DOOR WEDGE TOOL INSTRUCTIONS (MT-114390-8 & MT-114390-9)

NOTE: FOR USE BY ELEVATOR INSPECTORS AND TRAINED ELEVATOR MAINTENANCE AND REPAIR PERSONNEL ONLY.

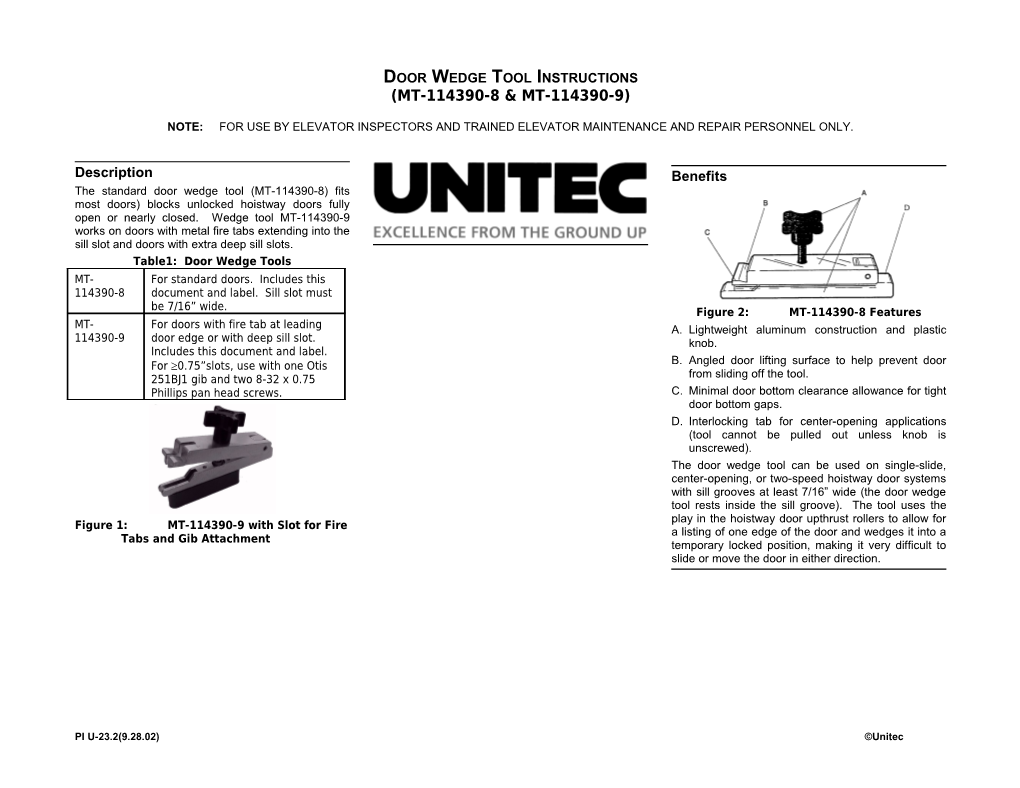

Description Benefits The standard door wedge tool (MT-114390-8) fits most doors) blocks unlocked hoistway doors fully open or nearly closed. Wedge tool MT-114390-9 works on doors with metal fire tabs extending into the sill slot and doors with extra deep sill slots. Table1: Door Wedge Tools MT- For standard doors. Includes this 114390-8 document and label. Sill slot must be 7/16” wide. Figure 2: MT-114390-8 Features MT- For doors with fire tab at leading A. Lightweight aluminum construction and plastic 114390-9 door edge or with deep sill slot. knob. Includes this document and label. B. Angled door lifting surface to help prevent door For 0.75”slots, use with one Otis from sliding off the tool. 251BJ1 gib and two 8-32 x 0.75 Phillips pan head screws. C. Minimal door bottom clearance allowance for tight door bottom gaps. D. Interlocking tab for center-opening applications (tool cannot be pulled out unless knob is unscrewed). The door wedge tool can be used on single-slide, center-opening, or two-speed hoistway door systems with sill grooves at least 7/16” wide (the door wedge tool rests inside the sill groove). The tool uses the play in the hoistway door upthrust rollers to allow for Figure 1: MT-114390-9 with Slot for Fire a listing of one edge of the door and wedges it into a Tabs and Gib Attachment temporary locked position, making it very difficult to slide or move the door in either direction.

PI U-23.2(9.28.02) ©Unitec Instructions WARNING: This tool may wear or become damaged. Inspect your door wedge tool before and after each use and replace it if it is worn, bent, or damaged. These instructions apply to both door wedge tools. Select the procedure that matches your application. Before using, apply caution label to tool.

Inspect Tool for Damage Prior to Each Use. CAUTION Confirm Door Security when Using.

1. Door Wedge Tool Between Doors or At Door’s Leading Edge (Single-Slide, Two-Speed, Center-Opening Doors) Refer to Figures 3 and 4. 1. Slip tool into sill. 2. Slide tool's lifting surface under door gap at bottom edge of door. 3. Position door(s) as desired. 4. Center-Opening Doors: To keep doors nearly closed, slide tab on opposite end of tool underneath opposite door bottom. This prevents tool from accidentally dislodging or being easily removed. 5. Turn jack knob to lift door. Number of knob turns required to obtain desired wedge force will become obvious once done a few times. 6. Test door security by attempting to slide door.

PI U-23.2(9.28.02) ©Unitec

Figure 3: Single-Slide and 2-Speed Door Figure 4: Center-Opening Doors Figure 5: Door Trailing Edge Wedge Application Application Application

2. Door Wedge Tool at Door’s Reduce potential for thrown or kicked 1. With doors in desired position, slip door wedge Trailing Edge objects into opening from hall. tool into sill at trailing edge. (Single-Slide, Two-Speed, Center-Opening Doors) NOTE: Deep hoistway pits or other restrictions may 2. Slide angled lifting surface underneath door gap Refer to Figure 5. prevent you from easily holding the door(s) at bottom trailing door edge. Use this process to block hoistway doors when in place while the door wedge tool is applied 3. Turn jack knob to lift the door. Number of knob working in hoistway pit) or on car top to keep to the trailing edge of the door. Before turns required to obtain desired wedge force will hoistway doors unlocked but nearly closed. entering the hoistway pit or car top, it may become obvious once done a few times. be necessary to use a narrow temporary Additional reasons for this procedure: 4. Test door security by attempting to slide the block (of desired width). Do so at the door. Wind causing safety problems with blown junction of the sill and strike jamb (for S/S or dust and debris. 2-Spd) or at the center of the span (for C/O). 5. If necessary, remove temporary block from Inhibit public access through opening Upon entry into the hoistway or onto the leading edge to prevent it from being between hoistway door panels vs. if doors were hoistway pit ladder, allow the doors to close accidentally kicked or dislodged in hoistway. blocked at leading edge. onto this block. PI U-23.2(9.28.02) ©Unitec