DRAFT VA DCR STORMWATER DESIGN SPECIFICATION No. 6: RAIN TANKS

DRAFT VA DCR STORMWATER DESIGN SPECIFICATION No. 6 RAIN TANKS VERSION 0.55

Note to Reviewers of the Stormwater Design Specifications

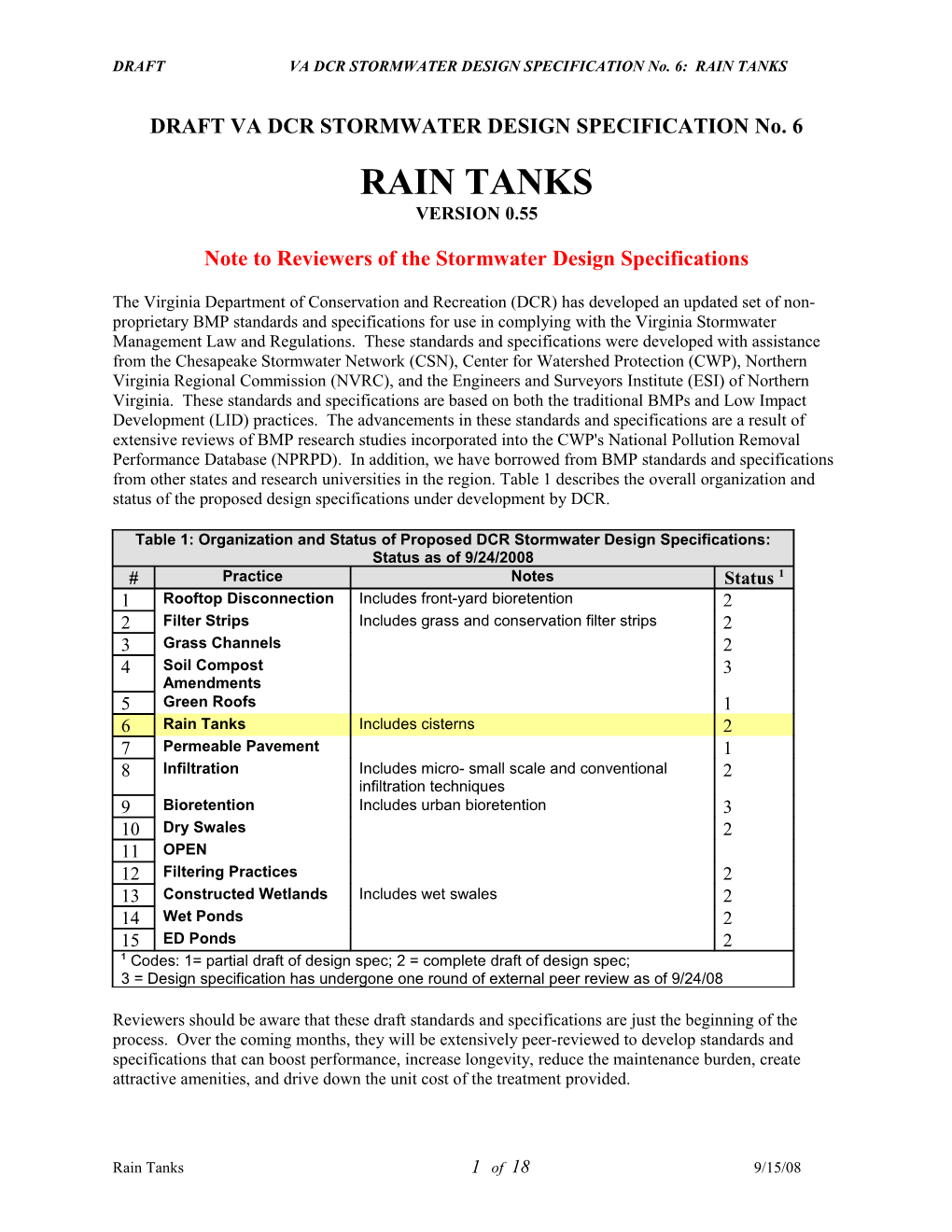

The Virginia Department of Conservation and Recreation (DCR) has developed an updated set of non- proprietary BMP standards and specifications for use in complying with the Virginia Stormwater Management Law and Regulations. These standards and specifications were developed with assistance from the Chesapeake Stormwater Network (CSN), Center for Watershed Protection (CWP), Northern Virginia Regional Commission (NVRC), and the Engineers and Surveyors Institute (ESI) of Northern Virginia. These standards and specifications are based on both the traditional BMPs and Low Impact Development (LID) practices. The advancements in these standards and specifications are a result of extensive reviews of BMP research studies incorporated into the CWP's National Pollution Removal Performance Database (NPRPD). In addition, we have borrowed from BMP standards and specifications from other states and research universities in the region. Table 1 describes the overall organization and status of the proposed design specifications under development by DCR.

