HR2360 - Roll on Heat Release Decal Application Machine

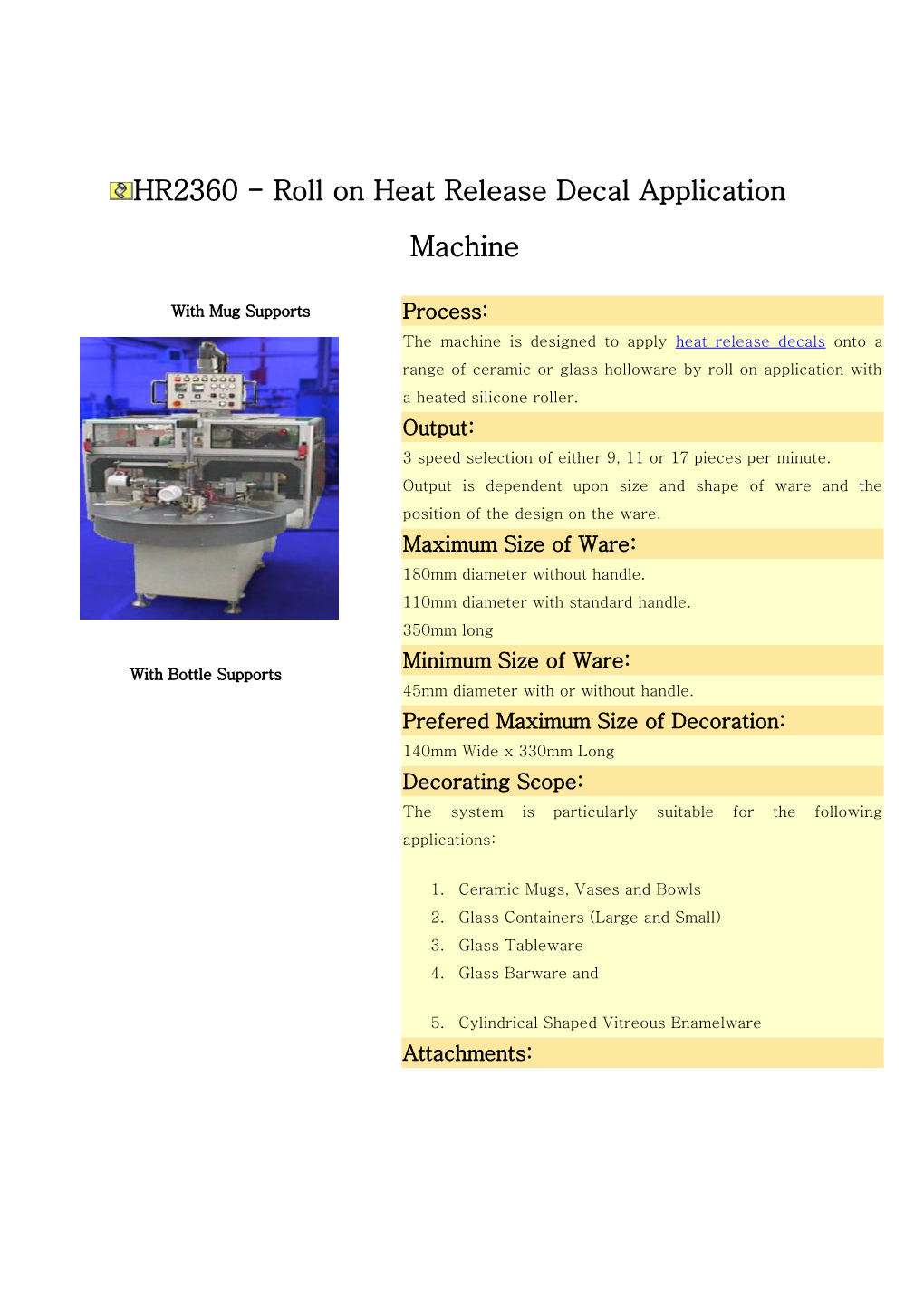

With Mug Supports Process: The machine is designed to apply heat release decals onto a range of ceramic or glass holloware by roll on application with a heated silicone roller. Output: 3 speed selection of either 9, 11 or 17 pieces per minute. Output is dependent upon size and shape of ware and the position of the design on the ware. Maximum Size of Ware: 180mm diameter without handle. 110mm diameter with standard handle. 350mm long Minimum Size of Ware: With Bottle Supports 45mm diameter with or without handle. Prefered Maximum Size of Decoration: 140mm Wide x 330mm Long Decorating Scope: The system is particularly suitable for the following applications:

1. Ceramic Mugs, Vases and Bowls 2. Glass Containers (Large and Small) 3. Glass Tableware 4. Glass Barware and

5. Cylindrical Shaped Vitreous Enamelware Attachments: Lifting Decal Cassette

Please contact our sales team for assistance, or click below for an online Enquiry Form. Select picture below to go to a machine directory, or select a specific model number

Flatware Forming Holloware Forming HEAT-RELEASE DECALS

The process of heat release decal decoration is well known to many ceramics and glass decorators, but for those unfamiliar, here is a brief synopsis.

