SYLLABUS FOR THE TRADE OF MOTOR MECHANIC VEHICLE

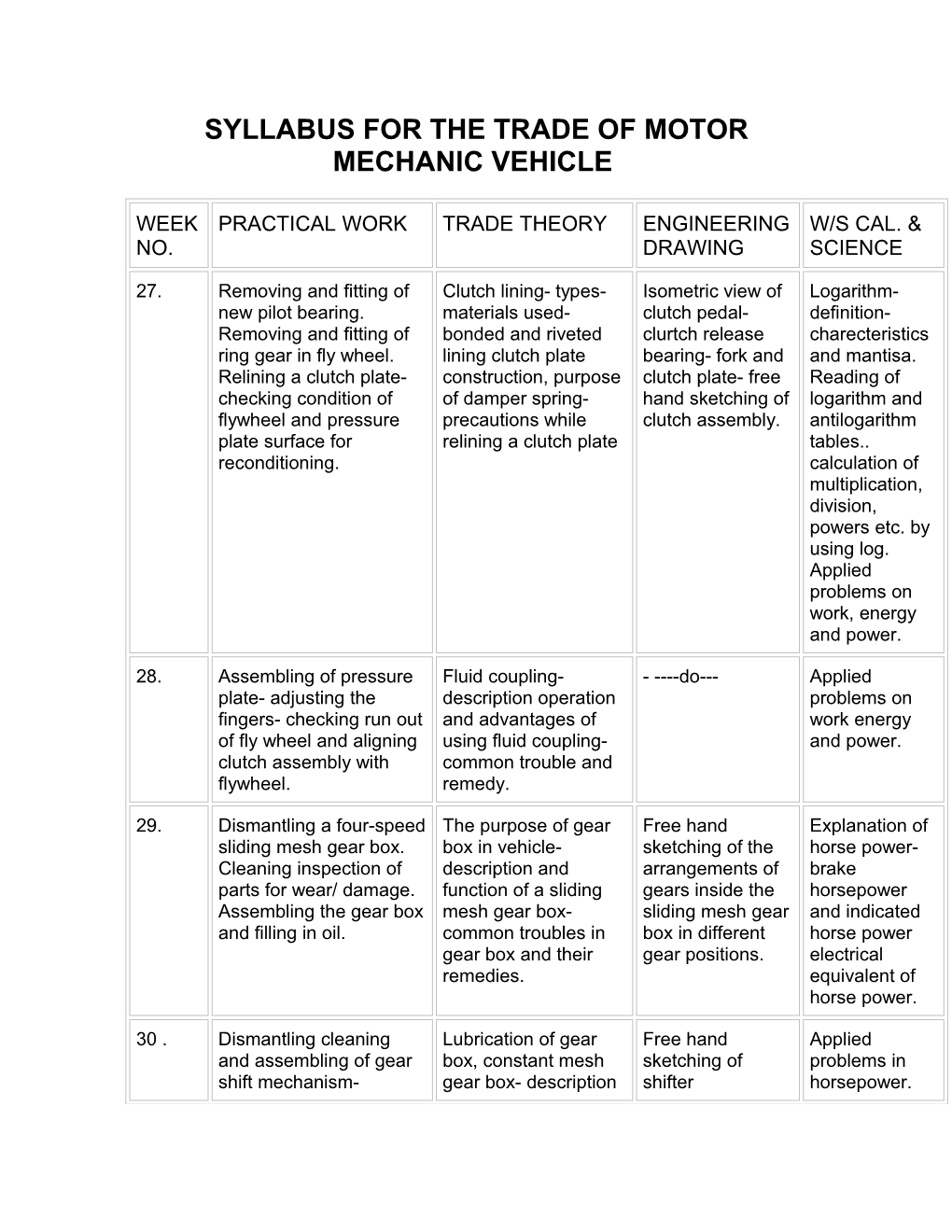

WEEK PRACTICAL WORK TRADE THEORY ENGINEERING W/S CAL. & NO. DRAWING SCIENCE

27. Removing and fitting of Clutch lining- types- Isometric view of Logarithm- new pilot bearing. materials used- clutch pedal- definition- Removing and fitting of bonded and riveted clurtch release charecteristics ring gear in fly wheel. lining clutch plate bearing- fork and and mantisa. Relining a clutch plate- construction, purpose clutch plate- free Reading of checking condition of of damper spring- hand sketching of logarithm and flywheel and pressure precautions while clutch assembly. antilogarithm plate surface for relining a clutch plate tables.. reconditioning. calculation of multiplication, division, powers etc. by using log. Applied problems on work, energy and power.

