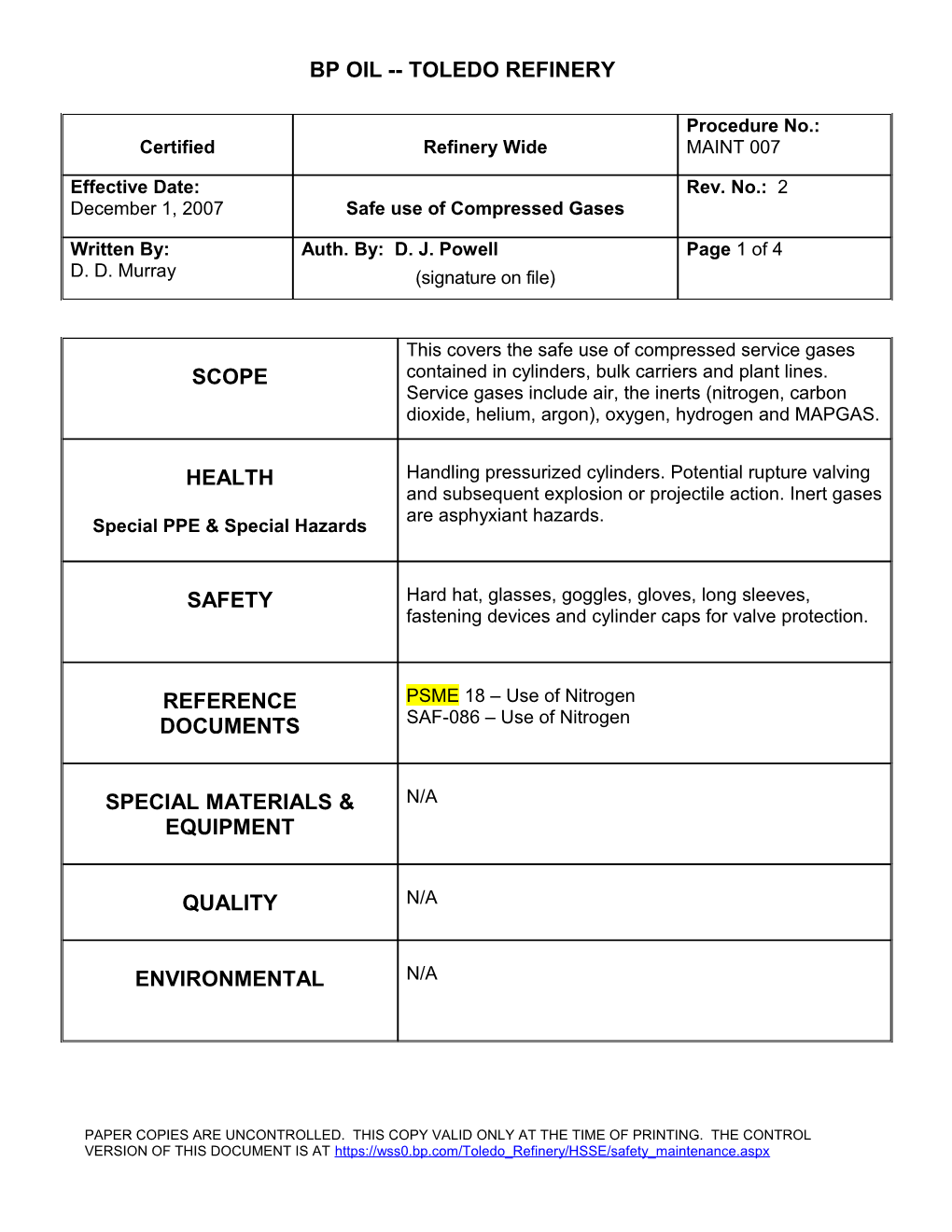

BP OIL -- TOLEDO REFINERY

Procedure No.: Certified Refinery Wide MAINT 007

Effective Date: Rev. No.: 2 December 1, 2007 Safe use of Compressed Gases

Written By: Auth. By: D. J. Powell Page 1 of 4 D. D. Murray (signature on file)

This covers the safe use of compressed service gases SCOPE contained in cylinders, bulk carriers and plant lines. Service gases include air, the inerts (nitrogen, carbon dioxide, helium, argon), oxygen, hydrogen and MAPGAS.

HEALTH Handling pressurized cylinders. Potential rupture valving and subsequent explosion or projectile action. Inert gases are asphyxiant hazards. Special PPE & Special Hazards

SAFETY Hard hat, glasses, goggles, gloves, long sleeves, fastening devices and cylinder caps for valve protection.

REFERENCE PSME 18 – Use of Nitrogen DOCUMENTS SAF-086 – Use of Nitrogen

SPECIAL MATERIALS & N/A EQUIPMENT

QUALITY N/A

ENVIRONMENTAL N/A

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_maintenance.aspx Procedure No. MAINT 007 Rev. No. 2

1.0 Procedures 1.1 Container contents must be positively determined to avoid disastrous mistakes. It is not enough to rely on color coding or labels to identify contents. Color coding is not uniform and wrong labels have been known to result in some tragic mistakes. Testing is the only safe way to determine contents.

__1.2 Cylinders must be carefully handled and stored, and special care is required in handling and storing bulk carriers.