Table 1: Organization and Status of Proposed DCR Stormwater Design Specifications: Status as of 9/24/2008 # Practice Notes Status 1 1 Rooftop Disconnection Includes front-yard bioretention 2 2 Filter Strips Includes grass and conservation filter strips 2 3 Grass Channels 2 4 Soil Compost 3 Amendments 5 Green Roofs 1 6 Rain Tanks Includes cisterns 2 7 Permeable Pavement 1 8 Infiltration Includes micro- small scale and conventional 2 infiltration techniques 9 Bioretention Includes urban bioretention 3 10 Dry Swales 2 11 OPEN 12 Filtering Practices 2 13 Constructed Wetlands Includes wet swales 2 14 Wet Ponds 2 15 ED Ponds 2 1 Codes: 1= partial draft of design spec; 2 = complete draft of design spec; 3 = Design specification has undergone one round of external peer review as of 9/24/08

Reviewers should be aware that these draft standards and specifications are just the beginning of the process. Over the coming months, they will be extensively peer-reviewed to develop standards and specifications that can boost performance, increase longevity, reduce the maintenance burden, create attractive amenities, and drive down the unit cost of the treatment provided.

Rain Tanks 1 of 18 9/15/08 DRAFT VA DCR STORMWATER DESIGN SPECIFICATION No. 6: RAIN TANKS

Timeline for review and adoption of specifications and Role of the Virginia’s Stormwater BMP Clearinghouse Committee:

The CSN will be soliciting input and comment on each standard and specification until the end of 2008 from the research, design and plan review community. This feedback will ensure that these design standards strike the right balance between prescription and flexibility, and that they work effectively in each physiographic region. The collective feedback will be presented to the BMP Clearinghouse Committee to help complement their review efforts. The Virginia Stormwater BMP Clearinghouse Committee will consider the feedback and recommend final versions of these BMP standards and specifications for approval by DCR.

The revisions to the Virginia Stormwater Management Regulations are not expected to become finalized until late 2009. The DCR intends that these stormwater BMP standards and specifications will be finalized by the time the regulations become final.

The Virginia Stormwater BMP Clearinghouse Committee will consider the feedback and recommend final versions of these BMP standards and specifications for approval by DCR, which is vested by the Code of Virginia with the authority to determine what practices are acceptable for use in Virginia to manage stormwater runoff.

As with any draft, there are several key caveats, as outlined below:

Many of the proposed design standards and specifications lack graphics. Graphics will be produced in the coming months, and some of graphics will be imported from the DCR 1999 Virginia Stormwater Management (SWM) Handbook. The design graphics shown in this current version are meant to be illustrative. Where there are differences between the schematic and the text, the text should be considered the recommended approach.

There are some inconsistencies in the material specifications for stone, pea gravel and filter fabric between ASTM, VDOT and the DCR 1999 SWM Handbook. These inconsistencies will be rectified in subsequent versions.

While the DCR 1999 SWM Handbook was used as the initial foundation for these draft standards and specifications, additional side-by-side comparison will be conducted to ensure continuity.

Other inconsistencies may exist regarding the specified setbacks from buildings, roads, septic systems, water supply wells and public infrastructure. These setbacks can be extremely important, and local plan reviewers should provide input to ensure that they strike the appropriate balance between risk aversion and practice feasibility.

These practice specifications will be posted in Wikipedia fashion for comment on the Chesapeake Stormwater Network’s web site at http://www.chesapeakestormwater.net, with instructions regarding how to submit comments, answers to remaining questions about the practice, useful graphics, etc. DCR requests that you provide an email copy of your comments, etc., to Scott Crafton ([email protected]). The final version will provide appropriate credit and attribution on the sources from which photos, schematics, figures, and text were derived.

Thank you for your help in producing the best stormwater design specifications for the Commonwealth.

Rain Tanks 2 of 18 9/15/08 DRAFT VA DCR STORMWATER DESIGN SPECIFICATION No. 6: RAIN TANKS

DRAFT VA DCR STORMWATER DESIGN SPECIFICATION No. 6 RAIN TANKS VERSION 0.55

Important Note. DCR and the Chesapeake Stormwater Network gratefully acknowledges the assistance of Sally Lawton and her colleagues at Rainwater Management Solutions, Inc. of Salem, Virginia for providing text and graphics for this new specification, and working out a design sizing process for on-site stormwater disposal. Given that the sizing element of this specification has not been finalized, it should be considered a very rough draft and is henceforth labeled as Version 0.5.