28. Assembling of pressure Fluid coupling------do--- Applied plate- adjusting the description operation problems on fingers- checking run out and advantages of work energy of fly wheel and aligning using fluid coupling- and power. clutch assembly with common trouble and flywheel. remedy.

29. Dismantling a four-speed The purpose of gear Free hand Explanation of sliding mesh gear box. box in vehicle- sketching of the horse power- Cleaning inspection of description and arrangements of brake parts for wear/ damage. function of a sliding gears inside the horsepower Assembling the gear box mesh gear box- sliding mesh gear and indicated and filling in oil. common troubles in box in different horse power gear box and their gear positions. electrical remedies. equivalent of horse power.

30 . Dismantling cleaning Lubrication of gear Free hand Applied and assembling of gear box, constant mesh sketching of problems in shift mechanism- gear box- description shifter horsepower. changing oil in gearbox, and advantages. mechanism and Calculation of studying gear ratios in gear shift lever. speed ratios in the gearbox. the 4 speed gear box.

31. Removing open type Universal joints and Use of drawing Ratios and propeller shaft from propeller shaft- open instruments, T- proportions- vehicle,. Removing and closed type square and simple universal joints- propeller shaft. Types drawing board. problems. cleaning, inspecting- of universal joints- Construction of Gear ratios in replacing of worn out care and simple figures. gear box and parts, reassembling and maintenance, rear axles. fitting to vehicle. Special constant velocity precautions while joints-special features removing torque tube and advantages. drive shaft.

32. Removing rear brake Description and Construction of ---do--- drums and adjusting the purpose of different simple solid wheel bearings in full types of rear axles- figures with floating rear axles and special feature and dimensions – and semi- floating axles advantages of each titles- use of replacing oil seals in rear type, lubrications of different types of axles. rear axles-reasons for scales. oil in brake drums.

33. Removing rear axles Description and Free hand Calculation of assembly from vehicle, functions of final drive sketching of areas of dismantling, cleaning, assembly-crown different types of square, inspecting parts for wear wheel and tail pinion- rear axles. rectangles, and damage, cutting hypoid gear and its triangles, packings/gaskets, lubrication Description circles, and removing tail pinion and of differential and its regular bearings-cleaning and principle of operation. polygons. inspection of oil-seals and bearings.

34. Checking tooth contact Description and Free hand Same as in in crown and opinion and function of differential sketching of work 33. adjusting backlash. gears- types- tooth universal joints, Assembling the rear axle contact and back silencer brackets and fitting rear axle lash, preloading and spring assembly on vehicles adjustment . common shackless. and testing. trouble and their remedy in axle assembly. Trouble shooting in the Description and ----do---- Calculation of transmissions system of purpose of optional volume of .35 vehicle- detecting noises fittings such as square, from clutch, gear box, transfer case-free rectangular universal joints, and rear wheel- power take off- and conical axles assembly. common troubles in blocks, volume Dismantling transfer these units and their of cylinder case from vehicle- remedy care and solid and cleaning, inspecting, maintenance. hollow. replacing worn parts, reassembling and fitting to vehicle.

ACHIEVEMENTS FOR 10 WEEKS OF TRAINING FROM 26 TH TO 35 TH WEEK:

TRAINEES SHOULD BE ABLE TO:

1. . Do relining of clutch plate and adjust clutch paddle free play

2. repair defects in clutch assembly, gear box universal joints and rear axle.

Identify defects and noises in the transmission system and rectify.

