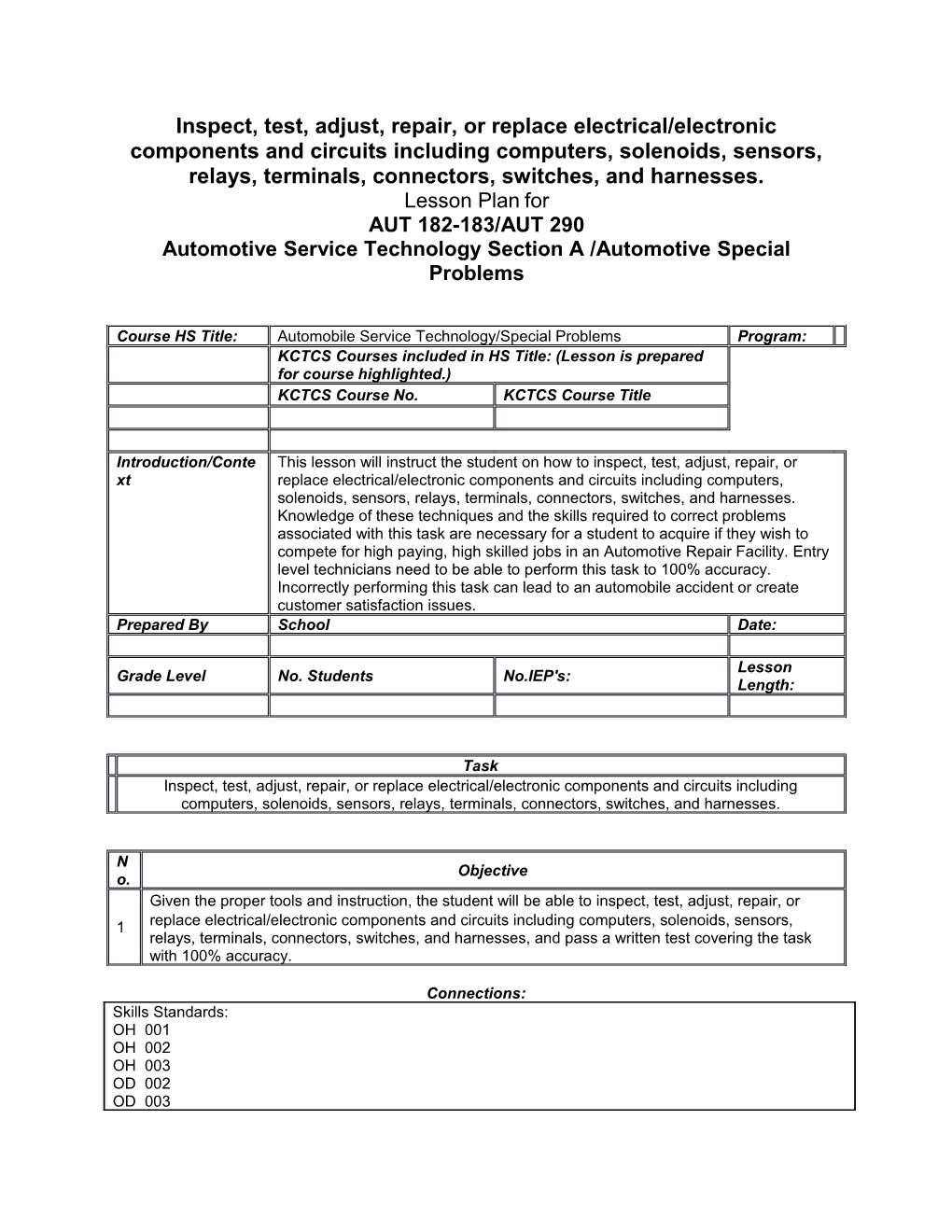

Inspect, test, adjust, repair, or replace electrical/electronic components and circuits including computers, solenoids, sensors, relays, terminals, connectors, switches, and harnesses. Lesson Plan for AUT 182-183/AUT 290 Automotive Service Technology Section A /Automotive Special Problems

Course HS Title: Automobile Service Technology/Special Problems Program: KCTCS Courses included in HS Title: (Lesson is prepared for course highlighted.) KCTCS Course No. KCTCS Course Title

Introduction/Conte This lesson will instruct the student on how to inspect, test, adjust, repair, or xt replace electrical/electronic components and circuits including computers, solenoids, sensors, relays, terminals, connectors, switches, and harnesses. Knowledge of these techniques and the skills required to correct problems associated with this task are necessary for a student to acquire if they wish to compete for high paying, high skilled jobs in an Automotive Repair Facility. Entry level technicians need to be able to perform this task to 100% accuracy. Incorrectly performing this task can lead to an automobile accident or create customer satisfaction issues. Prepared By School Date:

Lesson Grade Level No. Students No.IEP's: Length:

Task Inspect, test, adjust, repair, or replace electrical/electronic components and circuits including computers, solenoids, sensors, relays, terminals, connectors, switches, and harnesses.

N Objective o. Given the proper tools and instruction, the student will be able to inspect, test, adjust, repair, or 1 replace electrical/electronic components and circuits including computers, solenoids, sensors, relays, terminals, connectors, switches, and harnesses, and pass a written test covering the task with 100% accuracy.

Connections: Skills Standards: OH 001 OH 002 OH 003 OD 002 OD 003 OD 005 New Common Core Standards: RST 11-12 3 A-CED-4 N-Q.1 Common Core Technical Standards: TD-OPS 2 TD-SYS 2 New Generation Science Standards: HS-PS2-5. HS-PS3-3. HS-PS3-5.

