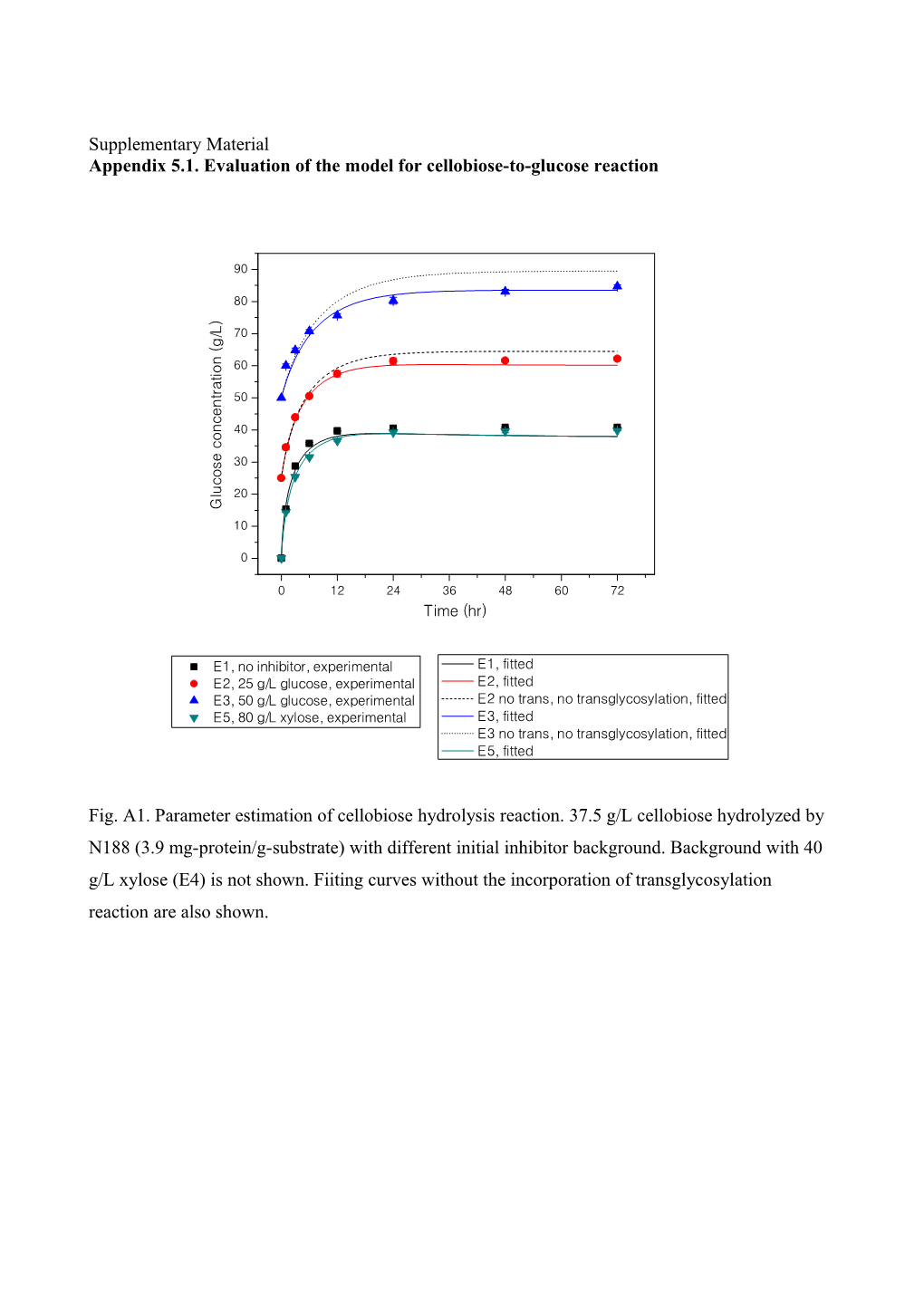

Supplementary Material Appendix 5.1. Evaluation of the model for cellobiose-to-glucose reaction

90 E1, fitted E2, fitted 80 E2 no trans, no transglycosylation, fitted ) L

/ 70 E3, fitted g (

E3 no trans, no transglycosylation, fitted n 60 o

i E5, fitted t a r

t 50 n e c

n 40 o c

e 30 s

90 o E1 mean, no inhibitor, experimental c u

l 20 90 E1, fitted E2 mean, 25 g/L glucose, experimental 80 G E2, fitted E3 mean, 50 g/L glucose, experimental 10 80 70 E2 no trans, no transglycosylation, fitted E5 mean, 80 g/L xylose, experimental

) E3, fitted L

0 / 70

60 g

( E3 no trans, no transglycosylation, fitted

n 60 E5, fitted o

50 0 i 12 24 36 48 60 72 t a r t 50 Time (hr) 40 n e c

n 40

30 o c

E1, no inhibitor,e 30 experimental E1, fitted s

20 o E2, fitted

E2, 25 g/L glucose,c experimental u E3, 50 g/L glucose,l 20 experimental E2 no trans, no transglycosylation, fitted

10 G E5, 80 g/L xylose, experimental E3, fitted 10 0 E3 no trans, no transglycosylation, fitted 0 E5, fitted 0 12 24 36 48 60 72 0 12 24 36 48 60 72 Time (hr) Fig. A1. Parameter estimation of cellobiose hydrolysis reaction. 37.5 g/L cellobiose hydrolyzed by N188 (3.9 mg-protein/g-substrate) with different initial inhibitor background. Background with 40 g/L xylose (E4) is not shown. Fiiting curves without the incorporation of transglycosylation reaction are also shown. 90

80 ) L

/ 70

g D1 (

n 60 D2 o i t D3 a r t 50 D5 n e c

n 40 o

c D1 90 e 30 90 D2 s o

80 c D3

u 80 l 20 ) D5 G L ) / 70 L g

/ 70 D1, predicted (

10 g ( n 60 D2, predicted o n i

t 60 o

i D3, predicted a 0 t r t 50 a r

n D5, predicted t 50 e n c

0 e 12 24 36 48 60 72 n

40 c o n 40 c o Time (hr) c e 30 s e

o 30 s c o u c l 20 D1, no inhibitor, experimental D1, predicted D1, no inhibitor, experimental u l G D2,20 25 g/L glucose, experimental D2, predicted

