Developed for Settlement Purposes (SIA v. EPA, D.C. Cir. No. 11-1024) Deliberative – Do Not Cite or Quote

Questions for SIA on Abatement System DRE, Uptime, and Related Requirements

On January 10, 2012, SIA provided data to EPA on abatement system uptime, abatement system inventories, and destruction or removal efficiency (DRE) measurement. This document represents EPA’s questions on the data and information submitted with respect to SIA’s concerns about DRE measurement. These questions are to ensure that the Agency understands SIA’s data/analyses and has enough information to support a new rulemaking to address these technical concerns. For the most part, the questions are clarifications on the information presented by SIA and not requests for additional data. We do not intend for these questions to result in extensive additional analysis or work, please let us know if that is not the case.

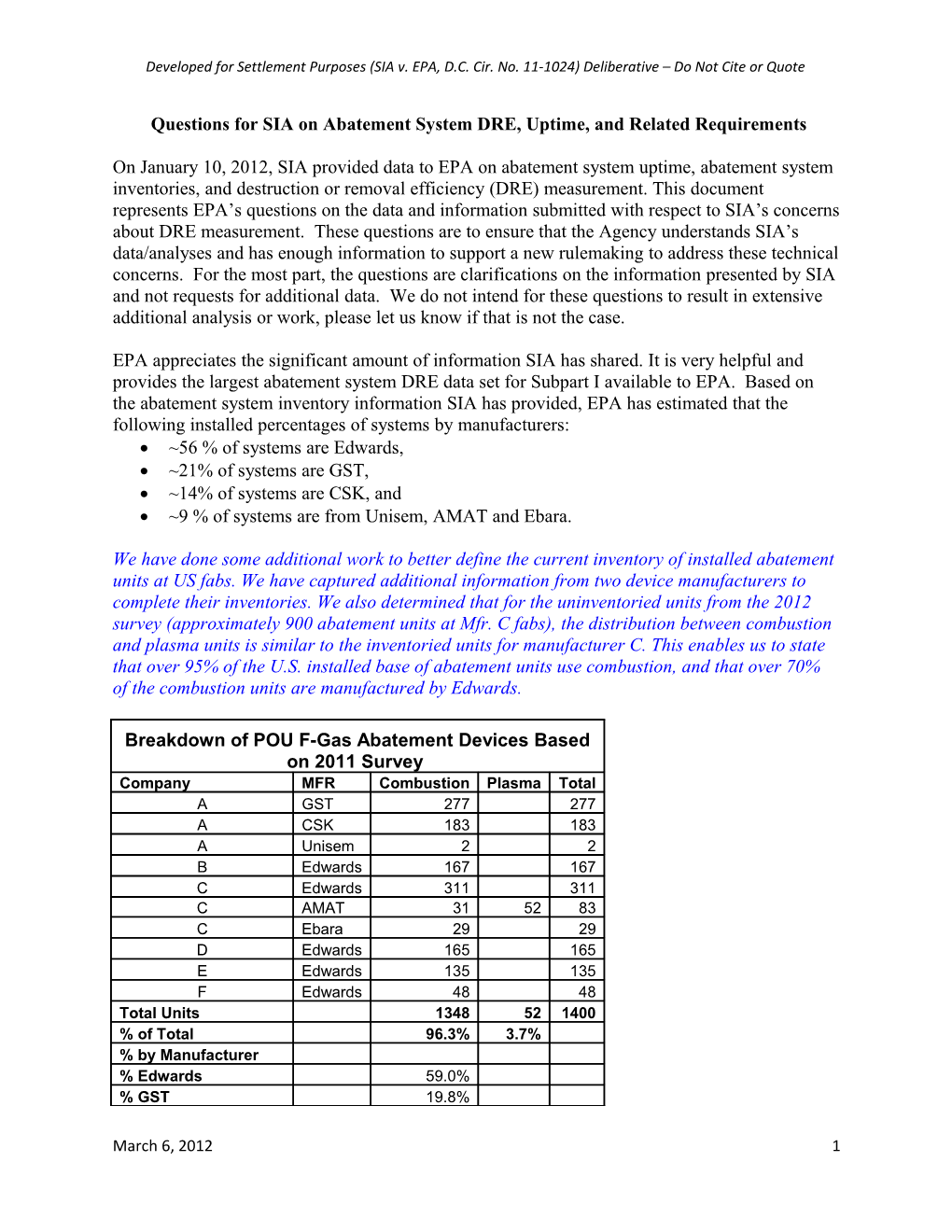

EPA appreciates the significant amount of information SIA has shared. It is very helpful and provides the largest abatement system DRE data set for Subpart I available to EPA. Based on the abatement system inventory information SIA has provided, EPA has estimated that the following installed percentages of systems by manufacturers: ~56 % of systems are Edwards, ~21% of systems are GST, ~14% of systems are CSK, and ~9 % of systems are from Unisem, AMAT and Ebara.

We have done some additional work to better define the current inventory of installed abatement units at US fabs. We have captured additional information from two device manufacturers to complete their inventories. We also determined that for the uninventoried units from the 2012 survey (approximately 900 abatement units at Mfr. C fabs), the distribution between combustion and plasma units is similar to the inventoried units for manufacturer C. This enables us to state that over 95% of the U.S. installed base of abatement units use combustion, and that over 70% of the combustion units are manufactured by Edwards.

