How Do I Recognize Safety Glasses and When to Wear Them?

LENSES: Lenses are divided into two protection levels: Basic Impact and High Impact. To identify a device’s level of impact protection, look for a marking on the lenses. Basic Impact lenses will have the manufacturer’s mark, for example a Pyramex product will have a P. High Impact spectacle lenses will also have a plus + sign, i.e. P+. While not required, some manufacturer’s, like Pyramex, will include Z87denoting the American National Standard number (P Z87+). Goggles and faceshields are required to have the manufacturer’s and ANSI Z87 markings (Basic = P Z87; High Impact = P P Z87+ S Z87+).

Note: Lenses/windows may have additional markings. Shaded lens may have markings denoting a shade number such as 3.0, 5.0 etc. Special purpose lenses may be marked with S”. A variable tint lens may have a V” marking.

LENS MATERIAL: Lens material may be tinted for UV protection and may also have anti-fog protection.

Polycarbonate – strongest material for impact resistance - can be coated for scratch-resistance & UV protection - lightweight - can be molded or bent Plastic – resistant to solvents; lightweight; cannot be molded or bent Glass - Basic Impact lens only/no impact resistance; - heavier than polycarbonate or plastic - greater scratch resistance

LENS COLOR: Clear Safety Glasses - For general indoor applications where impact protection is required. Gray Safety Glasses - For outdoor applications where light and glare can cause eye strain and fatigue. Provides good color recognition. Indoor/Outdoor Safety Glasses - A clear lens with a slight mirror coating serves the same purpose as gray lens, yet allows more visible light through the lens for indoor/outdoor use. Reduces glare from artificial light.

LENS THICKNESS: No minimum lens thickness requirement for High Impact spectacle lenses. The protective advantages of wrap-around lenses and other advancements in eyewear design eliminated the need. Glass lenses, which still fall into the Basic Impact lens category, must have a minimum lens thickness” of 3 millimeters.

