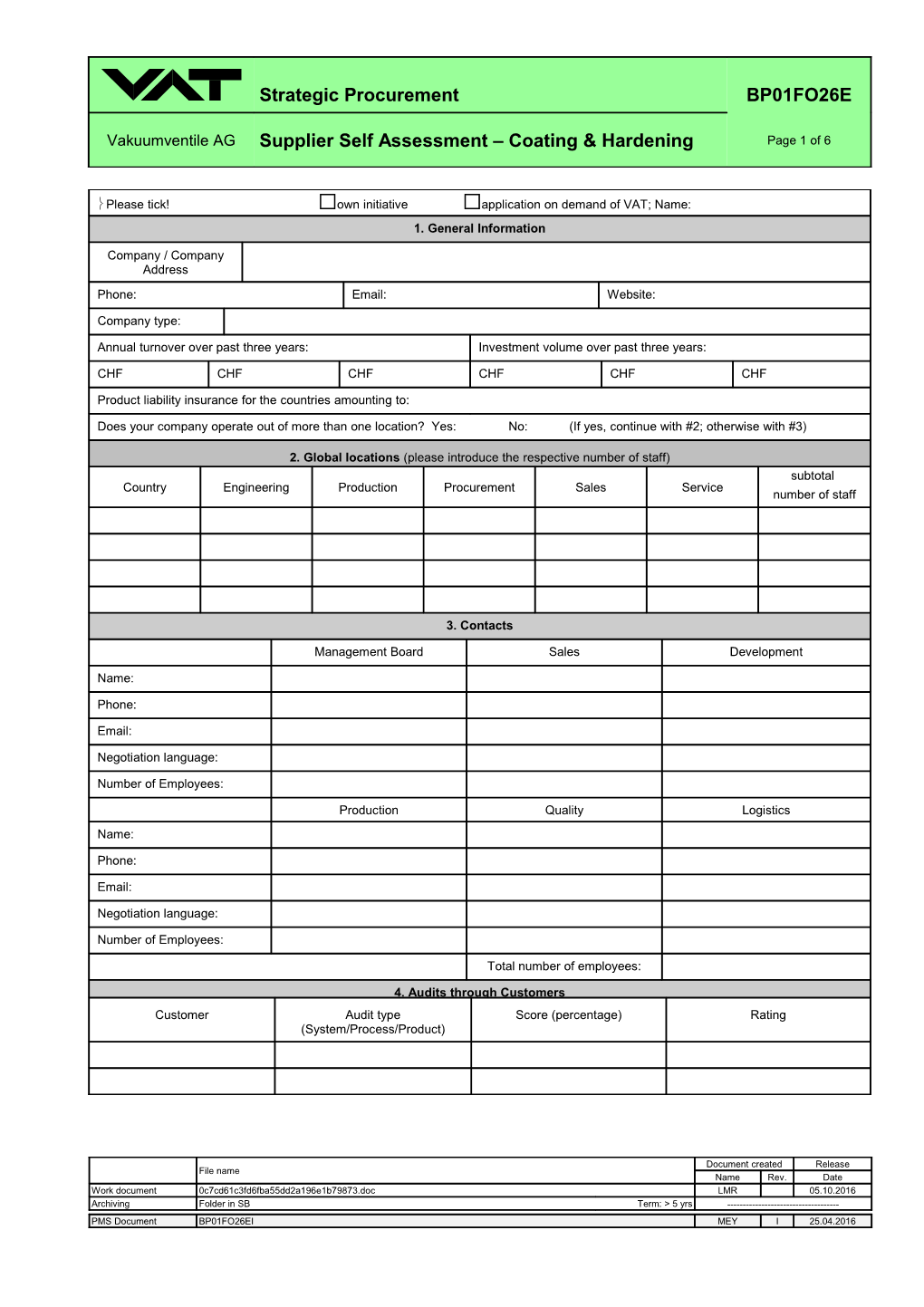

Strategic Procurement BP01FO26E

Vakuumventile AG Supplier Self Assessment – Coating & Hardening Page 1 of 6

Please tick! own initiative application on demand of VAT; Name: 1. General Information

Company / Company Address

Phone: Email: Website:

Company type:

Annual turnover over past three years: Investment volume over past three years:

CHF CHF CHF CHF CHF CHF

Product liability insurance for the countries amounting to:

Does your company operate out of more than one location? Yes: No: (If yes, continue with #2; otherwise with #3)

2. Global locations (please introduce the respective number of staff) subtotal Country Engineering Production Procurement Sales Service number of staff

3. Contacts

Management Board Sales Development

Name:

