4. BS 476 Part 4: 1970 Non-combustible

Fire tests on building materials and structures. Non- combustibility test for materials

Page 8 S/N Test Standard Criteria/Remarks

5. EN 13501-1: 2007 +A1: 2009 -

Fire classification of construction products and building elements. Classification using test data from reaction to fire tests

C Acoustic Properties

6. ASTM E90: 2004 -

Standard test method for laboratory measurement of airborne sound transmission loss of building partitions and elements

E Green Label and Mold Resistance

7. Singapore Green Building Product Labelling Scheme (SGBPLS) Panel board used in the In-Built Bathroom system must be Category: Panel Board certified under SGBPLS

8. ASTM D3273 – 12* To achieve a rating of 9 and above Standard test method for resistance to growth of mold on the surface of interior coatings in an environmental chamber

*Test to be conducted on uncoated panel boards (e.g. without water proofing, paint, tiles etc)

F Physical and Moisture Related Properties

9. BS EN 12467: 2012* *Test standards and requirements to adopt Fibre-cement flat sheets – Product specification and test Category A unless otherwise methods stated

a) Flexural strength (Bending strength) -

b) Moisture movement Value of moisture movement to achieve ≤ 0.07%

c) Water impermeability* *For panel boards used as floor panels within the In-Built Bathroom, please adopt a water height of 50mm above the sample panel board during the test

d) Warm water* RL shall not be less than 0.75

Page 9 S/N Test Standard Criteria/Remarks

* Please adopt a water bath in excess of lime for this test

e) Heat-rain* *Test to be conducted on uncoated panel boards (e.g. without water proofing, paint, tiles etc) for 50 cycles. Any additional material which appears on the back panel surface during the test should be sampled and tested for identification purpose

f) Soak-dry* *Test to be conducted on uncoated panel boards (e.g. without water proofing, paint, tiles etc) for 50 cycles

10. BS EN 317:1993 Swelling in thickness to achieve ≤ 1.5% Particleboards and fibreboards – Determination of swelling in thickness after immersion in water

Note

1 Singapore Accreditation Council (SAC) signs bilateral Mutual Recognition Arrangement (MRA) with other national accreditation bodies. It is a signatory to the International Laboratory Accreditation Cooperation (ILAC) Arrangement and regional cooperation bodies such as the Asia Pacific Laboratory Accreditation (APLAC).

Page 10