Breakdown of POU F-Gas Abatement Devices Based on 2011 Survey Company MFR Combustion Plasma Total A GST 277 277 A CSK 183 183 A Unisem 2 2 B Edwards 167 167 C Edwards 311 311 C AMAT 31 52 83 C Ebara 29 29 D Edwards 165 165 E Edwards 135 135 F Edwards 48 48 Total Units 1348 52 1400 % of Total 96.3% 3.7% % by Manufacturer % Edwards 59.0% % GST 19.8%

March 6, 2012 1 Developed for Settlement Purposes (SIA v. EPA, D.C. Cir. No. 11-1024) Deliberative – Do Not Cite or Quote

% CSK 13.1% % Unisem, AMAT, Ebara 4.4% 3.7%

We believe that the fact that the over 95% of the abatement units are combustion units enable the use of the available test data that we submitted to EPA to establish industry level DREs. Setting industry level, default DREs is justified by the following information: o the tested units are representative of over 68% of the inventoried abatement units, o combustion technology is straightforward; and o the manufacturer’s design DREs are consistent across the different brands of combustion units.

Also based on the information SIA provided, EPA estimated that the data that SIA has collected was based on testing of abatement systems from predominantly one manufacturer, Edwards (~97% of tests).

Based on EPA’s initial review, it appears that the data in SIA’s DRE report supports the concept that achievable DREs vary by gas, process, and abatement system design/model. EPA agrees that an approach to provide a variety default DREs (e.g., by gas, process, abatement device, etc.) appears to be a viable option, with some further discussion and work.

Default DRE Measurements and Data 1. On pages 4 and 7, SIA indicates that in the testing, the abatement DRE test results for some CF4 and NF3 units were lower than expected and below the manufacturer’s DRE. SIA further indicates that one company “performed five retests after the abatement device was serviced to address a low DRE identified by the first test.” It is further stated that, while some units performed as intended, some operations and maintenance procedures needed to be revised to achieve the expected CF4 DREs. a. Can SIA explain why the CF4 and NF3 DREs were low on the malfunctioning units? A key contributing cause to the low DREs on abatement units treating CF4 is the fact that process flow rates (the volume into the abatement system) and/or the abatement discharge flow rates (the volume out) exceeded the manufacturer’s recommended flow rates. These combustion units have a recommended volume into the abatement unit of up to 250 standard liters per minute ( slpm) and a recommended volume out of up to 1,000 slpm. A review of the files “Etch Abatement Units with flow data. Xls”, which provides the flow rates in and out of the tested abatement units and the associated dilution rates, illustrate the relationship between these two flow rates and lower CF4 DREs. That relationship is not present for the DREs of other F-gases, which are more easily destroyed. The higher flow rates resulted either from inaccurately sized Mass Flow Controllers that were measuring/delivering the process gas and dilution flows to provide the correct mix of gases needed for safe handling of pyrophoric gases on the tool or the failure of the switching mechanism that adjusts the dilution rates based on the gas being fed to the process (for example, higher dilution rates are required for safety reasons during a H2 gas feed). For the CF4 DREs, the abatement system manufacturer is assessing other potential contributing causes of lower than expected DREs. SIA will provide an expanded response to this

March 6, 2012 2 Developed for Settlement Purposes (SIA v. EPA, D.C. Cir. No. 11-1024) Deliberative – Do Not Cite or Quote question sometime in March based on the additional information supplied by the equipment manufacturer.

For the CVD clean abatement units, which abate only NF3, there were only three tested units with a DRE lower than the manufacturer’s design DRE, out of the 35 units tested. Two systems were likely affected by high flow rate and one system was not. The file “CVD abatement units with flow rates.xls” provides the flow rates and dilution rates for the CVD clean abatement unit tests. The abatement system manufacturer is assessing other potential contributing causes which resulted in lower than expected DREs on the two CVD clean abatement units. SIA will provide an expanded response for both the NF3 and CF4 abatement units in March based on the additional information supplied by the equipment manufacturer.

b. Can SIA indicate whether there are any general criteria that could be applied to ascertain whether a unit is under performing or needs service without having to measure the abatement system DRE?

SIA is still considering the answer to this question and will provide a response before the end of March.

. c. Can SIA clarify whether the initial testing data and the retest data for the retested units are in Tables VI and VII in Appendix B? If so, please identify this data. Tables VI and VII have been updated to clearly identify the retests.

d. Can SIA indicate what criteria were used to determine whether a retest needed to occur? Retests were done where abatement units were performing significantly below the abatement equipment manufacturer’s design DRE and where the initial test was done in the first set of tests in April and May so a retest could be scheduled during the second set of testing in August and September.

