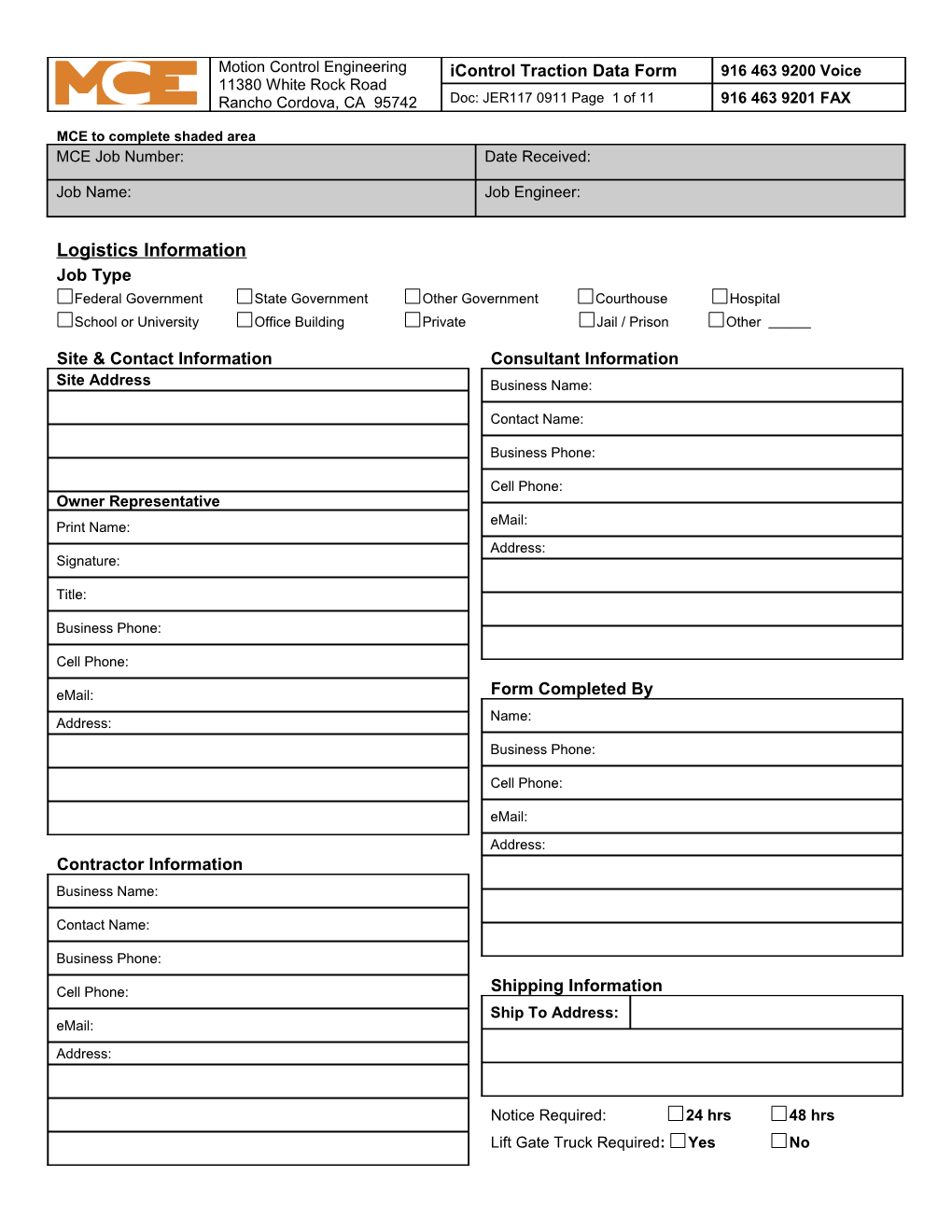

Motion Control Engineering iControl Traction Data Form 916 463 9200 Voice 11380 White Rock Road Rancho Cordova, CA 95742 Doc: JER117 0911 Page 1 of 11 916 463 9201 FAX

MCE to complete shaded area MCE Job Number: Date Received:

Job Name: Job Engineer:

Logistics Information Job Type Federal Government State Government Other Government Courthouse Hospital School or University Office Building Private Jail / Prison Other

Site & Contact Information Consultant Information Site Address Business Name:

Contact Name:

Business Phone:

Cell Phone: Owner Representative eMail: Print Name: Address: Signature:

Title:

Business Phone:

Cell Phone: eMail: Form Completed By Name: Address: Business Phone:

Cell Phone:

eMail: Address: Contractor Information Business Name:

Contact Name:

Business Phone:

Cell Phone: Shipping Information Ship To Address: eMail: Address:

Notice Required: 24 hrs 48 hrs

Lift Gate Truck Required: Yes No Motion Control Engineering iControl Traction Data Form 916 463 9200 Voice 11380 White Rock Road Rancho Cordova, CA 95742 Doc: JER117 0911 Page 2 of 11 916 463 9201 FAX

Logistics Information (continued) Elevator Safety Code Compliance Accurate information is essential. Both hardware and software Delivery & Payment Schedule are affected. Standard MCE terms of payment (net 30 days) apply to your order. If you require special terms of payment, please provide an Job Location (City/State): Alternative Payment Schedule. Contract Date: Per state tax laws, it is critical that MCE receive exemption or Project Type: New Construction Modernization resale certificates prior to the material being shipped and billed. If the job is a tax exempt job, send the exemption Elevator Duty: Passenger Service Freight certificate with this form. If you are a resale customer and Measurements: U.S./English S.I./Metric have a resale certificate, please make sure that the MCE accounting department has a copy on file. U.S. compliance Customer Job Number: ASME A17.1-2007 A17.1-2004 A17.1-2000 Customer PO Number: ASME A17.1-1996/98 ASME A17.1- Job Name: Specify code and addenda.

Number of cars: International compliance Control Delivery Date Payment Date Australia AS 1735 Car “ ” Britain EN 81/ BS 5655 Canada B44-07 B44-04 B44-00 Car “ ” Other: TSSA

Car “ ” Additional state or local code compliance Car “ ” California OSHPD Medical facility Certification Required Car “ ” Shake Test (Special Seismic Certification) and Seismic Anchorage OPA Car “ ” Shake Test (Special Seismic Certification) and Center of Gravity Drawings Car “ ” Chicago Denver Pressurized Hoistway Car “ ” GSA / Federal Heat detectors ( MR Floors ) Group “ ” Hawaii Maryland Delivery & Payment Schedule Michigan Detroit Mach room sprinklers If different payment terms are required, please provide an New York state New York City White Plains alternative proposal. Please include specifics of building owner Nassau County payments and provide a copy of your contract. Alternative Proposal Provided: Yes No Pennsylvania Contract Attached: Yes No Washington ( Seattle) Number of Fire Phase 1 switches: Job Push-Outs and Cancellation Jobs pushed out by the customer more than 90 days beyond the # of 3-position # of 2-position originally scheduled date may be subject to cancellation charges switches: switches: as follows: Washington DC * Before engineering commences: 10% of total sales order Other: * After engineering completed: 30% of total sales order * After construction completed: 75% of total sales order Additional Compliance Requirements? Explain: Extra Documentation If this job requires additional engineering drawing packages or Job Specification additional manuals, please indicate below. Does project have job specifications? Yes No Drawing Sets # Required: If yes, number of pages: Manuals # Required: Have specifications been forwarded to MCE? Yes No

Motion Control Engineering iControl Traction Data Form 916 463 9200 Voice 11380 White Rock Road Rancho Cordova, CA 95742 Doc: JER117 0911 Page 3 of 11 916 463 9201 FAX

Control Information Type of Operation Simplex Home Landing#: Floor Label:

2 Groupless Automatic (iComm-Connect w/o iCue)

2 Group Automatic (iCentral w/ enhanced iCue) Number of Cars: Lobby Landing #1: Floor Label: Lobby Landing #2: Floor Label: Number of Hall Call Risers: Swing Car Operation Car(s): Activated by keyswitch Switch location: Car Hall Autoswing ( w/ keyswitch) iCentral Group to Controller Ethernet Cable Lengths: 5’ 10’ 25’ 50’ 75’ 100 150’ Standard 25 ft. Measure distance from group control(iCentral) to most distant iControl, add 10 ft. for inside cabinet connections. Order one cable for each iControl in the group. There is no daisy chaining. Each control will communicate directly with the group.