Ceramic colours specially selected for the The required number of ware are printed onto a wax-coated colours are successively release paper. Registration and print printed onto the release quality are excellent, because this process paper, including bright is carried out by specialist printers who metals, etch effects- it is use high speed, precision printing even possible now to equipment. This has an extremely produce raised colours for important advantage over printing colours enhanced aesthetic appeal. A directly onto products such as plates, protective coating bottles and cups, because it achieves ("covercoat") is then applied accurate registration of colours even in over the colours. These complex designs and on shaped surfaces. decals are typically printed on large sheets, and then die-cut or guillotined ready for supply to the glass or ceramic decorator. Many decal suppliers have "open stock" designs on the shelf for immediate delivery, as well as printing customer뭩 own designs from original artwork or disc.

Decals printed in this manner thus contain the entire "finished design", ready to be applied to the product in a single hit. Service (Engineers) Ltd specialise in production machinery for applying heat release decals. Our machines use heat to soften the wax coating, and hence allow the image to be lifted from the paper (on a hot silicone pad or roller), and then transferred to the ware. These diagrams show the basic application process:

1. A single decal is 2. The pad presses 3. The pad lifts, positioned below a hot down onto the decal, releasing the image silicone pad softening the wax which now adheres to the pad 4. The item to be 5. The pad presses 6. The pad lifts, decorated is positioned down onto the item, leaving the decorated below the pad conforming precisely item below to the contour of the item

The application cycle is fast, and the product can be handled as soon as the decal has been applied; this is a dry process, and the image is immediately ready for firing, with no further preparation, in a kiln, decorating lehr or tempering plant, where the colours become permanently fused to the surface.

Today we have a range of machinery using this decorating technology, to suit a variety of needs:

HR250P for Ceramic and Glass Tableware; Small and Large Glass and Ceramic Containers; Liquor and Wine Bottles; Barware; Tiles; Giftware; Collectors Plates HR280P for higher speed applications as above HR150P for smaller ceramic and glassware items HR2360 for Ceramic Mugs, Vases and Bowls; Glass Bottles and holloware; Cylindrical Shaped Vitreous Enamelware HR650RF for flat glass and ceramic tiles

SUPPLIERS of Heat Release Decals

We can recommend the following small selection of suppliers of heat release decals. We have experience of using their decals, and know them to be satisfactory for application by our machines All these printers are familiar with our range of application machinery, and fully appreciate the technical requirements. Many more companies around the world are able to print decals for heat release transfer application; this is a highly competitive area with many specialists. We hope this listing will be useful both for our existing customers and for those about to introduce heat release decoration into their operations.

Name of Supplier Area Key Capabilities Contact details Covered

Capper Rataud Worldwide High quality Ceramic and Glass +44 (0)1782 525100 Limited heat release decals. www.capper-rataud.co.uk On/ In glaze, underglaze and single-fire underglaze decals. "Multical" low temperature curing decals for metals, plastics, wood, etc. Precious metal decals.

GB Decor Ltd UK Ceramic and Glass decals. +44 (0)1782 271828 Specialist in raised colours. www.gbdecor.co.uk Underglaze decal specialists. Open Stock ceramic range

John Walker UK Ceramic and Glass decals. +44 (0)1782 414 916 Ceramic Transfers UK Agent for Keram Druck www.keramdruck.dc Specialists in Ceramic onglaze and underglaze. Collectibles and glass decals Low fired decals for glass, collectibles and plastics

Johnson Matthey Worldwide Ceramic and Glass decals. +44 (0)1782 590000 Specialist in Tableware heat www.cmd.matthey.com release decals Complete design service available Special effect decals including gold and platinum Metallic and irridescent Imitation gold and etch Keram Druck Europe, Ceramic and Glass decals. +49 (0)681 588 260 USA Specialists in Ceramic onglaze and www.keramdruck.dc underglaze. Collectibles and glass decals Low fired decals for glass, collectibles and plastics

Leipold Group Worldwide Ceramic and Glass decals. +49 911 96900 Specialist in raised colours. www.fxl.de Underglaze decal specialists. Open Stock ceramic range

Rathbone Worldwide Ceramic and Glass decals. +44 (0)1782 202244 International Specialist in toughed glass www.cms-colours.co.uk Limited transfers. Gold products Open Stock ceramic range Four-colour process specialists Heat release and under-glaze transfers Raised and reactive transfers

Tung Hsing Far East Ceramic and Glass decals. +8862 279 72188 Specialists in precious metals. Over glaze 4 colours plus process. E-mail: Glass Packaging specialists [email protected] Inglaze reactive crystalized for stoneware.

Agents for: South Korea

Kosco International Limited Send an e-mail 2nd Floor Koam Building +82 2 511 6177 41-12 Jamwon-Dong Seocho-Gu Seoul Contact: B J Ahn +82 2 511 6176 KOREA