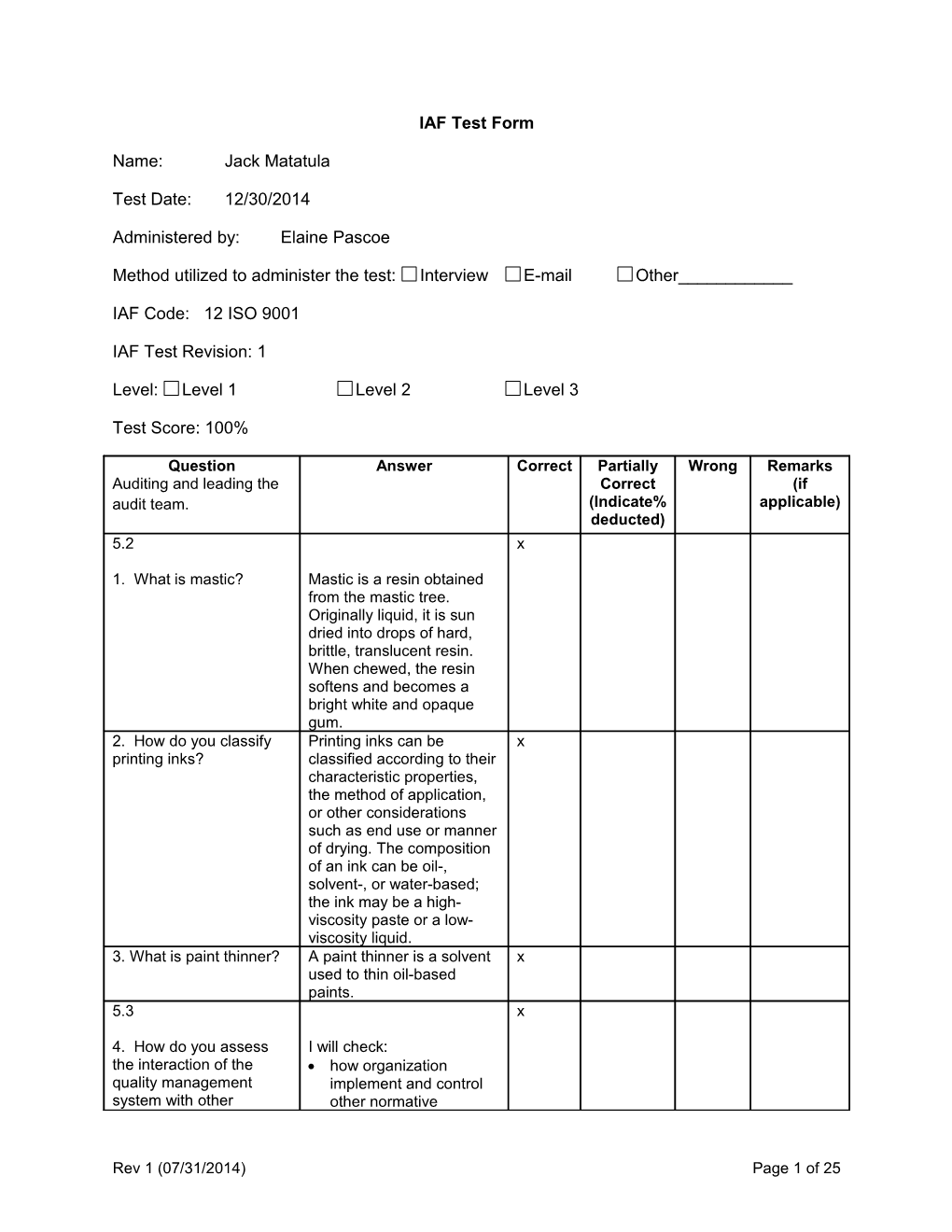

IAF Test Form

Name: Jack Matatula

Test Date: 12/30/2014

Administered by: Elaine Pascoe

Method utilized to administer the test: Interview E-mail Other______

IAF Code: 12 ISO 9001

IAF Test Revision: 1

Level: Level 1 Level 2 Level 3

Test Score: 100%

Question Answer Correct Partially Wrong Remarks Auditing and leading the Correct (if audit team. (Indicate% applicable) deducted) 5.2 x

1. What is mastic? Mastic is a resin obtained from the mastic tree. Originally liquid, it is sun dried into drops of hard, brittle, translucent resin. When chewed, the resin softens and becomes a bright white and opaque gum. 2. How do you classify Printing inks can be x printing inks? classified according to their characteristic properties, the method of application, or other considerations such as end use or manner of drying. The composition of an ink can be oil-, solvent-, or water-based; the ink may be a high- viscosity paste or a low- viscosity liquid. 3. What is paint thinner? A paint thinner is a solvent x used to thin oil-based paints. 5.3 x

4. How do you assess I will check: the interaction of the how organization quality management implement and control system with other other normative

Rev 1 (07/31/2014) Page 1 of 25 normative documents, document and other standard and other standard that may relevant standard? applies to product and/or service, it can be as external document application to the product and/or service the evaluation of compliance to the product and/or service 5.4 X

5. Can you describe the Objectives are the goals general business set out by an entity based management concept, on the policies that are practice and inter- already in existence. The relationship between strategies are the methods policy, objectives and employed to carry out the result? objectives.