As discussed above, this round of abatement DRE testing was done to generate data for use in addressing DREs for the reporting rule. Where tested values are below the design DREs, they reduce the average DRE for the gas/process category and are represented in the average DRE in the installed base. Device manufacturers have an incentive to work to maximize the DRE of each unit as they are making significant investments in capital and operating expense for the units. The need for retesting should be left to the device manufacturer based on their corrective actions to improve the unit DREs, their current testing plans for the abatement units (where they are using a site specific DRE), and the expected increase in the DRE that will be realized through their investment in unit testing. Abatement unit testing in an operating semiconductor fab costs $6-8,000 per unit or $10-20,000 per unit when only a few units are being tested; moreover, testing requires production disruptions and engineering resources. On this basis, retesting should not be mandated in the rule so long as the data from the low DRE test is included in the site specific process/gas type average.

March 6, 2012 3 Developed for Settlement Purposes (SIA v. EPA, D.C. Cir. No. 11-1024) Deliberative – Do Not Cite or Quote

2. What method/protocol did SIA use for the DRE measurement tests (e.g., the EPA DRE Protocol) and did that method/protocol account for dilution by the abatement system? The 57 tests performed at the one facility were performed in accordance with the procedure for Method 1 as described in the “Protocol for Measuring Destruction or Removal Efficiency (DRE) of Fluorinated Gas Abatement Equipment in Electronics Manufacturing March 2010” as specified in the Subpart I regulations. F-gases were flowed to the abatement units without operation of the tool plasma generator to simplify the testing process. Dilution rates were measured as required by the Protocol. Two example test reports, one for a tool specific abatement system and one for an area abatement system that abates several etch tools are provided in the files “FE05-002 DRE Test Report 13 Dec 2011.pdf” and “FK04 05 06 Backup DRE Test Report 13 Dec 2011.pdf” (This is the test of the area unit). These example files detail the methods use for measuring the dilution rates.

The majority of the testing reported from the other manufacturer was completed prior to March 2010. They were, however, done in general accordance with the Method 2 requirements and tested the DREs for the abatement units under actual fab operating conditions (with process gases flowing through the chamber with the tool plasma generator activated). Dilution measurements varied over the variety of tests due to various methods being developed over the course of time. Some of the dilution measurement methods used were primarily the QMS method specified in the rule and the post-POU FTIR dilution method. Variations of these methods may have been used, depending on the year in which the measurement was made.

In the context of the testing methodology, SIA is also asking EPA to include the 2009 ISMI Guideline tracer release/FTIR monitoring approach as an acceptable method for determining POU abatement system effluent flow. Inclusion of the effluent flow measurement method can be done by incorporating the method into the EPA Protocol referenced above or specifically adding the method as a referenced method in Section 98.7 of the Subpart I regulation. The efficacy and appropriateness of using the FTIR monitoring methodology has been demonstrated by the stack testing work completed by SIA members over the past 12 months. SIA has attached the report “Comparison of Fourier Transform Infrared (FTIR) and Quadrupole Mass Spectroscopy (QMS) Methods for Determining POU Abatement System Effluent Flow”. This report provides the data needed to justify the inclusion of this method in Subpart I. This method is more efficient, costs significantly less per test, and provides results which are comparable to the approved methods detailed in the “Protocol for Measuring Destruction or Removal Efficiency (DRE) of Fluorinated Gas Abatement Equipment in Electronics Manufacturing March 2010”.

In addition, the modifications to Subpart I should also set broad criteria, similar to that found in Subpart L 98.124(e)(1) & (2), that assures the quality of the testing procedure and analytical method used to perform required testing. 98.124(e) provides example methods, but also allows qualification of alternative methods, using accepted validation procedures, to enable development and early adoption of more efficient testing and analytical protocols using new or existing technologies.

March 6, 2012 4 Developed for Settlement Purposes (SIA v. EPA, D.C. Cir. No. 11-1024) Deliberative – Do Not Cite or Quote

3. Can SIA clarify how the measurements were taken at the facilities? Were they taken with different GHG flow rates over a variety of processes and tools? Can SIA provide the flow rates, or the normalized flow rates, of the gases for which DREs were measured?

The two abatement system test reports provided with this response detail the test procedures used for the 57 tests performed in 2011. The file “2011 DRE flow summary 02812.xls” details the range of flow rates used in each test for each gas.

The remaining tests were done using actual process conditions and flows. The table below is a summary of the range of gas flows and the pre- and post-dilutions for the process conditions tested for each category and gas type.

# of NF3 SF6 CF4 CHF3 POU Inlet POU Outlet emissions Range Range Range Range flow range flow range tests (sccm) (sccm) (sccm) (sccm) (L/min) (L/min) in-situ 6 1000- 100-200 750-1000 plasma 3000 chamber clean

Plasma 2 10-30 100-300 70-200 20-80 300-600 Etch remote 3 200- 50-200 400-800 plasma 2000 chamber clean

4. Can SIA please clarify whether all measurements were done on abatement systems specifically designed to abate F-GHGs?

All tested abatement systems were specifically designed to treat F-gases.

5. Can SIA please indicate if their testing supports any conclusions regarding how the performance of abatement systems changes (or does not change) between maintenance events?

The testing data that SIA has provided to EPA does not provide any basis for reaching any conclusions regarding the impact of the maintenance program on abatement system DRE.

