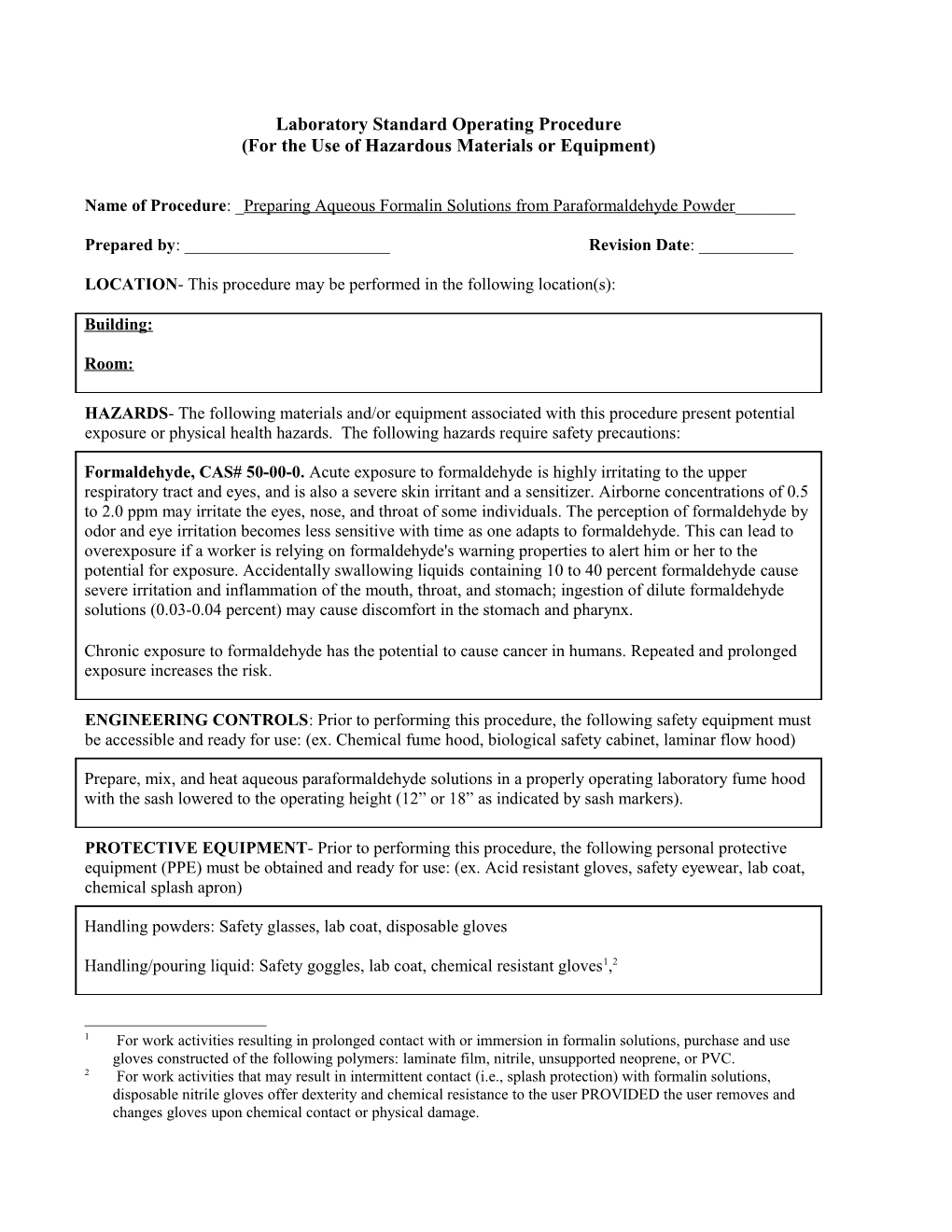

Laboratory Standard Operating Procedure (For the Use of Hazardous Materials or Equipment)

Name of Procedure: _Preparing Aqueous Formalin Solutions from Paraformaldehyde Powder______

Prepared by: ______Revision Date: ______

LOCATION- This procedure may be performed in the following location(s):

Building:

Room:

HAZARDS- The following materials and/or equipment associated with this procedure present potential exposure or physical health hazards. The following hazards require safety precautions:

Formaldehyde, CAS# 50-00-0. Acute exposure to formaldehyde is highly irritating to the upper respiratory tract and eyes, and is also a severe skin irritant and a sensitizer. Airborne concentrations of 0.5 to 2.0 ppm may irritate the eyes, nose, and throat of some individuals. The perception of formaldehyde by odor and eye irritation becomes less sensitive with time as one adapts to formaldehyde. This can lead to overexposure if a worker is relying on formaldehyde's warning properties to alert him or her to the potential for exposure. Accidentally swallowing liquids containing 10 to 40 percent formaldehyde cause severe irritation and inflammation of the mouth, throat, and stomach; ingestion of dilute formaldehyde solutions (0.03-0.04 percent) may cause discomfort in the stomach and pharynx.

Chronic exposure to formaldehyde has the potential to cause cancer in humans. Repeated and prolonged exposure increases the risk.

ENGINEERING CONTROLS: Prior to performing this procedure, the following safety equipment must be accessible and ready for use: (ex. Chemical fume hood, biological safety cabinet, laminar flow hood)

Prepare, mix, and heat aqueous paraformaldehyde solutions in a properly operating laboratory fume hood with the sash lowered to the operating height (12” or 18” as indicated by sash markers).

PROTECTIVE EQUIPMENT- Prior to performing this procedure, the following personal protective equipment (PPE) must be obtained and ready for use: (ex. Acid resistant gloves, safety eyewear, lab coat, chemical splash apron)

Handling powders: Safety glasses, lab coat, disposable gloves

Handling/pouring liquid: Safety goggles, lab coat, chemical resistant gloves1,2

1 For work activities resulting in prolonged contact with or immersion in formalin solutions, purchase and use gloves constructed of the following polymers: laminate film, nitrile, unsupported neoprene, or PVC. 2 For work activities that may result in intermittent contact (i.e., splash protection) with formalin solutions, disposable nitrile gloves offer dexterity and chemical resistance to the user PROVIDED the user removes and changes gloves upon chemical contact or physical damage. WASTE DISPOSAL- This procedure will result in the following regulated waste, which must be disposed of in compliance with the REHS Hazardous Waste Policy:

Follow university requirements for waste disposal in satellite accumulation areas.

ACCIDENTAL SPILL- In the event of a leaking container and/or spill, follow these procedures:

Transfer the contents from a leaking container to an undamaged container in a laboratory fume hood. Apply absorbent materials to pick up small spills, place the waste into properly labeled containers within secondary containment areas, and request waste pick up consistent with the university policy.

PRIOR APPROVAL- This procedure is considered hazardous enough to warrant prior approval from the PI or department safety coordinator: NO

WORK PROCEDURES – Attach a copy of the work procedures used to complete the procedure identified in this document, or describe (outline) the steps below.