Background Statement for SEMI Draft document 4566 REVISION OF SEMI F58-1000 TEST METHOD FOR DETERMINATION OF MOISTURE DRY-DOWN CHARACTERISTICS OF SURFACE-MOUNTED AND CONVENTIONAL GAS DISTRIBUTION DELIVERY SYSTEMS BY ATMOSPHERIC PRESSURE IONIZATION MASS SPECTROMETRY (APIMS)

Note: This background statement is not part of the balloted item. It is provided solely to assist the recipient in reaching an informed decision based on the rationale of the activity that preceded the creation of this document.

Note: Recipients of this document are invited to submit, with their comments, notification of any relevant patented technology or copyrighted items of which they are aware and to provide supporting documentation. In this context, “patented technology” is defined as technology for which a patent has issued or has been applied for. In the latter case, only publicly available information on the contents of the patent application is to be provided.

SEMI F58-1000 is due for 5 year review. The document was reviewed and made with minor changes.

This letter ballot will be reviewed and adjudicated by the Facilities and Gases Committee at their meetings in Dallas, TX, during the week of 7 April, 2008.

Note: Additions are indicated by underline and deletions are indicated by strikethrough. Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone:408.943.6900 Fax: 408.943.7943Phone:408.943.6900 Fax: CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and can also be used by a sufficiently sophisticated user as user sophisticated sufficiently a by used be also can delivery gas of ranking 1.2 time. at this available commercially which APIMS to and limits time detection response similar with techniques other of application the for guidelines provide may method test This time. response fastest the ppt with of analysis moisture capable technique available the commercially isthe currently it because tests is dynamic such for choice APIMS of method systems). distribution (integrated gas systems distribution gas conventional mount and surface of moisture) removable of (quantity characteristics dry-down moisture the of determination 1.1 1 IONIZATION SPECTROMETRY MASS (APIMS) PRESSURE GAS OFCHARACTERISTICS SURFACE-MOUNT DRY-DOWNFOR MOISTURE DETERMINATION METHOD TEST OF SEMIF58-1000 OF REVISION Draft Document SEMI 4566 reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International of SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in result document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to the is page this on material No program. Standards International SEMI the of document draft a is This from be or manufacture, may its system in arising delivery contamination gas a gas other 2.3 in use for intended applications. systems to caution due with applied may be which design,in differences of present result a as arising contribution moisture the to respect with of ranking a provide will results The studies. scope corrosion in the outside prove althoughtheprocedure test useful may document, corrosion are to relating resistance Considerations moisture. with more system a chemically react may gases Reactive slowly. dry or quickly may and characteristics purging different have will gases “inert” Other nitrogen. in out 2.2 in processing. used semiconductor mount 2.1 2 of behavior.system simulation numerical for input

Scope Purpose

— Medium Test Operating Situations — — Situations Operating The results of this test can be used for qualitative for used be can test this of results The This test method applies to all types of surface of types all to applies method test This hs dcmn ecie h rcdr for procedure the describes document This ed DISTRIBUTION n ovninl gs dsrbto systems distribution gas conventional and of the North American Facilities Committee. Current edition approved by the North American Regional American North the by approved edition August Committee Initiallyon 28, Standards 2000. available www.semi.org 2000; on August Current Committee. Facilities American North the of responsibility direct the is and Committee Facilities Global the by approved technically was method test This The test procedure will be carried be will procedure test The system Moisture contribution from contribution Moisture based on the design. It design. the on based DELIVERY DELIVERY r o not are a gas a may not be not may distribution SYSTEMS BY ATMOSPHERIC BY SYSTEMS ed Page jn l jn n te sse a eevd ih te efcs of effects the with together. and convoluted packaging treatment received) (as pre- quality, surface design, and process manufacturing system the in components the of content moisture the by determined 2.3.1 gas. non-dry or air situations: istwomain consider Thus, it to necessary ambient to exposure subsequent 4.1 adopted of publications standards. latest the be shall cited documents NOTICE: 4 purposes production for used certification/testing.and/or be cannot It designs. on different based systems delivery gas for qualification 3.2 distribution simulationsystem of numerical behavior. a situations, through or qualitatively of either used, be will consideration they how different requires system in “best” the moisture moisture selecting permissible of decreasing are degrees of interaction different order Because in interaction. systems rank to example, for used, be can which interactions moisture 3.1 3 health priorlimitations use. to and regulatory this of applicability safety of the determine users and appropriate practices the establish of to responsibility the standard is It use. its with associated any, if issues, safety address to purport receipt. after exposure any in released subsequently and system the by up taken moisture of amount the by determined 2.3.2 2 aey Issues Safety