4. Overhaul differential and able to adjust and check and do preload bearings.

5. Observe safety precautions.

8. PRIMARY ENGINE WORK:

36. Dismantling of Description of Free hand Calculation of volumes unserviceable engine- internal and external sketching of 4 and weight of cubes, cleaning, studying the combustion engines stroke cycle and hexagonal prisms- parts in the engine and different types of 2 stroke cycle. shop problems. assembling the engine, I.C.engines, practice in the use of important working correct tools and right parts in the engine procedure. the 4-stoke cycle. 37. Dismantling an Two stroke cycle, ----do------do--- unserviceable engine, difference between 4 cleaning of parts in the store and 2 stroke engine, measuring of cycle engine. cylinder bore- crank Description of valve pins, main journals, operating pistons, studying mechanism and valve-operating valve timing. mechanism. Description and function of valve springs , guide, tappets, valve seals and locks.

38. Checking compression Description and Drawing of 3 Calculation of cylinder pressure in a running function of cylinder views stepped wear- ovality taper and engine, dismantling the block, cylinder head and taper blocks compression ratios- cylinder head from the cylinder liners. in the 3rd angle problems on engine decarbonising Reconditioning of projection. compression ratios. the cylinder head, cylinder heads. removing the valves cleaning reassembling and adjusting tappets.

39. Removing pistons and Description and ----do--- Center of gravity- connecting rods from function of different example- problems engine- dismantling types of pistons , involving center. of cleaning, inspecting piston rings and gravity in vehicles. checking clearance, piston pins- common installing rings and troubles and remedy. piston pins.

40. Removing connecting Description and Drawing of plan, Heat and temperature- rod assembly- function of elevation and thermometer- cleaning, checking connecting rods side and side centigrade and bearing clearances materials used for views of tapered Fahrenheit scales their replacing bearing connecting rods–big hollow objects. conversion- use of shells, setting correct and end main temperature clearance, measuring bearing shells- piston measuring wear in crank pins and pins and locking instruments- their main journals in crank method of piston description and uses. shaft. pins –crank shaft- description function and types. Common troubles and remedies.

41 Assembling crankshaft, Firing order of the ---do------do--- main bearing, engine , crankshaft connecting, rods and balancing. piston assembly in the Description of the fly engine. Fitting cylinder wheel and its head and starting the function, crank case engine and tuning up and oil sump. engine for smooth, slow speed running.

42. Checking and cooling Engine cooling Drawing the 3 Geometry- properties system for methods, air and views in 3rd angle of angles, triangles, overheating, cleaning water cooling- projection of a and circles. radiators, dismantling, radiators pump curved object. cleaning, assembling themostat and fans- and testing water their description, pumps, reverse care and flushing the system maintenance. and adjusting the fan Reason for engine belt tension. overheating.

43. Studying the Need for lubrication Free hand Properties of angles, lubrication, oil flow of engine parts- sketching of oil triangles and circles – system in engine. Friction, lubricant filters – oil flow continued. Over-hauling oil filters, and its properties, circuits – oil oil pump and setting lubrication system, pumps. the pressure release types- full flow and valves for correct oil by-pass flow system, pressure. Maintenance components in and repair in the lubrication system, lubrication system in oil filters and pump engine. -–types, their special feature and uses. Types of lubricants and their properties.

44. Simple repair in fuel Fuel feed system in ---do------do--- feed system – motor vehicles – overhauling of petrol description and pump, carburetors, fuel layout of the system. filters and air cleaners. Description, Introduction to petrol operation, injector. maintenance of petrol pump, petrol filters and Repair to solex and SU carburetors. Types of carburetors adjusting fuel and their float level and slow properties. Petrol speed adjustments – injection system. studying the fuel flow circuit in carburetor. Types of carburetors, special features , - advantages, different adjustments and their purposes. Reading of Reading of simple simple blue graphs. prints.

45. Practice in engine tune Explanation of Exercises in blue Plotting and reading of up in a vehicle. – engine tune up, job print reading. graphs. testing vacuum and description of compression of engine, compression and adjusting tappets vacuum testing – setting ignition timing description of ignition and adjusting timing setting and carburetor for slow slow speed speeds. adjustment.

ACHIEVEMENTS FOR 10 WEEKS OF TRAINING FROM 36 TH TO 45 TH WEEK;

TRAINEES SHOULD BE ABLE TO:

i. Dismantling and assembling of different components of the engine. ii. Repair operations of engine, valve refacing, valve seat cutting, Descarbonising, fitting of bearings, piston rings, gudgeon pins. iii. Overhauling of water pump, oil pump and petrol pump. iv. Follow safety precautions while doing the above repairs. v. Locate trouble and rectify in cooling, lubrication and fuel feed system of the engine.