SECTION 1: DESCRIPTION OF PRACTICE

Rain tanks intercept, divert, store, and release rainfall for future use. The term rain tank is used in this specification, but it is also known as a cistern or rainwater harvesting system. Rainwater that falls on a rooftop is collected and conveyed into an above- or below-ground storage tank where it can be used for landscape irrigation, non-potable water, and on-site stormwater disposal. Typically, pre-fabricated rain tanks range from 200 to 10,000 gallons in size. The capture and re-use of rainwater can significantly reduce stormwater runoff volumes and pollutant loads. By providing a reliable and renewable source of water to end users, rain tanks can also have environmental and economic benefits beyond stormwater management (increased water conservation, water supply during drought, decreased demand on municipal or groundwater supply, etc). Rain tanks can be combined with other on-site practices, such as rain gardens, to enhance their runoff reduction and nutrient removal capability.

From a stormwater standpoint, there are four basic rain tank configurations, which are described below in descending order of runoff reduction capability:

Rain Tanks 3 of 18 9/15/08 DRAFT VA DCR STORMWATER DESIGN SPECIFICATION No. 6: RAIN TANKS

1. Rain tanks that provide interior non-potable water to meet a constant internal water demand throughout the year, provide seasonal outdoor water to an automated irrigation system, and provide year round on-site stormwater disposal in an approved practice.

2. Rain tanks that provide interior non-potable water and rely on on-site stormwater disposal to de-water the tank in between storms.

3. Rain tanks that provide indoor non-potable water and seasonal outdoor irrigation, but lack on-site disposal.

4. Rain tanks that only provide seasonal outdoor irrigation.

Rain barrels are not addressed or included in this specification. Rain tanks and cisterns are preferable.

Most recent rain tank guidance does not include on-site stormwater disposal to enhance runoff reduction rates. The basic approach is to gradually release flows from the tank in between storm events through a secondary runoff reduction practice such as a front yard filter path or bioretention area (Design Specification No.9), a grass filter strip (Design Specification No. 2), a rain garden (Design Specification No. 9) or a grass channel or dry swale (Design Specifications No. 3 and 10).

SECTION 2: PERFORMANCE CRITERIA

The overall stormwater functions of the four rain tank configurations are described in Table 1. Illustrations of three rain tank configurations used at typical residential sites are shown in Figures 1, 2 and 3.

Table 1: Stormwater Functions of Rain Tanks Stormwater Function Outdoor Only Indoor and Outdoor No SRP 1 With SRP No SRP With SRP Annual Runoff Reduction Rate 15% 60% 45% 90% Total Phosphorus Removal 2 0% 0% Total Nitrogen Removal 2 0% 0% Channel Protection Moderate. RRv can be subtracted from CPv. Flood Mitigation Partial. Reduced Curve Numbers and Time of Concentration. 1 SRP = Secondary runoff reduction practice as defined in Section 9.6 of this specification 2 Zero removal rate for rain tank only. Higher removal rates may apply to SRPs. (NOTE: Tables 1 and 2 in the CWP Technical Memo an RR rate of 40% to this practice. Assume the RR rates above are more current and correct. DCR and CSN will resolve the difference prior to finalizing this specification.)

Rain Tanks 4 of 18 9/15/08 DRAFT VA DCR STORMWATER DESIGN SPECIFICATION No. 6: RAIN TANKS

Laundry

Rain garden or soakaway unit

Pre-tank filter and first-flush diverter Storage tank

Pump

Irrigation

Toilet flushing

Gutter downspouts

Figure 1. Indoor/outdoor water supply with on-site discharge to a rain garden

Rain garden or soakaway unit

Pre-tank filter and first-flush diverter Storage tank

Pump

Irrigation

Gutter downspouts

Figure 2. Seasonal outdoor water supply and year-around on-site disposal

Pre-tank filter and first-flush diverter Storage tank

Pump

Irrigation

Gutter downspouts

Figure 3. Configured only for a seasonal automated outdoor irrigation system

Rain Tanks 5 of 18 9/15/08 DRAFT VA DCR STORMWATER DESIGN SPECIFICATION No. 6: RAIN TANKS

SECTION 3: PRACTICE APPLICATIONS AND FEASIBILITY

A number of site-specific features influence how rain tanks are designed. Some of the key considerations include the following:

Available Space: Adequate space is necessary to house the tank and any overflow. Space limitations are rarely a concern with rain tanks if they are considered during the initial building design and site layout of a residential or commercial development. Storage tanks can be placed underground, indoors, on rooftops, and adjacent to buildings. Designers can work with architects to creatively site the tanks.

Site Topography: While no strict guidelines exist for site topography and tank location, site topography should be considered to reduce the amount of pumping needed and provide adequate overflow. Locating storage tanks in low areas of the site will likely increase the volume of rainwater that can be stored for later use, but will increase the amount of pumping needed to distribute the harvested rainwater. Conversely, placing storage tanks at higher elevations will likely reduce the volume of rainwater that can be stored, but will also reduce the amount of pumping needed for distribution.

Available Hydraulic Head: The needed head depends on intended use of the water. For residential landscaping uses, the rain tank should be sited up-gradient of the landscaping areas or on a raised stand. Gravity-fed operations may also be used for indoor residential uses, such as laundry, that do not require high water pressure. For larger-scale landscaping operations, locating a rain tank on the roof may be the most cost efficient way to provide water pressure.