__1.3 Plant air is unsafe for some purposes. It must never be used as a source for supplied breathing air.

__1.4 Finally, the fire hazard of welding gases must be kept under control by careful handling and use.

CAUTION Refer to SAF-086 (Use of Nitrogen) and PSME 18 (Use of Nitrogen) concerning the risks of and requirements involving nitrogen.

2.0 Handling and storing 2.1 Keep valve caps screwed in place at all times except when transfer Cylinders lines or regulators are connected.

2.2 Always remove regulators and install valve caps to transport cylinders.

2.3 Secure cylinders, in an upright position, to a solid support with wire or chain. If they must be laid on their sides, block securely to prevent movement. Never lay an MAPGAS cylinder on its side for storing or use

2.4 Handle, place and use cylinders with care to avoid dropping, toppling, striking or other abuse that might cause sudden pressure release.

__2.5 Do not use rope, chains or electromagnets to hoist cylinders. Use a hoisting cradle or platform. Use carts or hand cradles, wherever possible, to move or load for transport. __2.6 Secure cylinders to prevent toppling, hanging, sliding or rolling during transport. Never drag them behind a truck.

__2.7 Separate full and empty cylinders and handle empties with the same care required for full ones.

__2.8 Store cylinders away from radiant heat sources (radiators, heaters, steam coils), fire hazards (gasoline, oil , grease, rags, paper), corrosives (salt, acids, caustics) and moisture (rain, snow, steam).

__2.9 Store oxygen cylinders away from hydrogen, acetylene or other flammable gases. Keep grease and oil away from oxygen.

Page 2 of 4

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_maintenance.aspx Procedure No. MAINT 007 Rev. No. 2

__2.10 Keep inert gas cylinders separated from flammable gases to avoid mistakes in procuring.

__2.11 Cylinders may be stored in the sun except in temperatures where ambient temperatures exceed 125°F. If the gas supplier recommends storage in the shade for a particular gas, observe such recommendations.

__2.12 If outlet valve leaks are not stopped by tightening packing nuts, do not attempt valve repair. Isolate cylinders in a safe spot and contact supplier. Never tamper with safety devices.

3.0 Using Compressed 3.1 Secure cylinder to prevent movement. Cap those not in active Gases service. Attach caps to cylinders to avoid loss or damage.

3.2 Before making connections, “crack” the outlet valve to clear out dirt. Do not “crack” toxic gas valves or the valves of flammable gas cylinders close to ignition sources. Always stand back of valve outlets.

3.3 Always use regulators except for the special uses that require direct connections. Make sure threads on regulators of fittings match those on valve outlets. do not interchange regulators, and make sure that any adapters are suited to the gas used. Never use grease or oil on threads.

__3.4 Before opening a cylinder valve, release the regulator adjusting screw by turning it counterclockwise. Open cylinder valve slowly to avoid sudden pressure surge. Adjust regulator to proper pressure by turning screw clockwise.

__3.5 To remove a regulator, close cylinder outlet valve and release pressure before removing.

__3.6 To stop leaks at outlet valve packing or coupling, always remove regulator. Tighten valve packing nut or clean coupling threads and retighten.

__3.7 Fittings used for direct transfer of cylinder contents must be approved for this use by gas suppliers.

__3.8 Use only approved transfer lines and fittings. Inspect for damage before each use and maintain in safe condition.

4.0 Plant Compressed 4.1 Do not use plant air to blow dust from clothing. To do so may Air embed sharp bits of rust in skin or cause air to enter the bloodstream thorough an open wound.

4.2 Use low pressure jet devices for cleaning machines, etc. Direct jet away from working areas. Never direct toward people. Protect eyes.

4.3 Never use plant air to supply breathing masks. Page 3 of 4

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_maintenance.aspx Procedure No. MAINT 007 Rev. No. 2

4.4 Use only fittings and hoses approved for use with high-pressure air. Inspect “quick-connects”, clamps and hoses before using.

5.0 Welding Gases 5.1 Do not test contents of Welding gas cylinders.

5.2 Keep MAPGAS cylinders upright while using or when storing. Store MAPGAS distant from oxygen, preferably with a solid wall between. Keep both away from radiant heat, oil, grease, combustibles.

5.3 Before using gases, “crack” valves to clear dirt and rust from outlets. Do this in a safe spot away from ignition sources.

5.4 Do not use a cylinder with a leaking valve. Close outlet valve and tighten packing gland nut. If leakage continues, remove cylinder to a safe open spot, install a danger tag and contact supplier.

__5.5 Make sure safety check valves are in place on hoses or torches before using. Inspect hoses and torches for damage. Follow proper methods for installing new hoses.

__5.6 Follow safe practices defined by gas suppliers for installing regulators and opening gas valves. Stand clear of gauge glasses when opening cylinder valves.

__5.7 Use only friction lighters to light MAPGAS. Do not allow oil or grease to contact oxygen. Do not hang torches on regulators or used dish top of acetylene cylinders for “catchalls”.

__5.8 When cylinders with attached outfits are left unattended, always close cylinder valves and release hose pressures.

__5.9 Keep empty MAPGAS and oxygen cylinders separated in a safe spot where they will be protected from heat and damage. Remove gases from job sites when work is completed.

THIS IS THE LAST PAGE

Page 4 of 4

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_maintenance.aspx