9.BASIC ELECTICAL AND ELECTRONICS WORK: 46. Practice in jointing Simple electrical Freehand sketching Electricity and its wires and soldering. circuits series and of electrical symbols effects, static and Forming simple parallel circuits, and drawing of dynamic electricity – electrical circuits. Identification of simple circuits AC & DC Measuring of current, alternating current differences. voltage and and direct current residence. Cleaning meters. Insulators, and topping up of a conductors types of lead acid battery. resistance – ohm’s Testing battery with law and its hydrometer. Cell application, Common tester. Connecting electrical terms and battery to charger. symbols – primary and secondary cells- lead acid battery – description – construction – common troubles and remedies

47 Studying electrical Description of Freehand sketching Magnets –natural circuits in the engine electrical circuits – of ignition circuits of and artificial types assembly checking ignition system and a vehicle – poles of magnets loose, open and the components – sketching the Magnetic fields short circuit in purposes of induction circuits lines ignition circuits. coil, condenser, diagram of magneto Cleaning and testing spark plugs. ignition spark plugs. Common troubles in Overhauling of ignition circuits and distributor assembly. remedies Checking and setting ignition timing

48 Removing dynamo Description of Free hand sketching Definition of ampers from vehicle- charging circuits – of charging system volt and Ohm – Units dismantling, cleaning operation of dynamo of current , voltage , checking for defects and regulator Unit – and resistance- –assembling and Ignition warning lamp testing for motoring – trouble and remedy Ohm’s law action of dynamo and in charging system fitting to vehicle.

Removing starter Motor from vehicle and overhauling the starter motor –testing of starter motor

Description of starter motor circuit -constructional details of starter motor . Solenoid Sketching starter Calculations based switches . Common motor circuit and on Ohm’s Law. troubles and solenoid switch remedies in starter circuit circuit

49 Identification of Introduction to Sketching of various Advanced calculation different Electronic electronics – electronic devices relating to electrical Devices, Testing of Definition of resistor, used in motor circuits. electronic device, capacitor and vehicles fault finding in inductor and their Electronic circuits principles of working. and remedies. Different types of Diodes, transistors, power supply for electronic circuit

ACHIEVEMENT : - After 4 weeks of training from 46th to 49 th week Trainee should be able to do

i. Practice in making wire connections and soldering. ii. Forming series and parallel circuits in the motor vehicle iii. Maintain and testing battery. iv. Trace and rectify defects in wiring circuits v. Overhaul Dynamo self starter vi. Recognize basic electronic components – viz. Diodes, capacitors, Resistors, etc. and locate and rectify faults

vii. Follow safety precautions while doing the above repair

50 REVISION

51

52

WEEK PRACTICAL WORK TRADE THEORY ENGINEERING W/S CAL. & NO. DRAWING SCIENCE

53 Further practice on petrol engine repair work

Removing a petrol engine from a motor vehicle – dismantling Methods of engine Drawing of Problems on cylinder head, repair fitting new riveted joints – straight and bell decarbonising checking liners – types and Lap and Butt crank levers. valves – cutting valve advantages of liners, joints A freehand seats, replacing worn procedure of sketching valve guides and weak decarbonising and operating springs , assembling valve reconditioning mechanism. valves and cylinder in an engine – head and adjusting common defects in tappet clearance in a valves – valves side valve engine reface and seat angles. Reasons for valve bouncing _importance of correct tappet clearances

54 Removing piston and Reasons for cylinder Drawing of Meaning of connecting rods from wear – methods of locking devices of stress, strain, engine checking reconditioning worn different types modulus of cylinder bore wear for out cylinders. with dimensions . elasticity , ovality and taper. Precautions to be Freehand ultimate strength Checking piston ring observed while sketching of examples grooves and cleaning – removing and fitting piston and measuring piston size – piston and connecting rod removing gudge-on pin connecting rod and Bushes – checking assembly in cylinder wear – refitting new bore bushes and pins

