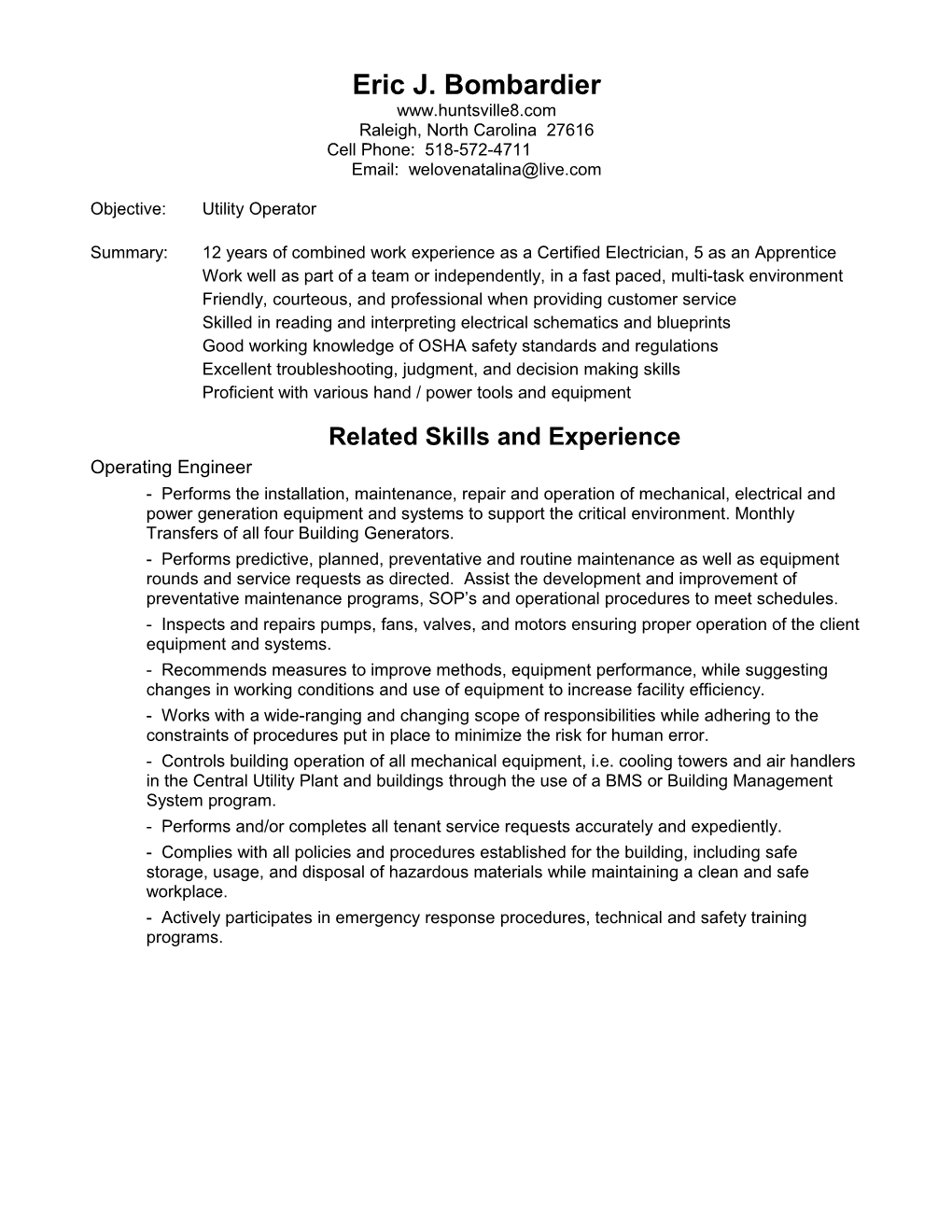

Eric J. Bombardier www.huntsville8.com Raleigh, North Carolina 27616 Cell Phone: 518-572-4711 Email: [email protected]