One manufacturer, in collaboration with ISMI, performed a test on the impact of maintenance activities on F gas abatement unit performance. This paper is not currently published, but is being reviewed to see if it can be made available. The basis was to test a POU abatement unit at the end of the PM cycle and after the PM was performed. The analytical results from the POU

March 6, 2012 5 Developed for Settlement Purposes (SIA v. EPA, D.C. Cir. No. 11-1024) Deliberative – Do Not Cite or Quote device before the PM was performed showed NF3 to be below the detection limit and therefore achieving a DRE of >99.9%. Based on this result, the decision was made not to perform any after PM measurements as there would not be any expected level of improvement.

6. Table B-1 indicates that there are 20 DRE measurements available for C4F8 etch and 22 measurements available for NF3 in-situ plasma chamber clean. However in tables VI and VII respectively, in Appendix B, there are only 14 measurements for C4F8 etch and 21 measurements for NF3 in-situ plasma respectively. Can SIA please clarify why these numbers do not match?

Response. A. Table B-1 was wrong in regard to the C4F8 etch measurements and a corrected table is given below in which new or changed information is highlighted in yellow. The analysis inadvertently grouped C4F6 and C4F8 into a single entry labeled C4F8 in the table. When the gases are divided and the tests recounted, we obtain the corrected values shown below that agree with EPA’s count. The new entry for C4F6 further supports the conclusion that consistently high DREs are achieved on average for the F-gases used in etch, with the exception of CF4.

Table B-1. Summary of Average DREs in Abatement Testing

N Average DRE (%) Process Gas (Tests) (± standard error)

Plasma Etch Etch (CF4) CF4 23 54.5 ± 7.5

Etch (Other Gases) NF3 14 99.27 ± 0.13 SF6 4 99.14 ± 0.31 C2F6 1 99.0 C4F6 5 99.06 ± 0.28 C4F8 14 98.85 ± 0.18 CHF3 19 99.18 ± 0.36 CH2F2 16 98.94 ± 0.19 All Etch (Excluding CF4) NF3/Other 73 99.07 ± 0.13

Chamber Cleaning In-situ Plasma NF3 22 88.7 ± 3.7 Remote Plasma NF3 26 88.4 ± 2.6 Thermal Clean NF3 1 98.9 All Chamber Cleaning NF3 49 88.7 ± 2.1

As a result, Table B-3 is also revised to indicate that, with the exception of CF4, default DREs can be established at the level of 99% for all of the gases used in etch considering both typical

March 6, 2012 6 Developed for Settlement Purposes (SIA v. EPA, D.C. Cir. No. 11-1024) Deliberative – Do Not Cite or Quote manufacturer DRE specifications and the consistency of the test data for individual gases. Test data exist to support this conclusion for NF3, SF6 and now five of the eight PFCs.

Table B-3. Coverage of NF3, SF6, and Other PFCs For Etch in SIA Database Typical Specification Average DRE in Edwards Abatement a/ SIA Database Group 1 NF3 ≥ 99% 99.3% Group 2 SF6 ≥ 95% 99.1% C2F6 ≥ 95% 99.0% C3F8 ≥ 95% Not tested Group 3 C4F8 ≥ 99% 98.9% C4F6 ≥ 99% 99.1% C5F8 ≥ 99% Not tested CHF3 ≥ 99% 99.2% CH2F2 ≥ 99% 98.8% CH3F ≥ 99% Not tested a/ Table 4. Design DRE Values for Edwards Abatement Systems. Columns 1 and 2 give the specifications for Edwards etch abatement devices in the SIA database.

B. In regard to the measurements for NF3 in-situ plasma, we have determined that one test was omitted from Table VII: Chamber Clean Abatement Measured DREs. A revised version of the table appears at the end of this document with the missing test added to the table and highlighted in yellow.

7. In Appendix B Table VI, what does a “NO” under the POU column indicate?

Response. “NO” indicates that the device is used for area abatement serving multiple gas streams, and not in a point of use (POU) setting.

Site-Specific Sampling Method 8. Can SIA please clarify whether the suggested percentages of abatement system testing in steps 2 and 3 apply to a specific “category” of abatement systems (i.e., by gas and process type) or to the entire facility abatement system inventory?

Response. The percentages would apply on a category basis to the inventory of abatement devices at the fab within the category. For example, to establish a site-specific DRE for NF3 used in chamber cleaning, the relevant inventory is that for devices abating NF3 from chamber cleaning processes. This category-specific inventory multiplied by the percentages specified in steps 1 and 2 would determine the number of tests to be conducted in the initial 2 years and in every 3-year period thereafter, respectively. As stated in step 3, after the first two years, the

March 6, 2012 7 Developed for Settlement Purposes (SIA v. EPA, D.C. Cir. No. 11-1024) Deliberative – Do Not Cite or Quote site-specific DREs used for the category in reporting under the MRR would be based on the latest 30 percent of the category-specific inventory.

9. Please describe the process SIA is proposing a facility would go through to select systems for testing and validation.