55 Checking main and Bearing types- their Drawing of Problems connecting rod bearing, special advantages different types of involving stress, Checking connecting and special features couplings strain modulus of rod alignment, fitting – bearing metals, Freehand Elasticity and new bearing shells and their composition, sketching of oil ultimate strength. setting correct oil bearing spread – nip pumps. clearances . Checking and crush – their and cleaning oil purpose, Lubricating passages in crank shaft pumps. Types and and engine block over their special features. hauling and testing oil By pass and full flow pumps . Cleaning oil oil filters filters

56 Cleaning fuel tank and A.C. Mechanical Drawing of Factors of safety checking for leaks in Petrol pump different types of examples of fuel tank. Overhauling Description and couplings. different types of petrol pumps testing operation – electrical stresses. petrol pumps for correct pump (S.U . Pump) – pressure vacuum and construction , delivery operation and care and maintenance.

57 Further practice in Special feature of Problems removing, dismantling, solex and S.U. involving factor of cleaning , inspecting, carburetors, petrol safety and replacing, worn parts flow circuits in these different types of and assembling and carburetors – stresses. fitting of solex and S,U. functions of each carburettors. Practice in component in the adjusting the slow carburettors, speed screw and setting common troubles and ------idling speed of engine remedies. do------

58 Removing valve timing – Valve timing gears – Drawing of Hydraulics- cover –checking and Timing marks, timing bearing pulleys elementary correct setting of valve chains and chain with dimensions, principles – timing replacing timing tensioners – effects Free hand incompressibility chains. Checking of stretched chains – sketches of valve of liquids- camshaft, and play and checking backlash in timing diagram Pascal’s Law and correcting it timing gears Archimedes Principles, Law of floatation – Problems involving properties of fluids

59 Assembling piston and Engine Assemble Problems on connecting rod procedure as various assembly, crank shaft , recommended by Trigonometric camshaft and timing Makers –Precautions ratios , Reading gears , fitting cylinder to be observed while of Trigonometric head and checking assembling engine tables. Problems valve tappet clearance , components, on height and starting and adjusting checking and distance engine speed adjusting engine idle speed with vacuum ----do------gauge

60 Removing inlet and Inlet and exhaust Freehand exhaust manifold – manifold – sketching of cleaning carbon and description and sectionised view checking for warpage purpose of manifolds, of silencer box – and crack – checking exhaust pipes and exhaust pipes heat control valve in silencer box. and tail pipe exhaust manifold for Constructional details proper working. and purpose and Removing and replacing types of silencers. of new manifold gaskets Common troubles in and checking leakage of exhaust system and ------exhaust gases. The their remedy do------removing and cleaning silencer and tail pipe and refitting

2. Trouble shooting in cooling Lubrication fuel feed and ignition systems,

61 Troubles shooting in Step by step method Freehand Properties of cooling and lubrication of locating troubles in sketching of gases and system. Checking up the lubrication and piston and composition of and connecting oil and cooling system. connecting rod gases. water leaks – changing Reasons for engine Compression defective packing and overheating flow test pressure gaskets. Testing rate recommended radiator for leaks – for radiator . Crank testing thermostat case dilution and crank case ventilation

62 Trouble shooting in fuel Systematic ------do------Applied problems feed and ignition system procedure of trouble on gas pressure , –starting engine- tracing in fuel feed compression checking air leaks. and ignition system in ratios and horse Repairing of silencer automobile engine – power and tail pipes. Adjusting Reasons for the slow speed of the excessive fuel and oil engine with vacuum consumption gauge.

ACHIEVEMENT FOR 10 WEEKS FROM 53RD TO 62ND WEEK

TRAINEES SHOULD BE ABLE TO ;-

i. Remove petrol engine from vehicle,. Dismantle cylinder head, piston connecting rod, crank shaft camshaft etc. ii. Decarbonise cylinder head, to cut, repair and grind valve seat iii. Check main and connecting rod bearing. Fit new shell bearing in main and big end, set oil clearance. iv. Clean ring grooves , set piston rings and assemble v. Overhaul oil pump , oil filters, fuel filter, fuel pump and to set correct pressure and vacuum of fuel pump vi. Overhaul carburetor – repair , test and adjust. vii. Locate troubles and rectify them in cooling , lubrication, fuel feed and ignition system. viii. Follow safety precautions

ix. Set ignition timing and valve timing

3. DISEL ENGINE REPAIR WORK

63 Practice on History and Freehand Lubricants _ unserviceable diesel development of sketching of types specials engine – removing compression ignition combustion purpose, jammed nuts, broken engines. chamber of viscosity , effects studs and reconditioning Classification of C.I. different types of temperature damaged threaded Engine , Advantages on viscosity High holes – removing and disadvantages detergent oil and cylinder head, over petrol engines – its applications connecting rods and constructional details pistons, cleaning, of single and Multi – inspecting and refitting cylinder engine them, Writing reports of damaged parts and repairs to be carried out on engine,