ReferencedStandards Limitations for used be only can test this of results The SEMI SEMI hs ts ehd alw h eemnto of determination the allows method test This

h rsos o ust iuto, wih is which situation, upset” to “response The h iiil dydw” stain hc is which situation, dry-down” “initial The As listed or revised, or listed As ED Standards AND CONVENTIONAL

NOTICE:

Unless otherwise indicated, indicated, otherwise Unless

hs sadr os not does standard This Document Document Number: Doc. Date: SEMI 4/23/2018 DRAFT all

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone:408.943.6900 Fax: 408.943.7943Phone:408.943.6900 Fax: CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and The same as ppmv. same as The 6.1.3 6.1.2 Spectrometry. 6.1.1 6.1 6 surface-mount both for systems. gas delivery conventional tests input moisture 5.1 5 Gas by for Contribution Method Moisture SystemDistribution Components Test of Standard Determination — ASTM-F1397-93 4.2 Mass (APIMS) Spectrometer Pressure Ionization Atmospheric of Calibration for Method — F33 SEMI (APIMS) Spectrometry Mass Ionization Pressure Atmospheric by Components and Systems Distribution Gas of Content and Interaction Moisture for Method Test — F27 SEMI Standards Humidity ppb and ppm for Method Test — C15 SEMI reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This Wide Web: http://www.astm.org.9555. World Conshohocken, 19428.Fax: Dr,1-610-832-Barr Harbor West PA 1 system. ingas the the of time residence the to equal is time induction the moisture, to transparent perfectly is which system test a and system test For analyzer. moisture the the at detected is moisture when to introduced is gas humidified 6.2.3 inert. usually atmosphere, controlled 6.2.2 conditions. state 6.2.1 6.2 at minute and0°C 1atm. per liters in measured rate flow volumetric 6.1.6 as pptv. same 6.1.5 as ppbv. same 6.1.4

Available from American Society for Testing and Testing American Materials,100 for from Society Available

Terminology Summary of Test Method

Abbreviations andAcronyms ASTM Standards Definitions This test method consists of initial dry initial of consists method test This

EPSS APIMS induction time — — time induction ppb — — ppb ppt — — ppt baseline p — ppm slpm lv box glove — electropolished stainlesssteel. —electropolished tnad ltr e iue h gas the minute, per liters standard — molar parts per trillion (pmole/mole). The (pmole/mole). trillion per parts molar — Atmospheric Pressure Ionization Mass Ionization Pressure Atmospheric — molar parts per billion (nmole/mole). The (nmole/mole). billion per parts molar — an instrument response under steady under response instrument an — molar parts per million (µmole/mole). million per parts molar n ecoue ta otis a contains that enclosure an — 1 the elapsed time between when between time elapsed the . - down and down ed and Page jn l jn be left to the discretion of the operator; however, it is it however, operator; the of discretion the to left be may calibrations between interval the met, is condition this Provided other. each of 5% within be shall results conditions analytical same the the and tests the as etc.) voltages, plate pressures, (flow, under shall made calibrations be These series. both the of end the at one and beginning the at one F33, SEMI per as performed be shall APIMS the of Calibration type. any of be can 7.1 7 in change a 6.2.6 after state steady concentration. reach to system 6.2.5 system. test a to introduced is concentration and length pre- defined of input moisture a when recorded concentration 6.2.4 u seily toe lns bten V between lines those especially but lines, gas all design, this In removed. is system test the bypass a APIMS to flowbe sothat the loop can maintained when is there that gas Note vent. other to directed the is while stream system test the through directed V V valves switching simultaneously By times. all at andlines the humidified both dry maintained in is gas of flow design, this example In 1. Figure in shown is design An a such required. also is nitrogen humidified and dry between instantaneously switching of capable test 7.4 the of place in inserted be system. to it enable to end EPSS 1/4" of m) tubing 1 than more (no length convenient shall the testingblank. shortest Theresults blank be of a 7.3 connection for the system. test to bench test the into incorporated be therefore, should, connector of type same The connectors. type gasket metal with fitted 7.2.1 verified to SEMIC15. according be shall generator the of output The APIMS. the calibrate to used as same the be may generator This 13 to up required. is moisture ppb delivering 200 with doped nitrogen slpm of capable generator moisture a and moisture) ppt 200 than (less nitrogen dry extremely 7.2 out carried two every be and/or operation. of weeks moved is should equipment the calibration whenever that suggested 3 3