Response. There would be three steps in the proposed process: a) Given a total number of tests to be performed in a category (determined from the category-specific inventory as described above), the tests will be allocated to abatement device make/model type groups in proportion to the distribution of devices in the category-specific inventory to establish targets for the sampling. This allocation assures that the sampling will match the distribution of devices in service within the category for the purpose of establishing a site-specific DRE for the category. b) Abatement devices will be chosen randomly to fill the allocated targets by make/model type from the pool of matching devices that have not been tested in the current period. For example, we propose to test 15 percent of the installed category-specific device inventory in each 3-year period once the initial 2 year period has been concluded. A device already tested during the 3-year period would be excluded from the pool of devices to be sampled so that it will not be tested again in the same period. The pools will be reinitialized, without exclusions, at the beginning of each new 3-year period. c) A device selected for sampling that is located at a pinch point in the production process cannot be made available for testing. When pinch point devices are selected, they will be replaced by another random draw from the pool of matching devices and then returned to the pool so that they are available for selection in the next round of testing.

March 6, 2012 8 Developed for Settlement Purposes (SIA v. EPA, D.C. Cir. No. 11-1024) Deliberative – Do Not Cite or Quote

Calculation and Reporting Requirements

10. Does SIA have any suggested revisions to equations I-14 and I-15 in subpart I based on SIA’s DRE data?

Equation I-14 should be modified as follows:

Dip = dip * UipT where:

Dip = The fraction of the input gas consumed by abatement units.

dip= Industry level or site specific abatement system DRE for the process type/gas combination.

UipT= Total uptime for abatement systems supporting tools for a specific process type/gas combination as calculated by equation I-15.

i = gas type p = process type

In the abatement system briefing paper delivered to EPA on January 10, 2012, SIA proposed an alteration to equation I-15 in section E.1 and E.2 of the briefing paper to simplify the uptime calculation.

SIA recommends that EPA allow companies to calculate abatement system uptime by the process categories in which F-gas use and emissions are reported. This will allow companies to easily match abatement uptime to the reported F-gas use and emissions estimates calculations. Allowing this type of grouping avoids the serious difficulty in apportioning gas usage at an individual tool level, as noted by SIA in its petition for reconsideration and its continuing dialogue with EPA on modifications to the Subpart I rule. It is important to allow abatement system uptimes to be matched to the use categories to minimize the reporting burden associated with applying abatement DREs to the emissions estimates.

In order to calculate the abatement system uptime for a process type/ gas combination, the Equation and its associated variables should be revised as follows:

UipdT = (1 – TipdT/TopsT ) where:

UipT : the total uptime, expressed as a fraction, of all of the abatement systems abating a given process type/gas combination.

TipdT : the total time, in minutes, that all of the abatement systems abating a given process type/gas combination are not operational when the abated tool is in operation for the reporting year.

Tiops:T : The total number of minutes in the year times the number of abatement units for a given process/gas type. Where a tool and its associated abatement unit is only operational (installed and available for use) for a portion of the year (e.g. it is removed from or installed in the fab in May) then the total operational minutes for that tool would be prorated for the time it is available for use to prevent overestimating the abatement system uptime.

i = gas type

March 6, 2012 9 Developed for Settlement Purposes (SIA v. EPA, D.C. Cir. No. 11-1024) Deliberative – Do Not Cite or Quote

p = process type d = abatement unit ops = operational process tools of a given gas/process combination whose emissions are abated. A tool is considered operational when it is installed and available for use. T = Total time

Fabs with more sophisticated monitoring systems, which are currently a very limited subset of fabs, may be able to track tool operational time to a more refined definition of tool operation. Where systems allow better tracking of the operational metric, the fab should be allowed to identify how operational time is being tracked in its GHG monitoring plan and report abatement system up-time using that operational definition.

11. Please clarify whether the issue with reporting 40 CFR 98.96(n) and (o) or the inputs to equation 1-14 is with respect to requiring this information to be reported or the calculation methods associated with these reporting elements?

SIA has two concerns with the current reporting requirements detailed in 40 CFR (n),(o) and (p). 1. Under 98.96, the regulations specifically state that facilities “…must include in each annual report the following information for each electronics manufacturing facility.” Sections (n),(o), and (p) then require detailed information about the allocation of gas use to and detailed information about abatement units, whether or not a given facility is claiming the abatement system DRE to reduce its estimated emissions for the facility. SIA submits that this data should only be required to be supplied if the facility is reducing its estimated emissions based on the DRE of deployed abatement units.

2. Sections (o) and (p) require the submission of volumes of documents to EPA about the abatement units. It is SIA’s belief that these requirements will result in the submission of hundreds of pages of documents by each fab with abatement systems to EPA each year. Sections (n) and (o) should be combined with section (q), required only when the facility is applying abatement system DRE to the gas use to reduce estimated emissions, and the records should be maintained at the facility for inspection, not submitted to EPA each year. The portion of section (p) requiring identification of the manufacturing equipment and gases abated by each unit should also be maintained at the facility. For annual reporting to EPA, SIA proposes the following approach to managing abatement system test and O&M data.

a) A report of the abatement systems groupings and the number of abatement units in each group. Where a site is testing for one or more site specific DREs for process type/gas combinations, it should also report to EPA the number of tests required to be done for each process type/gas group over the specified testing period, the number of tests done to date by year in the specified testing period, the DREs of the individual units tested in each grouping, the average DRE of those tests completed in that reporting year, and the average DRE for the category that is being used

March 6, 2012 10 Developed for Settlement Purposes (SIA v. EPA, D.C. Cir. No. 11-1024) Deliberative – Do Not Cite or Quote

to report emissions (reflecting the first two years of testing or the most recent 30% of the testing results.). This requirement would replace the requirements in sections 98.96 (n) to (q) for reporting to EPA b) A certification, signed by the designated facility manager, that the abatement units are being installed and maintained in accordance with the facility O&M plan, which is based on the manufacturer’s recommended installation and O&M plan requirements.

