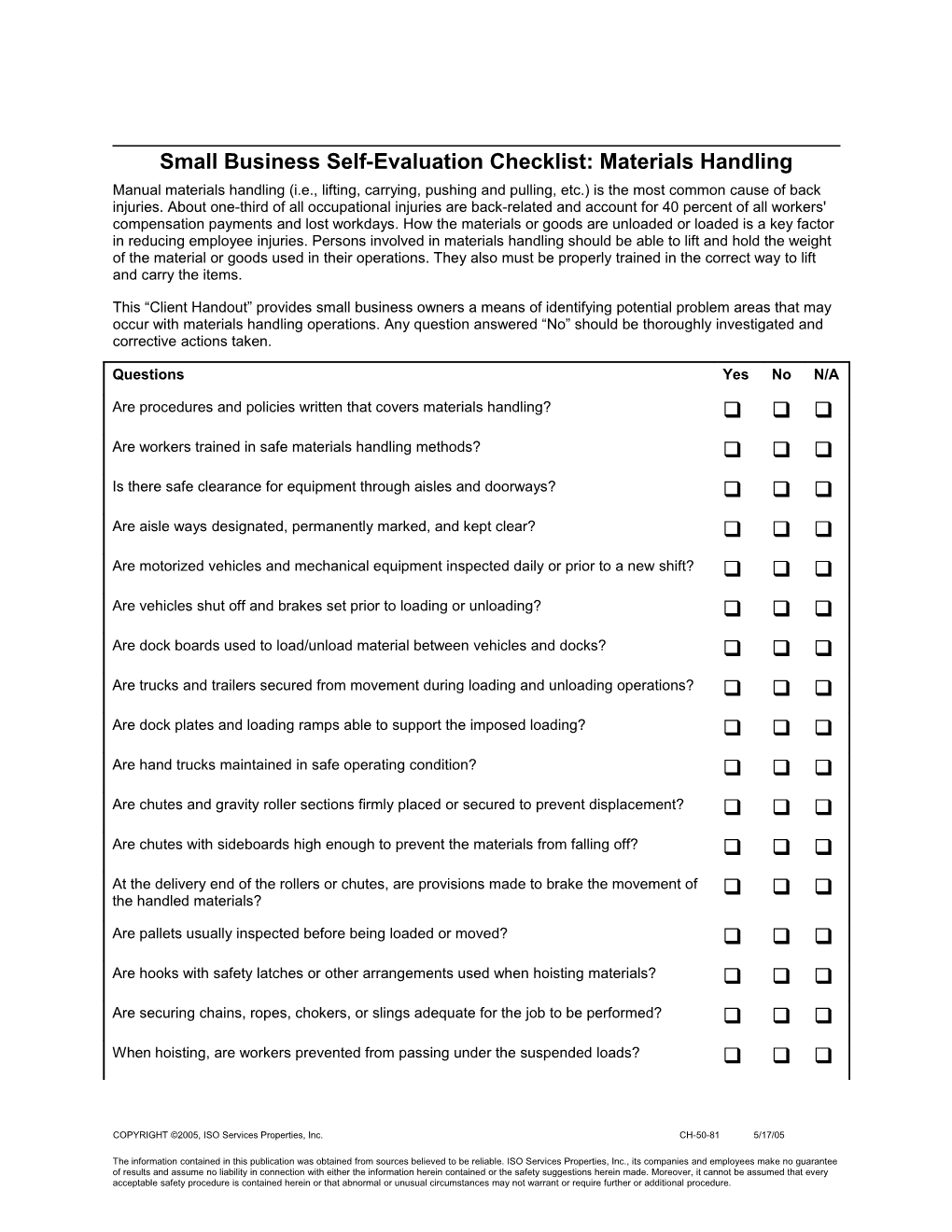

Small Business Self-Evaluation Checklist: Materials Handling Manual materials handling (i.e., lifting, carrying, pushing and pulling, etc.) is the most common cause of back injuries. About one-third of all occupational injuries are back-related and account for 40 percent of all workers' compensation payments and lost workdays. How the materials or goods are unloaded or loaded is a key factor in reducing employee injuries. Persons involved in materials handling should be able to lift and hold the weight of the material or goods used in their operations. They also must be properly trained in the correct way to lift and carry the items.

This “Client Handout” provides small business owners a means of identifying potential problem areas that may occur with materials handling operations. Any question answered “No” should be thoroughly investigated and corrective actions taken.

Questions Yes No N/A Are procedures and policies written that covers materials handling? Are workers trained in safe materials handling methods? Is there safe clearance for equipment through aisles and doorways? Are aisle ways designated, permanently marked, and kept clear? Are motorized vehicles and mechanical equipment inspected daily or prior to a new shift? Are vehicles shut off and brakes set prior to loading or unloading? Are dock boards used to load/unload material between vehicles and docks? Are trucks and trailers secured from movement during loading and unloading operations? Are dock plates and loading ramps able to support the imposed loading? Are hand trucks maintained in safe operating condition? Are chutes and gravity roller sections firmly placed or secured to prevent displacement? Are chutes with sideboards high enough to prevent the materials from falling off? At the delivery end of the rollers or chutes, are provisions made to brake the movement of the handled materials? Are pallets usually inspected before being loaded or moved? Are hooks with safety latches or other arrangements used when hoisting materials? Are securing chains, ropes, chokers, or slings adequate for the job to be performed? When hoisting, are workers prevented from passing under the suspended loads?

COPYRIGHT ©2005, ISO Services Properties, Inc. CH-50-81 5/17/05

The information contained in this publication was obtained from sources believed to be reliable. ISO Services Properties, Inc., its companies and employees make no guarantee of results and assume no liability in connection with either the information herein contained or the safety suggestions herein made. Moreover, it cannot be assumed that every acceptable safety procedure is contained herein or that abnormal or unusual circumstances may not warrant or require further or additional procedure. Risk Management Information 2 [Report Title]

Are Material Safety Data Sheets available to employees handling hazardous substances?

THE INFORMATION PRESENTED IN THIS “SAMPLE” SAFETY PROGRAM HAS BEEN COMPILED FROM VARIOUS SOURCES BELIEVED TO BE RELIABLE. HOWEVER, IT CANNOT BE ASSUMED THAT ALL ACCEPTABLE MEASURES ARE CONTAINED IN THIS PROGRAM WITH REGARDS TO YOUR INDUSTRY STANDARDS AND REQUIREMENTS UNDER PARTICULAR FEDERAL, STATE, PROVINCIAL AND LOCAL LAW.

COPYRIGHT ©2005, ISO Services Properties, Inc. [email protected]