G D2, 25 g/L glucose, experimental 10 D3, 50 g/L glucose, experimental D3, predicted 10 D3, 50 g/L glucose, experimental D5, 80 g/L xylose, experimental D5, predicted 0 D5, 80 g/L xylose, experimental 0 0 12 24 36 48 60 72 0 12 24 36 48 60 72 Fig. A2. Validation of cellobioseTime (hr)hydrolysis reaction. 37.5 g/L cellobiose hydrolyzed by N188 (1.95 Time (hr) mg-protein/g-substrate) with different initial inhibitor background. Background with 40 g/L xylose (D4) is not shown. Appendix 5.2. Evaluation of Model 1 (Strategy 1)

140 130 120 110 ) L

/ 100 g (

90 n o i

t 80 a r t 70 n e

c 60 A1, predicted n o

140 c 50 A2, predicted

140 e A3, predicted 130 s 40

o 130 c 30 A4, predicted

120 u l 120

G 20 110 110 A1, no inhibitor, experimental ) )

L 10 L A2, 50 g/L glucose, experimental

/ 100 / 100 g g (

( A3, 30 g/L cellobiose, experimental

0 90

n 90 n A4, 80 g/L xylose, experimental o o i i t 80 0t 80 24 48 72 96 120 144 168 a a r r t 70 t n 70 Time (hr) n e e c 60 c 60 n n o 50 o c c

50 e e

s 40 s 40 o o c A1, predicted 30 A1,c no inhibitor, experimental u 30 u l A2,l 50 g/L glucose, experimental A2, predicted G 20 G 20 A3, 30 g/L cellobiose, experimental A3, predicted A1, no inhibitor, experimental 10 A4,10 80 g/L xylose, experimental A4, predicted A2, 50 g/L glucose, experimental 0 0 A3, 30 g/L cellobiose, experimental A4, 80 g/L xylose, experimental 0 24 48 72 0 96 24 120 48 144 72 168 96 120 144 168 Time (hr) Time (hr) Fig. A3. Validation of Model 1 (strategy 1). 100 g/L Avicel hydrolyzed by Celluclast (15.8 mg- protein/g-substrate) + N188 (5.9 mg-protein/g-substrate) with different initial inhibitor background.

90

80 B1, predicted 70 B2, predicted )

L B3, predicted /

g 60 (

B4, predicted n

o B5, predicted i

t 50

a B6, predicted r t

n B7, predicted

e 40 c n o

c 30 B1, no inhibitor, experimental e

s B2, 25 g/L glucose, experimental o

c 20

u B3, 50 g/L glucose, experimental l 90 G B4, 15 g/L cellobiose, experimental 10 B5, 30 g/L cellobiose, experimental 90 80 0 B6, 40 g/L xylose, experimental B7, 80 g/L xylose, experimental 80 0 70 24 48 72 96 120 144 168 ) L / Time (hr) 70 g 60 ( )

L n / o g i

( 60 t 50 a n r t o i t 50 n B1 a e 40 r c t B1, fitted B2 n n B1, no inhibitor, experimental o e 40

c B2, fitted c 30 B3

B2, 25 g/L glucose, experimental n e o B3, fitted B4 s B3, 50 g/L glucose, experimental c 30 o 20 c B4, fitted e B4, 15 g/L cellobiose, experimental B5 u s l o 20 B5, 30 g/L cellobiose, experimental B5, fitted B6 G c 10 u l B6, 40 g/L xylose, experimental B6, fitted B7 G 10 B7, fitted B70 , 80 g/L xylose, experimental 0 0 24 48 72 96 120 144 168 0 24 48 72 96 120 144 168 Time (hr) Fig. A4. ParameterTime estimation (hr) of Model 1 (strategy 1). 100 g/L Avicel hydrolyzed by Celluclast (10.5 mg-protein/g-substrate) with different initial inhibitor background. 100

90

80 ) L / 70 g (

n o

i 60 t a r t 50 n e c

n 40 o c

e 30 s o c u

l 20 G 10 100 100 0 90 90 0 24 48 72 96 120 144 168 ) 80

80 L / )

g Time (hr) L ( / 70

g 70 n (

o i n t o

a 60 i 60 r t t a n r t 50 e 50 n c e n c C1, predicted o C1, no inhibitor, experimental n

40 c 40 o C2, predicted c C2, 25 g/L glucose, experimental e

s e 30 C3, predicted o 30 C3, 50 g/L glucose, experimental s c o u c C4, 15 g/L cellobiose, experimental C4, predicted l u 20 l 20 G C5, 30 g/L cellobiose, experimental C5, predicted G 10 10 C6, 40 g/L xylose, experimental C6, predicted C7, 80 g/L xylose, experimental C7, predicted 0 0

0 24 480 7224 96 48 120 72 144 96 168 120 144 168 Fig. A5. ValidationTime (hr) of Model 1Time (strategy (hr) 1). 100 g/L Avicel hydrolyzed by Celluclast (21.1 mg- protein/g-substrate) with different initial inhibitor background.

90

80

70 ) L / g (

60 n o i t

a 50 r t n e

c 40 n o

c F, predicted 30 e

s G, predicted o c 20 H, predicted u l

G F, Cel / N188 = 15.8 / 3, experimental 10 G, Cel / N188 = 15.8 / 1, experimental 0 H, Cel / N188 = 31.6 / 5.9, experimental

0 24 48 72 96 120 144 168 Time (hr)

Fig. A6. Validation of Model 1 (strategy 1). 100 g/L Avicel hydrolyzed by different ratio of Celluclast/N188 loading with initial 40 g/L xylose background.

130 120 110

) 100 L / g

( 90

n o

i 80 t a r

t 70 n e

c 60 n o

c 50

e

s 40 o c

u 30 l I, 150 g/L, experimental G 20 J, 50 g/L, experimental 10 I, predicted 0 J, predicted

0 24 48 72 96 120 144 168 Time (hr) Fig. A7. Validation of Model 1 (strategy 1). 50 and 150 g/L Avicel hydrolyzed by Celluclast (15.8 mg-protein/g-substrate) + N188 (5.9 mg-protein/g-substrate). 100

90

80 ) L

/ 70 g (

n 60 o i t

a N, predicted r

t 50 n O, predicted e

c P, predicted

n 40 o

c Q, predicted

100

e 30 s

o 90 c N, no inhibitor, experimental

u 20 l

G 80 O, 50 g/L glucose, experimental 10 ) P, 30 g/L cellobiose, experimental L / 70 g Q, 80 g/L xylose, experimental (

