PETROLÁTEX NX 43 TECHNICAL DATA

PRODUCT DESCRIPTION

PETROLÁTEX NX 43 is an aqueous emulsion of PETROLÁTEX NX 43 is modified with the a Carboxylated Butadiene-Acrylonitrile homogeneous introduction of specific carboxyl copolymer produced by hot emulsion groups which promote the selfcrosslinking of the polymerization using an anionic soap and polymer chains backbone. stabilized with a nonstaining antioxidant. The PETROLÁTEX NX-43 is a protein free latex so glass transition temperature of the polymer (Tg the risk of alergenic reactions is minimized . DSC) is around -24ºC (8ºF).

CHARACTERISTICS The main characteristics of PETROLÁTEX NX-43 Good film formation and flexibility . are : The polymer presents high resistance to Excelent mechanical stability (stable during mineral oils, greases , fuels and solvents. pumping and other high shear operations). Good mechanical properties, mainly fatigue Coagulum free product. resistance. Excelent chemical stability to wide pH Good heat resistance and low permeability variations . to gases. Excelent compound stability. Production of odor free articles. Protein free.

TYPICAL APPLICATIONS The main applications of PETROLÁTEX NX 43 The latex may be coagulated using aqueous are: solutions of CaCl2 , MgCl2 , Al2(SO4) 3 or Articles produced by dipping process: synthetic polyelectrolytes. The use of mineral acids alone doesn´t coagulate the supported gloves resistant to solvents , latex. greases and fuels. The viscosity may be increased by adding For agglomeration of cellulose and asbestos conventional thickeners such as CMC or in the sealing articles production . polyacrylates. For impregnation of oil resistant carpets . In the dipping processes when it is desired a In the production of sealants in contact with fine control of compound rheology we oils and aerossol. recommend the use of PETROFLEX SX-700 As a binder for non-woven fabrics and all thickener which enables the compound to kinds of fibres. have behaviour as a Bingham fluid.