2 Cross Cancellation/Registration Panel (iCue required)* Temporary hall call panel used during modernization process when existing dispatcher and MCE dispatcher are to operate simultaneously as one dispatching system. Cross Registration Cross Cancellation *Copy of the existing hall call schematics must be provided. Existing Hall Call Bus Voltage: _____ AC DC Existing control type: Relay logic Microprocessor

Fire Service Operation Fire Service Phase I Main Landing #: Floor Label: Doors will open: Front Rear Phase 1 Switch is: 2-position 3-position Alternate Landing #: Floor Label: Doors will open: Front Rear Additional 2-position switch: Yes No Switch location: Landing #: Floor Label: “Master Fire Service” switch (Chicago High Rise only)

2 Fire Service Phase II Type of switch: 3-position 2-position Call Cancel Button: Yes No Additional Fire Operation Requirements for Nassau County NY, Detroit MI, California or GSA/Federal Jurisdictions: Shunt Trip Delay Heat Detectors: ( Machine Room Each floor ) Motion Control Engineering iControl Traction Data Form 916 463 9200 Voice 11380 White Rock Road Rancho Cordova, CA 95742 Doc: JER117 0911 Page 4 of 11 916 463 9201 FAX

time; fan / lights to turn on if car in demand. (Std. 30 secs) Other Operating Features Load Weighing and Related Operating Modes Attendant Service: Yes No Annunciator Panel in Car EMCO Rope Tension Load Weigher ( Monitoring Hall Calls Registered ): Yes No EMCO Rope Tension Load Weigher, Car: Car to Lobby Switch: Yes No Number of ropes: 4 5 6 7 8 Recall Landing: ___ Floor Label: _____ Roping: 1:1 2:1 Park with doors: Open Closed Location of switch: Car Hall Rope diameter: 10mm 1/2 in 9/16in 5/8 in Earthquake Service: Yes No If additional cars use same roping, and more load weighers are Code Compliance: ASME California required, indicate quantity here: Machine Type: Traction Winding Drum Seismic switch ( By MCE By Customer) If car roping varies, provide information for each car below. C/W derailment device ( By MCE By Customer) EMCO Rope Tension Load Weigher, Car: Earthquake light / buzzer Number of ropes: 4 5 6 7 8 Car to operate on fire or hospital service Roping: 1:1 2:1 Emergency Power Operation: Yes No Rope diameter: 10mm 1/2 in 9/16in 5/8 in Does generator power cars from other banks? Yes No EMCO Rope Tension Load Weigher, Car: If so, is sequential lowering required amongst elevators from Number of ropes: 4 5 6 7 8 different banks? Yes (Overlay req’d) No Number of cars allowed to run simultaneously: Roping: 1:1 2:1 Split or multiple power feeders to the elevators? Yes No Rope diameter: 10mm 1/2 in 9/16in 5/8 in Status of EP contact during normal power: Open Closed EMCO Rope Tension Load Weigher, Car: Power pre-transfer contact – 10 sec minimum: Yes No Number of ropes: 4 5 6 7 8 Manual Selector Switch Roping: 1:1 2:1 Number of positions: Labels: Rope diameter: 10mm 1/2 in 9/16in 5/8 in Is switch located at the designated level in view of all

elevator entrances? Yes No (Indicator req’d) Other Load Weighing Devices: Emergency Medical Technician (EMT) Service: Yes No LW-MCEIP (Isolated Platform type required)

