1. BROMINE

1. PRODUCT CHARACTERISTICS

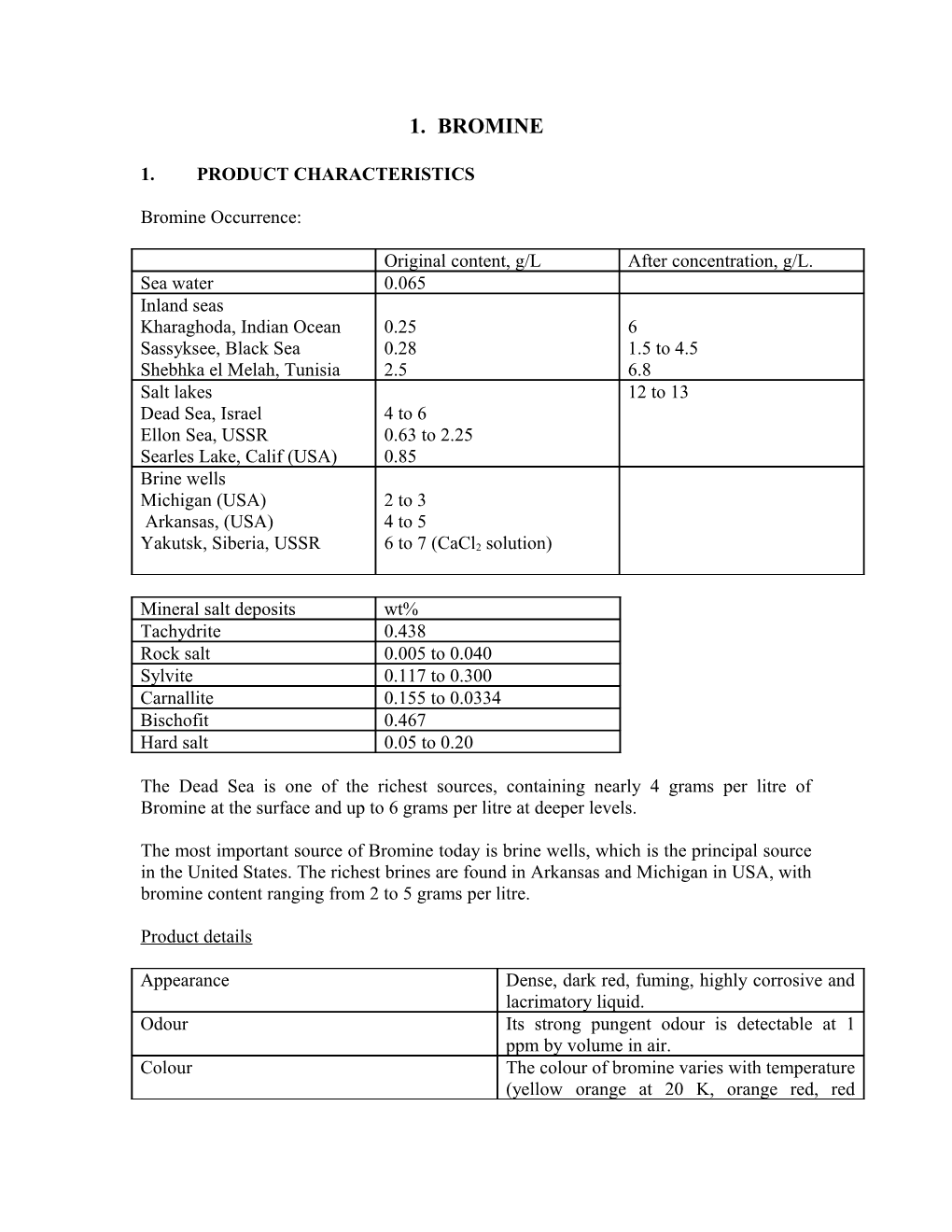

Bromine Occurrence:

Original content, g/L After concentration, g/L. Sea water 0.065 Inland seas Kharaghoda, Indian Ocean 0.25 6 Sassyksee, Black Sea 0.28 1.5 to 4.5 Shebhka el Melah, Tunisia 2.5 6.8 Salt lakes 12 to 13 Dead Sea, Israel 4 to 6 Ellon Sea, USSR 0.63 to 2.25 Searles Lake, Calif (USA) 0.85 Brine wells Michigan (USA) 2 to 3 Arkansas, (USA) 4 to 5 Yakutsk, Siberia, USSR 6 to 7 (CaCl2 solution)

Mineral salt deposits wt% Tachydrite 0.438 Rock salt 0.005 to 0.040 Sylvite 0.117 to 0.300 Carnallite 0.155 to 0.0334 Bischofit 0.467 Hard salt 0.05 to 0.20

The Dead Sea is one of the richest sources, containing nearly 4 grams per litre of Bromine at the surface and up to 6 grams per litre at deeper levels.