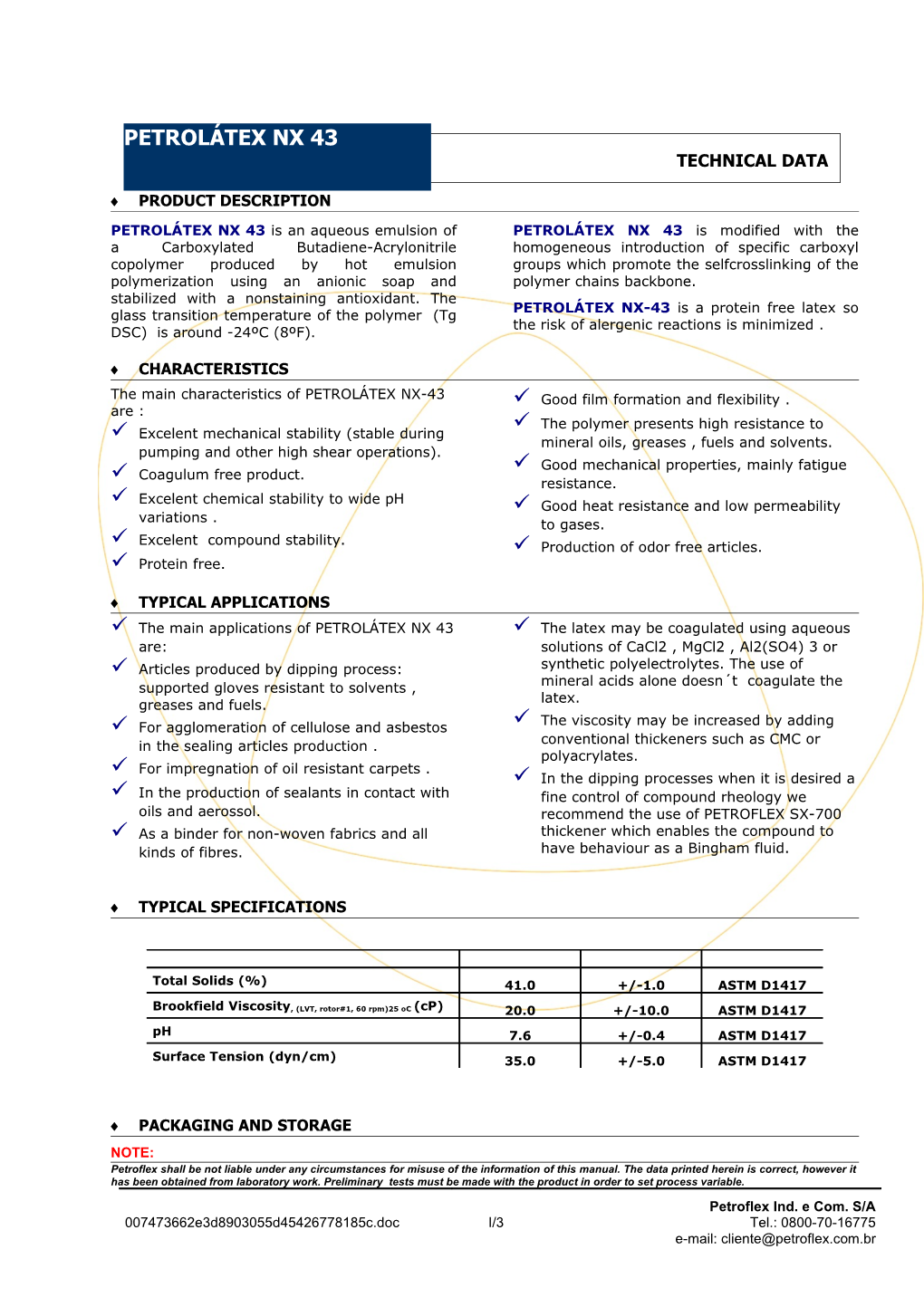

TYPICAL SPECIFICATIONS

PROPERTIES VALUES LIMITS METHOD

Total Solids (%) 41.0 +/-1.0 ASTM D1417

Brookfield Viscosity, (LVT, rotor#1, 60 rpm)25 oC (cP) 20.0 +/-10.0 ASTM D1417

pH 7.6 +/-0.4 ASTM D1417

Surface Tension (dyn/cm) 35.0 +/-5.0 ASTM D1417

PACKAGING AND STORAGE NOTE: Petroflex shall be not liable under any circumstances for misuse of the information of this manual. The data printed herein is correct, however it has been obtained from laboratory work. Preliminary tests must be made with the product in order to set process variable. Petroflex Ind. e Com. S/A 007473662e3d8903055d45426778185c.doc I/3 Tel.: 0800-70-16775 e-mail: [email protected]

PETROLÁTEX NX 43 TECHNICAL DATA

PETROLÁTEX NX 43 is supplied in 200 liters drums . It may also be supplied in bulk by road tankers or in non-returnable 1,000 liters containers. PETROLÁTEX NX 43 should be stored in dry even conditions at temperatures between 10 and 30ºC and away from direct sunlight . When stored in tanks , vertical cylinder types are recommended. The tanks may be stainless steel , fiberglass or epoxy lined carbon steel . The tanks should be protected from normal weather conditions and out from direct sunlight to avoid over heating. To avoid bacteria accumulation, a complete cleaning of the tubing and tanks 2 to 3 times a year is recommended. Two sterilizations per year of the tanks, pumps and lines are recommended. The latex should be stirred slowly 15 to 20 minutes daily .

If the above conditions are followed PETROFLEX warranties the product for six months from the production date.

NOTE: Petroflex shall be not liable under any circumstances for misuse of the information of this manual. The data printed herein is correct, however it has been obtained from laboratory work. Preliminary tests must be made with the product in order to set process variable. Petroflex Ind. e Com. S/A 007473662e3d8903055d45426778185c.doc II/3 Tel.: 0800-70-16775 e-mail: [email protected]

PETROLÁTEX NX 43 TECHNICAL DATA

SAFETY AND HANDLING PETROLÁTEX NX 43 is not considered dangerous . We strongly recommend the use of EPIs when processed as recommended in the MSDS besides the Good Manufacturing Practices however we recommend handling in well procedures . ventilated areas away from electric ignition fonts

NOTE: Petroflex shall be not liable under any circumstances for misuse of the information of this manual. The data printed herein is correct, however it has been obtained from laboratory work. Preliminary tests must be made with the product in order to set process variable. Petroflex Ind. e Com. S/A 007473662e3d8903055d45426778185c.doc III/3 Tel.: 0800-70-16775 e-mail: [email protected]