Objective: Utility Operator

Summary: 12 years of combined work experience as a Certified Electrician, 5 as an Apprentice Work well as part of a team or independently, in a fast paced, multi-task environment Friendly, courteous, and professional when providing customer service Skilled in reading and interpreting electrical schematics and blueprints Good working knowledge of OSHA safety standards and regulations Excellent troubleshooting, judgment, and decision making skills Proficient with various hand / power tools and equipment Related Skills and Experience Operating Engineer - Performs the installation, maintenance, repair and operation of mechanical, electrical and power generation equipment and systems to support the critical environment. Monthly Transfers of all four Building Generators. - Performs predictive, planned, preventative and routine maintenance as well as equipment rounds and service requests as directed. Assist the development and improvement of preventative maintenance programs, SOP’s and operational procedures to meet schedules. - Inspects and repairs pumps, fans, valves, and motors ensuring proper operation of the client equipment and systems. - Recommends measures to improve methods, equipment performance, while suggesting changes in working conditions and use of equipment to increase facility efficiency. - Works with a wide-ranging and changing scope of responsibilities while adhering to the constraints of procedures put in place to minimize the risk for human error. - Controls building operation of all mechanical equipment, i.e. cooling towers and air handlers in the Central Utility Plant and buildings through the use of a BMS or Building Management System program. - Performs and/or completes all tenant service requests accurately and expediently. - Complies with all policies and procedures established for the building, including safe storage, usage, and disposal of hazardous materials while maintaining a clean and safe workplace. - Actively participates in emergency response procedures, technical and safety training programs. Industrial / Commercial Electrician - Install electrical panels from start to finish - Utilize blueprints for project layout and coordination - Test electrical wiring, equipment, and fixtures using a digital multi-meter - Install raceways for branch circuits, control wiring, data lines, and phone lines - Install, Repair or replace wiring, equipment, or fixtures using hand and power tools - Connect wires to circuit breakers, transformers, motors and other components - Perform troubleshooting and maintain existing electrical wiring, equipment and fixtures - Copper and Fiber Network Installations - Built electrical system in a brand new state of the art surgical wing at a hospital

Robotics and Facilities Maintenance Technician - Installation and maintenance of Genesis System Fanuc Robotic Welding System, SPR custom Bombardier spot welding robots, MEDAR 500S weld controllers, longitudinal seam welder, WTC weld controllers, PLR Programmable Logic Relay set up, Allen Bradley IMC motion controllers, AC/DC motor speed controls, pneumatics, hydraulics - Monitor and maintain all HVAC on campus which includes 22 Air Handlers and 8 Roof Top Units, 15 Exhaust Fans - Stick, Spot, and Mig Welders. Lincoln and Miller - Shuttle Wagon train car mover - Hydraulics/ Pneumatics - Fork lift/Scissor lift/Platform lift operator - Installation of a DuPont Paint System - RCRA trained for environmental issues / concerns - ANSI RIA compliance trained including ESD Electrostatic Sensitive Devices - Split all plant electrical maintenance and troubleshooting duties with one other electrician - VARIAC variable voltage train car power supplies, 600 and 1000 Volts, installation and maintenance of/ installation and design of safety circuits - 130 Ton Bridge Cranes-Preventative Maintenance and operation of Work Experience Operating Engineer Apr 2016 to Present Jones Lang LaSalle, Durham, North Carolina Electrician Nov 2015 to Apr 2016 Wayne J. Griffin Electric Incorporated, Durham, North Carolina Industrial Electrician/Maintenance Technician Feb 2013 to Nov 2015 Bombardier Transportation, Plattsburgh, New York Maintenance Technician / CDI Temp Aug 2012 to Feb 2013 Bombardier Transportation, Plattsburgh, New York Journeyman Wireman Jun 2004 to Aug 2012 William J. Murray Electrical Contractors, Plattsburgh, New York Education New York State Certified Electrician Received Jun 2009 Completed Electrical Apprenticeship Training Jun 2009 1,000 hours classroom / over 10,000 hours on-the-job training (5 years) Plattsburgh, New York Green Tradesman Program 40 hour Photovoltaic class 10 hour National Electric Code update class OSHA 30 Hour Class Apr 2005 OSHA 10 Hour Class Jan 2016 American Council on Education - 56 Semester Hours for the Electrical Industry A.A.S Degree in Humanities and Social Sciences/Arts Jun 2015 Completed Courses Toward an A.A.S. Degree in Electronics Technology 2003-2004 Clinton Community College, Plattsburgh, New York High School New York State Regents Diploma Jun 1998 Northeastern Clinton Central School, Champlain, New York