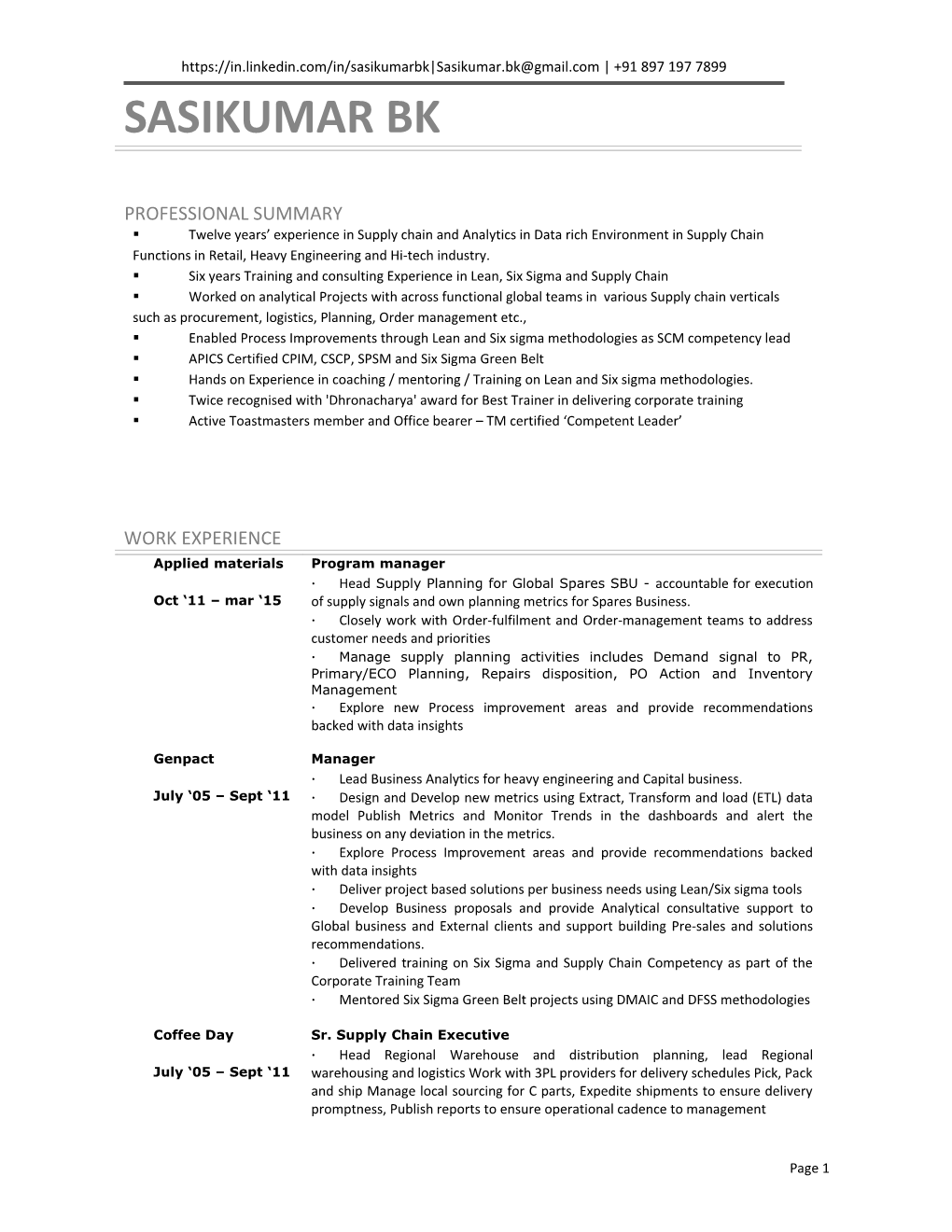

https://in.linkedin.com/in/sasikumarbk|[email protected] | +91 897 197 7899 SASIKUMAR BK

PROFESSIONAL SUMMARY . Twelve years’ experience in Supply chain and Analytics in Data rich Environment in Supply Chain Functions in Retail, Heavy Engineering and Hi-tech industry. . Six years Training and consulting Experience in Lean, Six Sigma and Supply Chain . Worked on analytical Projects with across functional global teams in various Supply chain verticals such as procurement, logistics, Planning, Order management etc., . Enabled Process Improvements through Lean and Six sigma methodologies as SCM competency lead . APICS Certified CPIM, CSCP, SPSM and Six Sigma Green Belt . Hands on Experience in coaching / mentoring / Training on Lean and Six sigma methodologies. . Twice recognised with 'Dhronacharya' award for Best Trainer in delivering corporate training . Active Toastmasters member and Office bearer – TM certified ‘Competent Leader’

WORK EXPERIENCE Applied materials Program manager · Head Supply Planning for Global Spares SBU - accountable for execution Oct ‘11 – mar ‘15 of supply signals and own planning metrics for Spares Business. · Closely work with Order-fulfilment and Order-management teams to address customer needs and priorities · Manage supply planning activities includes Demand signal to PR, Primary/ECO Planning, Repairs disposition, PO Action and Inventory Management · Explore new Process improvement areas and provide recommendations backed with data insights

