EIN 6133 Enterprise Engineering Fall, 2017

Guidelines for Term Project Implementation in SAP 1. SAP Environment for Implementation Server: WARSAW Client: 620 SAPGUI configuration:

Team 1 (Brenda’s Team): use US06 organization structure, Team 2 (Estrella’s team): use US23 organization structure, Team 3 (Daniel’ Team): use US13 organization structure, Team 4 (Quynh’ Team): use US08 organization structure, Team 5 (Bria’s Team): use US07 organization structure, Team 6 (Carlos’ Team): use US05 organization structure,

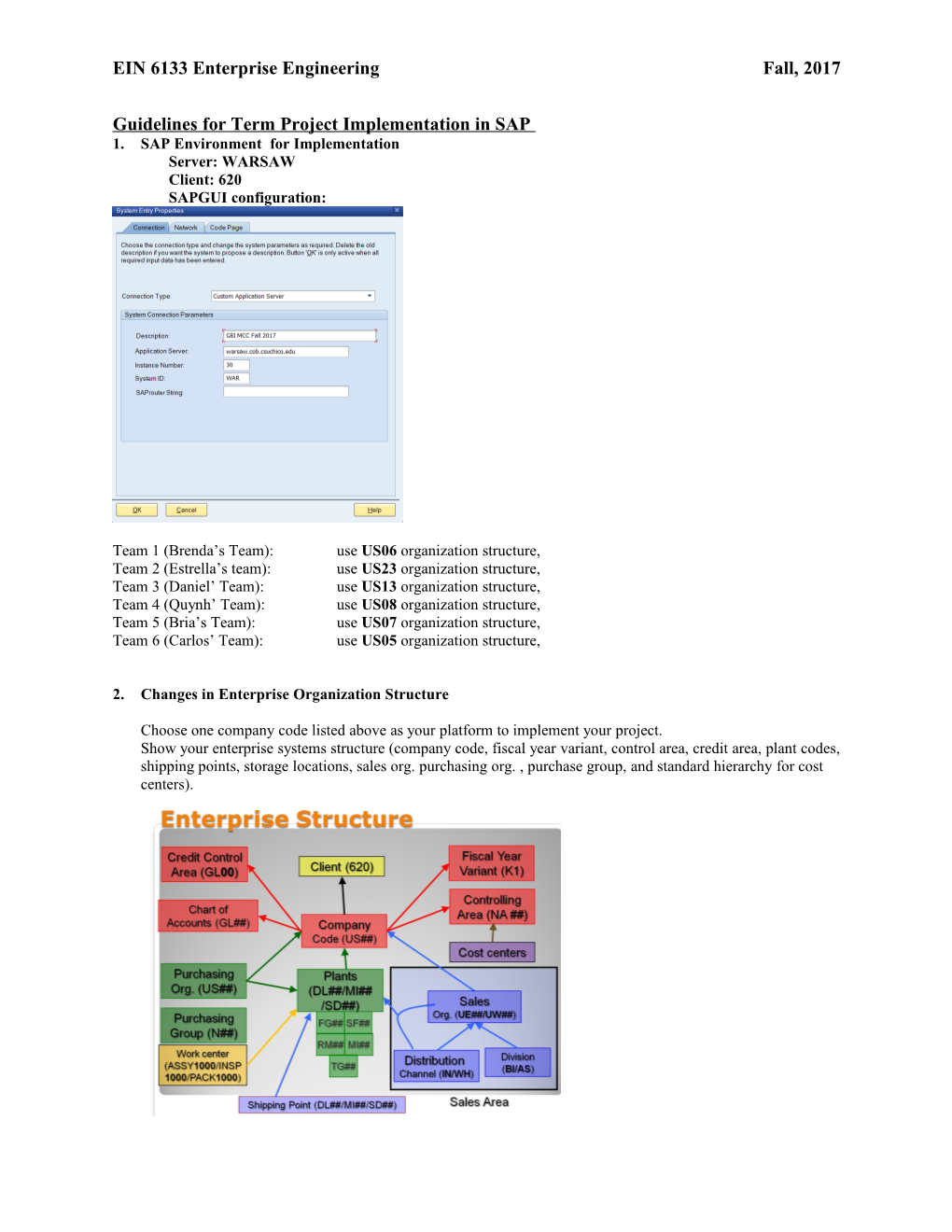

2. Changes in Enterprise Organization Structure

Choose one company code listed above as your platform to implement your project. Show your enterprise systems structure (company code, fiscal year variant, control area, credit area, plant codes, shipping points, storage locations, sales org. purchasing org. , purchase group, and standard hierarchy for cost centers). EIN 6133 Enterprise Engineering Fall, 2017

1) Change the description for your company code US## (T-code: SPRO) 2) Change the plant description for your plant DL## (T-code: SPRO) 3) Change the sales organization description for your sales org. UW## (T-code: SPRO) 4) Change the purchase organization description for your purchase org. US## (T-code: SPRO)

3. New Master Data for Materials Management 1) Create one new finished good (T-code: MMF1) at DL##, Sales Org. UW##, Division BI, and distribution channel WH. The finished product has at least two new raw materials. 2) Create relative raw materials for the new product at DL##. (T-code: MMR1). 3) Create two new vendors “0## Chen and Associates, Inc.” and “0## ABC and Associates, Inc.” in purchase org. US## and company code US## (T-code: XK01). 4) Create new info records for new raw materials at DL##. (T-code: ME11).

4. New Master Data for Sales Management 1) Create two new customers (0## Shen and Associates, Inc.) and (0## King and Associates, Inc. ) in US##, UW##, BI, and WH. (T-code: XD01) 2) Create pricing conditions for your new finished product at UW##, BI, and WH. (T-code: VK31) 3) Setup credit limit for your new customers. (T-code: FD32)

5. New Master Data for Production Management 1) Modify labor activity price in your controlling area NA##. (T-code: KP26, optional) 2) Create at least one new work center for production at DL##. (T-code: CR01) 3) Create BOMs for your new finished product at DL##. (T-code: CS01) 4) Create routings for your new finished good at DL##. (T-code: CA01) .

6. Operation Activities 1) After implementation, send an email to your instructor to introduce your new finished product with prices in UW##, WH, and credit limit. 2) Create a sales order for your new finished product at UW##, BI, and WH. (T-code: VA01) 3) Run MPS/MRP to generate purchase requisitions and planned orders at DL##. (T-code: MD41). 4) Create purchase order for required raw materials to your new vendor. (T-code: ME21N) 5) Make a goods receipt for your PO at DL##. (T-code: MIGO) 6) Post invoice receipt for your new vendor. (T-code: MIRO) 7) Post outgoing payment to your new vendor. (T-code: F-53) 8) Convert your planned order to a production order for your new finished product. (T-code: MD04) 9) Make goods issue to production order at DL##. (T-code: MB1A) 10) Confirm production completion. (T-code: CO15) 11) Make goods receipt of your finished good for the production order at DL##. (T-code: MB31) 12) Make production order costs settlement. (T-code: KO88) 13) Create delivery notes for your sales order. (T-code: VL01N) 14) Ship materials (make goods issue) at DL##. (T-code: VL02N) 15) Bill your new customer. (T-code: VF01) 16) Receive payment. (T-code: F-28)

Note: 1. For the final written project report, take screen shots to show each implementation and operation activity. 2. A list of T-codes used during the implementation and operation (separated them by each of the 3 modules)