1

2 Supplementary Figures

3

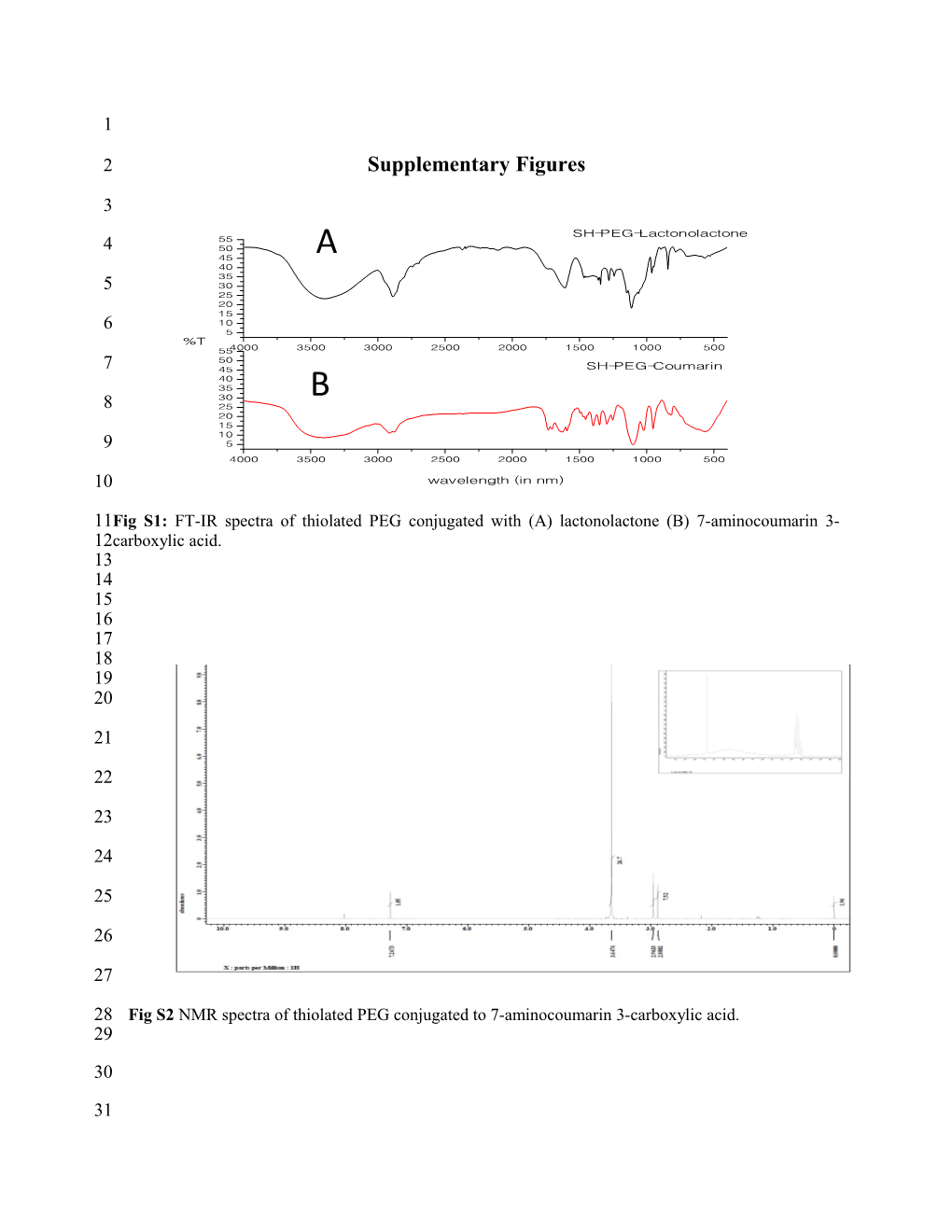

SH-PEG-Lactonolactone 55 4 50 45 A 40 35 5 30 25 20 15 10 6 5 %T 554000 3500 3000 2500 2000 1500 1000 500 50 7 45 SH-PEG-Coumarin 40 35 30 B 8 25 20 15 10 9 5 4000 3500 3000 2500 2000 1500 1000 500 10 wavelength (in nm)

11Fig S1: FT-IR spectra of thiolated PEG conjugated with (A) lactonolactone (B) 7-aminocoumarin 3- 12carboxylic acid. 13 14 15 16 17 18 19 20

