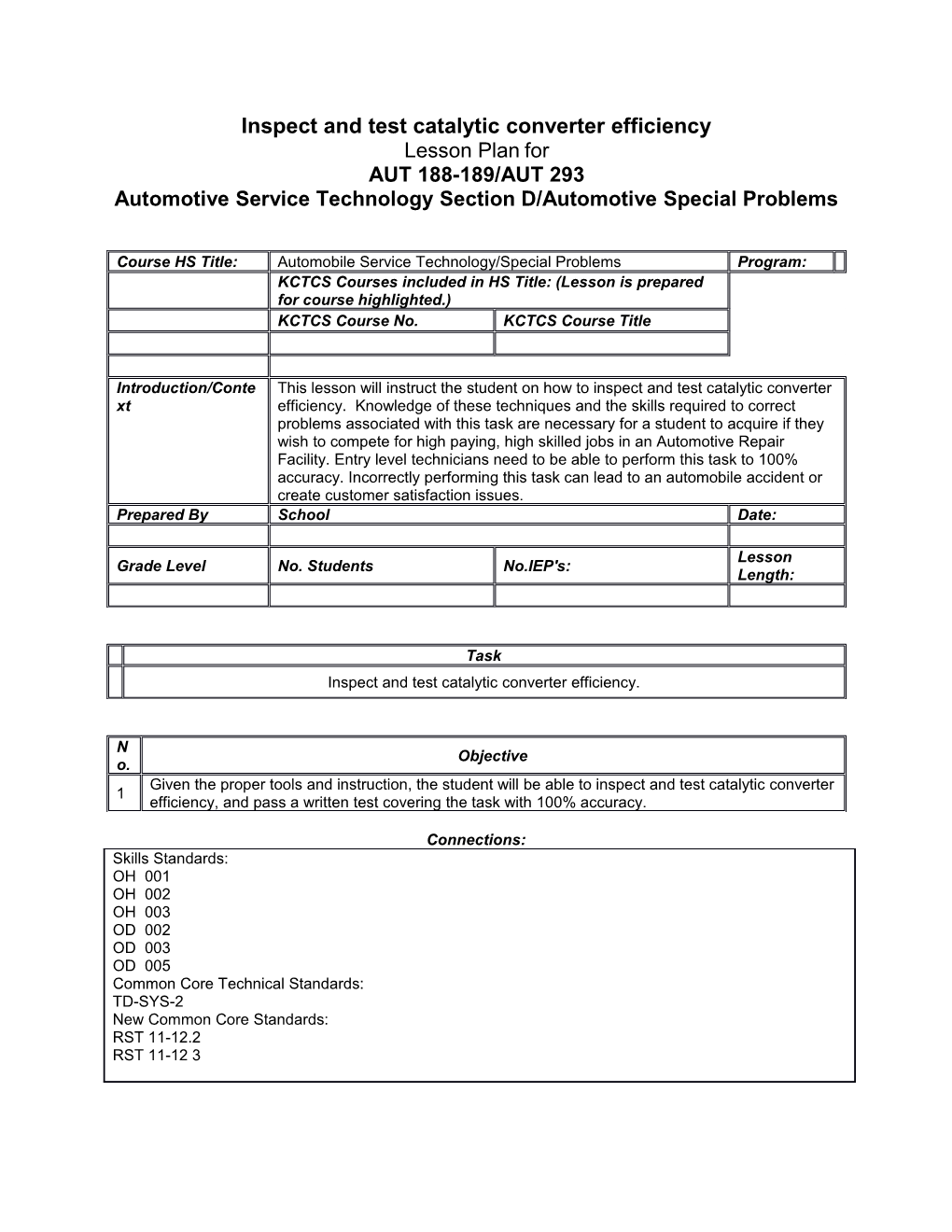

Inspect and test catalytic converter efficiency Lesson Plan for AUT 188-189/AUT 293 Automotive Service Technology Section D/Automotive Special Problems

Course HS Title: Automobile Service Technology/Special Problems Program: KCTCS Courses included in HS Title: (Lesson is prepared for course highlighted.) KCTCS Course No. KCTCS Course Title

Introduction/Conte This lesson will instruct the student on how to inspect and test catalytic converter xt efficiency. Knowledge of these techniques and the skills required to correct problems associated with this task are necessary for a student to acquire if they wish to compete for high paying, high skilled jobs in an Automotive Repair Facility. Entry level technicians need to be able to perform this task to 100% accuracy. Incorrectly performing this task can lead to an automobile accident or create customer satisfaction issues. Prepared By School Date:

Lesson Grade Level No. Students No.IEP's: Length:

Task Inspect and test catalytic converter efficiency.

N Objective o. Given the proper tools and instruction, the student will be able to inspect and test catalytic converter 1 efficiency, and pass a written test covering the task with 100% accuracy.