Water Table: Belowground storage tanks are only appropriate in areas where the tank can be buried above the water table or the tank used is designed to be buried below the water table.

Soils: Storage tanks should only be placed on native soils or on fill in accordance with the manufacturer's guidelines. Belowground tanks must be buried and weighted appropriately to avoid uplift.

Proximity of Underground Utilities: All underground utilities must be marked and avoided during the installation of an underground tank and any associated piping.

Contributing Drainage Area: The contributing drainage area to the rain tank is the impervious area draining to the tank. In general, only rooftop surfaces should be used. Parking lots and other paved areas may be used in rare circumstances, with appropriate treatment (oil/water separators) and approval of the locality. Areas of any size, including portions of roofs, may be used based on the sizing guidelines in this document.

Rooftop Material: The quality of the harvested water will vary according to the roof material it serves. Water harvested from certain types of rooftops, such as asphalt sealcoats, tar and gravel, or galvanized metal roofs, may leach trace metals and other toxic compounds. Designers should also note that the pH of rainfall in the Bay watershed ranges from 4.0-5.0, which is low enough to leach metals from the roof surface or tank lining. The 2007 Virginia Rainwater Harvesting

Rain Tanks 6 of 18 9/15/08 DRAFT VA DCR STORMWATER DESIGN SPECIFICATION No. 6: RAIN TANKS

Manual (Cabell Brand Center, 2007) and other references listed at the end of this specification describe the advantages and disadvantages of different roofing materials.

Hotspot Land Uses: Rain tanks can be an effective method to avoid contamination of rooftop runoff with ground-level runoff from a stormwater hotspot operation. In some cases, however, industrial roof surfaces may also be designated as stormwater hotspots.

Setbacks from Buildings: Rain tank overflow devices should be designed to avoid causing ponding or soil saturation within 10 feet of building foundations. Storage tanks should be designed to be watertight to prevent water damage when placed near building foundations.

Vehicle Loading: Below-ground rain tanks should be placed in areas without vehicle traffic. Tanks under roadways, parking lots, or driveways must be designed for the live loads from heavy trucks, a requirement that will significantly increase construction costs.

SECTION 4: COMMUNITY AND ENVIRONMENTAL CONCERNS

Although rainwater harvesting is an ancient practice, it is enjoying a revival due to the inherent quality of rainwater and the many beneficial uses that it can provide (TWDB, 2005). Some common concerns associated with rainwater harvesting that must be addressed during design include the following:

Winter Operation: Rain tanks can be used throughout the year if they are located underground or indoors to prevent problems associated with freezing, ice formation, and subsequent system damage. Alternately, an outdoor system can be used seasonally. See Section 8.3 for further guidance on winter operation of rain tanks.

Local Plumbing Codes: Designers and plan reviewers should consult local building codes to determine if they explicitly allow the use of harvested rainwater for toilet and urinal flushing. Rain tanks should be required to have backflow preventers to keep harvested water separate from the main water supply. Pipes and spigots using rainwater must be clearly labeled as non-potable.

Mosquitoes: In some situations, poorly designed rain tanks can create habitat suitable for mosquito breeding and reproduction. Designers should provide screens on above- and below- ground tanks to prevent mosquitoes and other insects from entering the tanks. If screening is not sufficient in deterring mosquitoes, dunks or pellets containing larvicide can be added to rain tanks when water is intended for landscaping use.

Child Safety: Above grade home rain tanks shall not have unsecured openings large enough for children to enter the tank. For underground rain tanks, manhole access should be secured to prevent unwanted access.

SECTION 5: DESIGN APPLICATIONS AND VARIATIONS

Rain tanks can be applied on any residential, commercial, industrial, or institutional site where rainwater can be captured, stored, and used. They are particularly useful on infill and

Rain Tanks 7 of 18 9/15/08 DRAFT VA DCR STORMWATER DESIGN SPECIFICATION No. 6: RAIN TANKS redevelopment sites that have little room for other stormwater practices. Rain tanks are often placed on the ground next to a building, but when space is limited, system components can be placed underground, indoors or on rooftops.

Rainwater that is captured and stored can be used to meet both outdoor and indoor water demand. Outdoors, harvested rainwater can be used for residential lawn and garden watering; commercial and institutional landscape irrigation; or other non-potable uses such as pool filling, vehicle washing, building washing, and fire fighting.

Indoor uses of harvested rainwater are non-potable. Toilet flushing is the most common large- scale indoor use of harvested rainwater. Laundry is another common residential use. Both require minimal water pressure. Separate plumbing, pressure tanks, pumps, and backflow preventors are necessary for indoor use of harvested water.

SECTION 6: SIZING AND TESTING GUIDANCE

(Note: This Section is Incomplete. DCR and CSN continue to coordinate further with Sally Lawton regarding how to express her modeling into a step-wise design sequence.)