0 n 60 o i t

0a 24 48 72 96 120 144 168 r

t 50 n

e Time (hr) c

n 40 o c 190 e 30 180 s o 170 c 20 N, no inhibitor, experimental u N, no inhibitor, experimental N, predicted 160 l G O, 50 g/L glucose, experimental O, predicted O, 50 g/L glucose, experimental 150 10 P, 30 g/L cellobiose, experimental 140 P, 30 g/L cellobiose, experimental P, predicted 130 0Q, 80 g/L xylose, experimental Q, predicted Q, 80 g/L xylose, experimental 120

) 110 0 24 48 72 96 120 144 168 L /

g 100

( Time (hr) 90 Fig.e A8. Validation of Model 1 (strategy 1). 90 g/L Barley straw hydrolyzed by Celluclast (15.8 s 80 o

c 70 u mg-protein/g-substrate)l 60 + N188 (5.9 mg-protein/g-substrate) with different initial inhibitor G background.50 N 40 O 30 20 P 10 Q 0 -10 -20 0 20 40 60 80 100 120 140 160 180 time (hr)

Appendix 5.3. Evaluation of Model 1 (Strategy 2)

130 120 110 100 ) L / 90 g (

n 80 o i t

a 70 r t n

e 60

c A1 n 50 o A2 c

e 40 A3 140 s o 130 A4 c 30

130 u l 120

G 20 120 A1, fitted 10110 110 A2, fitted ) 100 L )

/ 100 0

L A3, fitted g / (

90 g 90

( A4, fitted n 0 24 48 72 96 120 144 168 o n i t 80 80 o i a t r Time (hr) t 70 a 70 r n t e n c 60

e 60 n

c A1 o n

c 50

50 o A2 e c

s 40 e o 40 A3 s c A1, no inhibitor, experimental A1, fitted

30 o u

l A4 c 30 A2, 50 g/L glucose, experimental A2, fitted G u

20 l

G 20 A3, 30 g/L cellobiose, experimental A3, fitted 10 10 A4, 80 g/L xylose, experimental A4, fitted 0 0 0 24 48 72 96 120 144 168 Fig. A9. Parameter estimation of Model 1 (strategy 2). 100 g/L Avicel hydrolyzed by Celluclast 0 Time (hr)24 48 72 96 120 144 168 (15.8 mg-protein/g-substrate) + N188 (5.9 mg-protein/g-substrate)Time (hr) with different initial inhibitor background. 90

80

70 ) L / g (

60 n o i t

a 50

r B1 t n

e B2

c 40

n B3 o c 30 B4 e

s B5 o

c 20 B6 u l

G B7 90 10

90 80 0

80 70 0 24 48 72 96 120 144 168

70 60 Time (hr) ) ) L / L / g 60 ( 50 g

( n e o i s t 50 40 o a c r t

u B1, predicted l n B1, no inhibitor, experimental

e 40 30 G B2, predicted c B2, 25 g/L glucose, experimental n o B3, 50 g/L glucose, experimental B3, predicted c 30 20 B4, predicted e B4, 15 g/L cellobiose, experimental s o 20 10 B5, 30 g/L cellobiose, experimental B5, predicted c u B6, predicted l B6, 40 g/L xylose, experimental G 10 0 B7, 80 g/L xylose, experimental B7, predicted

0 0 24 48 72 96 120 144 168 time (hr) 0 24Fig. A10.48 Validation72 of96 Model120 1 (strategy144 2).168 100 g/L Avicel hydrolyzed by Celluclast (10.5 mg- Time (hr) protein/g-substrate) with different initial inhibitor background. 100

90

80 ) L /

g 70 (

n o i 60 t a r t

n 50 e c n

o 40 C1 c

e C2

s 30 o C3 c u l 20 C4 G 100 C5 100 10 C6 90 90 0 C7

) 80 80 L / ) 0 24 48 72 96 120 144 168 g L ( / 70 g

70 n ( Time (g/L)

o i n t o

a 60 i 60 t r t a n r t

e 50 n 50 c e n c C1, predicted o C1, no inhibitor, experimental n

40 c 40 o C2, predicted c

e C2, 25 g/L glucose, experimental

s e C3, predicted 30 o 30 C3, 50 g/L glucose, experimental s c o u

c C4, predicted

l C4, 15 g/L cellobiose, experimental u 20 20 l G C5, 30 g/L cellobiose, experimental C5, predicted G 10 10 C6, 40 g/L xylose, experimental C6, predicted C7, 80 g/L xylose, experimental C7, predicted 0 0

0 24 48 0 72 24 96 48 120 72 144 96 168 120 144 168 Fig. A11. ValidationTime of (hr) Model 1 (strategyTime (hr) 2). 100 g/L Avicel hydrolyzed by Celluclast (21.1 mg- protein/g-substrate) with different initial inhibitor background. 90 90 80 90 80 70 80 ) L / 70 g 70 (

60 n

o 60 i

t 60

a 50 r t 50 n 50 e 40 c F mean

n 40 o 40 F, predicted G mean c

30 F, predicted

e G, predicted H mean

s G, predicted 30 30 o H, predicted c 20 H, predicted u l F 20 20 G 10 F, Cel / N188 = 15.8 F, Cel / 3, / N188experimental = 15.8 / 3, experimental G 10 10 G, Cel / N188 = 15.8 G, Cel / 1, / N188experimental = 15.8 / 1, experimental H 0 H, Cel / N188 = 31.6 H, Cel / 5.9, / N188 experimental = 31.6 / 5.9, experimental 0 0 0 24 48 72 96 120 144 168 0 24 480 7224 9648 12072 14496 168120 144 168 Time (hr)

Fig. A12. Validation of Model 1 (strategy 2). 100 g/L Avicel hydrolyzed by different ratio of Celluclast/N188 loading with initial 40 g/L xylose background. 130 120 110

) 100 L / g

( 90

n o

i 80 t a r 130 t 70 140 n e

120 c 60

130 n o

c 50

120 110 e s ) 100 40

) 110 o L / c L / g u 30 I, 150 g/L, experimental l g 100 ( 90

(

G n J, 50 g/L, experimental n

90 o 20 i

o 80 i t t a a 80 r 10 r t 70 I, prediction I, predicted t n n

70 e J, predicted

e 0 J, prediction

c 60 c n n 60 o o

c 50 0 24 48 72 96 120 144 168 I c

50 e e

s J

s 40 Time (hr) o

o 40 c c

u 30 u l l 30 I G G 20 20 I, 150 g/L, experimental J 10 10 J, 50 g/L, experimental 0 0

0 024 2448 4872 7296 96120 120144 144168 168 Time (hr)Time (hr)

Fig. A13. Validation of Model 1 (strategy 2). 50 and 150 g/L Avicel hydrolyzed by Celluclast (15.8 mg-protein/g-substrate) + N188 (5.9 mg-protein/g-substrate).

