4 START POINT- FASHIONING CATAPULT FRAME SIDES

Safety glasses required Gloves required

Obtain two pieces of 3 x 4 ½ inch sheet metal. Using a ruler and a square, draw a line across the piece 4 inches from one end, so that the material will be 3 x 4 inches when cut.

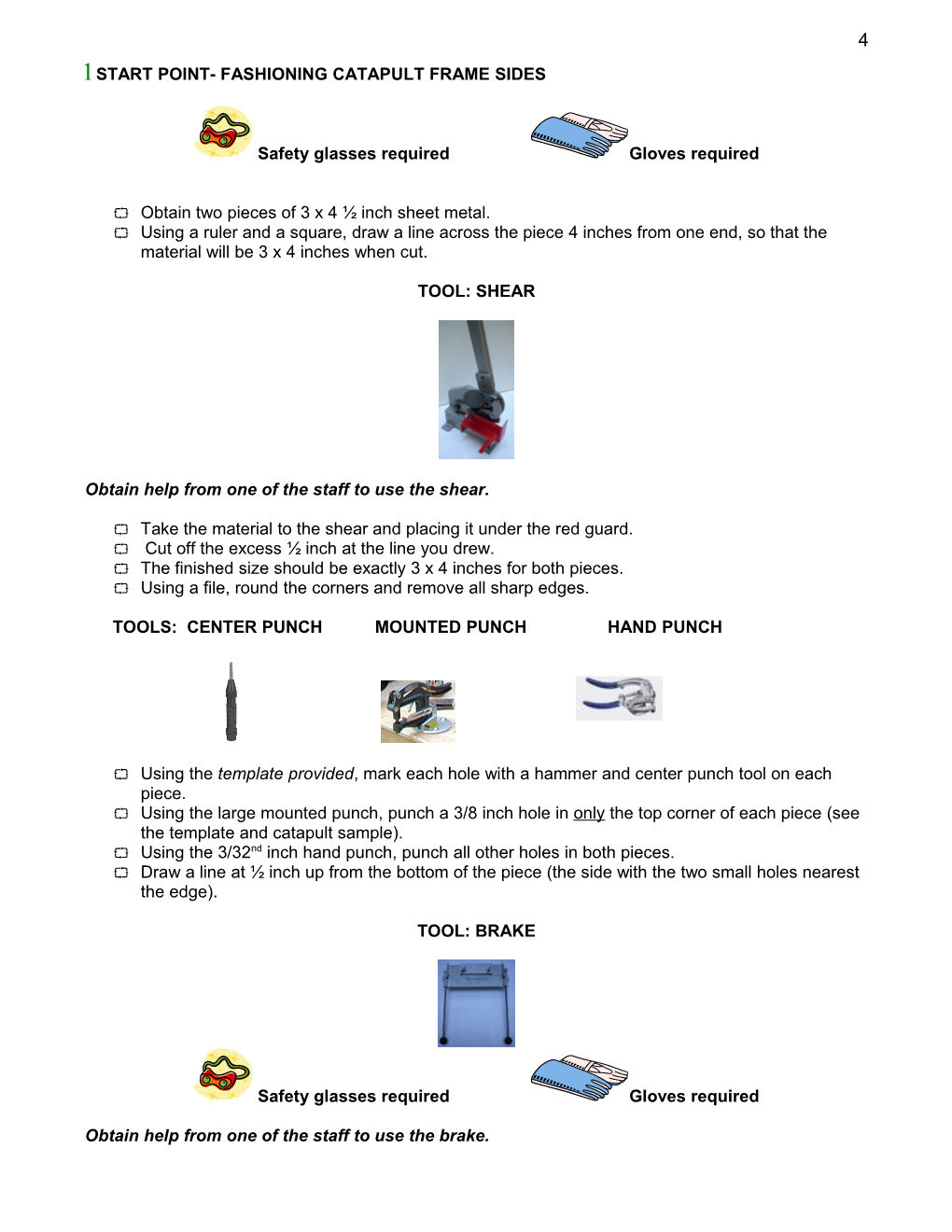

TOOL: SHEAR

Obtain help from one of the staff to use the shear.