The rain tank sizing criteria presented here was developed by comparing different conservative assumptions for indoor and outdoor water demand, long term rainfall statistics, and various roof area assumptions using a spreadsheet model (RMS, 2008). The spreadsheet has been modified to accommodate situations where tank overflow or dewatering is delivered to a secondary runoff reduction practice, such as an amended grass filter strip or a front yard bioretention area.

Sizing rain tanks begins with determination of the water demand. The following factors should be considered in determining the outdoor water demand:

Method of distribution and associated flow rate (e.g. sprinkler systems, soaker hoses)

Frequency of watering based on landscaping best management practices

Landscaping area to be watered

Indoor systems can be sized based on the demand principles used for site-specific traditional water and wastewater design. These estimates can be broken down into usage by aspects of the plumbing system such as toilets.

Demand calculations and methodology should be included with the stormwater management submittal for review.

Rain Tanks 8 of 18 9/15/08 DRAFT VA DCR STORMWATER DESIGN SPECIFICATION No. 6: RAIN TANKS

SECTION 7: DESIGN CRITERIA

7.1: Level 1 and Level 2 Design

Rain tank design is not subject to a Level 1 or Level 2 design table. Runoff reduction credits are based on the total amount of annual internal water reuse, outdoor water reuse, and tank dewatering discharge achieved by the tank system in the rain tank design spreadsheet. Runoff reduction rates can be sharply boosted when the discharge from the rain tank is coupled with a secondary runoff reduction practice (see Table 1).

7.2: Pretreatment

Pretreatment is needed to remove debris, dust, leaves, and other material that accumulates on rooftops and prevents clogging within the rainwater harvesting system. Different levels of pretreatment can be provided, depending on what the harvested water will be used for. Pretreatment devices include leaf screens, roof washers and first-flush diverters. Additional information about each of these pretreatment devices is provided, as follows:

Leaf Screens: Leaf screens are mesh screens installed either in the gutter or downspout and are used to remove leaves and other large debris from rooftop runoff. Leaf screens must be regularly cleaned to be effective; if not maintained, they can become clogged and prevent rainwater from flowing into the storage tanks. Built-up debris can also harbor bacterial growth within gutters or downspouts (TWDB, 2005).

First Flush Diverters: First flush diverters direct the initial pulse of stormwater runoff away from the storage tank. While leaf screens effectively remove larger debris such as leaves, twigs and blooms from harvested rainwater, first flush diverters can be used to remove smaller contaminants such as dust, pollen and bird and rodent feces (Figure 4). Simple first flush diverters require active management, by draining the first flush water volume to a pervious area following each rainstorm. However, if water is to be used for indoor uses, this may be a preferred pre-treatment technique.

Roof Washers: Roof washers are placed just ahead of storage tanks and are used to filter small debris from harvested rainwater (Figure 5). Roof washers consist of a tank, usually between 25 and 50 gallons in size, with leaf strainers and a filter with openings as small as 30-microns (TWDB, 2005). The filter functions to remove very small particulate matter from harvested rainwater. All roof washers must be cleaned on a regular basis.

Rain Tanks 9 of 18 9/15/08 DRAFT VA DCR STORMWATER DESIGN SPECIFICATION No. 6: RAIN TANKS

Figure 4. First Flush Diverter Figure 5. Roof Washer

SECTION 8: REGIONAL AND CLIMATE DESIGN ADAPTATIONS

8.1: Karst Terrain

Rain tanks are a preferred practice in the active karst regions of the Ridge and Valley province of the Bay watershed, as long as the rooftop surface is not designated as a stormwater hotspot.

8.2: Coastal Plain

Rain tanks work well in the flat terrain, low hydraulic head, and high water table conditions of many coastal plain sites.

8.3: Steep Terrain

Rain tanks are ideal in areas of steep terrain.

8.4: Winter Performance

Rain tanks have a number of components that can be impacted by freezing winter temperatures. Designers should give careful consideration to these conditions, to prevent system damage and costly repairs.

For above-ground systems, wintertime operation may not be possible. These systems must be taken off-line for the winter. At the start of the winter season, above-ground systems should be

Rain Tanks 10 of 18 9/15/08 DRAFT VA DCR STORMWATER DESIGN SPECIFICATION No. 6: RAIN TANKS disconnected and drained. It may be possible to reconnect the former roof leader systems for the winter.

For below-ground and indoor systems, downspouts and overflow components should be checked for ice blockages during snowmelt events.

8.5: Linear Highway Sites

Rain tanks are generally not applicable for linear highway sites.