21

22

23

24

25

26

27

28 Fig S2 NMR spectra of thiolated PEG conjugated to 7-aminocoumarin 3-carboxylic acid. 29

30

31 32

33 3.0

2.5 34 PEG conjugated Coumarine 2.0 Absorbance intensity 7-aminocoumarin 3-carboxylic acid 35 1.5

1.0 373nm

36 0.5 368nm

0.0 37 300 400 500 600 700 800 900 1000 1100 wavelength (in nm) 38

39

40Fig S3: UV-Vis analysis curve showing hypsochromic shift in λmax value for 7-aminocoumarin 3- 41carboxylic acid and its PEG conjugated derivative 42 43 44 45 46 47 48

49

50

51

52

53

54 FigS4: FT-IR spectra of bare gold nanoparticles 55

56

57

58

59

60

61 1.0 62 522nm Bare Gold Nanoparticles 0.8 63 Bioconjugated Gold nanoparticles 0.6 64 Absorbance 0.4 563nm

65 0.2

66 0.0 67 400 500 600 700 800 68 wavelength (in nm) 69 70 71 72 Fig S5: UV-Vis analysis data showing bathochromic shift in λmax value of gold nanoparticles up on 73 conjugation 74

75

76

77

78 A B 79

80

81

82

83

84 Fig S6: QELS Data (A) and TEM Micrograph (B) of conjugated gold nanoparticles

85

86

87

88

89

90

91 CH2OH CH2OH 92 OH O O OH OH

CH2OH CH2OH O 93 OH OH O O O O OH OH 94 OH OH

95 OH OH

96 Scheme S1: Synthesis of lactonolactone from lactose 97 98

99

100

101

CHO COOH HOOC 102 Aniline/Ethanol 70-80oC + CH2 HOOC 103 CHO O O

Conc H2SO4/ConcHNO3 104 0oC

105

COOH 106

O O 107 O2N

SnCl2/HCl RT 108

COOH 109

O O 110 H2N 111 112 Scheme S2: Synthesis of 7-aminocoumarin 3-carboxylic acid 113 114. 115

116

117

118

119 120

121

122 HO O O OMe 123 n Thioacetate N /RT 124 2

HO O 125 O SAc n

126 Tosylchloride/Et3N 60oC/RT 127 tsO O O SAc n 128 NaN3/RT

129 N N O O SAc n 130 LiAlH4 o 131 0 C Derivative 3. iv H2N O O SH 132 n

133 Scheme S3: - Synthesis of SH-PEG-NH2 from monomethoxy PEG 5000 134

135

136

137

138

139

140

141

142 143

144

145

HO O 146 O OMe n Tosylchloride 147 DMAP+Et3N 60oC

tsO O 148 O OMe Derivative 4. i n DMSO 149 Na2HP4

OHC O O OMe Derivative 4. ii 150 n

151 Thiacetate N2/RT

O 152 OHC O SAc n

NaOMe/MeOH 153 HCl/RT O OHC O SH 154

155

156Scheme S4: Synthesis of SH-PEG-CHO from monomethoxy PEG 2000 157

158

159

160

161

162

163

164

165 166

167

168 CH2OH CH2OH O OH HS O O 169 OH O OH O NH2 O n 170

OH 171 OH CH2OH CH2OH O 172 HO OH O OH HC OH HS O O 173 O N n H

174 OH OH 175

176 Scheme S5:- Coupling of lactonolactone to SH-PEG-NH2 to form Adduct 1 177

178

179

180

181 COOH

182 HS O CHO O O O n H N 183 2 1. Et N 3 184 COOH 2. NaBH CN 3 185 H HS O C O O 186 O NH n 187

188 Scheme S6:- Coupling of Coumarin derivative to SH-PEG-CHO to form Adduct 2 189 190

191 Suppelmentary Methods

1922.2 Synthesis of Targeting Moiety: Lactonolactone

193

194Lactonolactone was synthesised by oxidizing the sugar moiety Lactose17. Briefly, lactose (2g;) was

195dissolved in minimum amount of hot water followed by its addition to an iodine solution in

196methanol(3g/40mL) at 40˚C. The reaction mixture was stirred for 2 hours. Following this, a concentrated

197solution of potassium hydroxide in methanol was added drop-wise to the reaction mixture until the colour

198of iodine disappeared. The solution was then cooled externally in an ice bath which led to the

199precipitation of a crystalline product. The product was filtered, repeatedly washed with cold methanol and

200recrystallized using water/methanol system.