In addition, 98.96 sections (n)-(q)need to be modified to reflect the revised approach to calculating the abatement system uptime and the consumption of gas at the process type/gas level rather than at the recipe/gas level.

March 6, 2012 11 Developed for Settlement Purposes (SIA v. EPA, D.C. Cir. No. 11-1024) Deliberative – Do Not Cite or Quote

Revised Table VII: Chamber Clean Abatement Measured DREs

Chamber Cleaning Abatement Unit Type

Line In-Situ Remote Thermal Kronis Kronis Atlas Atlas Date of Device Age EPA DRE Test Test Date TCS TPU Helios Comments Input Gas DRE Number Plasma Plasma Clean TCS TPU TCS TPU Installation Yrs Method

1 8/30/2011 X X X 6/4/2010 Low Fire 1.2 1 NF3 98.93 2 8/16/2011 X X 2/20/2002 Low Fire 9.5 1 NF3 72.32 3 8/16/2011 X X 2/20/2002 Low Fire 9.5 1 NF3 79.46 4 8/23/2011 X X 4/14/2003 Low Fire 8.4 1 NF3 78.54 5 8/23/2011 X X 4/14/2003 Low Fire 8.4 1 NF3 74.85 6 8/23/2011 X X 4/14/2003 Low Fire 8.4 1 NF3 96.95 7 6/8/2011 X X 5/4/2010 High Fire 1.1 1 NF3 97.37 8 9/14/2011 X X 2/11/2008 TPU low fire 3.6 1 NF3 83.10 9 6/7/2011 X X 10/15/2008 High Fire 2.6 1 NF3 96.05 10 5/18/2011 X X 1/7/2003 TPU Low Fire 8.4 1 NF3 85.52 11 8/16/2011 X X 2/13/2003 Low Fire 8.5 1 NF3 91.12 12 7/26/2011 X X 3/19/2008 Low Fire 3.4 1 NF3 99.77 13 5/12/2011 X X 5/16/2002 Low Fire 9.0 1 NF3 49.55 Low Fire Retest of JN02 14 9/7/2011 X X 5/16/2002 Line 13 9.3 1 NF3 63.36 15 8/4/2011 X X 6/27/2007 TPU High Fire 4.1 1 NF3 99.97 16 6/15/2011 X X 3/7/2003 High Fire 8.3 1 NF3 99.95 17 6/15/2011 X X 3/7/2003 High Fire 8.3 1 NF3 99.95 18 5/4/2011 X X 10/5/2004 High Fire 6.6 1 NF3 99.94 19 6/14/2011 X X 7/2/2002 Low Fire 9.0 1 NF3 99.98 20 4/28/2011 X X 5/3/2007 Low Fire 4.0 1 NF3 84.07 Low Fire Retest of JQ03 21 8/24/2011 X X 6/27/2007 Line 20 4.2 1 NF3 84.07 22 5/19/2011 X X 6/24/2003 Low Fire 7.9 1 NF3 99.85 23 8/9/2011 X X 3/10/2003 Low Fire 8.4 1 NF3 84.93 24 5/24/2011 X X 6/27/2007 High Fire 3.9 1 NF3 100.00 25 7/26/2011 X X 11/2/2010 HI Fire 0.7 1 NF3 99.90 26 5/24/2004 X X 12/16/2002 1.4 2* NF3 85.33

27 10/21/2010 X X 11/19/2007 2.9 2* NF3 91.38

March 6, 2012 12 Developed for Settlement Purposes (SIA v. EPA, D.C. Cir. No. 11-1024) Deliberative – Do Not Cite or Quote

28 4/5/2011 X X 6/7/2010 High Fire 0.8 1 NF3 99.96 29 8/30/2011 X X 12/12/2002 Low Fire 8.7 1 NF3 92.09 30 5/5/2011 X X 7/17/2007 Low Fire 3.8 1 NF3 79.51 30.5 7/27/2011 X X 7/2/2002 Low Fire 9.1 1 NF3 50.51

31 9/19/2011 X X 7/2/2002 Low Fire 9.2 1 NF3 76.07 32 9/19/2011 X X 7/2/2002 Low Fire 9.2 1 NF3 85.44 33 9/27/2011 X X 7/2/2002 Low Fire 9.2 1 NF3 35.83 34 9/28/2011 X X 7/2/2002 Retest Low Fire 9.2 1 NF3 82.02 35 5/11/2011 X X 4/4/2002 TPU low fire 9.1 1 NF3 94.08 36 5/10/2011 X X 4/7/2003 TPU low fire 8.1 1 NF3 84.60 37 5/17/2011 X X 3/26/2003 TPU low fire 8.1 1 NF3 87.20 38 9/13/2011 X X 2/5/2009 Low Fire 2.6 1 NF3 99.94 39 7/13/2004 X X 12/24/2002 1.6 2* NF3 94.60 40 7/9/2004 X X 4/28/2004 0.2 2* NF3 99.99 41 2/8/2005 X X 11/6/2004 0.3 2* NF3 99.90 42 3/20/2006 X X 9/1/2005 0.5 2* NF3 96.86 43 7/3/2008 X X 11/20/2006 1.6 2* NF3 99.70 44 2/15/2008 X X 6/11/2007 0.7 2* NF3 93.00 45 4/29/2008 X X 3/3/2006 2.2 2* NF3 100.00 46 10/15/2009 X X 1/21/2009 0.7 2* NF3 99.83 47 10/19/2010 X X 5/19/2006 4.4 2* NF3 100.00 48 10/19/2010 X X 2/26/2007 3.6 2* NF3 99.71