Genpact Manager · Lead Business Analytics for heavy engineering and Capital business. July ‘05 – Sept ‘11 · Design and Develop new metrics using Extract, Transform and load (ETL) data model Publish Metrics and Monitor Trends in the dashboards and alert the business on any deviation in the metrics. · Explore Process Improvement areas and provide recommendations backed with data insights · Deliver project based solutions per business needs using Lean/Six sigma tools · Develop Business proposals and provide Analytical consultative support to Global business and External clients and support building Pre-sales and solutions recommendations. · Delivered training on Six Sigma and Supply Chain Competency as part of the Corporate Training Team · Mentored Six Sigma Green Belt projects using DMAIC and DFSS methodologies

Coffee Day Sr. Supply Chain Executive · Head Regional Warehouse and distribution planning, lead Regional July ‘05 – Sept ‘11 warehousing and logistics Work with 3PL providers for delivery schedules Pick, Pack and ship Manage local sourcing for C parts, Expedite shipments to ensure delivery promptness, Publish reports to ensure operational cadence to management

Page 1 https://in.linkedin.com/in/sasikumarbk|[email protected] | +91 897 197 7899 TRAINING EXPERIENCE White Belt Corporate Training, Applied materials June, 2014 White Belt Corporate Training, Applied materials February, 2014 Basic Supply Chain Corporate Trainer, Applied materials October, 2013 Lean Concepts Corporate Trainer, Genpact August, 2007 Supply chain Concepts Corporate Trainer, Genpact June, 2007 Basic Statistics Corporate Trainer, Genpact April, 2007

CONSULTING PROJECTS Project type – Surplus inventory Reduction, Applied materials, Analytics, Availability of surplus inventory in the network has a negative impact on the Material operational, availability and inventory turns. This project is aimed to efficiently redistribute the October 2014 surplus inventory at the consignment locations and driving a positive cost impact to the company. The focus of this project is to provide the short term impact on Surplus inventory burn down of 2.5 million USD, and setting up robust process for effective utilisation of inventory in long term. Project type – BI Engg Change Order Process workflow, Applied Materials June 2013 The Business was using multiple spreadsheets and emails to communicate and share information across functions for part qualification process. No standard metrics / tracking for the management to measure the process performance and was resulting in customer service issues. End to End Process mapping is done and Implemented SharePoint workflow solution, which resulted in increased speed of implementation from 90 days to 40 days and provided management to track the status of a part and a baseline metric for process improvements. Project type – Six Engine Assembly cycle time Reduction, GE Aviation sigma, BI Capturing High level Business Pain Areas and Functional Requirements for higher June 2008 Engine Assembly Cycle Times. Developed a Graphical User Interface (GUI) in MS Access so users can drill down cycle times for sub-assemblies and components so the management can narrow down to specific problem parts, this gave visibility for the team to identify and fix engineering issues and as a result of which cycle times reduced from 21 to 16 days.

EDUCATION MBA (Operations) Indian Institute of Science, Bangalore 2003 BE (Mechanical Engineering) College Of Engineering, Anna University, Chennai 2000

PROFESSIONAL CERTIFICATIONS CSCP – Certified Supply Chain APICS 2009 Professional CPIM - Certification in Inventory APICS 2008 Management

Page 2 https://in.linkedin.com/in/sasikumarbk|[email protected] | +91 897 197 7899 SPSM - Senior Professional in Next Level Purchasing 2008 Supply Management GB – Six Sigma Green Belt Genpact / GE 2007 CL – Competent Leader Toastmasters 2015

TOOLS Business Support Applications MS Office Suite applications Business Intelligence and Data Analysis MS Access, SQL, Minitab, R Project Management MS Visio, MS Project

PERSONAL Description September 26, 1977 Language Telugu, Tamil, Hindi, English Passport / Visa B1 – US multiple Entry Hobbies / Interests Teaching, Training

TRAINING OFFERINGS OVERVIEW

SIX SIMGA TRAININGS

WHITEBELT Description - Lean principles & Lean Tools, Value Stream mapping Duration - 8 hours

Page 3 https://in.linkedin.com/in/sasikumarbk|[email protected] | +91 897 197 7899

Mode - Classroom Batch size - 12 – 40

Target Audience - Business Analysts, Shop floor executives,

YELLOWBELT Description - 8D methodology Duration - 16 hours Mode - Classroom Batch size - 8 – 20 Prerequisite - Lean principles

Target Audience - Business Analysts, Shop floor executives, Process leads

GREENBELT Description - DMAIC methodology Duration - 40 hours Mode - Classroom Batch size - 8 – 16

Prerequisite - Basic Statistics, Basic Excel, Minitab (desired)

Target audience - Sr. Business Analysts and Executives, Process Experts, Aspiring Quality leads

SUPPLY CHAIN TRANINGS

Basic Supply Chain Management Description - Supply Chain fundamentals Duration - 16 hours Mode - Classroom

Page 4 https://in.linkedin.com/in/sasikumarbk|[email protected] | +91 897 197 7899

Batch size - 12 – 30

Target Audience - Business Analysts, Shop floor executives,

Advanced Supply Chain Management

Description - Overview of Supply Chain Management Building Competitive Operations, Planning, and Logistics Supplier Relationship Management, Customer Relationship Management Information Technology in Supply Chain Duration - 32 hours Mode - Classroom Batch size - 8 – 20 Prerequisite - Basic Supply Chain

Target Audience - Business Analysts, Shop floor executives, Process leads

Page 5