100

90

80 ) L

/ 70 g (

n 60 o i t a r

t 50 n e c

n 40 o c

N

e 30

s O o

c P

u 20 l

G Q 10

0

0 24 48 72 96 120 144 168 Time (hr) 100

90

80 ) L / 70 g (

n 60 o i t a r

t 50 n e c

n 40 o c 190

e 30

180 s o 170 c 20 N, no inhibitor, experimental N, no inhibitor, experimental u N, predicted 160 l

G O, 50 g/L glucose, experimental O, predicted O, 50 g/L glucose, experimental 150 10 140 P, 30 g/L cellobiose, experimental P, predicted P, 30 g/L cellobiose, experimental 130 0Q, 80 g/L xylose, experimental Q, predicted Q, 80 g/L xylose, experimental 120

) 110

L 0 24 48 72 96 120 144 168 /

g 100 ( 90 Time (hr) e

s 80 o

Fig. A14.c 70 Validation of Model 1 (strategy 2). 90 g/L Barley straw hydrolyzed by Celluclast (15.8 u l 60 G mg-protein/g-substrate)50 + N188 (5.9 mg-protein/g-substrate) with different N initial inhibitor 40 O background.30 20 P 10 Q 0 -10 -20 0 20 40 60 80 100 120 140 160 180 time (hr)

Appendix 5.4. Evaluation of Model 2 (Gcr,tetra = 75 g/L) 130 120 110

) 100 L / g (

90 n o i

t 80 a r t 70

n A1 e

c 60 A2 n

o A3 c 140 50

e A4 s 40 130 130 o c

u 120 120 l 30 A1 G 110 20 110 A2 )

L 100 100 ) / 10 A3 L g / (

90 90 g A4 ( n

0 o n i

t 80 80 o i a t r

t 0 24 48 72 96 120 144 168 70 a 70 r n t e n c 60 Time (hr)

e 60 n

c A1 o

50 n c

50 o A2 c e

s 40

e 40 A3 o s c A1, no inhibitor, experimental A1, fitted 30 o u A4 l c 30 A2, fitted u A2, 50 g/L glucose, experimental G 20 l

G 20 A3, 30 g/L cellobiose, experimental A3, fitted 10 10 A4, 80 g/L xylose, experimental A4, fitted 0 0 0 24 48 72 96 120 144 168 0 24 48 72 96 120 144 168 Time (hr) Fig. A15. Parameter estimation of Model 2 (Gcr,tetraTime = 75 (hr) g/L). 100 g/L Avicel hydrolyzed by Celluclast (15.8 mg-protein/g-substrate) + N188 (5.9 mg-protein/g-substrate) with different initial inhibitor background. 90

80

70 ) L /

g 60 (

n o i

t 50 a r t

n B1

e 40

c B2 n o

c 30 B3

e B4 s

o 20 c B5 u 90 l B6 G 10 B7 90 80 0 80 70 0 24 48 72 96 120 144 168 70 60 Time (hr) ) ) L / L / g 50

60 g (

( n e o i s t 50 40 o a c r t

u B1, predicted l

n B1, no inhibitor, experimental

e 30 40 G B2, predicted c B2, 25 g/L glucose, experimental n o B3, 50 g/L glucose, experimental B3, predicted c 30 20 B4, predicted e B4, 15 g/L cellobiose, experimental s o 20 10 B5, 30 g/L cellobiose, experimental B5, predicted c u l B6, 40 g/L xylose, experimental B6, predicted G 10 0 B7, 80 g/L xylose, experimental B7, predicted

0 0 24 48 72 96 120 144 168 time (hr) 0 24 48 72 96 120 144 168 Fig. A16. ValidationTime (hr) of Model 2 (Gcr,tetra = 75 g/L). 100 g/L Avicel hydrolyzed by Celluclast (10.5 mg-protein/g-substrate) with different initial inhibitor background. 100

90

80 ) L /

g 70 (

n o

i 60 t C1 a r t

n 50 C2 e

c C3 n 40 o C4 c

e C5

s 30

o C6 c u l 20 C7 G

100 10 100 90 0 90

) 80 0 24 48 72 96 120 144 168

80 L / ) g

L ( Time (hr) / 70 g

70 n (

o i n t 60 o a i 60 r t t a n r t

e 50

n 50 c e n c C1, predicted o C1, no inhibitor, experimental n 40 40 c o C2, predicted

c C2, 25 g/L glucose, experimental e

s e 30 C3, predicted 30 o C3, 50 g/L glucose, experimental s c o u c C4, 15 g/L cellobiose, experimental C4, predicted l u 20 l 20 G C5, 30 g/L cellobiose, experimental C5, predicted G 10 10 C6, 40 g/L xylose, experimental C6, predicted C7, 80 g/L xylose, experimental C7, predicted 0 0

0 24 480 7224 9648 12072 144 96 168 120 144 168 Fig. A17. Validation of Model 2 (Gcr,tetra = 75 g/L). 100 g/L Avicel hydrolyzed by Celluclast (21.1 Time (hr) Time (hr) mg-protein/g-substrate) with different initial inhibitor background. 90 90 80 8090

) 70 L

/ 80 g

) 70 (

L /

n 60

g 70 o ( i

t 60 n a r o

t 50 i

t 60 n

a 50 e r t c n n 4050 e o F c

c 40

n

e G o 3040 s c F, predicted F, predicted

o 30 H e c

s G, predicted

u G, predicted

l 2030 o c G 20 H, predicted H, predicted F mean u l 20 G 10 G mean F, Cel / N188 = 15.8 / 3, experimental 10 F, Cel / N188 = 15.8 / 3, experimental H mean 100 G,G, CelCel // N188N188 == 15.815.8 // 1,1, experimentalexperimental 0 H,H, CelCel // N188N188 == 31.631.6 // 5.9,5.9, experimentalexperimental 0 0 24 48 72 96 120 144 168 0 24 48 72 96 120 144 168 0 24 48 Time72 (hr)96 120 144 168 Time (hr)

Fig. A18. Validation of Model 2 (Gcr,tetra = 75 g/L). 100 g/L Avicel hydrolyzed by different ratio of Celluclast/N188 loading with initial 40 g/L xylose background. 130 120 110

) 100 L / g (

90 n o

i 80 130 t a r 120 t 70 130n e

110 c 60 120n o )

