QS ZÜRICH AG PO. Box 6335 - CH 8050 Zürich +41 (0)44 350 46 65 [email protected] Basic Qualification for Medical Device Personnel

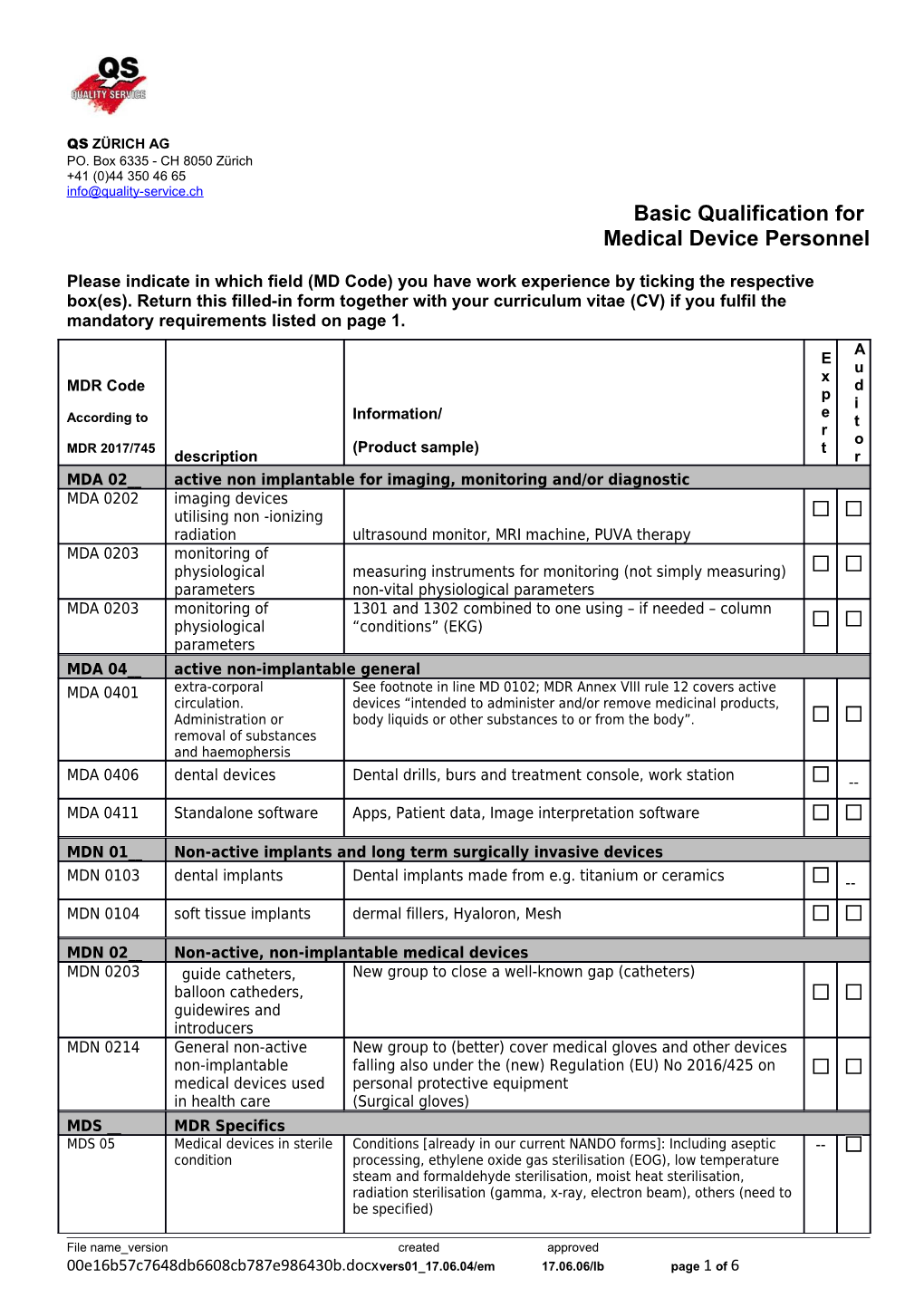

Please indicate in which field (MD Code) you have work experience by ticking the respective box(es). Return this filled-in form together with your curriculum vitae (CV) if you fulfil the mandatory requirements listed on page 1. A E u x MDR Code d p i e According to Information/ t r o MDR 2017/745 (Product sample) t description r MDA 02__ active non implantable for imaging, monitoring and/or diagnostic MDA 0202 imaging devices utilising non -ionizing radiation ultrasound monitor, MRI machine, PUVA therapy MDA 0203 monitoring of physiological measuring instruments for monitoring (not simply measuring) parameters non-vital physiological parameters MDA 0203 monitoring of 1301 and 1302 combined to one using – if needed – column physiological “conditions” (EKG) parameters MDA 04__ active non-implantable general MDA 0401 extra-corporal See footnote in line MD 0102; MDR Annex VIII rule 12 covers active circulation. devices “intended to administer and/or remove medicinal products, Administration or body liquids or other substances to or from the body”. removal of substances and haemophersis MDA 0406 dental devices Dental drills, burs and treatment console, work station -- MDA 0411 Standalone software Apps, Patient data, Image interpretation software

