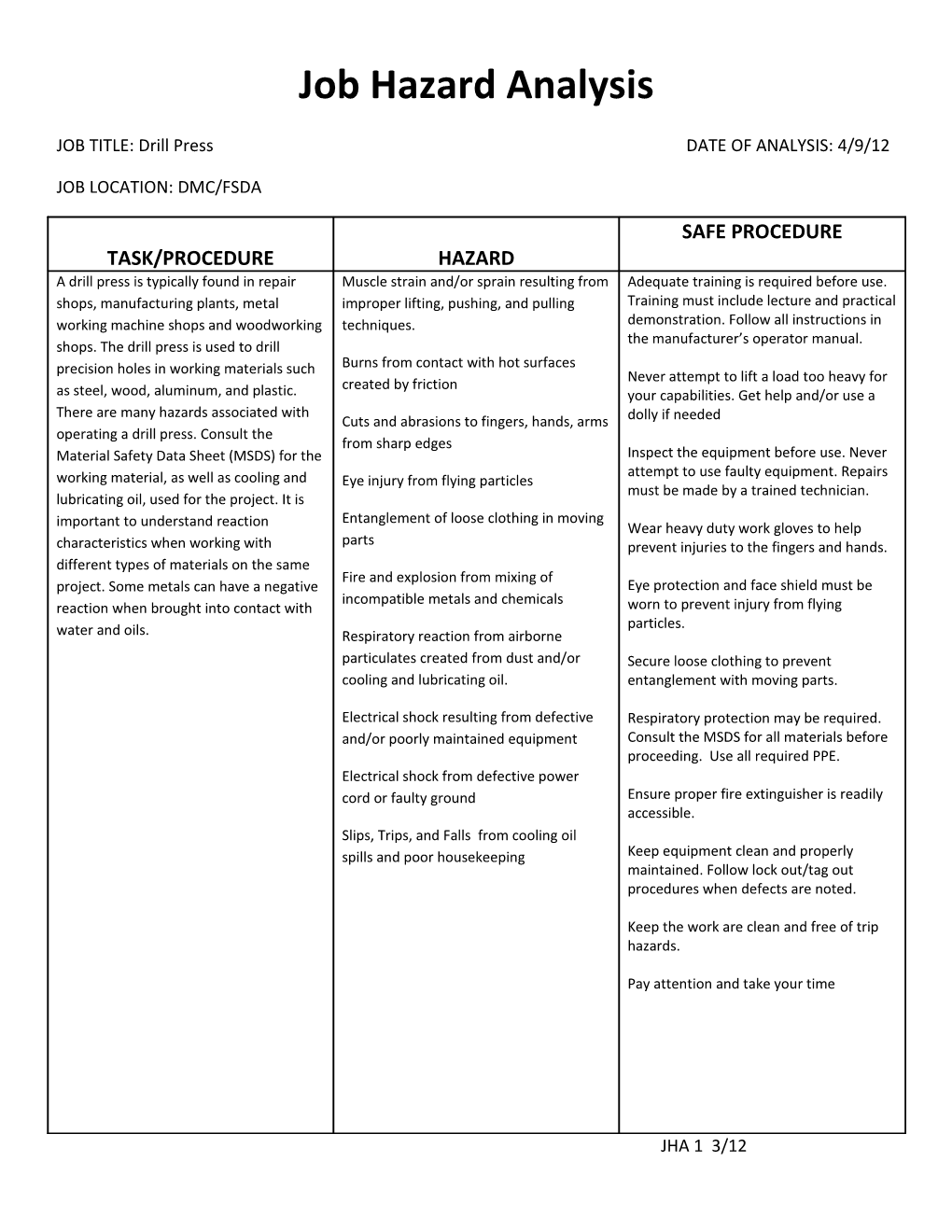

Job Hazard Analysis

JOB TITLE: Drill Press DATE OF ANALYSIS: 4/9/12

JOB LOCATION: DMC/FSDA

SAFE PROCEDURE TASK/PROCEDURE HAZARD A drill press is typically found in repair Muscle strain and/or sprain resulting from Adequate training is required before use. shops, manufacturing plants, metal improper lifting, pushing, and pulling Training must include lecture and practical working machine shops and woodworking techniques. demonstration. Follow all instructions in the manufacturer’s operator manual. shops. The drill press is used to drill precision holes in working materials such Burns from contact with hot surfaces created by friction Never attempt to lift a load too heavy for as steel, wood, aluminum, and plastic. your capabilities. Get help and/or use a There are many hazards associated with Cuts and abrasions to fingers, hands, arms dolly if needed operating a drill press. Consult the from sharp edges Material Safety Data Sheet (MSDS) for the Inspect the equipment before use. Never attempt to use faulty equipment. Repairs working material, as well as cooling and Eye injury from flying particles must be made by a trained technician. lubricating oil, used for the project. It is Entanglement of loose clothing in moving important to understand reaction Wear heavy duty work gloves to help characteristics when working with parts prevent injuries to the fingers and hands. different types of materials on the same Fire and explosion from mixing of project. Some metals can have a negative Eye protection and face shield must be incompatible metals and chemicals reaction when brought into contact with worn to prevent injury from flying water and oils. particles. Respiratory reaction from airborne particulates created from dust and/or Secure loose clothing to prevent cooling and lubricating oil. entanglement with moving parts.

Electrical shock resulting from defective Respiratory protection may be required. and/or poorly maintained equipment Consult the MSDS for all materials before proceeding. Use all required PPE. Electrical shock from defective power cord or faulty ground Ensure proper fire extinguisher is readily accessible. Slips, Trips, and Falls from cooling oil spills and poor housekeeping Keep equipment clean and properly maintained. Follow lock out/tag out procedures when defects are noted.

Keep the work are clean and free of trip hazards.

Pay attention and take your time

JHA 1 3/12