4.5 Lockout Tagout Policy

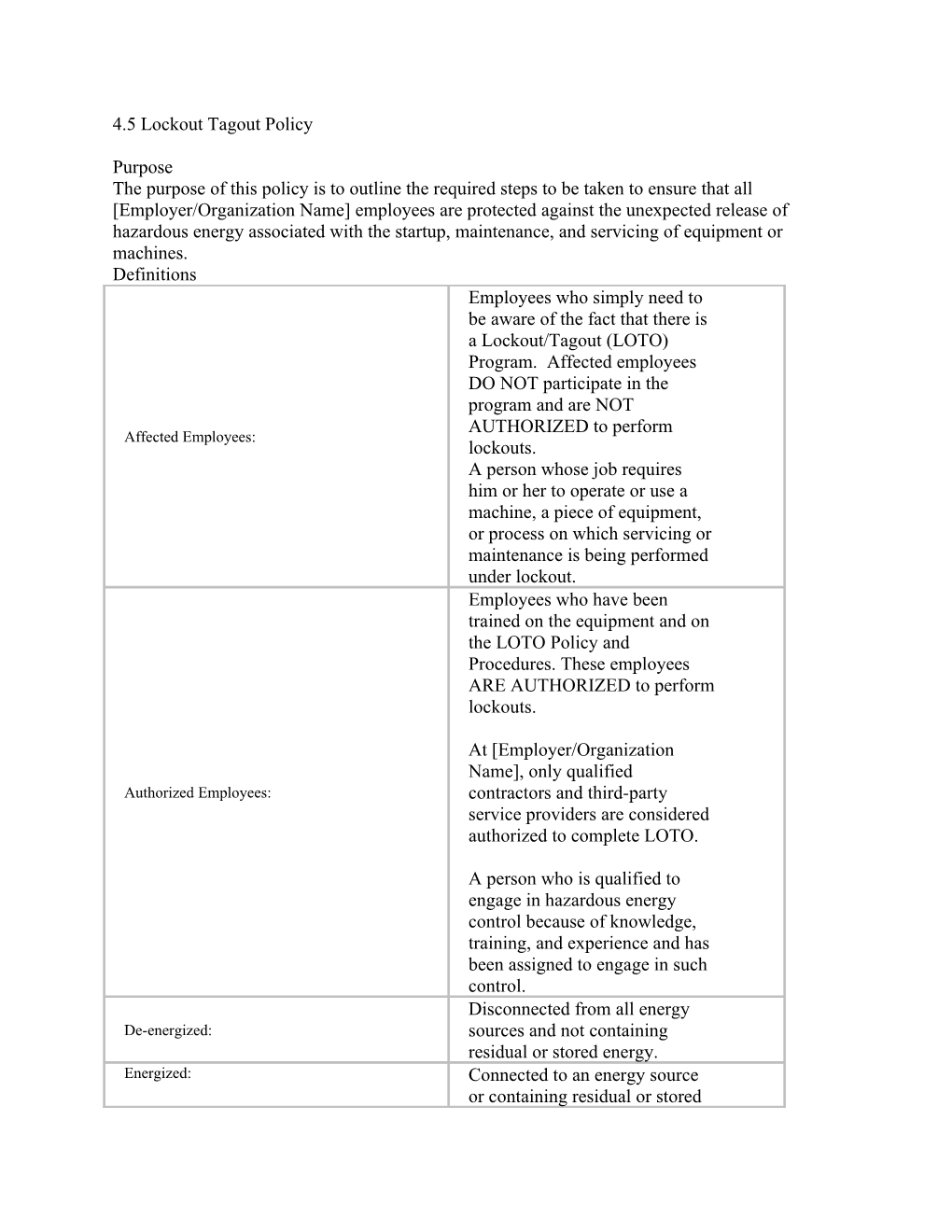

Purpose The purpose of this policy is to outline the required steps to be taken to ensure that all [Employer/Organization Name] employees are protected against the unexpected release of hazardous energy associated with the startup, maintenance, and servicing of equipment or machines. Definitions Employees who simply need to be aware of the fact that there is a Lockout/Tagout (LOTO) Program. Affected employees DO NOT participate in the program and are NOT AUTHORIZED to perform Affected Employees: lockouts. A person whose job requires him or her to operate or use a machine, a piece of equipment, or process on which servicing or maintenance is being performed under lockout. Employees who have been trained on the equipment and on the LOTO Policy and Procedures. These employees ARE AUTHORIZED to perform lockouts.

At [Employer/Organization Name], only qualified Authorized Employees: contractors and third-party service providers are considered authorized to complete LOTO.