64 Practice in starting and The four stroke and Freehand Lubricants – stopping of stationery two stroke diesel sketching of four types – viscosity and a transport vehicle engine – uniflow and stroke cycles and and effects of engine, General loop scavenging two stroke cycle temperature on maintenance of engines constant pressure engines viscosity. High – checking oil, fuel, and constant volume detergent oils water levels and cycles. Diesel cycle and their accessories of diesel indicator diagrams. application engines

65& 66 Removing cylinder Specification of Freehand Gear and belt head, pistons diesel engine . sketching of fuel drives – connecting rods, Materials used for feed system in problems on gear cleaning, decarbonising different engine parts diesel engine – and belt drives and cylinder head , working and diesel fuel checking, piston clearances , filters clearance, dismantling compression ratios – valve assemble , valve timing of diesel cleaning , checking and engines crankshaft , reconditioning valves , connecting rods, assembling valves and piston , valves and adjusting tappet valve operation . The clearances, assembling combustion engine parts and chambers – types , starting the engine after advantages and repairs and adjusting disadvantages ,. slow speeds. Heater plugs – types uses

67 Bleeding fuel lines for Fuels used in diesel Freehand gear and belt Air locks. Repairing fuel engine specification sketching of drives – leaks in the pipe – lines of diesel fuels diesel fuel feed problems on gear and unions. Cleaning of importance of clean system and fuel and belt drive oil and Air Filters in fuel general layout of filters diesel engine the fuel feed system in the stationary and transport diesel Engine

68 Cleaning and servicing Types of fuel Freehand Gear and bolt of primary fuel filters injection systems – sketching of drives – and pressure , stage air injection and air diesel fuel feed problems on gear filters – removing feed less injection . Fuel system and fuel and belt . Torque pump – dismantling, feed pumps – filters – definition, its cleaning , reassembling description operation relation with refitting and testing and – common troubles forces on engine feed pump and remedies mounting, steering gear box and torque wrench

69 Dismantling an Need for governors Free hand and Inclined plane unserviceable fuel types pneumatric and sketching of uses- example injection pump clearing mechanical components from and applied inspecting, studying governors. The assemblies . problems parts and reassembling. pumps phasing and Removing F.I pump calibration of pumps. from running engine Checking and fixing changing oil in it cutting injection timings. back to engine testing Governors types their the governor and setting description and injection timing. operation. Starting and adjusting slow speed.

70. Testing injection for Injector nozzles- Free hand Screws and missing on the vehicle- types description, sketching of fuel screw jack. removing, dismantling, operation testing of injectors of Problems on a cleaning, inspecting – injectors. Special; different types. screw jack. replacing defective parts features of pintle – reassembling the nozzles. injectors and testing them.

71. Trouble shooting with Need for governors- Free hand Area of circle, special reference to types- pneumatic and sketching of fuel ellipses, volume adjustments in the fuel mechanical injectors of and weight of feed system- checking governors, different types. regular solids exhaust gases- and maintenance of and spheres. adjusting the governor governors reason for slow speed adjustment black, white and blue and venturi control smoke in exhaust. adjustments. Checking oil, fuel water and exhaust gas leaks and correcting them.

72.. Further practice on Timing of injection in Free hand -do- cleaning and servicing single cylinder sketching of of injectors, adjustment engine.flange type single element of tappets and setting pumps and their flange mounted injection timing in special features. pump. engines(Both stationary Care and and transport vehicles maintenance of engines. single cylinder pumps.