March 6, 2012 13 Developed for Settlement Purposes (SIA v. EPA, D.C. Cir. No. 11-1024) Deliberative – Do Not Cite or Quote

Table VI: Etch Abatement Systems Measured DREs

Litmas Device USEPA Line Atlas Zenith Date of Input Test Date TPU Remote Comments Age Test POU DRE Number TPU TPU Installation Gas Plasma Yrs Method

1 9/7/2011 X 9/13/2004 7.0 1 YES CF4 42.49

2 9/7/2011 X 9/13/2004 7.0 1 YES CH2F2 99.51

3 9/7/2011 X 9/13/2004 7.0 1 YES CHF3 99.67

4 9/7/2011 X 9/13/2004 7.0 1 YES SF6 99.71

5 4/28/2011 X 7/3/2007 3.8 1 YES CF4 39.66

6 9/8/2011 X 7/3/2007 Retest 4.2 1 YES CF4 67.25

7 9/8/2011 X 7/3/2007 Retest 4.2 1 YES CH2F2 99.10

8 9/8/2011 X 7/3/2007 Retest 4.2 1 YES CHF3 99.55

9 9/8/2011 X 7/3/2007 Retest 4.2 1 YES SF6 99.31

10 4/13/2011 X 3/14/2007 4.1 1 YES CF4 49.01

11 4/13/2011 X 3/14/2007 4.1 1 YES C4F8 99.43

12 4/13/2011 X 3/14/2007 4.1 1 YES CH2F2 99.39

13 4/13/2011 X 3/14/2007 4.1 1 YES CHF3 99.42

14 4/13/2011 X 3/14/2007 4.1 1 YES NF3 99.34

15 9/15/2011 X 3/14/2007 Retest 4.5 1 YES CF4 47.26

16 9/15/2011 X 3/14/2007 Retest 4.5 1 YES CH2F2 96.65

March 6, 2012 14 Developed for Settlement Purposes (SIA v. EPA, D.C. Cir. No. 11-1024) Deliberative – Do Not Cite or Quote

17 9/15/2011 X 3/14/2007 Retest 4.5 1 YES C4F6 99.28

18 9/15/2011 X 3/14/2007 Retest 4.5 1 YES C4F8 99.01

19 9/15/2011 X 3/14/2007 Retest 4.5 1 YES CHF3 99.44

20 9/15/2011 X 3/14/2007 Retest 4.5 1 YES NF3 99.25

21 4/21/2011 X 3/28/2007 4.1 1 YES CF4 0.00

22 4/21/2011 X 3/28/2007 4.1 1 YES C4F8 97.76

23 4/21/2011 X 3/28/2007 4.1 1 YES CH2F2 99.12

24 4/21/2011 X 3/28/2007 4.1 1 YES CHF3 98.90

25 4/21/2011 X 3/28/2007 4.1 1 YES NF3 98.37

26 9/29/2011 X 3/28/2007 Retest 4.5 1 YES CF4 94.50

27 9/29/2011 X 3/28/2007 Retest 4.5 1 YES C4F6 98.81

28 9/29/2011 X 3/28/2007 Retest 4.5 1 YES C4F8 98.53

29 9/29/2011 X 3/28/2007 Retest 4.5 1 YES CH2F2 98.78

30 9/29/2011 X 3/28/2007 Retest 4.5 1 YES CHF3 98.98

31 9/29/2011 X 3/28/2007 Retest 4.5 1 YES NF3 98.87

32 5/26/2011 X 9/12/2007 3.7 1 YES CF4 98.39

33 5/26/2011 X 9/12/2007 3.7 1 YES C4F8 98.82

34 5/26/2011 X 9/12/2007 3.7 1 YES CH2F2 98.99

35 5/26/2011 X 9/12/2007 3.7 1 YES CHF3 99.85

36 5/26/2011 X 9/12/2007 3.7 1 YES NF3 98.97

37 8/2/2011 X 10/6/2004 6.8 1 YES CF4 67.96

March 6, 2012 15 Developed for Settlement Purposes (SIA v. EPA, D.C. Cir. No. 11-1024) Deliberative – Do Not Cite or Quote