A person who is qualified to engage in hazardous energy control because of knowledge, training, and experience and has been assigned to engage in such control. Disconnected from all energy De-energized: sources and not containing residual or stored energy. Energized: Connected to an energy source or containing residual or stored energy. A mechanical device that physically prevents the transmission or release of energy, including but not limited to the following: A manually operated electrical circuit breaker; a disconnect switch; a manually operated switch by which the conductors of a circuit can be disconnected Energy Isolating Device: from all undergrounded supply connectors and, in addition, no pole can be operated independently; a slide gate; a slip blind; a line valve; a block; and any similar device used to block or isolate energy. The term does not include a push button, selector switches, and other control circuit type devices. Any electrical, mechanical, hydraulic, pneumatic, Hazardous Energy: chemical, nuclear, thermal, gravitational, or other energy that can harm personnel The placement of a lockout device on an energy isolating device according to established procedure to ensure that the Lockout: energy isolating device and the equipment being controlled cannot be operated until the lockout device is removed. A mechanical means of locking that uses an individually keyed lock to secure an energy- isolating device in a position that prevents energy from being Lockout Device: restored to a machine, equipment, or a process Any device attached to a switch, valve, or any other energy source control to prevent it from being activated. A warning means and a means of attachment used in conjunction with the application of a lockout device to an energy- isolating device. It usually indicates the nature, purpose, and time of application of the Information Tag: lockout, as well as the identity of the authorized individual who performed the lockout. Label which identifies the Authorized Employee and their work area. Tags are affixed to the lock at the lockout disconnect point A state where equipment and machinery have been completely neutralized with respect to Zero Energy State: supplied or stored energy. Units in such a state are incapable of an unexpected release of harmful energy. Responsibilities Employer Ensuring the LOTO Policy is written and available. Ensuring adequate preventive maintenance for all equipment. Reviewing, updating and enforcing the LOTO Policy. Ensuring that new and modified equipment will be capable of energy isolation and lockout. Maintaining a current master list of all equipment requiring LOTO. Ensuring only qualified contractors and third-party service providers are authorized to perform lockouts. Supervisors Ensuring that all machines or equipment in their area are: Identified and listed on the LOTO Master List. Capable of being lockout out. Have machine/equipment specific procedures posted at each machine. Enforcing the LOTO Policy. Participating in the annual review of the LOTO Policy. Ensuring any new or modified equipment is capable of being locked out and added to the LOTO Master List. Affected Employees Affected employees are not authorized to perform lockouts. Affected employees are not to remove or otherwise tamper with any lockout or tagout hardware. Do not attempt to start or re-energize equipment that is locked out. Reporting any safety hazards to the employer and the Health and Safety Representative. Health and Safety Representative Identifying existing or new situations where LOTO is required. Reporting hazards to the employer and providing recommendations for control. Reviewing the LOTO Policy with management annually to ensure it is up to date and all hazards have been identified. Procedure A LOTO Master List must be kept of all machines/equipment that require LOTO Procedures at [Employer/Organization Name]. The LOTO Master List will identify: All equipment requiring LOTO Energy isolation point location(s) Energy isolation device(s) List of authorized contractors and third-party service providers, capable and qualified to perform LOTO Note: An emergency stop (e-stop), on-off switch or other manual switching device IS NOT A METHOD OF LOTO. All LOTO devices must be capable of completely and positively blocking all energy to the equipment or machine. However, there may be instances where lockout affects tasks that are vital to the production process by design, or traditional lockout prohibits the completion of specific tasks. In those cases, each task must be evaluated to provide safeguarding techniques to protect employees from machine, equipment or process exposures. Lockout Devices The following positive energy isolating devices must be made available if required as determined by the type of energy source and energy supply method to machines and equipment at [Employer/Organization Name]. It is recognized that not all of these devices may be required. Ball Valve Lockout Device - for air or fluids Gate Valve Lockout Device - for fluids Electrical Switch Lockout Device - for wall mounted electrical switches Single and Double Pole Lockout Device - for single or double pole breakers Plug Lockout Device - for cord and plug lockouts Scissors/Cable Lockout Device Locks used for the LOTO procedures will NOT BE USED FOR ANY OTHER PURPOSE. It is recommended that these locks all be colour-coded such that it is very easy to tell that the lock is to be used for lockouts only. There will be one single key for any one lock. Information tags are identifiers that accompany the locks which show who applied the lock. The tags will have: The authorized employee’s name. Date the lock and tag was applied. The reason for application of lock and tag. The authorized employee’s work area. Handling Contractors on Site All contractors performing work on site are required to be informed about the LOTO Policy. The representative from [Employer/Organization Name] who is responsible for the contractor must provide this information. Contractors performing maintenance or repair work on any equipment must follow a LOTO procedure. This can be clarified during the pre-work job safety discussion with the Contractor. [Employer/Organization Name] will secure written confirmation from the contractor(s) that they have reviewed, understand and will adhere to the agreed upon LOTO Policy. Training All training related to lockout procedures and legislative requirements will be provided by a qualified internal resource, or a qualified contract trainer, as determined by the employer. Affected Employees and Supervisors Affected employees and supervisors are required to understand the concept of LOTO and recognize a LOTO situation when they see it. This elementary training/introduction can be achieved through a brief orientation process, or through a new job transfer orientation. It is an expectation that all supervisors be familiar with the location and content of the LOTO Policy. Retraining Requirements Retraining of employees to machine specific equipment procedures is required whenever: An employee changes jobs. An employee works with a new piece of equipment/machinery or the existing equipment/machinery is modified. A change in machinery, equipment or process that present a new hazard. A change in energy control procedures. Additional retraining will be conducted whenever deviations in the policy are encountered. Documentation/Recordkeeping Requirements LOTO training/retraining records will be kept in the employee’s file. This documentation must be kept for a minimum of three years. Annual Review The LOTO Policy will be reviewed annually by the Health and Safety Representative and the employer to ensure it is up to date and all hazards have been identified. Additional Resources LOTO Master List LOTO Tag Form CSA Z460-05 Control of Hazardous Energy - Lockout and Other Methods NFPA 70E - Standards for Electrical Safety in the Workplace Document Management Effective Date: Revision Date: Lockout Tagout Tag Template DO NOT START THIS TAG & LOCK TO BE REMOVED ONLY BY THE PERSON NAMED ON THE BACK EQUIPMENT LOCKED OUT BY: DATE:______Lockout Tagout Master List Isolation Authorized Equipment Name Isolation Device Location Contractors