100 c 50

L

/ 110 e g s

( 90 40

o ) 100 n c L / o u

i 80 30 I, 150 g/L, experimental l t g

( 90 a

G

r J, 50 g/L, experimental t 70 n 20 n o

i 80 e t

c 60 a 10 I, predicted r n t 70 I, prediction I o n

c 50 0 J, predicted

e J, prediction J c e 60 s 40 n o o 0 24 48 72 96 120 144 168 c

c 50

I u 30 l e Time (hr) s G 40 J

20 o c

u 30 10 l G 0 20 I, 150 g/L, experimental 10 J, 50 g/L, experimental 0 24 48 72 96 120 144 168 0 Time (hr) 0 24 48 72 96 120 144 168 Time (hr)

Fig. A19. Validation of Model 2 (Gcr,tetra = 75 g/L). 50 and 150 g/L Avicel hydrolyzed by Celluclast (15.8 mg-protein/g-substrate) + N188 (5.9 mg-protein/g-substrate). 90

80

70 ) L / g (

60 n o i t

a 50 r t n e

c 40 100 n

o N c 30 90

e O s

o P c 20 80 u

l Q ) G L / 70

10g (

N n 60 o O i

0t a

r P t 50 n Q e 0 24 48 72 96 120 144 168 c

n 40

o Time (hr) c 190

e 30

180 s o 170 c 20 N, no inhibitor, experimental N, no inhibitor, experimental u N, predicted 160 l

G O, 50 g/L glucose, experimental O, predicted O, 50 g/L glucose, experimental 150 10 140 P, 30 g/L cellobiose, experimental P, predicted P, 30 g/L cellobiose, experimental 130 0 Q, 80 g/L xylose, experimental Q, predicted Q, 80 g/L xylose, experimental 120

) 110

L 0 24 48 72 96 120 144 168 / 100 g ( 90 Time (hr)

Fig. e A20. Validation of Model 2 (Gcr,tetra = 75 g/L). 90 g/L Barley straw hydrolyzed by Celluclast

s 80 o

c 70

(15.8u mg-protein/g-substrate) + N188 (5.9 mg-protein/g-substrate) with different initial inhibitor l 60 G background.50 N 40 O 30 20 P 10 Q 0 -10 -20 0 20 40 60 80 100 120 140 160 180 time (hr) Appendix 5.5. Evaluation of Model 2 (Gcr,tetra = 80 g/L)

130 120 110

) 100 L /

g 90 (

n

o 80 i

t A1 a r

t 70 A2 n

e 60 A3 c

n A4 o 50 c

140 e s 40

o 130 A1 130 c 30 u

l A2 120 120 G 20 A3 110 110 A4

) 10

L 100 / 100 ) g L 0 ( / 90 90 g n ( o i

n 0 24 48 72 96 120 144 168 t 80 80 o a i r t t

70 a Time (hr)

n 70 r t e n c 60

e 60 n c

o A1 n

c 50

50 o A2 e c

s 40 e

o 40 A3 s c A1, no inhibitor, experimental A1, fitted

30 o u A4 l c 30 A2, fitted

u A2, 50 g/L glucose, experimental G 20 l

G 20 A3, 30 g/L cellobiose, experimental A3, fitted 10 10 A4, 80 g/L xylose, experimental A4, fitted 0 0 0 24 48 72 96 120 144 168 0 24 48 72 96 120 144 168 Time (hr) Fig. A21. Parameter estimation of Model 2 (Gcr,tetraTime = 80 (hr) g/L). 100 g/L Avicel hydrolyzed by Celluclast (15.8 mg-protein/g-substrate) + N188 (5.9 mg-protein/g-substrate) with different initial inhibitor background. 90

80

70 ) L / g (

60 n o i t

a 50

r B1 t n

e B2

c 40

n B3 o c 30 B4 e

s B5 o

c 20 B6 u l

G B7 90 10

90 80 0

80 70 0 24 48 72 96 120 144 168

70 60 Time (hr) ) ) L L / / g 50

60 g ( (

n e o s i t 50 40 o a c r t

u B1, predicted l

n B1, no inhibitor, experimental 30 e 40 G B2, predicted c B2, 25 g/L glucose, experimental n B3, predicted o B3, 50 g/L glucose, experimental c 30 20 B4, predicted e B4, 15 g/L cellobiose, experimental s o 20 10 B5, 30 g/L cellobiose, experimental B5, predicted c u B6, predicted l B6, 40 g/L xylose, experimental G 10 0 B7, 80 g/L xylose, experimental B7, predicted

0 0 24 48 72 96 120 144 168 time (hr) 0 24 48 72 96 120 144 168 Fig. A22. ValidationTime (hr)of Model 2 (Gcr,tetra = 80 g/L). 100 g/L Avicel hydrolyzed by Celluclast (10.5 mg-protein/g-substrate) with different initial inhibitor background.

100

90

80 ) L /

g C1 ( 70

n C2 o i t 60 C3 a r t

n 50 C4 e

c C5 n

o 40 C6 c

e C7 s 30 o c u l 20 C1 G C2 10 C3 100 100 C4 0 90 90 C5 0 24 48 72 96 120 144 168 C6 80 ) 80

L C7 ) / L g Time (hr) / (

70 g 70 ( n

o i n t o 60 i

60 a t r t a r n t

50 e 50 n c e n c C1, predicted o C1, no inhibitor, experimental n 40 40 c o C2, predicted e

c C2, 25 g/L glucose, experimental

s

e 30 C3, predicted 30 o C3, 50 g/L glucose, experimental s c o u C4, predicted l c C4, 15 g/L cellobiose, experimental 20 u 20 G l C5, 30 g/L cellobiose, experimental C5, predicted G C6, predicted 10 10 C6, 40 g/L xylose, experimental C7, 80 g/L xylose, experimental C7, predicted 0 0

0 24 48 0 72 24 96 48 120 72 144 96 168 120 144 168 Fig. A23. Validation of Model 2 (Gcr,tetra = 80 g/L). 100 g/L Avicel hydrolyzed by Celluclast (21.1 Time (hr) Time (hr) mg-protein/g-substrate) with different initial inhibitor background. 90 9090 80 8080

) 70 L /

g 7070 ) (

L /

n 60 g o ( i

60

t 60 n a r o t 50i F t n

a 5050 e r G t c n

n 40

e H o 40 c 40 c F, predicted

n

e 30o c s G, predicted F, predicted 30 F o 30 e c H, predicted G, predicted s G u

l 20o

c 20 H, predicted G 20 H u l F, Cel / N188 = 15.8 / 3, experimental 10G F, Cel / N188 = 15.8 / 3, experimental 1010 G, Cel / N188 = 15.8 / 1, experimental H,G, Cel Cel / / N188N188 == 31.615.8 // 5.9,1, experimental experimental 00 0 H, Cel / N188 = 31.6 / 5.9, experimental

00 2424 4848 7272 9696 120120 144144 168 0 24 48 72 96 120 144 168 Time (hr) Time (hr)

Fig. A24. Validation of Model 2 (Gcr,tetra = 80 g/L). 100 g/L Avicel hydrolyzed by different ratio of Celluclast/N188 loading with initial 40 g/L xylose background.