Phone:

Email:

Negotiation language:

Number of Employees:

Production Quality Logistics Name:

Phone:

Email:

Negotiation language:

Number of Employees:

Total number of employees:

4. Audits through Customers Customer Audit type Score (percentage) Rating (System/Process/Product)

Document created Release File name Name Rev. Date Work document 0c7cd61c3fd6fba55dd2a196e1b79873.doc LMR 05.10.2016 Archiving Folder in SB Term: > 5 yrs ------PMS Document BP01FO26EI MEY I 25.04.2016 Strategic Procurement BP01FO26E

Vakuumventile AG Supplier Self Assessment – Coating & Hardening Page 2 of 6

5. Capabilities

5.1 What are your core competencies?

5.2 How do you evaluate and rate corporate operational risks (e.g. production equipment failure through natural disaster, fire etc.)?

5.3 How does your company evaluate and rate corporate organisational risks (e.g. shortage or inadequate distribution of staff, unavailability of specific skills, process disruptions due to organizational deficiencies)?

5.4 How does your company evaluate and rate corporate financial risks?

5.5 How does your company evaluate and rate supply risks / supply bottleneck risk towards your customers (including geopolitical risks)?

5.6 What actions are in place to minimize the above-mentioned risks?

5.7 Electro-plating l l l

t

g e g g g e e e m h g r k n n n n k k k i i i i u g n u c t i t t i i t c c c t r i i i p a a a a a g

l l m a b n n n v l h

n

– k b i p o m i

p p s s c r – c s

i o h i

s d s d s s t s h r l s n

s d e i o m e c e a h t o l l

a e e e n u h l t

a Others: P o o v C r s d l G l n r r o r P a i u a t t l r p a t a

c c e p B r m l c

G e H e r e l l u e P l l v e E E l A i v E s l l i S n e r S k o r e i c v e s i l r i v n l s i e s p s i

5.8 Conversion layersd I &

g D g g

s n n n – n n h i i i – k s t o o

i z i i z z s c i e E l i t i g t i g l t w e d r a d d F a n a

n i t i v o o o o l i r n n T e g l a t n i n n g a o g s n P o l Others: i

d m a a e l e A e a c . o

r r ( d a e E S h ) l d d p p C t r a e r r i d P e a m a m S t e w i I r a H H o l w o

c

5.8.1 According to which specifications A F

D H G k 6

5 c 7 2 9 1 i 2 t 5 6 8 7

6 3 4 4 4 e 8 6 2 - 2 2 s

- a A S S A S -

e Others: - l L M M M I L P I A A A M M

Document created Release File name Name Rev. Date Work document 0c7cd61c3fd6fba55dd2a196e1b79873.doc LMR 05.10.2016 Archiving Folder in SB Term: > 5 yrs ------PMS Document BP01FO26EI MEY I 25.04.2016 Strategic Procurement BP01FO26E

Vakuumventile AG Supplier Self Assessment – Coating & Hardening Page 3 of 6

5.9 Process/Technology

Please tick Tampon Rack Drum Others:

5.10 Coating

Powder Lubricant Other Cathode dip Please tick coating varnish varnishes coating Others:

5.11 Heat treatment

5.11.1 Thermic processes

Quenching and Please tick Annealing Hardening Tempering tempering Others:

5.11.2 Thermo-chemical processes

Case Nitriding and Please tick Nitro carbonizing Carbo nitriding hardening Oxidizing Others:

5.12 Pretreatment / After treatment

Selective coating / Please tick Etching Cleaning masking Others:

5.13 Metrology t s s s y s e k e t e

s l i t c s c c i

i n s h v a r e t n i r t y t k

t e n a o g c a m c c l e t n i r r h t n e s i u o d l h p e g e r t a d e s r C h u m i a t t e n Others: t l o T d l s a D o H P a A R o c S C

Document created Release File name Name Rev. Date Work document 0c7cd61c3fd6fba55dd2a196e1b79873.doc LMR 05.10.2016 Archiving Folder in SB Term: > 5 yrs ------PMS Document BP01FO26EI MEY I 25.04.2016 Strategic Procurement BP01FO26E

Vakuumventile AG Supplier Self Assessment – Coating & Hardening Page 4 of 6

6. Quality and Environmental Management

6.1 Does your company have a quality and environmental management system? Yes No

If yes, which ones: r k e c X

X i h t X t X X X 0 e 0 O X 2 X s 2 : 0 : 0 a 1 2 9 e 2 : l 0 : 4 1 0 1 P 9 0

8 0 6

0 1 0 1

4

9

1 S

S

A O T

/ O S S I S O I H S I O

If not

Do you plan any certification? Yes, Which one(s): No When:

Are all processes that are pertinent to Yes, Which one(s): No your customers described and implemented throughout your company?