INSTRUCTIONAL MATERIALS/TECHNOLOGY

Teacher Designed Materials and Other Handouts

Textbooks and Workbooks Author Title/ISBN No. Edition Publisher Pages Various ASE Test Prep Automatic Transmissions Fifth Delmar 28

Web Addresses Title Publisher URL Today's Class Melior www.todaysclass.com

Equipment Quantity Item Source As Needed DVOM Various As Needed Scan Tool Various

Content/Presentation/Demonstration Outline Instruct students that some electronic transmissions are only partially controlled. Let them know that only the engagement of the converter and third to fourth shifting is electronically controlled. Other models feature electronic shifting into all gears, plus electronic control of the TCC. Tell the students that the controls of an EAT (Electronic Automatic Transmission) direct the hydraulic flow through the use of solenoid valves. When it is used to control TCC (Torque Converter Clutch) operation, inform them that the solenoid opens a hydraulic circuit to the TCC spool valve, causing the spool valve to move and a regulated (reduced) form of line pressure to apply the converter clutch. Let them know that this clutch apply oil circuit has been given numerous names by manufacturers. Explain that electronically controlled shifting is accomplished in much the same way. Tell them that shifting occurs when a solenoid is either turned on or turned off. At least two shift solenoids are incorporated into the system, and shifting takes place by controlling the solenoids. Let them know that the desired gear is put into operation through a combination of on and off or constantly duty-cycled solenoids, with elevated ground potential to modulate flow and guard against overheating the solenoid. Tell students that several sensors and switches are used to inform the control computer about the current operating conditions. Most of these sensors are also used to calibrate engine performance. Explain that the computer then determines the appropriate shift time for maximum efficiency and best feel. The shift solenoids are controlled by the computer, which either supplies power to the solenoids or supplies a ground circuit. Inform students that the techniques for diagnosing electronic transmissions are basically the same techniques used to diagnose TCC systems. Teach students that although EATs are rather reliable, they have introduced new problems for the automatic transmission technician. Let them know that some of the common problems that affect shift timing and quality, as well as the timing and quality of TCC engagement, are wrong battery voltage, a blown fuse, poor connections, a defective TI’S or VSS, defective solenoids, crossed wires to the solenoid or sensors, corrosion at an electrical terminal, or the faulty installation of some accessory, such as a rear entertainment system. Instruct students that improper shift points can be caused by electrical circuit problems, faulty electrical components, or bad connectors, as well as a defective governor or governor drive gear assembly. Let them know that some EATs do not rely on the hydraulic signals from a governor. They rely on the electrical signals from electrical sensors to control a PWM solenoid that converts line pressure into a pressure linear to road speed, which controls the timing of the shift valves. Tell students that computer-controlled transmissions often start off in the wrong gear. This can happen due to either internal transmission problems or external control system problems. Explain that internal transmission problems can be faulty solenoids or stuck valves. Let them know that external problems can be the result of a complete loss of power or ground to the control circuit or a fail-safe protection strategy initiated by the computer to protect itself or the transmission from an observed problem. Teach students that sometimes, the default gear is simply the gear that is applied when all the shift solenoids arc off, usually second or third gear and reverse, to allow limp-in operation to continue driving. Tell them that if ECT is equipped with electronic pressure control, main line pressure will be defaulted to a fixed high level to prevent apply clutch or band burn-up. Instruct students that a visual inspection of the transmission and the electrical system should include a careful check of all electrical wires and connectors for damage, looseness, and corrosion. Explain that loose connections, even when clean, usually only make intermittent contact. Let them know that they will also corrode and collect foreign material, which can prevent contact altogether. Control devices, such as solenoids, are used in higher current applications. Tell students that the electrical portion of these control circuits is best checked with the circuit powered, using the voltage-drop method and a DVOM or oscilloscope to see what portion of the circuit has the poor connection. Let them know that some systems offer bi-directional testing with a scan tool that often allows control of the solenoid duty cycle. Tell them this presents an excellent opportunity for volt-drop testing under maximum current demand. Explain that low current input signals, such as speed sensors, often suffer from intermittent connections. Instruct students that a simple but effective method of checking these is with an ohmmeter attached across the disconnected sensor leads at the controller, while a wiggle test is performed on the circuit and its connections. Tell them an erratic meter reading indicates a faulty connection at the area being wiggled. Inform students to check all groundstraps to the frame or engine block. Let them know that this part of their inspection is especially important for electronically controlled transmissions that have a lockup torque converter. Tell them to check the fuse or fuses to the control module. To accurately check a fuse, Have students either test it for continuity with an ohmmeter or check each side of the fuse for open power when the circuit is activated.

Applications/Practice 1 Refer to content

Evaluation and feedback Prior to Testing or Lab Work 1 Objective 1. / Formative assessment / Instructor will observe students as they practice the procedure to assure correct procedure and safety practices are being followed. A checklist will be utilized to chart student progress on the task. Questioning techniques will be utilized as necessary to demonstrate student comprehension / Adaptations and/or accommodations for special needs students will be added if required.

STUDENT ASSESSMENT: (Assess student progress with performance criteria.) Objective 1 / Summative assessment / written test questions on stated objective / adaptation and / or 1 accommodations for special needs students will be added if required

IMPACT--Reflection/Analysis of Teaching and Learning: (How did students’ progress in relation to the state objectives? Was the instruction successful? Analyze samples of student work particularly that which is unsatisfactory, for the purpose of planning further instruction.)

REFINEMENT--Lesson Extension and Follow-up: (To be filled in as the lesson is modified during initial planning and/or during the teaching learning process.)