Depositing nano-sized Coatings by means of AS Coating Star as an Aerosol assisted large area cold atmospheric Plasma Technology

Tom Van Hove ۩

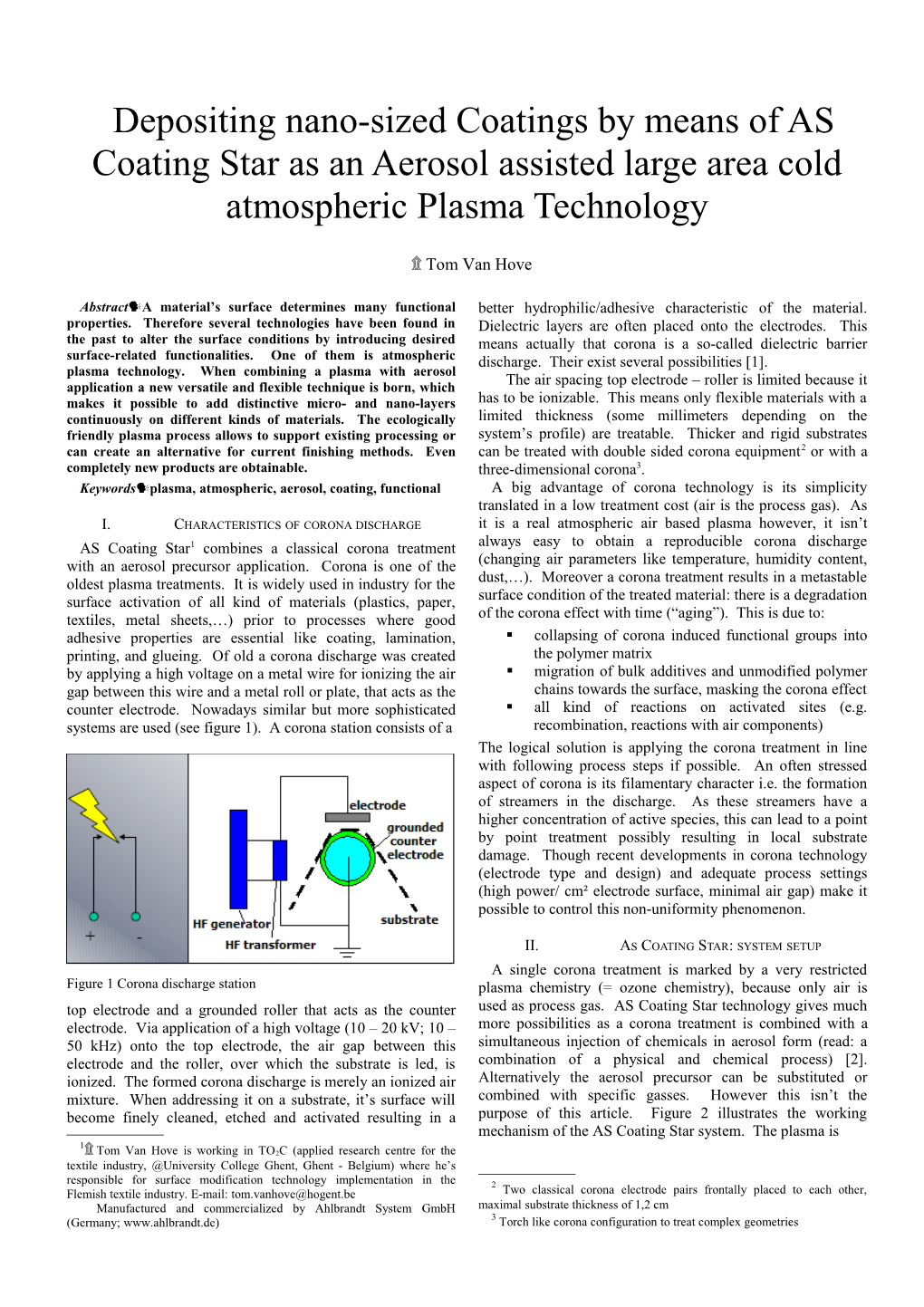

AbstractA material’s surface determines many functional better hydrophilic/adhesive characteristic of the material. properties. Therefore several technologies have been found in Dielectric layers are often placed onto the electrodes. This the past to alter the surface conditions by introducing desired means actually that corona is a so-called dielectric barrier surface-related functionalities. One of them is atmospheric discharge. Their exist several possibilities [1]. plasma technology. When combining a plasma with aerosol application a new versatile and flexible technique is born, which The air spacing top electrode – roller is limited because it makes it possible to add distinctive micro- and nano-layers has to be ionizable. This means only flexible materials with a continuously on different kinds of materials. The ecologically limited thickness (some millimeters depending on the friendly plasma process allows to support existing processing or system’s profile) are treatable. Thicker and rigid substrates can create an alternative for current finishing methods. Even can be treated with double sided corona equipment2 or with a completely new products are obtainable. three-dimensional corona3. Keywordsplasma, atmospheric, aerosol, coating, functional A big advantage of corona technology is its simplicity translated in a low treatment cost (air is the process gas). As I. CHARACTERISTICS OF CORONA DISCHARGE it is a real atmospheric air based plasma however, it isn’t AS Coating Star1 combines a classical corona treatment always easy to obtain a reproducible corona discharge with an aerosol precursor application. Corona is one of the (changing air parameters like temperature, humidity content, oldest plasma treatments. It is widely used in industry for the dust,…). Moreover a corona treatment results in a metastable surface activation of all kind of materials (plastics, paper, surface condition of the treated material: there is a degradation textiles, metal sheets,…) prior to processes where good of the corona effect with time (“aging”). This is due to: adhesive properties are essential like coating, lamination, . collapsing of corona induced functional groups into printing, and glueing. Of old a corona discharge was created the polymer matrix by applying a high voltage on a metal wire for ionizing the air . migration of bulk additives and unmodified polymer gap between this wire and a metal roll or plate, that acts as the chains towards the surface, masking the corona effect counter electrode. Nowadays similar but more sophisticated . all kind of reactions on activated sites (e.g. systems are used (see figure 1). A corona station consists of a recombination, reactions with air components) The logical solution is applying the corona treatment in line with following process steps if possible. An often stressed aspect of corona is its filamentary character i.e. the formation of streamers in the discharge. As these streamers have a higher concentration of active species, this can lead to a point by point treatment possibly resulting in local substrate damage. Though recent developments in corona technology (electrode type and design) and adequate process settings (high power/ cm² electrode surface, minimal air gap) make it possible to control this non-uniformity phenomenon.

II. AS COATING STAR: SYSTEM SETUP A single corona treatment is marked by a very restricted Figure 1 Corona discharge station plasma chemistry (= ozone chemistry), because only air is top electrode and a grounded roller that acts as the counter used as process gas. AS Coating Star technology gives much electrode. Via application of a high voltage (10 – 20 kV; 10 – more possibilities as a corona treatment is combined with a 50 kHz) onto the top electrode, the air gap between this simultaneous injection of chemicals in aerosol form (read: a electrode and the roller, over which the substrate is led, is combination of a physical and chemical process) [2]. ionized. The formed corona discharge is merely an ionized air Alternatively the aerosol precursor can be substituted or mixture. When addressing it on a substrate, it’s surface will combined with specific gasses. However this isn’t the become finely cleaned, etched and activated resulting in a purpose of this article. Figure 2 illustrates the working mechanism of the AS Coating Star system. The plasma is 1 Tom Van Hove is working in TO2C (applied research centre for the۩ textile industry, @University College Ghent, Ghent - Belgium) where he’s responsible for surface modification technology implementation in the 2 Flemish textile industry. E-mail: [email protected] Two classical corona electrode pairs frontally placed to each other, Manufactured and commercialized by Ahlbrandt System GmbH maximal substrate thickness of 1,2 cm (Germany; www.ahlbrandt.de) 3 Torch like corona configuration to treat complex geometries III. AS COATING STAR: APPLICATIONS Depending on the aerosol type various effects come within one’s reach. AS Coating Star treatments can be considered as a supporting step (better adhesion, higher hydrophilic nature) for existing production processes like printing, coating, laminating, glueing, dyeing, metallization,… On the other hand AS Coating Star technology can