MDN 01__ Non-active implants and long term surgically invasive devices MDN 0103 dental implants Dental implants made from e.g. titanium or ceramics -- MDN 0104 soft tissue implants dermal fillers, Hyaloron, Mesh

MDN 02__ Non-active, non-implantable medical devices MDN 0203 guide catheters, New group to close a well-known gap (catheters) balloon catheders, guidewires and introducers MDN 0214 General non-active New group to (better) cover medical gloves and other devices non-implantable falling also under the (new) Regulation (EU) No 2016/425 on medical devices used personal protective equipment in health care (Surgical gloves) MDS __ MDR Specifics MDS 05 Medical devices in sterile Conditions [already in our current NANDO forms]: Including aseptic -- condition processing, ethylene oxide gas sterilisation (EOG), low temperature steam and formaldehyde sterilisation, moist heat sterilisation, radiation sterilisation (gamma, x-ray, electron beam), others (need to be specified)

File name_version created approved 00e16b57c7648db6608cb787e986430b.docxvers01_17.06.04/em 17.06.06/lb page 1 of 6 Separate evidence necessary for aseptic processing, ethylene oxide gas sterilisation (EOG), low temperature steam and formaldehyde sterilisation, moist heat sterilisation, radiation sterilisation (gamma, x-ray, electron beam) MDS 09 Medical devices See MDR Annex VIII rule 10 “Active devices intended for controlling, incorporating software / monitoring or directly influencing the performance of active utilising software / [implantable] devices”. controlled by software, including devices almost any electronically based process programs intended for controlling, monitoring or directly influencing the performance of active or active implantable devices MDT __ Technology areas used for the manufacture of medical devices MDT 04 Non-metal non-mineral processing including -- textiles, rubber, leather, paper MDT 06 Chemical processing --

Basic Qualification for Medical Device Personnel Mandatory requirements expert techn. Documentation

Requirements Education Successful completion of a bachelor university degree or a technical college degree or equivalent qualification in relevant studies, e.g. medicine, natural science or engineering Non-active devices: medicine, pharmacy, human physiology, biology, microbiology, chemistry, biochemistry, material sciences, biomedical-, clinical-, bio-engineering, Active devices: Physics, biophysics, computer hardware and software technology, electrical and mechanical engineering Justification for accepting alternatives to the education requirements Experience A minimum of 4 years fulltime professional experience with at least two year work in area directly related to production technology to be assessed or - working in closely related industries such as research and development, manufacturing of medical devices or pharmaceuticals or - working in the application of medical device technology and its use in health care services and with patients or - testing medical devices concerned for compliance with the relevant national or international standards or - conducting performance testing, evaluation studies or clinical trials of medical devices. A master’s degree or PhD in a relevant subject e.g. including device design, clinical/performance requirements may be used to substitute 1 or up to 3 years working experience, respectively. Justification for accepting alternatives to the education requirements Competence Requirements Regulatory requirements of MDR 2017/745, risk management (ISO 14971, FMEA methods), understanding of relevant harmonized standards See also introduction program for new employee Training requirements 8 hours of training in risk management principles, preferably related to the design of a medical device (e.g. ISO 14971) and their application within a quality management system. (e.g. ISO 13485 / MEDDEV / NBOG). Any alternative evidence of equivalent training by other means shall be justified and documented. Procedures of QS Zurich AG’s quality management system Two reviews prepared as mock examinations in the specified area of expertise within the technical documentation by the trainee and peer reviewed by an expert, and critically discussed prior to being qualified to perform independent technical documentation reviews. QS Zurich AG may use evidence of technical documentation reviews performed for another Auditing Organization or experience in preparing clinical evaluations for medical device manufacturers. Continual Professional 8 hours of annual training on changes to regulatory requirements and updates on relevant guidance QS ZÜRICH AG PO. Box 6335 - CH 8050 Zürich +41 (0)44 350 46 65 [email protected] Basic Qualification for Medical Device Personnel

Requirements Development documents pertaining to the regulations, or equivalent.