Flood Operation: Yes No K-Tech Strain Gauge (from MCE) Lowest landing that the car can go in an event of a flood: K-Tech Strain Gauge (from other) Model: Landing: ___ Floor Label: _____ Other Load Weigher Brand: Model: Hoistway Access Operation: Yes No Discrete Load Weigher (Dry Contact Interface) 2-position switch in COP: Yes No Light load (Antinuisance) Top access switch: Yes No Heavy load (Hall call bypass) Switch location: Front Rear Overload Bottom access switch: Yes No Switch location: Front Rear Remote Monitoring (iMonitor/iReport/BMS/IDS): Hospital Service (Code Blue): Yes No Which Cars Used: ______Floors Served: _____ Remote Monitoring Required: Yes No In car activation: Keyswitch Other None Controller to be monitored by system that is: New Existing In car indicators: Yes No Monitor size: 17”LCD (Std) Other( )

Computer Type: Desktop(Std) Laptop Independent Service: Yes No Remote Access Hardware Features: (optional) Key switch location: Hall Car Ethernet Hyper Extender VPN Router Monitoring Application: In-Car Inspection Switch: Yes No iMonitor ( Campus View iLobby ) Switch must be of the 2-position type. iReport (Printer required: Yes No ) In-car inspection using top and bottom car calls: Yes No IDS Liftnet Sabbath Operation: Yes No BMS (Building Management System) JACE Interface required: Yes No Timed Fan Light Output: Yes No Existing Communication protocol: Used to turn cab fan/lights off after car idle for specified length of Ethernet BACnet LONworks Modbus Motion Control Engineering iControl Traction Data Form 916 463 9200 Voice 11380 White Rock Road Rancho Cordova, CA 95742 Doc: JER117 0911 Page 5 of 11 916 463 9201 FAX

Monitoring system indicated is to be located at: If an iCOMM-CONNECT is being used, the iVIEW component Security Room Engineer’s / Building Manager’s Office supplied is not enclosed into any cabinet or enclosure. Concierge Desk Other CRT Enclosure Required: Yes No

Machine Room Security Controller NEMA Requirement: Security Devices 1 12 4 4X Car Call Cutouts: Yes No If other than NEMA1, Controller ventilation type required: Card Reader Dry Contact AirConditioner Fans/filters By others Contact Rating: 120VAC (Std) 24VDC Other Controller Location: Keyed floor lockout switches In room with machine Switch Location: Car Hall Other location Number of switches: Distance between controller and machine ( ft) Car Call Code using Car Pushbuttons If gearless machine to drive wiring is greater than 50’ Hall Call Cutouts: Yes No (100’ for geared machine applications), a line choke Card Reader Dry Contact may be required on AC drive/motor systems. Contact Rating: 120VAC (Std) 24VDC Other Motor Line Choke required: Yes No Keyed floor lockout switches

Switch Location: Car Hall Number of switches: Isolation Transformer NEMA Requirement: 1 12 4 4X Door Control Options During Security: Isolation Transformer Location: Allow Door Open Button to operate after doors closed at a secure In same room with controller floor? Yes No Secondary machine room Car allowed to park at secured floor? Yes No Other location Bypass Security? (Fire Service to bypass per code) Number of Machine Rooms Independent Service Attendant Service 1 2 Other: Hospital Service Other ( ______) Traction Auxiliary Power Supply (TAPS): Special Security Features: Yes No Jail Security * Provide backup power for your AC controller, with sizing up to 40HP applications. Deputy/Marshal Service* Remote Car Station Control Machine room space limitations? Yes No Evacuation Service * Indicate enclosure space available. Otherwise, enclosure size Other * ( ) based on job requirements. (Check entry hall and door sizes.) * additional details must be provided H x W x D Child / Infant Abduction / Bracelet Operation Show existing equipment and distances to obstructions in all Number of landings with detection device: directions. At which landings: Landing #: Floor Label: Allow car to continue to run if not at affected landing: Yes No

Machine Room Monitoring (iVIEW): iView is a graphical user interface used to configure, adjust, and troubleshoot the iControl platform. It can also be used for simple machine room monitoring. It is typically used in a machine room environment adjacent to the control equipment.