130 120 110 100 ) L /

g 90 (

n 80 o i t a

r 70 I, prediction t n

e 60 J, prediction c n

o 50 c

e

s 40 o c

u 30 l G 20 I, 150 g/L, experimental 10 J, 50 g/L, experimental 0

0 24 48 72 96 120 144 168 Time (hr) 130 120

130 110

) 100 L

120 / g ( 110 90 n o

i 80 t ) 100 a L / r t 70 g n ( 90

e n c 60 o n

i 80 t o a

c 50 r

t 70 e n s

e 40 o

c 60

c I n

u 30 I, 150 g/L, experimental o 50 l c J G J, 50 g/L, experimental

e 20

s 40 o

c 10 I, predicted I

u 30 l J, predicted J

G 0 20 10 0 24 48 72 96 120 144 168 0 Time (hr)

0 24 48 72 96 120 144 168 Time (hr)

Fig. A25. Validation of Model 2 (Gcr,tetra = 80 g/L). 50 and 150 g/L Avicel hydrolyzed by Celluclast (15.8 mg-protein/g-substrate) + N188 (5.9 mg-protein/g-substrate). 90

80

) 70 L / g ( 60 n o i t a

r 50 t n e

c N 40 n

o O c

e P 30 100 s

o Q c

u 90

l 20

G N 80 10 O )

L P / 70 g

0 ( Q

n 60 o i t

0 a 24 48 72 96 120 144 168 r

t 50 n

e Time (hr) c 40 n o c 190

e 30

180 s o 170 c 20 N, no inhibitor, experimental u N, no inhibitor, experimental N, predicted 160 l G O, 50 g/L glucose, experimental O, predicted O, 50 g/L glucose, experimental 150 10 P, 30 g/L cellobiose, experimental 140 P, 30 g/L cellobiose, experimental P, predicted 130 Q,0 80 g/L xylose, experimental Q, predicted Q, 80 g/L xylose, experimental 120

) 110 0 24 48 72 96 120 144 168 L / 100 g

( Time (hr) Fig. A26. 90 Parameter estimation of Model 2 (Gcr,tetra = 80 g/L). 100 g/L Avicel hydrolyzed by e

s 80 o

Celluclastc 70 (15.8 mg-protein/g-substrate) + N188 (5.9 mg-protein/g-substrate) with different initial u l 60 G inhibitor 50background. N 40 O 30 20 P 10 Q 0 -10 -20 0 20 40 60 80 100 120 140 160 180 time (hr) Appendix 5.6. Evaluation of Model 3 (Gcr,tetra = 75 g/L)

120 110 100

) 90 L / g

( 80

n o

i 70 t a r t 60 n e

c 50 A1 n

o A2 c

40

e A3 s

o 30 A4 c u l 20 140 I G 10 130 120 0 110 ) L

0 / 10024 48 72 96 120 144 168 g ( 90

n Time (hr) o i

t 80 a r t 70 n e

c 60 n o

c 50

A1, no inhibitor,e 100 g/L Avicel, experimental A1, fitted s 40 A1, no inhibitor, 100 g/L Avicel, experimental o

c A2, fitted A2, 50 g/L glucose,30 100 g/L Avicel, experimental A2, 50 g/L glucose, 100 g/L Avicel, experimental u 140 A3, 30 g/Ll cellobiose, 100 g/L Avicel, experimental A3, fitted A3, 30 g/L cellobiose, 100 g/L Avicel, experimental G 20 A1 130 A4, 80 g/L xylose, 100 g/L Avicel, experimental A4, fitted A4, 80 g/L, xylose, 100 g/L Avicel, experimental 10 A2 120 I, no inhibitor, 150 g/L Avicel, experimental I, fitted I, no inhibitor, 150 g/L Avicel, experimental 0 A3 110 A4 100 0 24 48 72 96 120 I144 168 90 Time (hr) )

L 80 Fig. / A27. Parameter estimation of Model 3 (Gcr,tetra = 75 g/L). 100 and 150 g/L Avicel hydrolyzed by g (

70 e

Celluclasts 60 (15.8 mg-protein/g-substrate) + N188 (5.9 mg-protein/g-substrate) with different initial o c

u 50 inhibitorl background. G 40 30 20 10 0

0 24 48 72 96 120 144 168 time (hr) 90

80

) 70 L / g ( 60 B1 n o

i B2 t a

r 50 B3 t n

e B4

c 40

n B5 o c

B6

e 30

s B7 o c

u 20 l B1 90 G 10 B2 B3 90 80 0 B4 B5 80 70 0 24 48 72 96 120 144 168 B6 70 60 Time (hr) B7 ) ) L / L / g

( 60 50 g

( n e o i s t 50 40 o a r c t

u B1, predicted l n B1, no inhibitor, experimental

e 40 30 G c B2, 25 g/L glucose, experimental B2, predicted n o B3, 50 g/L glucose, experimental B3, predicted c 30 20

e B4, 15 g/L cellobiose, experimental B4, predicted s o 20 10 B5, 30 g/L cellobiose, experimental B5, predicted c u l B6, 40 g/L xylose, experimental B6, predicted G 10 0 B7, 80 g/L xylose, experimental B7, predicted

0 0 24 48 72 96 120 144 168

0 24 48 72 96 120 time144 (hr) 168

Fig. A28. ValidationTime of (hr) Model 3 (Gcr,tetra = 75 g/L). 100 g/L Avicel hydrolyzed by Celluclast (10.5 mg-protein/g-substrate) with different initial inhibitor background. 100

90

) 80 L / g (

70 n o i t 60 C1 a r

t C2 n

e 50 C3 c

n C4 o

c 40 C5 e s

o 30 C6 c

u C7 l

G 20

10 100 100 0 90 90 0 24 48 72 96 120 144 168 80 ) 80 ) L / L / g Time (hr) (

g 70 70 (

n n o i t o i 60 60 a t r a t r n t

50 e n 50 c e n c C1, no inhibitor, experimental C1, predicted o n 40 40 c o C2, predicted c C2, 25 g/L glucose, experimental e

s e 30 30 C3, predicted

o C3, 50 g/L glucose, experimental s c o u c C4, 15 g/L cellobiose, experimental C4, predicted l u 20 20 l G C5, 30 g/L cellobiose, experimental C5, predicted G 10 10 C6, 40 g/L xylose, experimental C6, predicted C7, 80 g/L xylose, experimental C7, predicted 0 0