Mandatory requirements clinical evaluation experts Requirements Education Successful completion of a bachelor university degree, e.g. medicine, natural science medicine, biomedical-, clinical-, bio-engineering

Justification for accepting alternatives to the education requirements Experience A minimum 4 years fulltime professional experience with at least two year work in area directly related to production technology to be assessed or - working closely in clinical investigation or has academic study on the relevant clinical code. - working in the application of medical device technology and its use in health care services and with patients or - testing medical devices concerned for compliance with the relevant national or international standards or - conducting performance testing, evaluation studies or clinical trials of medical devices. A master’s degree or PhD in a relevant subject e.g. including device design, clinical/performance requirements may be used to substitute 1 or up to 3 years working experience, respectively. Justification for accepting alternatives to the education requirements Competence Requirements Regulatory requirements of MDR 2017/745, risk management (ISO 14971, FMEA methods), understanding of relevant harmonized standards See also introduction program for new employee; awareness about ISO 14155 and Annex X of MDD Training requirements 8 hours of training in risk management principles, preferably related to the design of a medical device (e.g. ISO 14971) and their application within a quality management system. (e.g., ISO 13485 / MEDDEV / NBOG). Any alternative evidence of equivalent training by other means shall be justified and documented. Procedures of QS Zurich AG’s quality management system Two clinical evaluation reviews prepared as mock examinations by the trainee and peer reviewed by an expert, and critically discussed prior to being qualified to perform independent technical documentation reviews. QS Zurich AG may use evidence of technical documentation reviews performed for another Auditing Organization or experience in preparing clinical evaluations for medical device manufacturers. Continual Professional 8 hours of annual training on changes to regulatory requirements and updates on relevant guidance Development documents pertaining to the regulations, or equivalent. On an annual basis, show evidence of having performed 3 technical file reviews in the specified area of expertise: clinical evaluation review. Mandatory requirements Sterilization expert Requirements Education Successful completion of studies in medicine, natural science or engineering at a university or higher technical college, or equivalent knowledge in special cases. Experience At least four years' professional experience with at least two years' work in areas directly related to the sterilization technology to be assessed as well as special experience and/or training in clean room technology, determination of bioburden, validation of cleaning, disinfection and sterilization processes, and in sterile packaging, proof of successful participation in at least one course in the validation of ethylene oxide sterilization and/or sterilization by irradiation and/or sterilization by moist heat according to EN ISO 11135, EN ISO 11137-1, -2, -3, EN ISO 17665-1 as well as in requirements for medical devices labelled sterile according to EN 556-1, proof of participation in at least two sterilization validations based on every harmonised standard for which an authorization is requested. Instead of two years’ work in areas directly related to the sterilization technology to be assessed, the following will also be recognised: an appropriate training programme/further education in connection

File name_version created approved 00e16b57c7648db6608cb787e986430b.docxvers01_17.06.04/em 17.06.06/lb page 3 of 6 with attendance at least three sterilization process audits, the validation of which is based on the respective harmonized standard, under the supervision of an appropriately qualified specialist. Competence Requirements Application of EN ISO 11135, EN ISO 11137-1, -2, -3 or EN ISO 17665-1 Different types of sterilization processes Steam (ISO 11134)

Ethylene oxide (ISO 11135)

Radiation (ISO 11137)

Dry heat (ISO 11138-4)

Application of the following standards: ISO 11138 (General Requirements – Sterilization of Health Care Products), and ISO 11139 (Definitions - Sterilization of Health Care Products) Various types of qualification (IQ, OQ, and PQ). Revalidation of each type of sterilization. Biological indicators selection and use. Microbiological-hygienic inspections (e.g. bioburden control, examinations of room air, water, surfaces, sterile work benches, validation of cleaning processes). Suitability of sterile packaging and packaging technology selected for the sterilization. Procedure applied and whether these ensure that sterility is maintained until the product is used. Labelling requirement related to sterilization EN ISO 15223-1. Ageing process which could endanger the integrity of the packaging. Requirements for validation reports on sterilization validation report. Mandatory requirements biocompatibility expert Requirements Education Successful completion of studies in medicine, natural science or engineering at a university or higher technical college, or equivalent knowledge in special cases. Experience At least 4 years' professional experience with at least two years' work in areas directly related to implantation or invasive application of medical devices or pharmaceutical products. Special experience and/or training in anatomy, physiology, pathology, toxicology or related area. Competence Requirements Theoretical knowledge of EN ISO 10993 norms and at least two years working experience in one or more subnorms. Training requirements Regulatory requirements of MDR 2017/745, understanding of relevant harmonized standards 8 Hours of training in risk management principles, preferably related to the design and application of a medical device (e.g. ISO 14971). Any alternative evidence of equivalent training by other means shall be justified and documented. Procedures of QS Zurich AG’s quality management system Two reviews prepared as mock examinations in the specified area of expertise within the technical documentation by the trainee and peer reviewed by an expert, and critically discussed prior to being qualified to perform independent technical documentation reviews. Continual Professional 4 hours of annual training on changes to regulatory requirements and updates on relevant guidance Development documents pertaining to the regulations, or equivalent.