simulate existing finishing steps (antifogging, antistatic and antimicrobial treatment, soil release, anti-blocking,…) or can even create completely new effects in a revolutionary way (e.g. self- Figure 2 AS Coating Star: working principle cleaning). By doing so it can be a surplus above an existing made in a box with a temperature controlled housing enabling finish. Two existing AS Coating Star applications are the creation of a specific microclimate in this box. Normally described below. a temperature just above 40 °C is set, so the typical ozone problem of corona is eliminated (ozone disintegrates A. Supplementary enhancement of adhesion via AS Coating spontaneously in oxygen when temperature is above 40 °C). Star treatment with water aerosol The thermostatically controlled walls of the box also provide a Corona treatment of a polypropylene foil leads to an cooling of the top electrode pair, which is needed because of oxidation of the surface translated in a higher surface tension heat dissipation effects when working with high power levels (test results: see table 1 and table 2). The well-known ageing (10 W/cm²). The aerosol can be injected between the two phenomenon can be noticed too. This deteriorating of the corona electrodes. The intimate contact between aerosol and corona effect can be diminished somewhat by ionization of an corona discharge will lead to a polymerization/crosslinking of air/nitrogen gas mixture. The best result however is booked the chemical product, and finally a deposition of a coating when injecting a pure water aerosol into this discharge: a onto the through plasma activated material’s surface. This clearly higher surface tension is reached through extra oxygen opens new ways towards the building-up of nano-topcoats that built-in onto the PP foil’s surface. This concept can be used are preferentially covalently bonded to the substrate. There in pre-treatment applications were high adhesive/hydrophilic are configurations available with aerosol injection just behind values are requested. Nevertheless the effect isn’t stable. the electrode pair. In this case there will only be a partial Table 1 Surface tension values directly and four weeks after plasma aerosol/plasma –interaction: most aerosol particles are simply deposited onto the corona activated substrate. This is a more Material: PP foil surface tension surface tension easily controllable application; but the lower the plasma 150 µm (mN/m) - directly (mN/m) - 4 weeks activation grade of the aerosol particles, the worse the after plasma after plasma permanency of the finish will be. corona (air) 48 42 The easiest and cheapest is to work with an air based corona corona (air + nitrogen) 48 44 discharge. Logically the aerosol can be produced in this case corona (air + nitrogen) with dried and degreased compressed air. Air has a high + aerosol 60 52 oxygen content (21 %) what means a strong oxidizing plasma Table 2 XPS analysis data will be obtained. This will definitely eliminate the possibility of hydrophobic and oleophobic treatments. Besides the Material: PP foil 150 µm XPS chemical structure of the aerosol can be modified or even C 1s N 1s O 1s destroyed by very aggressive oxygen particles (like O°). A corona (air) 83,7 < 1 15,6 solution to this problem is working with aerosol and corona discharges on noble/inert gas basis (helium, argon, nitrogen). corona (air + nitrogen) 84 3,4 12,7 This will make the plasma application more complicated, but corona (air + nitrogen) + aerosol 73,5 2,1 24,4 the possibilities are much higher [3]. By means of special nozzles an aerosol is formed with B.Smart plasma priming for superior adhesion of UV-curable droplets that have an average diameter of 1 micron, resulting formulations in very thin surface coatings. Considering the dimensions of The concept smart plasma priming is presented the electrode pair (two centimetres long plasma zones) linked schematically in figure 3 [4]. Normally the plasma priming is to an aerosol application, only nano-coatings are obtainable at done in two steps. First a plasma treatment induces a high industrial processing speeds (> 10 m/min). In addition, the radical built-up on the surface of the material. Afterwards an very limited add-on eliminates the need for a subsequent application of acrylate or methacrylate photoinitiators that drying process, proving the economical and ecological contain double bonds is done. The radicals can react with benefits of this ‘dry’ technology. During formation the these double bonds. The result is a partially crosslinked layer aerosol will be warmed up to 35 °C. Leading the substrate of photoinitiator covalently linked to the substrate. A one step over a water cooled roller (20 °C) will assure an optimal solution is an AS Coating Star treatment that uses an aerosol condensation (i.e. take-up) of the aerosols droplets onto the of photoinitiator. The plasma deposited nano-layer will substrate. By means of an exhaustion unit, precisely placed permanently increase the surface tension (no diffusion of after the plasma treatment zone, particles that haven’t reacted photoinitiator towards the bulk because of its semi-crosslinked with the substrate are drained away. state) and involves a latent functionality towards UV-light. ACKNOWLEDGEMENTS The author of this article would like to thank the company Ahlbrandt System GmbH for the provision of technical information about their plasma systems.