r V or , RequiredEquipment

APIMS — — APIMS Moisture Pulse Generator — — Generator Pulse Moisture Test Blank — — Blank Test r a n osueGnrtr—— Generator Moisture and Gas Dry

test systemtest

response time response Most ultra-high purity gas panels are currently are panels gas purity ultra-high Most with suitable fittings and/or adapters at either at adapters and/or fittings suitable with ek hih — height peak 2 n V and The APIMS used for moisture detection moisture for used APIMS The — the gas delivery system under —thesystem gas delivery test 3 Any series of tests shall include the include shall tests of series Any ihr hmdfe r dy gs is gas dry or humidified either , — the time required for the test the for required time the — h aiu moisture maximum the Document Document Number: A valve arrangement valve A Doc. Date: 1 n V and A source of source A SEMI 4/23/2018 DRAFT 3 1 and and

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone:408.943.6900 Fax: 408.943.7943Phone:408.943.6900 Fax: CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and sd eprtr oto hud b o ± 1C A 1ºC. maintained.be ± shall test the to during temperature be of record continuous should control Temperature be can tape used. heating a impractical, chamber. is this temperature-controlled if However, a BE in maintained be CANNOT AT should system TESTS test and blank the Ideally, COMPARED. TEMPERATURES 30ºC. at kept be DIFFERENT shall system importance. critical test of The is test the during temperature 7.5 in moisture level. a input to change blank the of response possible fastest the give to as so designed be should is generator pulse moisture The used. switching 7.4.2 simultaneous and recommended. rapid facilitate to valves pneumatic of Use separately. each through as well as simultaneously system test the and loop bypass the through maintained be can flow some that such be be should V Valve thereafter. loop contamination atmospheric the from protected and 200°C) loop, ≥ (at out baked bypass thoroughly the in gas contained the with fed is it whenever upset moisture large a to APIMS the exposing avoid To testing. during gas of quality. high 7.4.1 of tubing possible 80ºC also recommended. is 50 and wherever EPSS between temperature constant at a gas lines Maintaining of constructed V between reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This V to blank test the reconnect Immediately box. glove the from blank test the remove not do used, a If system. the from completely blank test the Remove blank. test the through flow small a maintaining while loop bypass the 8.1.1.1 than 200ppt. in case nohigher and any interest, of level moisture lowest the at with be equilibrium should output APIMS The APIMS. the through gas dry of flow a and system test the of place in blank 8.1.1 level. this above temperatures at observed been moisture have in interaction changes be Permanent not 200ºC. should above blank heated test the that except convenient, most is manner whatever in gas zero with equilibrium to brought blank test the and omitted be may blank test of testing dry-down the of test dry-down initial the interest, of initial not is system If calibration. each after 8.1 8

Procedure

Temperature Control and Measurement — — Measurement and Control Temperature ln et — Tests Blank

Initial Dry-down — — Dry-down Initial Other arrangements than that shown may also be also may shown that than arrangements Other The bypass loop will contain a stagnant volume stagnant a contain will loop bypass The

Switch the gas flow to pass primarily through primarily pass to flow gas the Switch 2 and V and