The most important source of Bromine today is brine wells, which is the principal source in the United States. The richest brines are found in Arkansas and Michigan in USA, with bromine content ranging from 2 to 5 grams per litre.

Product details

Appearance Dense, dark red, fuming, highly corrosive and lacrimatory liquid. Odour Its strong pungent odour is detectable at 1 ppm by volume in air. Colour The colour of bromine varies with temperature (yellow orange at 20 K, orange red, red brown, to almost black at its melting point).

Liquid bromine is always dark red, whereas bromine vapours are usually orange to red brown.

Specification

Description - The material shall be in the form of reddish-brown fuming liquid.

Requirements for Bromine, Technical

Sl. No. Characteristics Requirement 1. Relative density* at 27/27 C, Min 3.092** 2. Bromine, Percent by mass, Min. 99.5 3. Chlorine (as Cl), percent by mass Max. 0.3 4. Non-Volatile matter, percent by mass, Max. 0.05 5. Iodine (as I), percent by mass, Max 0.05 6. Sulphates, (as SO4), percent by mass, Max. 0.015

* Relative density is the term adopted by ISO for specific gravity with water as reference substance.

** The relative density determined at any temperature within the range 15 to 30 C can be adjusted to 27/27 deg C using the correction factor +0.0034 for every degree Celsius fall and -0.034 for every degree Celsius rise in temperature.

Packing: The material shall be packed in glass bottles with lead caps or ground glass stoppered bottles sealed with an inert material. These bottles shall then be packed in expanded mica, diatomaceous silica or other inert absorbent. For larger packing, homogeneously lead-lined mild steel drums or monel metal drums conforming to the rules can be used.

2. PRODUCT APPLICATIONS

The primary use of elemental Bromine is in the manufacture of Bromine compounds that have chemical and biological activity, high density or fire retarding and extinguishing properties.

Other applications of Bromine directly or as its compounds are given below.

* In Pharmaceuticals * In Pesticides, In Dyes and Photography * In Sanitary preparations * Water disinfection * De sizing of cotton * Hair waving compounds * Absorption fluids * In some perfumes * Air conditioning * Ore flotation and drilling fluids * Zinc bromide storage batteries are used as load leveling devices in electric utilities. * In the manufacture of Purified Terephthalic Acid.

The important downstream products of Bromine and its applications is given below :

Bromo Compounds Major Applications

*. Potassium Bromide In Photography, Medicine, as Heat stabilizer in Nylon, Brominating agent.

*. Ammonium Bromide Preparation of Photographic products, Industrial water systems, Paper Mills

*. Sodium Bromide Preparation of Photographic Products, Brominating agent, Oilfield chemicals, Waste water treatment, Pharmaceuticals.

*. Hydrogen Bromide/ Hydrobromic acid Source of Bromine in industrial Synthesis.

*. Isopropyl Bromide/ Intermediate for Pharmaceuticals, N-propyl bromide Insecticides, Quaternary Ammonium Compounds, Flavours and fragrances.

*. N-Butyl Bromide Intermediate for Pharmaceuticals, Insecticides, Quaternary Ammonium Compounds and Pigments.

*. Ethylene di bromide As fumigant and an important constituent of Ethyl petrol used as a motor fuel. Ethylene dibromide finds use as an agricultural fumigant but this use in the United States is now prohibited because of ground water contamination. Some minor fumigation uses are allowed to continue, but the predominant volume of Ethylene dibromide used in soil fumigation will cease.

*. Ethyl bromide Used in the manufacture of Pharmaceutical like Vitamin A etc., in flame retardants, refrigerant.

*. Potassium Bromide Baking and Brewing processes.

*. Methyl Bromide As fumigant for soil fumigation and for space fumigation to control insects in stored products.

*. Methylene bromide In the manufacture of pesticides.