73. VISIT TO LOCAL GARAGES AND INDUSTRIES- DEMONSTRATION OF SERVICE STATION EQUIPMENTS:

ACHIEVEMENTS FOR 11 WEEKS FROM 63 RD TO 73 RD WEEKS

TRAINEES SHOULD BE ABLE TO:

1. Bleed and air in the diesel fuel system, check and correct fuel leak and service diesel fuel fitters..

2. Remove clean and test fuel injectors and find out the defective/ missing injectors

3. Overhaul fuel feed pump.

4. Check and correct injection timing in single and multi-cylinder engine and know service station equipment.

5. Follow necessary safety precautions.

5. ELECTRICAL/ ELECTRONIC ACCESSORIES REPAIR WORK:

74. Studying the light Description of light Free hand sketching Measurement of circuit- test bulbs, circuits and different of light circuit of a electrical power- watt align head lamps, components in light vehicle with and kilowatt find out short and circuits- description electrical symbols. relationship with open circuits in the and function of each. horse power. light wiring- replacing Prefocussed bubles fuses testing the tail and sealed beams. and brake lights in Fuses and their vehicle. importance.

75. Removing and Electric horn circuit- Freehand sketching Applied problems electrical horn from description of electric of horn circuit, involving watt, vehicle- horn- operation of drawing the kilowatt, volt, ampere dismantling.,cleaning relay and horn sectional view of and horse power. point, testing wires, switches. Common horn. assembling the horn troubles and their and adjusting the remedies. horn for correct sound, tuning double horn, repairing of horn relay and horn switches.

76. Removing a wiper Description and Free hand sketching Applied problems on motor dismantling, operation of electric of wipier motor resistance in the cleaning, inspecting, wiper motor care and circuit. series ands parallel repairing electrical maintenance. circuits. wiper motors, Common troubles assembling and and remedies. fitting, setting blades for correct functioning.

77. Studying the wiring Flasher circuit its Sketching the Problems on circuit of traffic signal description and flasher light circuit resistance in series flasher light circuit operation common, with parallel circuits. tracing defects in the troubles in the circuit symbols.freehand conductors and tracing defects in the and remedies sketching of insulators- example flasher circuit .magnetors ignition magneto ignition and uses. replacing fuse system- description circuit. bulb.removing and operation dismantling cleaning advantages rotating and assembling armature and magnetos- adjusting flywheel magnetos gap in points- testing special features. magnetos.

78. Studying the Description and Freehand sketching Conductors and alternators in vehicle- operation of of alternator insulators- type and removing and refitting alternators in vehicle. charging unit. uses. alternator in vehicle Advantages of using precautions to be alternators. Common observed while troubles and connecting battery in remedies. alternation circuit. General maitanence,adjusting fan belt play/ tension

79. Further practice in Positive and negative Freehand sketching Explanation of open dismasntling earthing of battery- of braker plate and short circuits- cleaning, testing and advantages and assembly and locating short circuits reassembling of precautions. advance and retard with the help of starter motor and Electrical measuring plate meters. generators . meters their use care overhauling of and maintenance. distributor assembly.

WEEK PRACTICAL WORK TRADE THEORY ENGINEERING W/S CAL. NO. DRAWING & SCIENCE

80 Trouble tracing in Iucas- color code for Free hand -do- electrical wiring of the wiring in the ;motor sketching of vehicle. Use of resistance vehicles. Binary complete wiring of meter, voltmeter and numbers logic gates, the vehicle. ammeter. Attending amplifiers and multi mechanical repairs to vibrators. electrical accessories such as fuel gauge, temprature gauge, brake light switch, and solenoid switch.

81 Tracing fault in different Principle of electronic -do- -do- electronic ignition ignition advantages systems and rectification types of electronic ignition system as capacitor discharge ignition system thyristor based ignition system and microprocessor based contactless ignition system.

ACHIEVEMENTS FOR 8 WEEKS FROM 74 TH TO 81 ST WEEK:

TRAINEES SHOULD BE ABLE TO: 1. Trace fault in electrical wiring and accessories and rectify them.

2 Trace faults in electronic circuits and accessories and rectify them.

3 Follow necessary safety precautions.

1. DRIVING PRACTICE:

82 Practice in straight Motor vehicle Act : to driving on wide 88 roads. Driving Driving road rules – through lanes and Road traffic signals – curves. Practice in hand signals. reversing. Practice Precautions to be overtaking another taken while vehicle. Practice in overtaking, reversing driving through sand driving through and wet surface. narrow lanes, curves Practice in parking and slopes. vehicles, paralled parking and diagonal parking. Practice in driving over slope and down hill. Practice in driving over narrow bridges.