Take the material to the shear and placing it under the red guard. Cut off the excess ½ inch at the line you drew. The finished size should be exactly 3 x 4 inches for both pieces. Using a file, round the corners and remove all sharp edges.

TOOLS: CENTER PUNCH MOUNTED PUNCH HAND PUNCH

Using the template provided, mark each hole with a hammer and center punch tool on each piece. Using the large mounted punch, punch a 3/8 inch hole in only the top corner of each piece (see the template and catapult sample). Using the 3/32nd inch hand punch, punch all other holes in both pieces. Draw a line at ½ inch up from the bottom of the piece (the side with the two small holes nearest the edge).

TOOL: BRAKE

Safety glasses required Gloves required

Obtain help from one of the staff to use the brake. 5 Take the pieces to the table mounted brake (bender) Attach one piece under the holding plate so that the line is just visible in front of the plate. Bend the small tab up 90 degrees

Obtain help from staff to avoid bending both pieces the same way.

To have a right and left side, turn over the other piece to bend in the opposite direction and bend as before.

. Obtain two graphite bearings. Using the arbor rotate its base plate to align the small slot under the press rodd. Press, press in the graphite bearings into the large hole in each frame side’s upper corner, making sure that you press the bearings out toward the tab of each side piece.

START POINT – TRIGGER

Safety glasses required Gloves required

Obtain flat strapping material. With a tin snip, cut a 5 1/2 inch piece of flat strapping material. With a file, remove all sharp edges. Using the mounted trigger-bending vise, form the piece like the trigger on the catapult example. Create an attach hole by punching a 5/32 inch hole with the small hand punch Use the ¼ inch large hand punch (not the table mounted punch) to create the nylon screw hole. Obtain shrink tubing for the trigger and slip it over the curved trigger. Use the heat gun to shrink the tubing onto the trigger Obtain a nylon screw and nut Attach the nylon screw and nut in the hole (observe the example)

START POINT – SPRING WIRE

Obtain help from one of the staff to avoid incorrectly bending the wire.

Safety glasses required

Obtain one of the 12 inch pieces of spring wire from the materials table. With the spring bender tool form a U bend on one end only to match the example wire. Observe the example catapult and insert the other end of the spring wire into the catapult arm spring hole from the cup side. Bend the last ½ inch over 90 degrees to exactly match the catapult example. 6

FINAL ASSEMBLY

Safety glasses required Gloves required

(Gloves until sharp edges are all removed).

START POINT – WOOD BASE

Obtain a wood base. Using a rasp and sanding block, remove all sharp edges. Observe the example catapult for placement of catapult components. Place the axle shaft into the side plates through the bearings. Center the side plates on the wood base near one end with the side plates as close to parallel as possible. Measure 1 3/8 inch from the long side. Use the square to draw a straight line – This is for the center of the two holes. Mark with a pen Put in pilot holes. Mark one mounting hole only with a marker. Remove the plates. With a scribe and hammer, make a shallow pilot hole on the mark you made. Using a #7 x ½ inch sheet metal screw, lightly fasten the plate in place. Carefully position the side plates, so that the axle shaft moves freely, with the least possible amount of binding. Mark the remaining three holes. Remove the plates. With the scribe and hammer, create the other three pilot holes. Fasten the two plates to the wood base with #7 x ½ inch sheet metal screws – DO NOT OVER TIGHTEN. Observe the example catapult to see how to attach the spring and trigger assemblies with #7 x ½ inch sheet metal screws as indicated above. Obtain a 3 inch nail. Cut off the tip of the nail using the bolt cutter. Obtain a piece of foam cut about 2 inches by two inches. Insert the nail through the foam and into one of the four sets of holes in the side plates.

Catapult Parts