SECTION 9: TYPICAL GRAHPIC DETAILS

There are six primary components of a stormwater rain tank:

1. Rooftop Surface

2. Collection and Conveyance System (e.g. gutter and downspouts)

3. Pre-screening and First Flush Diverter

4. Storage Tank

5. Distribution System

6. Overflow, Filter Path or Secondary Runoff Reduction Practice

9.1: Rooftop Surface: The rooftop should be made of smooth, non-porous material with efficient drainage either from a sloped roof or an efficient roof drain system. Slow drainage of the roof leads to poor rinsing and a prolonged first flush, which can degrade water quality. If the harvested rainwater will be used for potable uses, or uses with significant human exposure (e.g. pool filling, watering vegetable gardens), care should be taken in the choice of roof materials. Some materials may leach toxic chemicals making the water unsafe for humans. Rainwater can also be harvested from other impervious surfaces, such as parking lots and driveways.

9.2: Collection and Conveyance System

The collection and conveyance system consists of the gutters, downspouts, and pipes that channel stormwater runoff into storage tanks. Gutters and downspouts should be designed as they would for a building without a rainwater harvesting system. Aluminum, round bottom gutters and round downspouts are generally recommended for rainwater harvesting. Gutters should be hung at a minimum 2% slope. Gutters and downspouts should be kept clean and free of debris and rust.

Rain Tanks 11 of 18 9/15/08 DRAFT VA DCR STORMWATER DESIGN SPECIFICATION No. 6: RAIN TANKS

Figure 6 Rain Tank System Detail

9.3: Pre-Screening and First Flush Diverters

Pre-filtration is required to keep sediment, leaves and other debris from the system. Leaf screens and gutter guards are the minimal requirement for pre-filtration. All pre-filtration devices should be low maintenance or maintenance-free.

Before rainwater enters the storage tank, the initial first flush, which carries the majority of leaves, debris and contaminants, must be diverted from the system. Designers should note that the term first flush in rain tank design is not the same term that had been historically used in the design of stormwater treatment practices. In this specification, first flush refers to the first 0.05 inches of rooftop runoff. A variety of first flush diverters are described in Section 7.2. The diverted flows from the first flush must be directed to an acceptable pervious flow path on the property, and preferably the same on-site runoff reduction practice used for disposal of tank overflows and dewatering (e.g., simple disconnection, grass filter or micro-bioretention device). A pre-tank filter is an appropriate option when harvested rainwater is used for potable uses.

9.4: Storage Tanks

The storage tank is the most important and typically the most expensive component of a rainwater harvesting system. Rain tank capacity ranges from 250 to over 10,000 gallons. Typical

Rain Tanks 12 of 18 9/15/08 DRAFT VA DCR STORMWATER DESIGN SPECIFICATION No. 6: RAIN TANKS rain tanks for residential use are 500-1500 gallons. Storage tank volume is calculated to meet the water demand and stormwater detention requirements, as described in Section 6 of this specification.

Aboveground storage tanks should be UV and impact resistant.

Belowground storage tanks must be designed to support the overlying sediment and any other anticipated load (e.g., vehicles, pedestrian traffic).

Belowground rain tanks should have a standard size manhole opening or equivalent to allow access for maintenance purposes. This access point should be secured to prevent unwanted access.

All rain tanks should be sealed using a water safe, non-toxic substance.

Rain tanks may be ordered from a manufacturer or can be constructed on site from a variety of materials. Table 2 compares the advantages and disadvantages of different storage tank materials.

Table 2: Comparison of Rain Tank Materials (Cabell Brand, 2007) Tank Material Advantages Disadvantages Fiberglass Commercially available, alterable and Must be installed on smooth, level footing moveable, little maintenance, light weight Pressure proof for below-ground installation. Polyethylene Commercially available, alterable, UV- degradable; must be painted or tinted. moveable, affordable, available in wide Pressure proof for below ground installation range of sizes, can install above or below ground, little maintenance needed Plastic Barrels Commercially available Low storage capacity (20-50 gallons) Inexpensive Galvanized Commercially available, alterable and Possible external corrosion and rust. Steel moveable, available in a range of sizes, Must be lined for potable use. film develops inside to prevent corrosion Can only install above ground. Steel Drums Commercially available, alterable and Small storage capacity. moveable Prone to corrosion and rust. Verify for toxics prior to reuse. FerroConcrete Durable and immoveable. Potential to crack and leak. Above or belowground installation. Neutralizes acid rain. Cast-in-Place Durable, immoveable, versatile, above or Potential to crack and leak. Concrete below ground installation. Permanent. Decreases rainwater corrosiveness. Neutralizes acid rain. Do not place underground in clay soils. Stone or Durable and immoveable. Difficult to maintain. Concrete Block Keeps water cool in summer months. Expensive to build.

The storage tank should be opaque or otherwise protected from direct sunlight to inhibit algae growth and screened to discourage mosquito breeding and reproduction.

Tanks should be accessible for cleaning, inspection, and maintenance.