201

202The potassium salt of lactobionic acid thus formed was converted to its free acid form by passing it

203through a column of Acidic amberlite resin. The acidic elute was concentrated and evaporated several

204times with methanol to get the final lactone as a highly viscous colourless oil. The scheme for the

205synthesis of lactonolactone from lactose is shown in Scheme S1. IR spectra: - 3371, 2898, 1736, 1647,

2061421, 1226, 1139, 1077, 1035, 891, 787

207

2082.2.3 Synthesis of Fluorescent moiety: 7-aminocoumarin 3-carboxylic acid

209

210The scheme for the synthesis of fluorescent 7-aminocoumarin 3-carboxylic acid is shown in Scheme S2.

211Synthesis of the fluorescent moiety was performed in three consecutive steps, the first one involving the

212synthesis of 3-carboxycoumarin from Salicyldehyde and Malonic acid as per the procedure discussed by

213Besson et al18, followed by its controlled nitration at cold temperatures to give 7-nitrocoumarin 3- 214carboxylic acid. The later was reduced with SnCl2/HCl mixture to yield the final product as a bright

215yellow solid.

216

217Data for 7-aminocoumarin 3-carboxylic acid: 1H N.M.R: - 8.93(d, COOH), 8.52(d, ArH), 7.65 (d, ArH),

-1 2184.18 (NH2), 3.86 (CH=C) IR spectra (ᶹ/CM ): - 3428, 3369-3400 (d, primary amine), 3069, 2855, 1741

219(C=O for lactone), 1705 (C=O for carboxylic acid), 1610 () N-H), 1096 (C-O), 1001, 947, 845.

220

2212.2.4 Synthesis of SH-PEG-NH2 from monomethoxy PEG 5000

222

223The synthesis of hetero bi-functional PEG derivative from monomethoxy PEG 5000 involves a sequence

224of steps as illustrated in Scheme S3. The synthetic procedures have been referred from a few

225publications19, 20 and were performed with slight modifications.

226

227Derivative 3.i: - Monomethoxy PEG 5000 (1.0Eq) was dissolved in minimum amount of DMF followed

228by the addition of Potassium thioacetate (10.0 Eq) under inert atmosphere. The reaction mixture was

229allowed to stir under nitrogen atmosphere for about 24 hours. The progress of the reaction was monitored

230through TLC (methanol/CH2Cl2 system). After the completion of the reaction, the crude reaction mixture

231was treated with CH2Cl2 and excess thioacetate was washed by adding equal portions of saturated solution

232of NH4Cl and brine. The aqueous and the organic layer were then separated followed by 4-5 times

233extraction of the aqueous layer with CH2Cl2. Finally, the organic layer aliquots were combined, evaporated

234and purified over alumina (methanol/CH2Cl2 system) to get the final crude product as yellow oil with foul

235smell. The yellow oil when triturated with Diethyl ether gave pale yellow solid as the final product. 1H

-1 236N.M.R 2.15 (S, CH3), 3.14 (t, AcS-CH2), 3.60-3.68 (m, CH2-CH2-O-CH2-CH2), IR Spectra (ᶹ/cm ) – 3433

237(br, m), 2888 (br, vs), 1680, 1467, 1343 (asymmetric S=O stretch), 1281, 1250, 1112 (C-O stretch), 963,

238842

239 240Derivative 3.ii - Thioacetate derivative of PEG was tosylated using the procedure as follows: - AcS-PEG-

241OH (1.0eq) was dissolved in minimum amount of toluene followed by addition of base triethylamine

242(3.0eq) and p-tosylchloride (1.5eq). The reaction mixture was stirred for about 5 hrs at a maintained

243temperature of 60˚C after which it was left on stirring for another 10 hrs at ambient temperature. Progress

244of the reaction was monitored through TLC (methanol/CH2Cl2 system). Following the completion of the

245reaction, the solvent was removed from the reaction mixture over Buchi rotary evaporator. The crude

246product was then dissolved in CH2Cl2, and treated with 0.25M aqueous HBr solution and brine which

247served as washing agents for excess triethylamine and tosylchloride, respectively. The aqueous and

248organic layers were separated. The aqueous layer was extracted 4-5 times with CH2Cl2. Finally, the organic

249layer aliquots were combined, evaporated and purified over alumina (Methanol/ CH2Cl2) to get the

250product as pale yellow coloured oil, which upon trituration with ether yielded pale yellow final product. .