3. IMPORTS Around 2500 tonnes per annum.

4. EXPORTS Nil

5. INDIAN MANUFACTURERS

* DCW Limited, Mumbai * Tata Chemicals Ltd.Mumbai * Ballarpur Industries Ltd.,Karnataka * Chemplast Sanmar Ltd.,Tamil Nadu * South India Bromine and Allied Chemicals (P) Ltd.,Tamil Nadu

6. DEMAND SUPPLY TRENDS

Demand level : Around 3250 tonnes per annum

Indian requirements are largely met by imports.

Estimated growth rate in demand: 6 to 7% per annum

7. MANUFACTURING PROCESS AND TECHNOLOGY DEVELOPMENT

The process of manufacture of Bromine from Sea Bitterns is given below :-

The bittern is acidified with Sulphuric acid to a pH of 3.5 and pre-heated to 85 to 90 deg C. The hot bittern is run through a tall granite tower packed with raschig rings while low pressure stress and a 10% excess of the theoretical chlorine are introduced slightly above the bottom of the tower and made to pass in counter current direction at suitable rates.

MgBr2 + Cl2 > MgCl2 + Br2

The Bromine is liberated in vapour form which is condensed in a tantalum condenser along with steam and some chlorine and then taken to the gravity separator, where Bromine and water layer are separated.

Manufacturing Process of Bromine (Developments in the process routes).

The first economically successful recovery of Bromine directly from the sea was carried out near Wilmington, North Carolina (USA), using an air-blowing process originally developed for brine operations by H.H. Dow, USA.

The use of air rather than steam has been preferred, because the cost of steam to heat ocean water, with its Bromine content of only about 65 mg/litre. would be prohibitive.

Another process for the recovery of Bromine from sea water was developed on a commercial scale by Ethyl Corporation in the US. The process involved the treatment of seawater with chlorine and aniline and collection of the precipitated Tri bromo aniline.

Current bromine production methods are based on modified Kubierschky or steaming out processes and the Dow chemicals blowing out process.

Technology Developments

Bromine producers have formed the Bromine Science and Environmental Forum to tout the safety and value of bromine products, including bromine based flame retardants.

The group says that it will sponsor research on bromine compounds to evaluate health and environmental effects. It will also "act as the industry's global voice" on environmental issues and seek to ensure that scientific information on its products is advanced and more widely understood." The group consists of Albemarle, Dead Sea Bromine, Great Lakes Chemicals, Elf atochem and Tosoh.

8. GLOBAL SCENARIO

Global demand

Present Global demand for Bromine is estimated to be around 500,000 tonnes per annum.

The annual growth rate in demand is estimated to be around 3% per year.

World Producers: United States is the major world producer of Bromine, followed by Israel.

Israel has been able to increase its production substantially from 23,000 tonnes in 1976 to around 2,00,000 tonnes per annum at present, due to the availability of the richest source of Bromine i.e., Dead Sea Brine and its concentrates and the process innovations brought about by the technologists.

Global outlook

Recovery of Bromine form seawater is mainly done in US, erstwhile USSR, Italy and Japan.

Phasing out of methyl bromide and ethylene bromide has forced bromine production to diversify into new markets.

Still the largest end-use for bromine compounds, flame retardants account for 30% of world bromine consumption.

About 45% of this is consumed in the US, with 31% in western Europe and 14% in Japan. By 2000 the brominated flame retardants market is predicted to have grown by 8% per year, with Asia leading the way.

Aside from flame retardants, several major producers are developing their fine chemicals capabilities for bromine to meet the demand from the pharmaceutical industry. During the mid-1990s, a number of anti-hypertension drugs were introduced using bromotoluene as an intermediate in manufacture. Another intermediate, bromethoxy naphthalene, is important in making naproxen, an anti-inflammatory that came off-patent in 1997.

Other promising new sectors for bromine include swimming pool disinfectants, industrial water treatment, air conditioning absorption systems and precious metal leaching.

9. RECOMMENDATIONS

Generally, the facilities for manufacturing Bromine are located near the source of availability of natural brines or bitterns containing usable levels of Bromine.

Keeping the availability of the source of bromine in view, the project for the manufacture of Bromine can be favourably considered in TamilNadu.

Manufacturers with Organic Bromine compounds production facilities near their bromine-producing plants have lower production costs than non-bromine producers because Bromine shipping and handling costs are minimized and by product inorganic bromides can be readily processed to recover bromine values.

Recommended capacity 300 tonnes per annum Estimated project cost Rs.700 lakhs