glove box or other such enclosure is enclosure such other or box glove 3 , should be as short as possible and possible as short as be should , A blank test shall be carried out carried be shall test blank A Start the experiment with the with experiment the Start 4 , leaving it leaving , A stable A 4 should Page jn l jn eut f ti et wl elc, b ein any 8.2.1.1 design, by remove to reflect, taken maintain shipping. drynessmoisture and its during has will supplier the test which precautions this of the Thus, supplied. results typically is removable it the which in of system in the condition of quantity surfaces wetted the the on moisture determine to designed 8.2.1 8.2 sets. data it 8.1.1.2 until output APIMS whichever less. oris 800ppt 48hours, reaches the Record moisture in increase concentration. an show will APIMS The loop. bypass the through not and blank the through only flow V toreconnecting before inside from air the purge to minutes five for blank test the through V from disconnected heater tapes at 60°C for 12 h to remove atmospheric remove to contamination. h 12 for 60°C at tapes using heater channels process appropriate the the to Bake connecting line APIMS. sample the to panel gas the of outlet the appropriate Connect system. test through the of channels process moisture) ppt (200 gas nitrogen 8.2.2 dominate have filters since done is This pieces. spool special install and system test the from filters the Remove terminated. be can test the 8.2.1.2 in 200ppt forwhichever less. reaches is or 24–48hours, it increase an show until output APIMS the will Record concentration. moisture APIMS The loop. bypass the through not and system test the through only slpm) then V minutes, to five system the for connect system the in air ambient any system. test of N under installation and blank be test of will removal the APIMS during purge to going lines gas the that V valve to the system connect test and blank sample the Remove point. this shipping or andontheat system plugs any caps packing of layer ion final the APIMS Undo min. the 10 for and 150°C min at chamber 10 for 170°C at APIMS to a line sample the maintaining Bake blank. test the while through flow small loop bypass the through pass to flow nitrogen dry the Switch box. glove the in system the unpack used, is enclosure such other or box glove a If level. moisture background the with equilibrated has APIMS the after until unpacked be not should system 4

Tests on Actual Test System Test onActual Tests

nta r-onDry-down Initial Moisture Input Test Input Moisture

After 24–48 hours, the initial dry-down part of part dry-down initial the hours, 24–48 After Repeat the above test twice for a total of three of total a for twice test above the Repeat tr h et a n Scin 811 h test The 8.1.1. Section in as test the Start and skew and Allow the dry nitrogen flow to purge out purge to flow nitrogen dry the Allow the dry-down performance. the dry-downperformance. a ag ufc ra ad would and area surface large 5 4 lo r irgn t flow to nitrogen dry Allow . as quickly as possible. possible. as quickly as — This portion of the test is test the of portion This — 5 . Switch the gas to flow (1.2 flow to gas the Switch . — Flow 1.2 slpm of dry of slpm 1.2 Flow — Document Document Number: 5 Doc. . Switch the gas togas theSwitch . Date: SEMI 4/23/2018 Ensure DRAFT 2

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone:408.943.6900 Fax: 408.943.7943Phone:408.943.6900 Fax: CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and osue n oio h dry-down. the monitor and moisture) ppt (200 nitrogen dry to gas min input the 20 switch then for and input this Maintain response. APIMS the (by moisture ppb recording while used) is 1 Figure in shown arrangement 200 with V valves nitrogen switching to the gas Switch min. input 30 for APIMS the up nitrogen, warming in after gas methane 1% using system test the of min. 10 for connections outlet and inlet 150°C the at check leak a at Perform APIMS of source ion and min 10 for 170°C at line sample the Bake 30°C. to system 8.2.2.1 reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This relevant other and subjectchangewithout to standards notice. These mentionedherein. are any respectto materials with literature sheets, data product labels, product user. instructions, the manufacturer’s of to responsibility refer to the cautioned solely are is Users standard the of suitability the of determination The application. particular NOTICE:

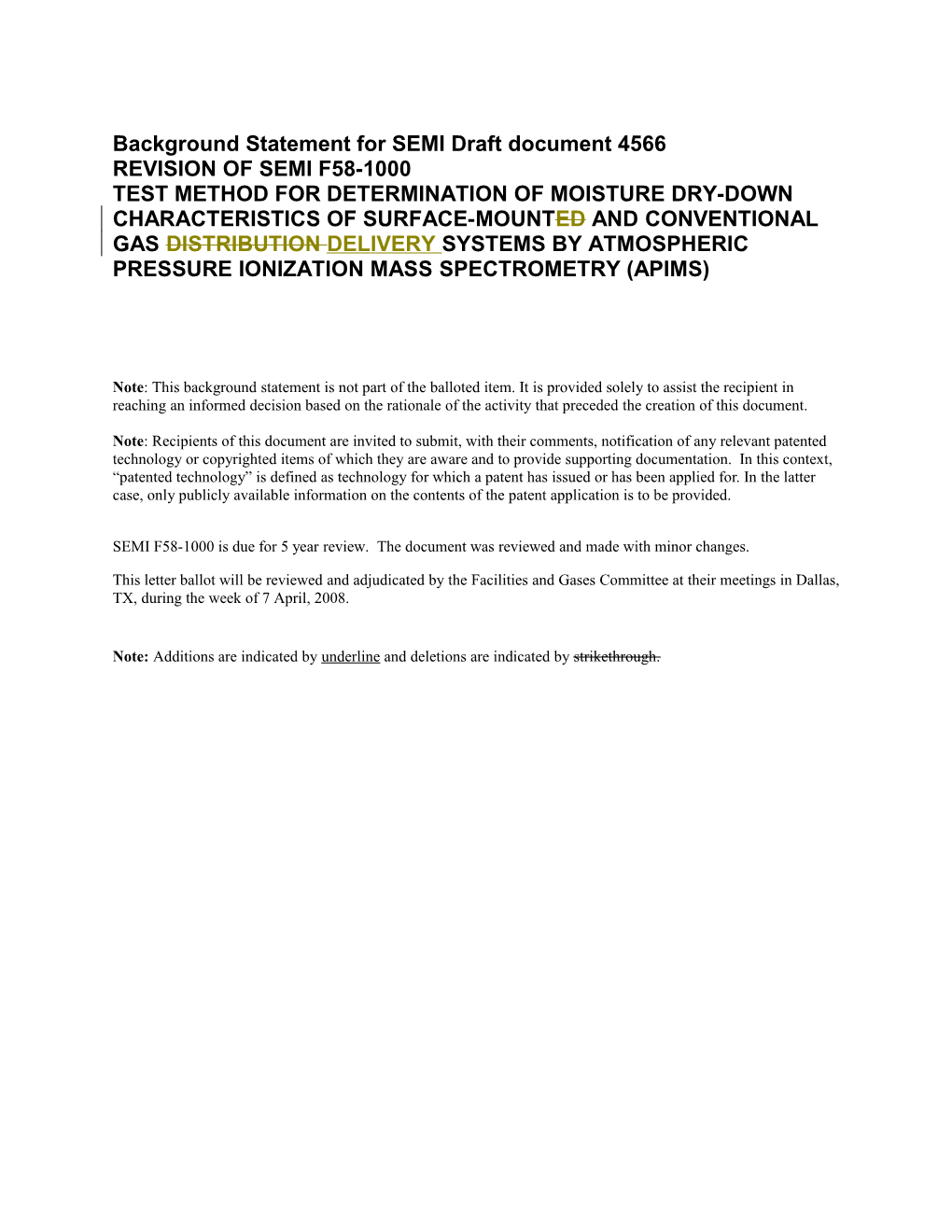

At the conclusion of baking, equilibrate the test the equilibrate baking, of conclusion the At SEMI makes no warranties or representations as to the suitability of the standards set forth herein for any for herein forth set standards the of suitability the to as representations or warranties no makes SEMI UHP N UHP UHP N UHP 2 1 2 , V , Regulator 2 , and V and , Generator Moisture 3 simultaneously, if the if simultaneously, MFC Transducer Pressure gauge/ 3-port Valve Regulator P1 Filter Dryer + APIMS Moisture Schematic Test APIMS eod the Record V3 Figure 1 Figure Page V2 Tovent jn l jn be noted.be should variables experimental all a of possible complete as record as and Temperature, measurements, systems). flow test and pressure, the for time time of decay function a as and/or plotted be of may height, concentrations moisture terms (detected peak in time,” systems compare “induction may sheet summary A included. be should blanks test relevant and systems 9.1 9 less. is whichever hours, 24-48 or ppt 200 reaches it until output APIMS 5

V1 Reporting ResultsReporting

opee mitr epne cre o l test all for curves response moisture Complete (At30°C) Testsystem To ventTo V4 Bypassloop

Tovent V5 APIMS Document Document Number: MFC Doc. P2 Date: SEMI 4/23/2018 DRAFT

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone:408.943.6900 Fax: 408.943.7943Phone:408.943.6900 Fax: CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and the risk of infringement of such rights, are entirely their own such responsibility. infringementposition rights,areentirelythe of their risk of this no in mentioned takes item SEMI any and copyrights or rights with patent such standard, any of determination connection that advised expressly are this in standard this of Users standard. asserted of copyrights or publication rights By patent any rights. of patent validity the by respecting covered invention an copyrighted of of use or require may material standard this with compliance that possibility the to called is attention user’s The reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This Page jn l jn 6 Document Document Number: Doc. Date: SEMI 4/23/2018 DRAFT

LETTER (YELLOW) BALLOT