38 5/26/2011 X 1/25/2010 1.3 1 YES CF4 95.58

39 5/26/2011 X 1/25/2010 1.3 1 YES NF3 99.56

40 9/15/2011 X 11/4/2002 8.9 1 NO CF4 31.00

41 9/15/2011 X 11/4/2002 8.9 1 NO C4F8 99.57

42 9/15/2011 X 11/4/2002 8.9 1 NO CH2F2 99.40

43 9/15/2011 X 11/4/2002 8.9 1 NO CHF3 99.81

44 9/15/2011 X 11/4/2002 8.9 1 NO NF3 99.82

45 9/15/2011 X 11/4/2002 8.9 1 NO CF4 48.20

46 9/15/2011 X 11/4/2002 8.9 1 NO C4F8 99.54

47 9/15/2011 X 11/4/2002 8.9 1 NO CH2F2 99.49

48 9/15/2011 X 11/4/2002 8.9 1 NO CHF3 99.75

49 9/15/2011 X 11/4/2002 8.9 1 NO NF3 99.78

50 8/25/2011 X 7/17/2003 8.1 1 NO CF4 0.00

51 8/25/2011 X 7/17/2003 8.1 1 NO C4F8 99.16

52 8/25/2011 X 7/17/2003 8.1 1 NO CH2F2 99.18

53 8/25/2011 X 7/17/2003 8.1 1 NO CHF3 99.71

54 8/25/2011 X 7/17/2003 8.1 1 NO NF3 99.18

55 8/25/2011 X 7/17/2003 8.1 1 NO CF4 0.00

56 8/25/2011 X 7/17/2003 8.1 1 NO C4F8 99.24

57 8/25/2011 X 7/17/2003 8.1 1 NO CH2F2 99.13

58 8/25/2011 X 7/17/2003 8.1 1 NO CHF3 99.72

March 6, 2012 16 Developed for Settlement Purposes (SIA v. EPA, D.C. Cir. No. 11-1024) Deliberative – Do Not Cite or Quote

59 8/25/2011 X 7/17/2003 8.1 1 NO NF3 99.78

60 8/18/2011 X 3/18/2003 8.4 1 NO CF4 28.67

61 8/18/2011 X 3/18/2003 8.4 1 NO C4F8 99.48

62 8/18/2011 X 3/18/2003 8.4 1 NO CH2F2 99.62

63 8/18/2011 X 3/18/2003 8.4 1 NO CHF3 99.65

64 8/18/2011 X 3/18/2003 8.4 1 NO NF3 99.36

65 8/18/2011 X 3/18/2003 8.4 1 NO C4F6 99.41

66 8/18/2011 X 3/18/2003 8.4 1 NO CF4 14.95

67 8/18/2011 X 3/18/2003 8.4 1 NO CH2F2 98.97

68 8/18/2011 X 3/18/2003 8.4 1 NO C4F8 98.40

69 8/18/2011 X 3/18/2003 8.4 1 NO CHF3 99.69

70 8/18/2011 X 3/18/2003 8.4 1 NO NF3 99.38

71 8/18/2011 X 3/18/2003 8.4 1 NO C4F6 99.01

72 4/26/2011 X 12/5/2006 4.4 1 YES CF4 97.07

73 4/26/2011 X 12/5/2006 4.4 1 YES C4F8 97.49

74 4/26/2011 X 12/5/2006 4.4 1 YES CH2F2 97.98

75 4/26/2011 X 12/5/2006 4.4 1 YES CHF3 99.48

76 9/16/2011 X 6/2/2010 1.3 1 YES CF4 95.13

77 9/16/2011 X 6/2/2010 1.3 1 YES C4F8 98.34

78 9/16/2011 X 6/2/2010 1.3 1 YES CHF3 99.38

79 9/19/2011 X 5/12/2010 1.4 1 YES CF4 76.06

March 6, 2012 17 Developed for Settlement Purposes (SIA v. EPA, D.C. Cir. No. 11-1024) Deliberative – Do Not Cite or Quote

80 9/19/2011 X 5/12/2010 1.4 1 YES C4F6 98.78

81 9/19/2011 X 5/12/2010 1.4 1 YES C4F8 99.14

82 9/19/2011 X 5/12/2010 1.4 1 YES CH2F2 99.07

83 9/19/2011 X 5/12/2010 1.4 1 YES CHF3 99.22

84 9/19/2011 X 5/12/2010 1.4 1 YES SF6 99.09

85 9/22/2011 X 1/15/2008 3.7 1 YES CF4 4.09

86 9/22/2011 X 1/15/2008 3.7 1 YES CH2F2 98.67

87 9/22/2011 X 1/15/2008 3.7 1 YES CHF3 99.60

88 9/22/2011 X 1/15/2008 3.7 1 YES SF6 98.44

89 9/22/2011 X 1/15/2008 3.7 1 YES NF3 98.42

90 1/13/2009 X 10/23/2008 0.2 2* YES CF4 90.60

91 1/13/2009 X 10/23/2008 0.2 2* YES CHF3 92.90

92 12/14/2010 X tbd 2* YES CF4 84.00

93 12/14/2010 X tbd 2* YES C2F6 99.00

94 12/14/2010 X tbd 2* YES CHF3 99.70

95 7/14/2011 X tbd 2* YES CF4 82.00

96 7/14/2011 X tbd 2* YES NF3 99.70

March 6, 2012 18 Developed for Settlement Purposes (SIA v. EPA, D.C. Cir. No. 11-1024) Deliberative – Do Not Cite or Quote

March 6, 2012 19