When utilizing an iCentral-Cue, the iVIEW component of the iControl is built into the group dispatching enclosure. Monitor size: 17”LCD (Std) Other( ) Machine room Printer required: Yes No Motion Control Engineering iControl Traction Data Form 916 463 9200 Voice 11380 White Rock Road Rancho Cordova, CA 95742 Doc: JER117 0911 Page 6 of 11 916 463 9201 FAX

Hoistway Hoistway NEMA Rating: 1 12 4 4X Other: If other than NEMA 1, please consult MCE for additional options. Number of Hoistways 1 2 Other:

MCE Landing System: Yes No Car Guides: Roller Slide iLand (Standard) Installation Note: Check for adequate spacing for: *Vertical clearance where overhead clearance is limited. Horizontal clearance when car sheave exists on cartop. Note: iLand is not recommended on systems using slide guides due to wheel slip and contaminant issues. MCE iLand pedestal: Yes No *Roller clearance pedestal height: 14” 20” * 14” pedestal plus iLand height is 26” * 20” pedestal plus iLand height is 32” Live Axle Shaft Governor-mounted encoder with vanes Governor sheave diameter: 12” 16” Live axle shaft diameter: ¼” 1” NOTE: The live axle shaft is an alternative positioning setup in scenarios where the iLand may not be suitable. MCE does not recommend use of this setup for elevators with a high rise or high car speeds. Please consult with your MCE Sales rep for pricing details. MCE TLS Switches: Yes No Cartop (TLS-C- 12 16) Hoistway (TLS-1 Number of switches required: ) Guide rail size: 8 lbs to 12 lbs 15 lbs to 18.5 lbs 22.5 lbs to 30 lbs TM Switch (“Music Box”) Yes No MCE EECO Switches Yes No (Mechanical type, typically used for final limits) iControl Traveling Cable: Yes No Please complete additional iControl cable data sheet.

Special Instructions: Enter Here Motion Control Engineering iControl Traction Data Form 916 463 9200 Voice 11380 White Rock Road Rancho Cordova, CA 95742 Doc: JER117 0911 Page 7 of 11 916 463 9201 FAX

Machine Room (continued) Emergency Brake General Information ASME A17.1-2000/CSA B44-00 or later requires the addition of an emergency brake on all new traction elevators, per 2.19. Voltage Also note that some alterations will trigger the requirement to Line Voltage Available (@ disconnect): add an emergency brake as well (i.e., change in type of service or motion control; increase in rated load or speed; and replacing Line Voltage Measured: the driving machine) AC 3 Phase (symmetrical with respect to ground) Hollister Whitney Rope Gripper Thyssen Sheave Brake AC 3 Phase (grounded leg delta configuration)* Bode Rope Brake Other ( ______) AC 2 Phase AC Single Phase DC 60 Hz 50 Hz Secondary/Independent Brake on machine (not accepted in Nebraska) * Isolation Transformer required Power Supply of Brake: 120VAC (Std) Other Other Power Related Features: Add isolation transformer: Yes No If other, please specify:Voltage: FLA:

