Problem Statement

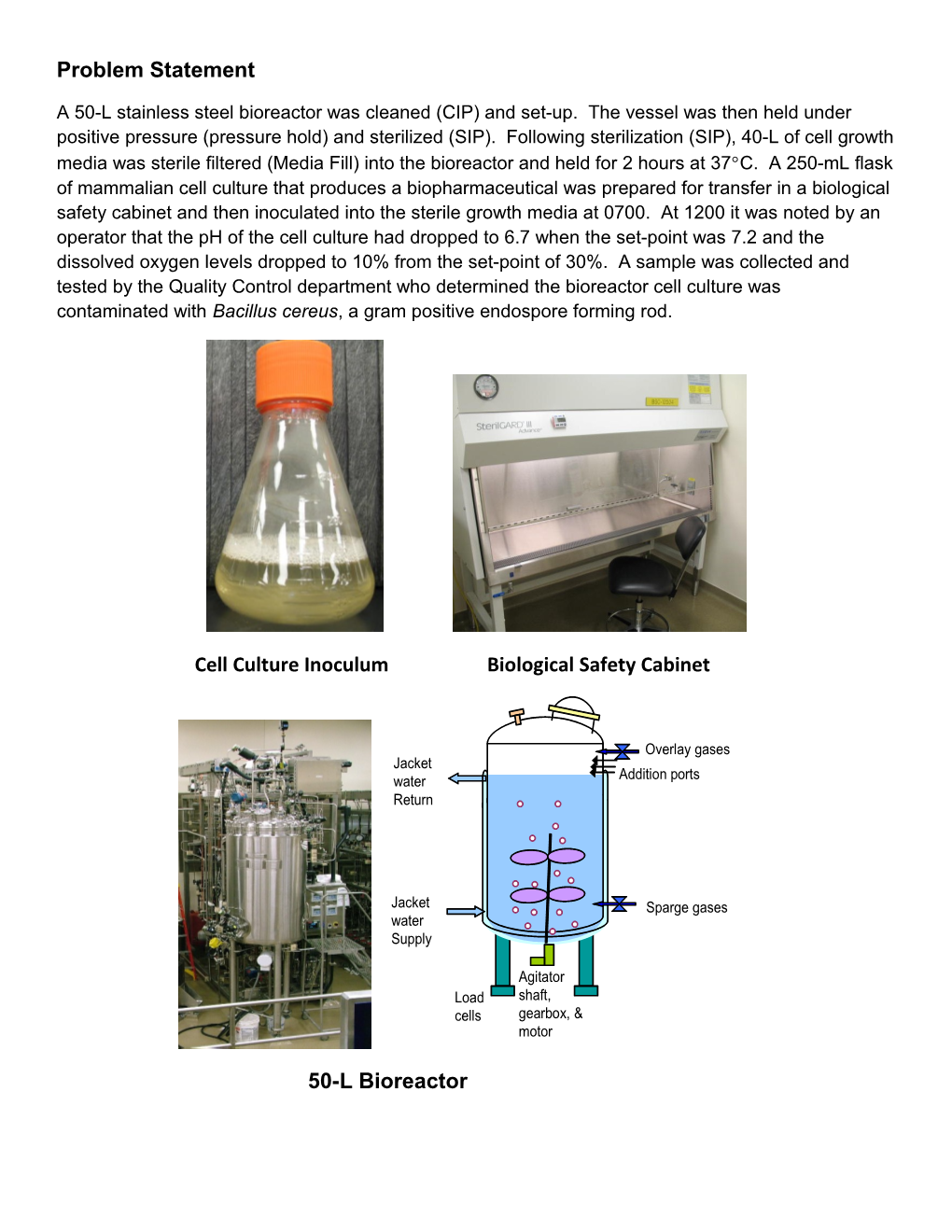

A 50-L stainless steel bioreactor was cleaned (CIP) and set-up. The vessel was then held under positive pressure (pressure hold) and sterilized (SIP). Following sterilization (SIP), 40-L of cell growth media was sterile filtered (Media Fill) into the bioreactor and held for 2 hours at 37C. A 250-mL flask of mammalian cell culture that produces a biopharmaceutical was prepared for transfer in a biological safety cabinet and then inoculated into the sterile growth media at 0700. At 1200 it was noted by an operator that the pH of the cell culture had dropped to 6.7 when the set-point was 7.2 and the dissolved oxygen levels dropped to 10% from the set-point of 30%. A sample was collected and tested by the Quality Control department who determined the bioreactor cell culture was contaminated with Bacillus cereus, a gram positive endospore forming rod.

Cell Culture Inoculum Biological Safety Cabinet

Overlay gases Jacket water Addition ports Return

Jacket Sparge gases water Supply

Agitator Load shaft, cells gearbox, & motor

50-L Bioreactor Bioreactor Set-up and Use Process

Activity

What is the cause of the bioreactor contamination?

Let’s use the Fishbone tool to begin investigating all of the potential causes of this major deviation.

1. Use the pictures, the scenario, your existing knowledge and the fishbone categories to help you think of potential causes to this problem.

1. Manpower 2. Machine 3. Method 4. Measures 5. Mother Nature 6. Materials

2. List the potential causes in the most appropriate category in the worksheet below. Be sure to be specific when writing the potential cause. Fishbone Worksheet

Man Mother Nature

Measures Machine

Method Materials