Rain Tanks 13 of 18 9/15/08 DRAFT VA DCR STORMWATER DESIGN SPECIFICATION No. 6: RAIN TANKS

Dead storage below the outlet to the distribution system and an air gap at the top of the tank should be added to the total volume. For gravity-fed systems, a minimum of 6 inches of dead storage should be provided. For systems using a pump, the dead storage depth will be based on the pump specifications.

9.5: Distribution Systems

Most distribution systems require a pump to convey harvested rainwater from the storage tank to its final destination, whether it is used inside the building, is directed to the automated irrigation system, or is gradually discharged to an on-site runoff reduction practice following a storm event. The rain tank should be equipped with an appropriately sized pump that produces sufficient pressure for all end-uses. Separate plumbing must be labeled as non-potable if required by local codes.

The typical pump and pressure tank arrangement consists of a multistage centrifugal pump, which draws water out of the storage tank and sends it into the pressure tank, where it is stored for distribution. When water is drawn out of the pressure tank, the pump kicks on and supplies additional water to the distribution system. The backflow preventer is required to separate harvested rainwater from mains.

Distribution lines from the rain tank should be buried beneath the frost line. Lines from the rain tank to the building should have shut-off values that are accessible when snow cover is present.

A drain plug or cleanout sump, also draining to a pervious area, should be installed to allow the system to be completely emptied if needed.

9.6: Overflow, Filter Path and Secondary Runoff Reduction Practice

An overflow system should be included in the rain tank design for when an individual storm exceeds the capacity of the tank or multiple storms that fill the rainwater storage tank occur in succession. Overflow pipes should have a capacity equal to or greater than the inflow pipe(s). The overflow usually consists of corrugated plastic hoses from the top of the rain tank to the pervious area down-gradient from the storage tank.

The filter path is a pervious or grass corridor that extends from the overflow to the next runoff reduction practice, the street, or the storm drain system. The filter path shall be graded to have a slope such that sheet flow conditions are maintained. If compacted or impermeable soils are present along the filter path, compost amendments may be needed (see Design Specification No. 4). It is also recommended that the filter path be used for overflows, first flush diversions, and any tank dewatering discharges.

In many cases, rain tank overflows are directed to a secondary runoff reduction practice to boost overall runoff reduction rates. Designers may wish to consider the following options:

Front yard bioretention area: Design Specification No.9

Rain Tanks 14 of 18 9/15/08 DRAFT VA DCR STORMWATER DESIGN SPECIFICATION No. 6: RAIN TANKS

Grass filter strip: Design Specification No. 2

Micro-bioretention (rain garden): Design Specification No. 9

Micro-infiltration: Design Specification No. 8

Grass channel: Design Specification No. 3

Dry swale: Design Specification No. 10

The development intensity often dictates the capacity of the rain tank relative to the capacity of the secondary runoff reduction practices. At higher density sites, more capacity is needed in the rain tank for stormwater storage and release, since there may not be enough space available to install the secondary runoff reduction practices. By contrast, in low-density sites, runoff storage and release can be maximized within the secondary runoff reduction practices, such that the rain tank is primarily sized for internal and outdoor water demand only.

SECTION 10: MATERIAL SPECIFICATIONS

The basic material specifications for rain tanks are presented in Table 4. Designers should consult with experienced rain tank and irrigation installers on the choice of recommended manufacturers of prefabricated tanks and other system components.

(Note: DCr is considering whether it be useful to add a table of contact information for rain tank installers .)

Table 4: Design Specifications for Rain Tanks Item Specification Materials commonly used for gutters and downspouts include polyvinylchloride (PVC) pipe, vinyl, aluminum and galvanized steel. Lead should not be used as a Gutters gutter and downspout solder, since rainwater can dissolve the lead and and contaminate the water supply. Downspou . The length of gutters and downspouts is determined by the size and layout of t the catchment and the location of the storage tanks. . Be sure to include necessary bends and tees. At least one of the following, with one device per inlet to the collection system: . First flush diverter Pre- . Roof washer Treatment . Leaf and mosquito screen (1 mm mesh size)

Rain Tanks 15 of 18 9/15/08 DRAFT VA DCR STORMWATER DESIGN SPECIFICATION No. 6: RAIN TANKS

. Materials used to construct storage tanks should be structurally sound. . Tanks should be constructed in areas of the site where native soils can support the load associated with stored water. . Storage tanks should be water tight and sealed using a water safe, non-toxic Storage substance. Tanks . Tanks should be opaque to prevent the growth of algae. . Re-used tanks should be fit for potable water or food-grade products. . Underground rain tanks should have a minimum of 1 meter of soil cover. . The size of the rain tank(s) is determined during the design calculations. Note: This table does not address indoor systems or pumps.

SECTION 11: CONSTRUCTION SEQUENCE

11.1: Construction Sequence

It is advisable to have a single contractor to install the rain tank, outdoor irrigation system and secondary runoff reduction practices. The contractor should be familiar with rain tank sizing, installation, and placement. A licensed plumber is required to install the rain tank components to the plumbing system

The following is a typical construction sequence to properly install a rain tank, which can be modified to reflect different rain tank applications or expected site conditions.