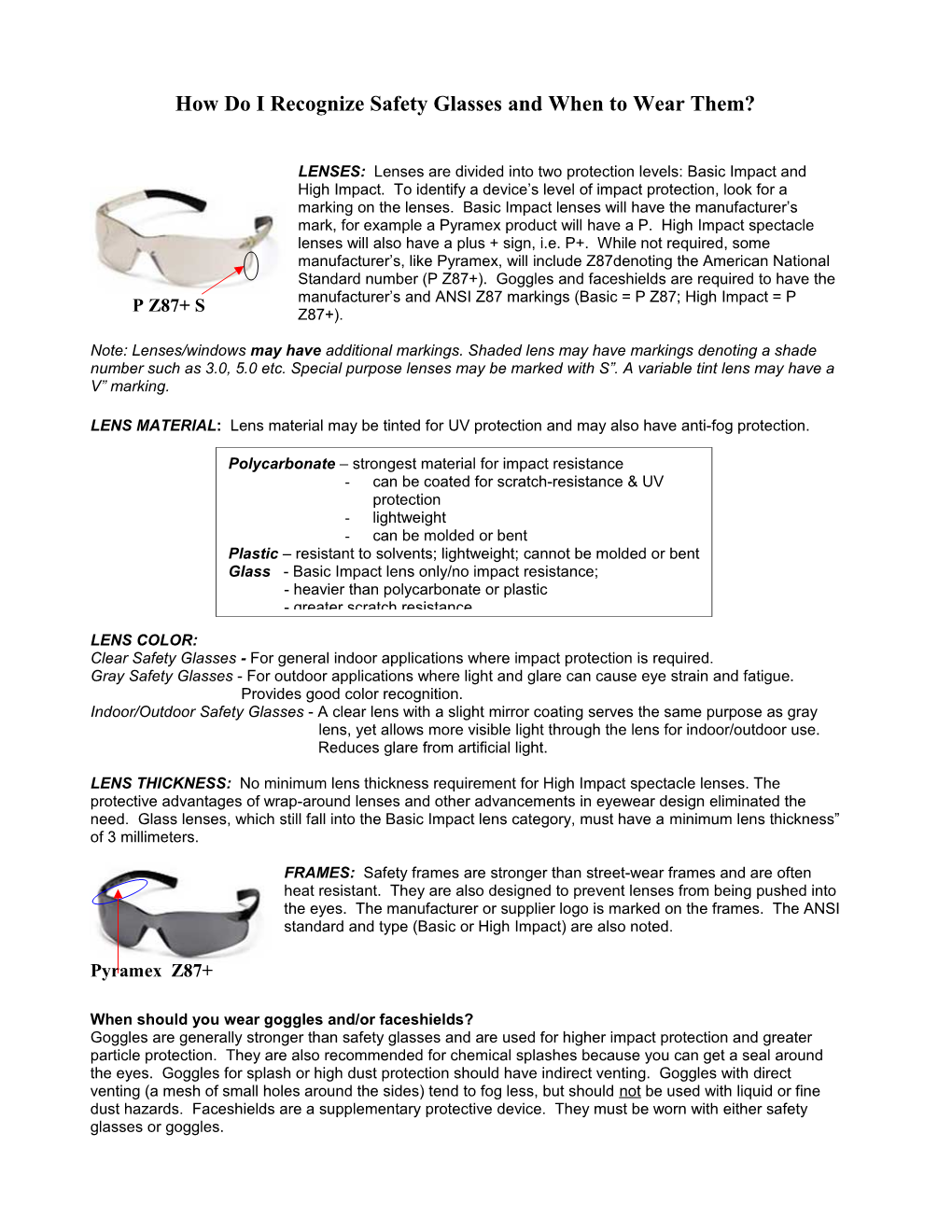

FRAMES: Safety frames are stronger than street-wear frames and are often heat resistant. They are also designed to prevent lenses from being pushed into the eyes. The manufacturer or supplier logo is marked on the frames. The ANSI standard and type (Basic or High Impact) are also noted.

Pyramex Z87+

When should you wear goggles and/or faceshields? Goggles are generally stronger than safety glasses and are used for higher impact protection and greater particle protection. They are also recommended for chemical splashes because you can get a seal around the eyes. Goggles for splash or high dust protection should have indirect venting. Goggles with direct venting (a mesh of small holes around the sides) tend to fog less, but should not be used with liquid or fine dust hazards. Faceshields are a supplementary protective device. They must be worn with either safety glasses or goggles. Safety Glasses Selection

Protection Required

Safety Face Hazard Type Common Related Tasks Goggles Welding Laser Glasses Shield

Impact—Flying objects Chipping, grinding, such as large chips, machining, x x x fragments, particles, sand masonry work, riveting and and dirt. sanding.

Heat—Hot sparks, splash Furnace operations, from molten metal and pouring, casting, hot x x x high-temperature dipping, gas cutting and exposure. welding.

Chemicals—Splash, Chemical handling, fumes, vapors and irritating degreasing x x mists. and plating.

Woodworking, buffing and Dust—Nuisance. x general dusty conditions.

Welding, torch cutting, brazing Optical Radiation—Radiant energy, glare and intense x x x energy, glare and intense light. soldering and laser light. work.

Safety glasses need maintenance.

Clean your safety glasses daily. Follow the manufacturer's instructions. Avoid rough handling that can scratch lenses. Scratches impair vision and can weaken lenses. Store your safety glasses in a clean, dry place where they cannot fall or be stepped on. Keep them in a case when they are not being worn. Replace scratched, pitted, broken, bent or ill-fitting glasses. Damaged glasses interfere with vision and do not provide protection.

Note: Safety glasses shall always be worn with side shields, unless they are the wrap around frame style. Polycarbonate Lens Performance

Most safety glass lenses are today made from Polycarbonate, or varieties of this material such as Lexan (a General Electric trade mark). Traditional hardened safety glass that was and is still used in safety glass lenses is only one tenth as impact resistant as a safety glass made from Polycarbonate. In the pictures above, a nail was hammered through the Polycarbonate lens. Note how the lens material remained intact – no shattering or cracking where the nail penetrated.

An Eye Saved by Safety Glasses

A Boeing employee convinced his 18 year old son working in Construction to wear Safety Glasses...

11/10/99 Machine Safeguarding Examples

As a result of Boeing’s Safety Glasses Program, an employee from Tubes & Cables began encouraging his eighteen year old son, who works in Construction installing siding on houses, to wear safety glasses. His son was resistant and stated he did not need them, he felt he wasn’t going to get hurt. His son got aluminum dust in his eyes while cutting gutter material. The employee told his son he really needed to wear them and the safety glasses would have kept the dust out of his eyes. His son finally relented and started wearing them. During the first or second week the son started wearing safety glasses he was applying siding with an air powered staple gun. When the son fired a staple it hit a metal plate behind the siding, ricocheted back towards his face and one leg of the staple penetrated the safety glasses’ lens. It hit with such force that the frames were cracked and the son received bruising on the eyebrow and cheekbone from the impact. The safety glasses definitely saved his eyesight and possibly his life!