1 251 H N.M.R 2.15 (s, S- CH3), 2.42 (s, CH3) 3.12 (t, AcS-CH2), 3.50-3.72 (m, CH2-CH2-O-CH2-CH2), 4.12 (t,

-1 252CH2-Ots), 7.31 (d, ArH), 7.79 (d, ArH) IR Spectra (ᶹ/cm ): - 3400 (absorbed water), 2888, 1735, 1673,

2531466, 1344 (asymmetric S=O stretch), 1281, 1112, 1034(S-O stretch), 980, 842.

254

255Derivative 3.iii - Derivative 3.ii (1.0eq) was dissolved in minimum amount of DMF followed by the

256addition of sodium azide NaN3 (1.25eq) under inert atmosphere at ambient conditions. The reaction

257mixture was allowed to stir at the same conditions for 24hrs. The formation of product was confirmed

258through TLC (CH2Cl2/MeOH). The crude product was then repeatedly precipitated out from the reaction

259mixture by addition of dry ether. Purification by chromatography over alumina (EtOAc/MeOH) yielded

260the final product as pale yellow oil which upon trituration with ether gave pale yellow coloured solid. . 1H

261N.M.R 2.15 (s, S-CH3), 3.14 (t, AcS-CH2), 3.32(t, CH2) 3.53-3.68 (m, CH2-CH2-O-CH2-CH2) IR spectra

262(ᶹ/cm-1): - 2936, 2888, 2098 (azide stretch), 1644, 1466, 1346, 1281, 1110, 1034, 981, 843.

263

264Derivative 3.iv Under complete Argon atmosphere, a solution of LiAlH4 (5.0eq) in dry DMF was stirred

265for about half an hour at -10 to 0˚C (maintained in ice/Sodium chloride bath) in a dry round bottom flask, 266before a solution of Azido-PEG-Thioacetate (1.0eq) in DMF was added drop wise into it. Stirring at the

267maintained conditions was continued for another 4hrs. The progress of the reaction was analysed via

268Ellman’s test for thiol group and ninhydrin test for the amino group. After the completion of the reaction,

269double distilled water was cautiously added. Lithium hydroxide thus precipitated out was filtered over a

270pad of celite and washed repeatedly with ethanol. The filterate was concentrated, dissolved in minimum

271amount of CH2Cl2 and purified over alumina (EtOAc/MeOH system) to yield colourless oil. Trituration

272with dry ether yielded off white coloured Solid. 1.1–1.28 (m, SH), 1.97-2.1 (s, NH 2), 2.23–2.56 (m, CH2),

-1 2733.51–3.76 (m, CH2-CH2-O-CH2-CH2) IR spectra (ᶹ/cm ): - 3369 (strong, primary amine), 2918 (SH

274stretch), 2887, 1598 (N-H bend), 1465, 1346, 1282, 1112, 963

275

276

2772.2.5 Synthesis of SH-PEG-CHO from monomethoxy PEG 2000

278

279A versatile hetero-bifunctional polyethylene glycol (PEG) derivative containing active end-groups thiol

280and aldehyde was efficiently prepared from monomethoxy PEG as per the scheme in scheme S4. Though

281the synthetic procedures were referred from a few publications19, 20, 21, the synthesis was performed with

282considerable modifications.

283

284Derivative 4.i - Purified monomethoxy PEG (1.0eq) was dissolved in minimum amount of toluene

285followed by the addition of Et3N (3.0eq), DMAP (catalytic amount; 0.25eq) and p-tosylchloride (1.5eq).