Choose the tank location on the site

Properly install the tank

Install the pump (if needed) and piping to end-uses (indoor, outdoor irrigation, or tank dewatering release)

Route all downspouts or roof drains to pre-screening devices and first flush diverters

Route all pipes to the tank

Stormwater should not be diverted to the rain tank until the overflow filter path has been vegetatively stabilized

11.2: Construction Inspection The following items should be inspected prior to final sign-off and acceptance of a rain tank:

Rooftop area matches plans

Diversion system is properly sized and installed

Pretreatment system is installed

Rain Tanks 16 of 18 9/15/08 DRAFT VA DCR STORMWATER DESIGN SPECIFICATION No. 6: RAIN TANKS

Mosquito screens are installed on all openings

Overflow device is directed as shown on plans

Rain tank foundation is constructed as shown on plans

Catchment area and overflow area are stabilized

SECTION 12: OPERATION AND MAINTENANCE

12.1: Maintenance Agreements

All rain tanks must be covered by a drainage easement to allow inspection and maintenance. The easement should include the tank, the filter path, and any secondary runoff reduction practice. If the tank is located in a residential private lot, its existence and purpose shall be noted on the deed of record. Homeowners will need to be provided a simple document that explains the purpose of the rain tank and routine maintenance needs. Legally binding maintenance agreements should specify the property owner’s primary maintenance responsibility, require homeowners to pay to have their system inspected by a qualified third party inspector, and authorize local agencies to access the property for inspection or corrective action in the event this is not done.

12.2: Maintenance Inspections

The property owner should inspect all rain tank components in the spring and fall of each year. A comprehensive inspection by a qualified third party inspector should occur every third year.

12.3: Rain Tank Maintenance Schedule

Maintenance requirements for rain tanks vary according to use. Systems that are used to provide supplemental irrigation water have relatively low maintenance requirements, while systems designed for indoor uses have much higher maintenance requirements. Table 5 describes routine maintenance tasks to keep rain tanks in working condition.

Table 5: Suggested Maintenance Tasks for Rain Tanks Activity Frequency Keep gutters and downspouts free of leaves and other debris. O: Twice a year Inspect and clean pre-screening devices and first flush diverters. O: Twice a year Inspect and clean storage tank lids, paying special attention to O: Once a year vents and screens on inflow and outflow spigots. Check mosquito screens and patch holes or gaps immediately. Inspect condition of overflow pipes, overflow filter path, and/or O: Once a year secondary runoff reduction practices. Inspect tank for sediment buildup. I: Every third year Clear overhanging vegetation and trees over roof surface. I: Every third year Check integrity of backflow preventor. I: Every third year

Rain Tanks 17 of 18 9/15/08 DRAFT VA DCR STORMWATER DESIGN SPECIFICATION No. 6: RAIN TANKS

Inspect structural integrity of tank, pump, pipe and electrical I: Every third year system. Replace damaged or defective system components. I: Every third year O = Owner I = qualified third party inspector

13: REFERENCES

Cabell Brand Center. 2007. Virginia Rainwater Harvesting Manual. Salem, VA. http://www.cabellbrandcenter.org

Center for Watershed Protection (CWP). 2007. Urban Stormwater Retrofit Practices. Manual 3 in the Urban Subwatershed Restoration Manual Series. Ellicott City, MD.

City of Portland, Environmental Services. 2004. Portland Stormwater Management Manual. Portland, OR. http://www.portlandonline.com/bes/index.cfm?c=dfbcc

City of Tucson, AZ. 2005. Water Harvesting Guidance Manual. City of Tucson, AZ. Tucson, AZ.

Coombes, P. 2004. Water Sensitive Design in the Sydney Region. Practice Note 4: Rainwater Tanks. Published by the Water Sensitive Design in the Sydney Region Project. http://www.wsud.org/planning.htm

Credit Valley Conservation. 2008. Credit River Stormwater Management Manual. Mississauga, Ontario

Gowland, D. and T. Younos. 2008. Feasibility of Rainwater Harvesting BMP for Stormwater Management. Virginia Water Resources Research Center. Special Report SR38-2008. Blacksburg, VA

Northern Virginia Regional Commission. 2007. Low Impact Development Supplement to the Northern Virginia BMP Handbook. Fairfax, Virginia

Schueler, T., D. Hirschman, M. Novotney and J. Zielinski. 2007. Urban stormwater retrofit practices. Manual 3 in the Urban Subwatershed Restoration Manual Series. Center for Watershed Protection, Ellicott City, MD

Schueler, T. 2008. Technical Support for the Baywide Runoff Reduction Method. Chesapeake Stormwater Network. Baltimore, MD www.chesapeakestormwater.net

Rain Tanks 18 of 18 9/15/08