Isolation Transformer Sequential Start: Yes No Hoist Motor TVSS (Surge suppressor) required: Yes No Variable Frequency AC Available Fault Current from AC Feed (kA): Standard controller SCCR (Short Circuit Current Rating) is Existing New New by MCE typically 5-10kA. If available fault current exceeds 10kA and cannot be reduced, please notify MCE for a quote. Brand: HP: Reduced Stroke Buffers: Yes No Voltage: FLA: # Poles: Buffer rating: fpm Buffer stroke: inches Sync RPM: FL RPM: Frequency: Counterweight safety Yes No For 2-speed motors, measure the high speed winding. Jawless Governor Yes No Other name plate data: Variable Voltage DC Controller Type iControl AC (AC Regenerative Drive Req’d): Yes No) Existing New New by MCE iControl DC Brand: HP: Voltage: FLA: RPM: Machine and Brake Other name plate data: Machine Existing New New by MCE Brand: Shunt Field Voltage: Machine location: Overhead Basement MRL Forcing: Full Speed: Standing: Geared Ring & Worm Helical Shunt Field Resistance: (ohms) External Tandem Measured Data Sheet # of coils: Gearless AC PM AC Induction Series Series/Parallel DC Roping: 1:1 2:1 Hot Cold For MRL Applications: Loop Circuit Armature Voltage while running: Battery Backup Passenger Rescue with Video (measured on motor brushes): Remote Governor Set / Reset Up empty car: VDC at speed: Coil Voltage: AC DC Down empty car: VDC at speed: Loop Circuit Current while running: Brake Existing New Brand: Up empty car: Amps at speed: DC Brake Down empty car: Amps at speed: Voltage: Pick: Hold: Velocity Feedback Device Coil Resistance: Measured Data Sheet By MCE By Customer Hot Cold Analog Tachometer (Mount: Flange Foot ) Contact on Brake: Yes No If gearless; Type: N/O N/C Drive sheave diameter: (in) AC Brake control is not available for iControl. Diameter of surface to run tach: (in) Digital Velocity Encoder (shaft driven device) Yes No Machine Blower: Encoder cable length (ft): Voltage: Phase: FLA: Motion Control Engineering iControl Traction Data Form 916 463 9200 Voice 11380 White Rock Road Rancho Cordova, CA 95742 Doc: JER117 0911 Page 8 of 11 916 463 9201 FAX

Fixture Information

Auxiliary Car Station Yes No Total Number of Car Stations in each car: 1 2 3 4 Status Indicators Call Registration Indicators Type Volts AC DC Car: Incandescent LED Attendant Light/Buzzer Voltage: AC DC Attendant Service Annunciator

Hall: Incandescent LED Panel Indicators Voltage: AC DC Call Registration Buzzer Serial Link Door Closing Warning Buzzer Call pushbuttons must be mechanical and fixtures must be 24VDC, 6 Watt maximum. Door Hold Light Car Calls (Optional – boards to be located behind car station) Door Left Open Bell Hall Calls (Standard – board located in each hall p/b station) Earthquake Light / Buzzer Serial fixture boards to be sent to fixture manufacturer / contractor EMT Service Light (Car, Hall) for pre-wire? Yes (If so, indicate where below) No Emergency Power Light Ship serial boards to:: C.E. Electronics EPCO Dupar Fire Light / Buzzer Innovation Industries Monitor MAD Hospital Light / Buzzer ERM PTL In-Service Light Elevator Contractor Office In-Use Light Please indicate Contact Person / Number in Special Notes below Which boards to be sent?: COP Hall Station Load Status Light Lanterns: Nudging Buzzer Hall Car (Indicate # of Jamb arrows: ) Other: Lantern Signal Format: Other: Serial (3-Wire Microcom type) Discrete Indicator: Voltage: AC DC Position Indicators Bulb wattage: MCE C.E. Electronics Serial Interface Driver (MicroComm)

MCE E-Motive Serial Interface Driver Gongs: Voltage: AC DC Chimes: Voltage: AC DC Other Serial Fixture Driver (Please provide details) Passing Floor Gong or Chime: Yes No Serial PI fixtures located in: Car Hall Passing Floor Gong Signal Format: If hall, indicate landing #: Floor label: Serial (3-Wire Microcom type) Discrete Discrete Multi-Light Fixture Voltage: AC DC Car with direction arrows Passing floor enable (S) button: Yes No Voltage: AC DC Voice Annunciation Yes No Hall with direction arrows Annunciator device provided by: CE Electronics Voltage: AC DC E-Motive At landing #: Floor label: Other: Annunciator Signal Format: Discrete Digital Brand & Model: Serial (3-Wire Microcom type) Car with direction arrows Discrete Hall with direction arrows One line per floor At landing #: Floor Label: Binary Signal Format: One line per floor Special Notes: Binary (Code begins at 1st landing 00 01) Grey Code Signal Voltage: 120VAC (Standard) 24VDC Other Motion Control Engineering iControl Traction Data Form 916 463 9200 Voice 11380 White Rock Road Rancho Cordova, CA 95742 Doc: JER117 0911 Page 9 of 11 916 463 9201 FAX