Mandatory requirements software experts

Requirements Education Successful completion of studies in medicine, natural science or engineering at a university or higher technical college, or equivalent knowledge in special cases. Experience At least 4 years' professional experience in the industry 2+ years as a system verification and test engineer under a quality system, preferably ISO13485 Competence Requirements Hands on harmonized standard for software life cycle IEC62304, and usability standard. Training requirements Awareness about MEDDEV 2.1/6 July 2016 GUIDELINES ON THE QUALIFICATION AND CLASSIFICATION OF STAND ALONE SOFTWARE USED IN HEALTHCARE WITHIN THE REGULATORY FRAMEWORK OF MEDICAL DEVICES Requirements Management & Traceability Continual Professional 4 hours of annual training on changes to regulatory requirements and updates on relevant guidance Development documents pertaining to the regulations, or equivalent.

Mandatory requirements auditors QS ZÜRICH AG PO. Box 6335 - CH 8050 Zürich +41 (0)44 350 46 65 [email protected] Basic Qualification for Medical Device Personnel

Auditors ISO 13485 (assessment of technical documentation and design dossier, assessment of product related technology aspects during on-site audits).

Requirements Education Successful completion of a bachelor university degree or a technical college degree or equivalent qualification in relevant studies, e.g. medicine, natural science or engineering Non-active devices: medicine, pharmacy, human physiology, biology, microbiology, chemistry, biochemistry, material sciences, biomedical-, clinical-, bio-engineering, Active devices: Physics, biophysics, computer hardware and software technology, electrical and mechanical engineering Justification for accepting alternatives to the education requirements Experience Four years in the field of healthcare products or related sectors (e.g. industry, auditing, healthcare, research experience) That means: - working in closely related industries such as research and development, manufacturing of medical devices or pharmaceuticals or - working in the application of medical device technology and its use in health care services and with patients or - testing or auditing medical devices concerned for compliance with the relevant national or international standards or - conducting performance testing, evaluation studies or clinical trials of medical devices. A master’s degree or PhD in a relevant subject e.g. including device design, clinical/performance requirements may be used to substitute 1 or up to 3 years working experience, respectively. Justification for accepting alternatives to the education requirements Competence Requirements Regulatory requirements of MDR 2017/745, risk management (ISO 14971, FMEA methods), understanding of relevant harmonized standards See also introduction program for new employee Training requirements 8 Hours of training in risk management principles, preferably related to the design of a medical device (e.g. ISO 14971) and their application within a quality management system. (e.g. ISO 13485 / MEDDEV / NBOG). Any alternative evidence of equivalent training by other means shall be justified and documented. Procedures of QS Zurich AG’s quality management system Continual Professional 8 hours of annual training on changes to regulatory requirements and updates on relevant guidance Development documents pertaining to the regulations, or equivalent.

Specific qualifications for auditors

Requirements For a first authorization, the a) Have gained experience in the entire process of auditing medical device quality auditor shall comply with management systems, including review of documentation and risk management of medical the following criteria, which devices, implementation audit and audit reporting. This experience shall have been gained shall be demonstrated in by participation as a trainee in a minimum of four audits for a total of at least 20 days in an audits under guidance and accredited QMS program, 50% of which shall be against ISO 13485:2012/2016 preferably in supervision: an accredited program, and the rest in an accredited QMS program. In addition to criteria a), audit team leaders shall fulfil the following: b) Have experienced an audit team leader role under the supervision of a qualified team leader at least three ISO 13485 audits. Experience At least two years of work experience shall be in the area of quality management Regular auditing in the relevant production technology may count as work experience. Training requirements 40 hours of class room training in quality management systems (e.g. ISO 9001) including a minimum of 8 hours dedicated to additional medical device quality management system requirements (e.g. ISO

File name_version created approved 00e16b57c7648db6608cb787e986430b.docxvers01_17.06.04/em 17.06.06/lb page 5 of 6 13485). In cases of already qualified quality management system auditors, a minimum of 8 hours of class room training in the additional medical device quality management system requirements. Any alternative evidence of equivalent training by other means shall be justified and documented. Continual Professional On an annual basis conducting 4 on-site audits to ISO 13485 or MDR 2017/745 or show relevant Development equivalent work experience for equivalent length of time in the medical device industry. In case of relevant equivalent work experience 2 on-site audits according to ISO 13485 or dir. 93/42/EEC are sufficient. Qualification for auditing Knowledge of sterilisation procedures, validation of sterilisation procedures and packaging validation sterilisation procedure (if applicable for a concerned MD scope)