Connections: Skills Standards: OH 001 OH 002 OH 003 OD 002 OD 003 OD 005 Common Core Technical Standards: TD-SYS-2 New Common Core Standards: RST 11-12.2 RST 11-12 3 INSTRUCTIONAL MATERIALS/TECHNOLOGY

Teacher Designed Materials and Other Handouts

Textbooks and Workbooks

Author Title/ISBN No. Edition Publisher Pages Jack Erjavec Automotive Technology Fifth Delman 967-969 Ken Pickerill Automotive Engine Performance Fourth Delmar 203-205

Web Addresses Title Publisher URL Today's Class Melior www.todaysclass.com How Catalytic Converters Work How Stuff Works http://auto.howstuffworks.com/catalytic-converter.htm

Equipment Quantity Item Source As Needed 5 Gas Analyzer with Ignition Analyzer Various As Needed Pyrometer Various

Content/Presentation/Demonstration Outline Let students know that catalytic converters can also be destroyed by overheating, usually caused by a very rich fuel mixture due to a fuel delivery problem. Leaded fuel, although not widely available, will also ruin a catalytic converter. Explain that there are many ways to test a catalytic converter. One of these is to simply strike the converter with a rubber mallet. If the converter rattles, it needs to be replaced and there is no need for further testing. Let students know that a rattle indicates loose catalyst substrate, which will soon rattle into small pieces. Inform students that this is one test and is not used to determine if the catalyst is good. Tell them to keep in mind a converter may also be bad if it is restricted or not working properly. Instruct students that another way to check for a restricted exhaust or catalyst is to insert a pressure gauge in the exhaust manifold's bore for the O2 sensor. Once the gauge is in place, tell them to hold the engine's speed at 2,000 rpm and watch the gauge. The desired pressure reading will be less than 1.25 psi. A very bad restriction will give a reading of over 2.75 psi. Inform students that the converter should be checked for its ability to convert CO and HC into CO2 and water. Let students know that there are three separate tests for doing this. The first method is the delta temperature test. Be sure that students know that in all converter tests, the catalyst is warmed up before conducting the test. Tell students that to conduct this test (delta temperature), they will use a hand-held digital pyrometer (an electronic device that measures heat). By touching the pyrometer probe to the exhaust pipe just ahead of and just behind the converter, let students know that there should be an increase of at least l00°F, or 8 percent above the inlet temperature reading, as the exhaust gases pass through the converter. If the outlet temperature is the same or lower, tell them that nothing is happening inside the converter. Let students know not be quick to condemn the converter. To do its job efficiently, explain that the converter needs a steady supply of oxygen from the air pump if so equipped. A bad pump, faulty diverter valve or control valve, leaky air connections, or faulty computer control over the air injection system could be preventing the needed oxygen from reaching the converter. If the converter fails this test, tell students to check those systems. If a problem is found, inform students to fix it, and then retest the converter. Instruct students that another test is called the O2 storage test and is based on the fact that a good converter stores oxygen. The following test is for closed-loop feedback systems. Have students begin by disabling the air injection system. Tell them to turn on the gas analyzer and allow it to warm up. Next, start the engine and allow the converter to warm up. Once the analyzer and converter are ready, have the students hold the engine at 2,000 rpm. Tell them to watch the readings on the exhaust analyzer. If the converter was cold, the readings will continue to drop until the converter reaches light-off temperature. Inform students that once the numbers stop dropping, check the oxygen level on the gas analyzers. The O2 readings should be about 0.5 to 1 percent. This shows the converter is using most of the available oxygen. Let students know that there is one exception to this. If there is no CO left, there may be a higher amount of oxygen in the exhaust. However, it still should be less than 2.5 percent. Let students know that if the level of O2 is too high and there is no CO in the exhaust, make sure the vehicle is in control of the air-fuel mixture. If it is, tell students to add propane to bring the O2 level to zero. Once the O2 level is stable, tell students to snap the throttle open and allow it to return to idle. The O2 level should not rise above 1.2 percent. This gives an indication of how well the converter stores oxygen. If the converter fails the test, tell students it should be replaced. Instruct students that the following test uses a principle that checks the converter's efficiency. Remind students that the catalytic converter changes CO and HC into CO2 and water. Again, tell students that before beginning this test to be sure the converter is warmed up. Have students calibrate a four-gas analyzer and insert its probe into the tailpipe. If the vehicle has dual exhaust with a crossover, tell them to plug the side that the probe is not in. If the vehicle has a true dual exhaust system, tell them to check both sides separately. Inform students to disable the ignition, and then crank the engine for 9 seconds while pumping the throttle. Have them watch the readings on the analyzer. The CO2 on fuel-injected vehicles should be over 11 percent. As soon as they have their readings, have them reconnect the ignition and start the engine. Tell them to do this as quickly as possible to cool off the catalytic converter. If while the engine is cranking the HC goes above 1,500 ppm, tell them to stop cranking, the converter is not working. Also, inform students to stop cranking once the CO2 readings reach 10 or 11 percent. This means the converter is good. Let students know that if the catalytic converter is bad, there will be high HC and low CO2 at the tailpipe. Instruct students to not repeat this test more than one time without running the engine in between! Teach students that if a catalytic converter is found to be bad, it is replaced.

Applications/Practice 1 Refer to content

Evaluation and feedback Prior to Testing or Lab Work Objective 1. / Formative assessment / Instructor will observe students as they practice the procedure to assure correct procedure and safety practices are being followed. A checklist will be utilized to chart 1 student progress on the task. Questioning techniques will be utilized as necessary to demonstrate student comprehension / Adaptations and/or accommodations for special needs students will be added if required.

STUDENT ASSESSMENT: (Assess student progress with performance criteria.) Objective 1 / Summative assessment / written test questions on stated objective / adaptation and / or 1 accommodations for special needs students will be added if required IMPACT--Reflection/Analysis of Teaching and Learning: (How did students’ progress in relation to the state objectives? Was the instruction successful? Analyze samples of student work particularly that which is unsatisfactory, for the purpose of planning further instruction.)

REFINEMENT--Lesson Extension and Follow-up: (To be filled in as the lesson is modified during initial planning and/or during the teaching learning process.)