Voltage: AC DC Automatic Passenger Style Doors If DC, common is: Positive Negative (See section below for freight style doors) Door Information MCE SmarTraq Complete (Complete SmarTraq data forms) Car Gate SmarTraq Upgrade (Upgrades existing operator to closed loop. Mark existing model below.) Automatic passenger style doors GAL MOVFR I MOM/MOH Powered freight style doors MOVFR II (230V) MOMVC/MOHVC Manual doors MOVFR II (115V) MOSVCL MOD (230V) MOPM-P/MOPM-PL Other: MOD (115V) MOCT/MOCTA/MODCT/ Gate Release Solenoid Yes No MODHA MOMCT/MOHCT MODVC/MODHVC Motor Voltage: 220 110 Voltage: AC 3-Phase AC 1-Phase DC MOA Logic Voltage: 220 110 Current/Fuse size: 2A 3A Other: MAC/Kone PM-SSC/104 Board MAC (old style) AMD/Kone Hoistway Doors TKE/Dover HD03 (120VAC) HD03M (Low Voltage) Automatic passenger style doors HD68/70/73/91 (Circle model number) Powered freight style doors HD98/85 (Requires SmarTraq upgrade kit) HD-LM Manual doors Smart tech Other: Otis Interlock brand and model: 6970A – Resistance 6970A – Reactance Closed contact Yes No 7300 A7770A 7782AA OVL Locked contact Yes No iMotion 1 & 2 AT400 Door locking cam ECI Retiring 895/1000 2000 VFE 2500 (not driven by automatic passenger style car gate) Other Voltage: AC 3-Ph AC 1-Ph DC IPC Encore (closed loop) Mitsubishi LV1/4K Current / Fuse size: 2A 3A Other: Delco (closed loop) Schindler QKS 14 & 15 Fixed cam Atlantic/Vertisys Model: Driven by automatic passenger style car gate Other (wiring diagram required):

Door Features Powered Freight Style Doors Door position monitoring switch required by ASME A17.1-1996 / Door Controller Model CAN/CSA B44-94 and later on power operated, horizontally Peelle New Model: sliding/mechanically coupled (automatic passenger style) doors. Existing (electrical schematic required) Contact must close when doors close. Courion New Model: Infrared detector unit/photo eye Existing (electrical schematic required) Mechanical safety edge EMS New Model: COP cut-out switch for photo-electric eye or IR detector Existing (electrical schematic required) Heavy doors at landings (at which floor(s)): Other New Model: Existing (electrical schematic required) Dual door operators on same side for wide opening Door Hold Operation (Non-Fire Operation) Door Operation (freight doors only) Pushbutton Switch Opening: Automatic If momentary, maximum hold time = 120 seconds Momentary pressure Nudging Closing: Automatic Reduced torque with buzzer Momentary pressure Constant pressure Buzzer only Fire Service Phase l Closing: Ignore photo eye after second interval Automatic If If safety edge or door open button activated, doors should: Momentary pressure Stop Re-open Constant pressure Door open button Front Rear Door close button Front Rear Motion Control Engineering iControl Traction Data Form 916 463 9200 Voice 11380 White Rock Road Rancho Cordova, CA 95742 Doc: JER117 0911 Page 10 of 11 916 463 9201 FAX

Landings & Openings If more than 32 landings and/or 10 cars, please use additional sheets.

Ldg Floor Floor Car Car Car Car Car Car Car Car Car Car # Label Height F R F R F R F R F R F R F R F R F R F R O.H.

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

PIT Capacity: kg lbs Up Speed: ms fpm Down Speed: Total Travel: m ft

NOTE: Hoistway Layout Forms are required for each unique landing configuration including riser, opening, and wall/barrier location. These forms must be filled out by hand and faxed to MCE. Enter the number of drawings you are submitting here: Motion Control Engineering iControl Traction Data Form 916 463 9200 Voice 11380 White Rock Road Rancho Cordova, CA 95742 Doc: JER117 0911 Page 11 of 11 916 463 9201 FAX