Achievements for 7 weeks from 82nd to 88th week :-

Trainees should be able to

i. Drive and road test a Motor vehicle. ii. Follow necessary safety precautions.

7. SYNCHROMESH GEAR BOX AND TRANFER CASE 4 WHEEL DRIVE PREPARE WORK :

89 Dismantling a Synchromesh gear Free hand sketches Calculation of area , Synchromesh gear boxes – advantages of Synchromesh volume and weight o f box- cleaning, – description , unit. hollow and solid inspecting parts operation in different bodies. replacing worn out gear positions. defective parts – Common trouble and assembling and remedies. Types of testing for correct Synchromesh gear performance, boxes- their special identifying noises features. from gear box and rectifying.

90 Removing transfer Description and Free hand sketching Revision of ratio and case from the vehicle operation of 4 wheel of intermediate shaft proportion – applied – dismentling, drive. The purpose of and shifter problems in 4 wheel cleaning, inspecting transfer case and the arrangement. drive. parts, replacing worn/ arrangement of damaged parts, re- shifting mechanism. assembling, testing Common troubles and fitting. Repairing and remedies. of 4 wheel drive shifter mechanism. Overhauling of front wheel drive propeller shaft unit.

91 Trouble shooting in Systematic Free hand sketching Revision of ratio and & the transmission procedure of locating of intermediate shift proportion, applied 92 system identifying noises from the and shifter problems in 4 wheel the noises from transmission units – arrangement. drive. clutch, assembly, common troubles in gearbox, universal the system and their joints- rear axle drive remedies. and the differential unit. Checking oil leaks and correcting.

Achievements for 4 weeks from 89th to 92nd week:-

Trainees should be able to

i. Overhaul a Synchromesh gear box. ii. Overhaul a transfer case. iii. Follow necessary safety precautions

8. ENGINE FAULT DYGNOSIS INCLUDING ENGINE SCANING :

93 Diagnosing noises Different types of Code of practice. & and faults in engine noises coming from General and rectifying them – engine – bearing Engineering 94 checking under knock, gudgeons pin Drawing. carriage noises and knock, pinging, rectifying them. Road tappet noise, testing vehicle. chipping noise.

95 Test Duel angle, Introduction to & Engine tuning and engine tuning, study exhaust gases engine torque, fuel 96 analysis. consumption, duel Demonstration of angle exhaust gases engine efficiency with etc. the help of Dynamometer

Achievements for 4 weeks from 93rd to 96th week :

Trainees should be able to

i. Diagnose noises and faults in engine and rectifying them. ii. Diagnose, faults in engine with the help of computerized machines. iii. Follow necessary safety precautions.

9. SERVICESTATION EQUIPMENTS AND WHEEL BALANCING :

97 Repairs of jacks, Garage equipment Sketching of screw Description and & grease guns, oil construction and jacks, grease guns operation of an 98 spray guns, other operation of air and oil spray guns. alternator. spray guns and other compressor, spark shop floor plug tester, valve equipment. Care and refacer, injector maintenance and tester, drilling lubrication of air machine care and compressor, valve maintenance. refacer, drilling machine, injector tester , spark plug tester.

99 Wheel balancing and Importance of wheel use of equipment. balancing. Details of equipment and method.

Achievements for 3weeks from 97th to 99th week :

Trainees should be able to

i. Repair jacks, grease guns, oil spray guns and other shop floor equipment. ii. Operate the wheel balancer. iii. Follow necessary safety precautions.

10. CAR AIR CONDITIONING SYSTEM REPAIR AND MAINTENANCE :

100 Fitting and repairing Introduction to Air & air conditioning unit conditioning system 101 in motor vehicle. in Motor vehicle. Tuning engine with Compatibility of Air respect to the Air conditioning system conditioning. with vehicle engine.

Achievements for 2 weeks from 100th to 101st week :

Trainees should be able to

i. Undertake servicing, rectification and installation of Air conditioning system in Motor vehicles.

ii. Follow necessary safety precautions.

102 REVISION AND ALL INDIA TRADE TEST. & 104