6.2 Have you installed a Continuous Improvement Process (CIP)? Yes No

6.3 Do you apply statistical process control (SPC) in your production? Yes No

6.4 Do you perform process FMEA? Yes No

6.5 Have you defined and implemented a process to manage and control faulty/non-conform products? Yes No

6.6 Do you calibrate your test equipment and do you monitor this regularly? Yes No

6.7 Can you perform initial sample inspections (FAIs)? Yes No

6.8 Do you record and archive test results (if and when required) to ensure evidentiary documentation? Yes No

6.9 Do you mark faulty/non-conform parts and control them as required, e.g., through separate storage? Yes No 7. Procurement / Logistics

7.1 Do you select your suppliers based on clearly defined processes and transparent criteria? Yes No

7.2 Do you include quality and environmental management requirements in your orders to your suppliers? Yes No

7.3 Do you do initial calculation for country of origin for your goods? Yes No

7.4 Do you deliver goods with confirmation of preferential origin? Yes No

7.5 How do you confirm preferential origin of goods? Declaration country of origin (COO) directly on the invoice as “Authorized exporter” with Yes No unlimited value Declaration of country of origin directly on the invoice with limited value as “not authorized Yes No exporter” Movement certificate (EUR1) Yes No Any other certification to declare country of origin such as (form A, ATR …) Yes No

7.6 Do you apply logistics concepts such as Kanban, JIT, or such when working with your customers and/or Yes No suppliers?

Document created Release File name Name Rev. Date Work document 0c7cd61c3fd6fba55dd2a196e1b79873.doc LMR 05.10.2016 Archiving Folder in SB Term: > 5 yrs ------PMS Document BP01FO26EI MEY I 25.04.2016 Strategic Procurement BP01FO26E

Vakuumventile AG Supplier Self Assessment – Coating & Hardening Page 5 of 6

7.7 Do you have special work instructions for handling delicate products? Yes No

7.8 Do you measure, evaluate and communicate supplier performance (delivery On Time/In Full (OTIF), Yes No Supplier Score Card)?

8. Production Processes

8.1 Are production processes monitored and continuously improved in a suitable manner? Yes No

8.2 Are identified deviations and customer complaints analyzed, and are corrective measures defined and Yes No implemented?

8.3 Are production processes / technologies subject to capability checks and qualification? Yes No

8.4 Have you implemented processes for the marking and traceability of your products? Yes No

8.5 Are you processing carbon steel and/or nonferrous metal, particularly copper or copper alloys? Yes No

8.6 Are you processing different materials with same tools and/or machines? Yes No

8.7 Are there actions in place to avoid any cross-contamination (even particles e.g. with tools or liquid media) Yes No by carbon steel and/or nonferrous material?

8.8 Are all required tests, checks and inspections planned and performed (incoming goods, production, Yes No shipping)?

8.9 Do you perform first article/last article tests as well as tests during the production process? Yes No

8.10 Have you installed preventive maintenance for your equipment, machines and plants? Yes No 9. Engineering

9.1 Number of engineers: employees

9.2 Which CAD system do you use? Type: Version:

9.3 What data export format(s) do you use? (Preferred = STEP; Parasolid):

9.4 Do you have in-house development activities/facilities? Yes No

9.5 Do you build your production devices/equipment in-house? Yes No 9.6 What infrastructure is available at your site? Please tick.

Endurance test station Leakage tests Material tests pneumatics/vacuum Welding seem inspection Other:

Date: Author:

Please return the duly completed questionnaire by email to: [email protected]

Document created Release File name Name Rev. Date Work document 0c7cd61c3fd6fba55dd2a196e1b79873.doc LMR 05.10.2016 Archiving Folder in SB Term: > 5 yrs ------PMS Document BP01FO26EI MEY I 25.04.2016 Strategic Procurement BP01FO26E

Vakuumventile AG Supplier Self Assessment – Coating & Hardening Page 6 of 6

This field is completed by VAT

Rating

Suitable Conditionally Suited Not Suitable Date/Signature

Category Management

SQE

Process specialist

Optional

Remarks:

Document created Release File name Name Rev. Date Work document 0c7cd61c3fd6fba55dd2a196e1b79873.doc LMR 05.10.2016 Archiving Folder in SB Term: > 5 yrs ------PMS Document BP01FO26EI MEY I 25.04.2016