REFERENCES [1] Technical paper Enercon Industries: “Corona Treater Station Design and Construction: meeting the converting Challenge” [2] Van Hove, T.; Van Parys, M.; “Reactive Atmospheric Plasma Treatment of Polymers by means of the AS Coating Star-Technology”; Proceedings ‘1st International Conference on Polymers & Moulds Innovations’ (PMI), University College Ghent; 2005 [3] Rau, A.; “Nano-Modifizierung von Oberflächen durch kombinierte Corona/Aerosol Behandlung“; Coating 3, p. 185-187; 2004 [4] Baurer, M.; Kunz, M.; “Smart Plasma Priming, a new Surface Modification Technology with superior Interface Features“; Fachzeitschrift Galvanotechnik, p. 1350; 2001 [5] Bolte, G.; “Nano-Primer Technology for UV Coating with Aerosols”; Conference Proceedings ‘RadTech Europe’; 2005

Figure 3 Smart plasma priming principle After plasma treatment a UV-curable formulation consisting of monomers, oligomers, functional and process additives, photoinitiators,… is applied. A UV-radiation step initiates a radical polymerisation of the added layer (print, coating, glue) and leads to superior adhesion characteristics, because the deposited plasma layer forms a covalent linkage between substrate and top layer. This is due to the fact that the previously added photoinitiator layer participates in the radical polymerization phase. This all opens new perspectives towards application fields where traditional technologies don’t give satisfying results. The above mentioned concept has been tested on a polypropylene foil that has, owing to its non-polar character, a bad adhesion for a UV-curable lacquer (results: see table 3) [5]. Corona pretreatment can’t solve this adhesion failure. An AS Coating Star pretreatment with injection of an acrylate photoinitiator aerosol between the top electrode pair results in a much better adhesion of the UV-lacquer on the PP film. The best results however are booked when pre-activating the added photoinitiator. This can be done by a UV-radiation step after AS Coating Star treatment, but just before the real UV- coating process. The alternative is applying a corona treatment after photoinitiator deposition and before the lacquering. The corona impact will lead to an anchoring of the initiator next to a partial activation of it through the impact of the UV-light component of the corona discharge. Table 3 Impact of smart plasma priming on the adhesion of UV- lacquer on PP foil

UV- corona photoini- UV-light corona lacquer Adhesion tiator + UV- aerosol light * - * * - * * * ++ * * * * +++ * * * +++ Legend: - = delamination; ++ = good adhesion; +++ = excellent adhesion