0 24 48 0 72 24 96 48 120 72 144 96 168 120 144 168 Fig. A29. ValidationTime (hr) of Model 3 (GTimecr,tetra (hr) = 75 g/L). 100 g/L Avicel hydrolyzed by Celluclast (21.1 mg-protein/g-substrate) with different initial inhibitor background. 9090

8080 90

) 70 ) 70 L / L 80 / g g (

( 60

n 60

n 70 o i o t i t a 50 r a t r 5060 t n n e e c 40 c n 4050 n o o c F, predicted

F c 30 e

s 40 G, predicted e 30 G

o F, predicted s c o 20 H, predicted H u c G, predicted l 30 u 20 l G F, Cel / N188 H, = predicted 15.8 / 3, experimental G 10 1020 G, Cel / N188 = 15.8 / 1, experimental F F, Cel / N188 = 15.8 / 3, experimental 0 H, Cel / N188 = 31.6 / 5.9, experimental G 010 G, Cel / N188 = 15.8 / 1, experimental H 0 24 H,48 Cel / N18872 = 31.696 / 5.9,120 experimental144 168 0 0 24 48 72 96 120 144 168 Time (hr) 0 24 48 Time72 (hr)96 120 144 168

Fig. A30. Validation of Model 3 (Gcr,tetra = 75 g/L). 100 g/L Avicel hydrolyzed by different ratio of Celluclast/N188 loading with initial 40 g/L xylose background.

130 120 110 130 100 120 ) L / 90

g 110

( J, 50 g/L, experimental

n 80 100 o ) i

t J, predicted L / a 70

r 90 g t ( n e 60 n 80 c o i n 50 t o a 70 r c

t J

n e 40

e 60 s c o c 30 n 50 u

o J l c

G 20

e 40 s

10 o

c 30 u 0 l

G 20 0 1024 48 72 96 120 144 168 0 Time (hr)

0 24 48 72 96 120 144 168 Time (hr) Fig. A31. Validation of Model 3 (Gcr,tetra = 75 g/L). 50 g/L Avicel hydrolyzed by Celluclast (15.8 mg-protein/g-substrate) + N188 (5.9 mg-protein/g-substrate). 90

80

) 70 L / g ( 60 n o i t a

r 50 t n e

c 40 n o c

e 30

s 100 o c

u 20 l 90 G 10 80 ) L

/ 70

0 g (

n 60 o i 0 t 24 48 72 96 120 144 168 a r

t 50 n Time (hr) e c

n 40 o c 190

e 30 180 s o 170 c 20 N, no inhibitor, experimental u N, no inhibitor, experimental N, predicted 160 l G O, 50 g/L glucose, experimental O, predicted O, 50 g/L glucose, experimental 150 10 P, 30 g/L cellobiose, experimental P, predicted P, 30 g/L cellobiose, experimental 140 Q, 80 g/L xylose, experimental 130 Q,0 80 g/L xylose, experimental Q, predicted 120

) 110 0 24 48 72 96 120 144 168 L /

g 100

( Time (hr) 90 Fig. A32.e Parameter estimation of Model 3 (Gcr,tetra = 75 g/L). 100 g/L Avicel hydrolyzed by s 80 o

c 70 u Celluclastl 60 (15.8 mg-protein/g-substrate) + N188 (5.9 mg-protein/g-substrate) with different initial G 50 N inhibitor40 background. 30 O 20 P 10 Q 0 -10 -20 0 20 40 60 80 100 120 140 160 180 time (hr) Appendix 5.7. Evaluation of Model 3 (Gcr,tetra = 80 g/L)

120

110

100 )

L 90 / g ( 80 n o i t 70 a r t

n 60 e c

n 50 o c

e 40 s o

c 30 u l 140 G 20 130 10 120 0 110 ) L

/ 100 g

0 ( 24 48 72 96 120 144 168 90 n o i

t 80 Time (hr) a r t 70 n e

c 60 n o

c 50

e A1, fitted A1, no inhibitor,s 40 100 g/L Avicel, experimental A1, no inhibitor, 100 g/L Avicel, experimental o

c A2, fitted A2, 50 g/L glucose,30 100 g/L Avicel, experimental A2, 50 g/L glucose, 100 g/L Avicel, experimental u 140 A3, 30 g/L cellobiose,l 100 g/L Avicel, experimental A3, fitted A3, 30 g/L cellobiose, 100 g/L Avicel, experimental G 20 A1 130 A4, 80 g/L xylose, 100 g/L Avicel, experimental A4, fitted A4, 80 g/L, xylose, 100 g/L Avicel, experimental 10 A2 120 I, no inhibitor, 150 g/L Avicel, experimental I, fitted I, no inhibitor, 150 g/L Avicel, experimental 0 A3 110 A4 100 0 24 48 72 96 120 I144 168 90 Time (hr)

Fig. ) A33. Parameter estimation of Model 3 (Gcr,tetra = 80 g/L). 100 and 150 g/L Avicel hydrolyzed by

L 80 / g ( Celluclast 70 (15.8 mg-protein/g-substrate) + N188 (5.9 mg-protein/g-substrate) with different initial e

s 60 o inhibitorc background.

u 50 l

G 40 30 20 10 0

0 24 48 72 96 120 144 168 time (hr) 90

80

) 70 L / g ( 60 n o i t a

r 50 B1 t

n B2 e

c 40

n B3 o c

B4

e 30

s B5 o

c B6

u 20 l

90 G B7 10 90 80 0 80 70 0 24 48 72 96 120 144 168 70 60 )

) Time (hr) L L / / g 50

60 g ( (

n e o s i t 50 40 o a c r t

u B1, predicted l

n B1, no inhibitor, experimental

e 30 40 G B2, predicted c B2, 25 g/L glucose, experimental n o B3, 50 g/L glucose, experimental B3, predicted c 30 20 B4, predicted e B4, 15 g/L cellobiose, experimental s o 20 10 B5, 30 g/L cellobiose, experimental B5, predicted c u l B6, 40 g/L xylose, experimental B6, predicted G 10 0 B7, 80 g/L xylose, experimental B7, predicted

