Appendix-E Kingpin Bracket Weld Analysis

Summary Section

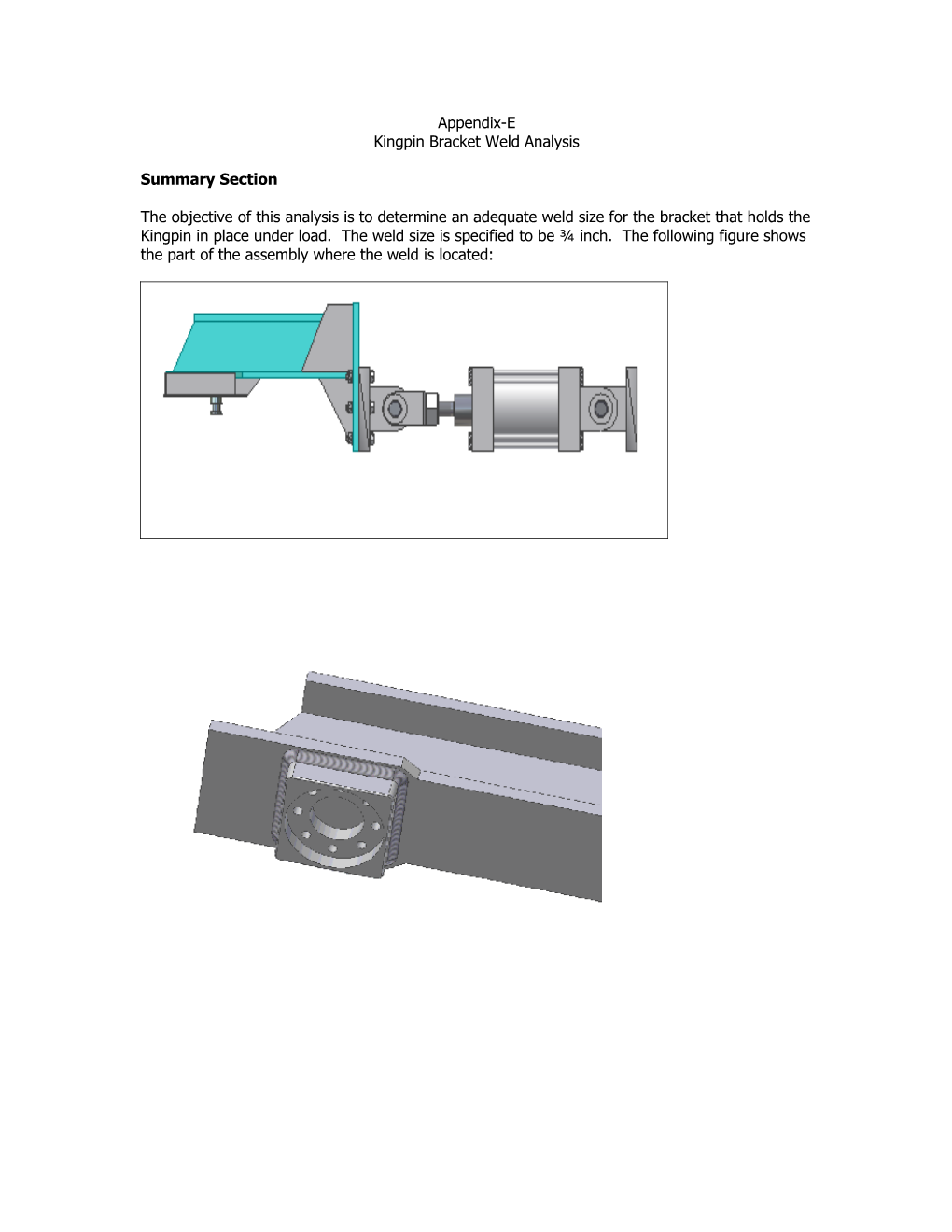

The objective of this analysis is to determine an adequate weld size for the bracket that holds the Kingpin in place under load. The weld size is specified to be ¾ inch. The following figure shows the part of the assembly where the weld is located: The result of this analysis would be a factor of safety against static failure of the weld bead under full pull force. The analysis indicates a factor of safety of 1.8 against weld failure.

Evaluation

The model represents a worst-case loading situation. The weld analysis is a conservative analysis. The assumptions do not cause much variation in results – lack of rigidity may just introduce some non-uniform loading. Since the cost of welding is low and the cost consequences of weld failure is high, a factor of safety of 1.5 is considered to be acceptable. The result of the analysis yields a factor of safety of 1.8 and therefore a weld size of ¾” is an acceptable design.

Formulation Section

Schematics 9

9

F=300000

4

1.25 9

The weld is all-around the bracket.

Given: Weld leg : 0.75 inch Weld length: 9 inch by 9 inch continuous weld Weld electrode: Yield strength is 100 ksi Force: F=300000 lbs

Find: Factor of safety guarding against static failure of the weld

Assumptions: Single-point loading. Rigid members. Uniform load distribution and centrally applied load.

Solution [See 1 for analysis method]:

Stresses due to direct shear 1.414F 1.414(300000) 1 15711 psi wAw 0.75(36)

Stresses due to bending is normal stress but is treated as shear stress in weld analysis procedures:

1.414M 1.414(300000)(4 1.25) 2 27494 psi wSw .75(108)

2 2 2 Sw bd d / 3 (9)(9) 9 / 3 108 in

Since these stresses act in directions 90 degrees apart, they are added vectorially to find the resultant stress:

2 2 2 2 1 2 15711 27494 31666 psi

The factor of safety is:

0.58(100000) FS 1.83 31666

Answer: FS = 1.8

Conclusion: The factor of safety is above the minimum acceptable level and therefore this weld is adequately designed.

References:

[1]: Robert L. Mott, Machine Elements in Mechanical Design, 3rd Edition, Prentice Hall, 1992, pp. 707-715