286The reaction mixture was then heated in an oil bath maintained at 80˚C for 72 hrs. The progress of the

287reaction was analysed through TLC (CH2Cl2/MeOH system). After completion of the reaction, the

288reaction mixture was cooled to room temperature, the solvent was evaporated and the crude oil thus

289obtained was treated with CH2Cl2. Excessive reagents were removed through vigorous washings with

290saturated solution of NaHCO3 & brine and 0.25M aqueous HBr. Finally, the aqueous and organic layers

291were separated. The Aqueous layer was extracted extensively with CH2Cl2. The organic layer aliquots 292were combined, evaporated and purified over alumina (CH2Cl2/MeOH system) to obtain crude final

293product as colourless oil. Trituration with dry ether gave the final product as off white coloured solid. 1H

294N.M.R: - 2.39 (s, ArCH3), 3.32 (s, O-CH3), 3.53-3.66 (m, CH2-CH2-O-CH2-CH2), 4.13 (t, CH2-CH2-Ots),

2957.33 (d, ArH), 7.77(d, ArH) Ir spectra (cm-1): - 3432, 2884, 1735, 1647, 1598, 1466, 1345 (asymmetric

296SO2 stretch), 1281, 1234, (symmetric SO2 stretch), 1112, 949, 842

297Derivative 4.ii - A solution of MeO-PEG-Ots (1.0eq) in 15mL DMSO was treated with Na2HPO4

298(20.0eq) and the mixture was stirred in an oil bath maintained at 100˚C for 20hrs. The progress of the

299reaction was monitored through TLC (CH2Cl2/MeOH system). After the completion of the reaction, the

300cooled reaction mixture was filtered and the filtrate was precipitated out several times with dry ether. The

301precipitate thus obtained was dissolved in minimum amount of water, dialysed and lyophilized to obtain

1 302the final product as an off-white coloured solid. H N.M.R- 3.32 (s, O-CH3), 3.56-3.71 (m, CH2-CH2-O-

-1 303CH2-CH2), 3.81(CH2-CH2-O-CH2-CHO), 4.17 (d CH2-CHO), 9.71(s, CHO) IR spectra (ᶹ/cm ): -3412

304(absorbed water), 2820-2835 (overtone for aldehyde) 2885, 1735 (C=O stretch), 1467, 1254, 1192, 1110,

305953, 847

306

307Derivative 4.iii- CHO-PEG-OMe was subjected to thioacetylation in the next step. To a solution of

308derivative 4.ii (1.0eq) in DMF, 1.5 equivalents of potassium thioacetate were added under inert

309atmosphere. The reaction was allowed to stir continuously at room temperature and nitrogen/argon

310atmosphere for 24 hrs. The progress of the reaction was monitored through TLC (methanol/CH2Cl2

311system). The work up of the reaction mixture was done following the same steps as done for derivative 3.i

1 312which gave the final thioacetated product as a pale yellow solid. H N.M.R- 2.16 (s, CH3), 3. 43(s,

313AcS-CH2), 3.51-3.68 (m, CH2-CH2-O-CH2-CH2), 3.81(CH2-CH2-O-CH2-CHO), 4.17 (d CH2-CHO),

3149.71(s, CHO) IR spectra (ᶹ/cm-1): -3412 (absorbed water), 2820-2835 (overtone for aldehyde) 2885, 1735,

3151687, 1467, 1350, 1254, 1192, 1110, 1034 (S-O strech), 953, 847

316 317

318Derivative 4.iv - To a solution of Derivative 4.iii (1.0eq) in degassed methanol, 5 equivalents of NaOMe

319in MeOH was added. The mixture was allowed to stir overnight at room temperature. Then, the mixture

320was acidified to pH 1–2 using 0.1N HCl. Solvent from the reaction mixture was evaporated over Buchi

321rotary evaporator to give the crude product. Purification by silica gel chromatography (CH 2Cl2/MEOH

322system) gave the bifunctional derivative as colourless oil, which upon trituration with Dry ether gave off-

1 323white coloured solid. H spectra 1.1–1.28 (m, SH), 2.23–2.56 (m, CH2), 3.51–3.76 (m, CH2-CH2-O-CH2-

324CH2), 3.81(CH2-CH2-O-CH2-CHO), 4.17 (d CH2-CHO), 9.71(s, CHO) IR spectra: - 3420 (absorbed

325water), 2918 (SH stretch) 2820-2835 (overtone for aldehyde), 2884, 2110, 1735, 1466, 1351, 1253, 1099,

3261022, 953, 845

327

328

329NOTE: The coupling reactions of the thiolated PEG with Gold nanoparticles, target specific and

330fluorescent moieties were done within 2-3days of their synthesis as the thiol linkages lack stability in

331oxidizing environment and have strong tendency to form disulfides.

332

333