0 0 24 48 72 96 120 144 168 Fig. A34. Validation of Model 3 (Gcr,tetra = 80 g/L). 100 g/L Avicel hydrolyzed by Celluclast (10.5 time (hr) 0 mg-protein/g-substrate)24 48 72 with96 different120 initial144 inhibitor168 background. Time (hr) 100

90

80 ) L

/ C1 g

( 70

C2 n o

i C3

t 60 a

r C4 t

n 50 C5 e c

n C6

o 40

c C7

e

s 30 o

c C1 u l 20

G C2 100 100 10 C3 C4 90 90 0 C5

80 ) 80 C6 L /

) 0 24 48 72 96 120 144 168

g C7 L / (

70

g 70 n

( Time (hr)

o i n t

o 60 a i 60 t r t a n r t 50 e 50 n c e n c C1, predicted o C1, no inhibitor, experimental n 40 40 c o C2, predicted e c C2, 25 g/L glucose, experimental

s e 30 C3, predicted 30 o C3, 50 g/L glucose, experimental s c o

u C4, predicted l c C4, 15 g/L cellobiose, experimental

u 20

20 G l C5, 30 g/L cellobiose, experimental C5, predicted G 10 10 C6, 40 g/L xylose, experimental C6, predicted C7, 80 g/L xylose, experimental C7, predicted 0 0

0 24 48 0 72 24 96 48 120 72 144 96 168 120 144 168 Time (hr) Time (hr) Fig. A35. Validation of Model 3 (Gcr,tetra = 80 g/L). 100 g/L Avicel hydrolyzed by Celluclast (21.1 mg-protein/g-substrate) with different initial inhibitor background. 9090 90 8080 80

) 70

L 70 / ) 70 g L ( / 60 g n (

60 o

i 60 n t o a

i 50 r t t

a 50 F n

r 50 t e n c 40 G e n

c 40 o 40 H c n F, predicted F, predicted

o 30 e c

s G, predicted G, predicted 3030 o e c s 20 H, predicted H, predicted u o l c

G 2020 F u

l F, Cel / N188 = 15.8 / 3, experimental 10 F, Cel / N188 = 15.8 / 3, experimental G G, Cel / N188 = 15.8 / 1, experimental G 1010 G, Cel / N188 = 15.8 / 1, experimental H, Cel / N188 = 31.6 / 5.9, experimental H 0 H, Cel / N188 = 31.6 / 5.9, experimental 00 0 24 48 72 96 120 144 168 0 24 48 72 96 120 144 168 0 24 48 Time72 (hr)96 120 144 168 Time (hr)

Fig. A36. Validation of Model 3 (Gcr,tetra = 80 g/L). 100 g/L Avicel hydrolyzed by different ratio of Celluclast/N188 loading with initial 40 g/L xylose background.

130 120 110 130 100 120 ) L / 90 110

g J, 50 g/L, experimental (

n 100

80 )

o J, predicted i L t /

a 90 70 g r ( t

n n 80

e 60 J, 50 g/L, experimental o i c t n 50 a 70 r o t

c J, predicted

n e

40 e 60 s c o n

c 30 50 o u c l

G 20 e 40 s o

10 c 30 u 0 l G 20 0 10 24 48 72 96 120 144 168 0 Time (hr) 0 24 48 72 96 120 144 168 Time (hr) Fig. A37. Validation of Model 3 (Gcr,tetra = 80 g/L). 50 g/L Avicel hydrolyzed by Celluclast (15.8 mg-protein/g-substrate) + N188 (5.9 mg-protein/g-substrate).

90

80

) 70 L / g (

n 60 o o i t

a 50 r t n e

c 40 100 n N o c 30 90 O e s

o P 80 c 20 u Q ) l L / G 70 g

10 (

n N

o 60 i 0 t O a r t 50

n P e

c 0 24 48 72 96 120 144 168 Q

n 40 o

c Time (hr) 190

e 30

180 s o 170 c N, no inhibitor, experimental N, no inhibitor, experimental u 20 N, predicted 160 l

G O, 50 g/L glucose, experimental O, predicted O, 50 g/L glucose, experimental 150 10 140 P, 30 g/L cellobiose, experimental P, predicted P, 30 g/L cellobiose, experimental Q, 80 g/L xylose, experimental 130 0 Q, predicted Q, 80 g/L xylose, experimental 120

) 110 L

/ 0 24 48 72 96 120 144 168

g 100 ( 90 Time (hr) e

s 80 o

c 70 u l 60

Fig. A38.G Parameter estimation of Model 3 (Gcr,tetra = 80 g/L). 100 g/L Avicel hydrolyzed by 50 N Celluclast40 (15.8 mg-protein/g-substrate) + N188 (5.9 mg-protein/g-substrate) O with different initial 30 P inhibitor20 background. 10 Q 0 -10 -20 0 20 40 60 80 100 120 140 160 180 time (hr) Appendix 5.8. Comparison of hydrolysis kinetics of Avicel by N188 and Xbg

90

80

) 70 L / g ( 60 n o i t

a 50 r t n e

c 40 n o c

e 30

s G, Fitted o c

u 20 l G, N188 + Cel, experimental G 10 K, Xbg + Cel, experimental

0

0 24 48 72 96 120 144 168 Time (hr)

Fig. A39. 100 g/L Avicel hydrolyzed by Celluclast (15.8 mg-protein/g-substrate) + BG (N188 or Xbg, 1 mg-protein/g-substrate) with initial 40 g/L xylose background. The dashed line is prediction of data set G by Model 2 (Gcr,tetra = 75 g/L). Appendix 5.9.Transglycosylation assay

20

) 18 L / g ( 16 n Xbg, 0.585 g/L o i t 14 Xbg, 0.293 g/L a r t

n 12 e c n

o 10 c

e 8 s o c

u 6 l g

d 4 e s

a 2 e r c

e 0 D 0 20 40 60 80 100 120 140 160 180 Glucose concentration (g/L) 20 )

L 18 / g ( 16 n

o N188, 0.585 g/L i t

a 14 N188, 0.293 g/L r t n

e 12 c n

o 10 c

e

s 8 o c u

l 6 g

d 4 e s a

e 2 r c

e 0 D 0 20 40 60 80 100 120 140 160 180 Glucose concentration (g/L)

20 ) L

/ 18 g (

n 16 o i t

a 14 r

t Cel, 1.58 g/L n

e 12 Cel, 0.585 g/L c n o

c 10

e

s 8 o c u l 6 g

d

e 4 s a e

r 2 c e

D 0

0 20 40 60 80 100 120 140 160 180 Fig. A40. Glucose concentration (g/L) Transglycosylation assay