I will check the result whether they achieved, if the result meets the objective, it means what stated by organization in the policy achieved.

5.5 x 6. What are the different types of pigment? Pigments can be classified as either natural or synthetic types. Natural pigments include various clays, calcium carbonate, mica, silica, and talc. Synthetics would include engineered molecules, calcined clays, blanc fix, precipitated calcium carbonate, and synthetic silica. 7. What are fillers? Fillers are a special type of x pigment that serve to thicken the film, support its structure and simply increase the volume of the paint. Fillers are usually made of cheap and inert materials, such as diatomaceous earth, talc, lime, baryte, clay, etc. Floor paints that will be subjected to abrasion may even contain fine quartz sand as

Rev 1 (07/31/2014) Page 2 of 25 a filler. Not all paints include fillers. On the other hand some paints contain very large proportions of pigment/filler and binder. 8. What is the purpose of The main purposes of the x solvent? solvent are to adjust the curing properties and viscosity of the paint. It is volatile and does not become part of the paint film. It also controls flow and application properties, and affects the stability of the paint while in liquid state. Its main function is as the carrier for the non- volatile components. In order to spread heavier oils (i.e. linseed) as in oil-based interior house paint, a thinner oil is required. These volatile substances impart their properties temporarily – once the solvent has evaporated or disintegrated, the remaining paint is fixed to the surface. This component is optional: some paints have no diluent. 9. What is mastic? Mastic is a resin obtained x from the mastic tree. Originally liquid, it is sun dried into drops of hard, brittle, translucent resin. When chewed, the resin softens and becomes a bright white and opaque gum. 10. What are the uses of Medicine (Mastic has x mastic? been used as a medicine since antiquity and is still used in traditional folk medicine of the Middle East) Food (One of the earliest uses of mastic was as chewing gum, hence the name) Varnish (Mastic is used as a raw material in the production of some varnishes. Mastic

Rev 1 (07/31/2014) Page 3 of 25 varnish was used to protect and preserve photographic negatives), etc. 11. How do you classify Printing inks can be x printing inks? classified according to their characteristic properties, the method of application, or other considerations such as end use or manner of drying. The composition of an ink can be oil-, solvent-, or water-based; the ink may be a high- viscosity paste or a low- viscosity liquid. 12. What solvents are • Acetone x used in paint thinner? • Mineral turpentine (turps) • True turpentine • Naphtha • Toluene • White spirit • Xylene • Methyl ethyl ketone (MEK) • Dimethylformamide (DMF) 13. What are the Although there are three x processes to manufacture ways of manufacturing dry laundry detergent? laundry detergent, only two are commonly used today. In the blender process favored by smaller companies, the ingredients are mixed in large vats before being packaged. The machines used are very large: a common blender holds 4,000 pounds (1,816 kilograms) of mixed material, but the blenders can accommodate loads ranging from 500 to 10,000 pounds (227 to 4,540 kilograms). By industry standards, these are small batches for which the blender process is ideal. While some settling may occur, the resulting detergent is of high quality and can compete with detergents made by other

Rev 1 (07/31/2014) Page 4 of 25 processes. The second commonly used method of production is called the agglomeration process. Unlike the blender process, it is continuous, which makes it the choice of very large detergent manufacturers. The agglomeration process can produce between 15,000 and 50,000 pounds (6,800 and 22,700 kilograms) of detergent per hour. In the third method, dry ingredients are blended in water before being dried with hot air. Although the resulting product is of high quality, the fuel costs and engineering problems associated with venting, reheating, and reusing the air have led to this method being largely replaced by agglomeration.

a) The blender process First, ingredients are loaded into one of two machines: a tumbling blender or a ribbon blender. The tumbling blender, shaped like a rectangular box, is turned and shaken from outside by a machine, while the ribbon blender is a cylinder fitted with blades to scrape and mix the ingredients. After the ingredients inside the blender have been mixed, a doorway at the bottom of the bowl is opened. With the blender still agitating the ingredients, the mix is allowed to run out onto a conveyor belt or other channeling device. The belt then moves the detergent to another area of the factory where it can be dropped into boxes or cartons for delivery to wholesalers or distributors.

Rev 1 (07/31/2014) Page 5 of 25 b) The agglomeration process In this method, dry ingredients for a detergent are first fed into a large machine known as a Shuggi agglomerator (Shuggi is the manufacturer). Inside the agglomerator, sharp, whirling blades mix the material to a fine consistency; the process resembles food being textured inside a food processor.

After the dry ingredients have been blended, liquid ingredients are sprayed on the dry mix through nozzles fitted into the agglomerator's walls. The blending continues, causing an exothermic (heat-producing) reaction to occur. The resulting mixture is a hot, viscous liquid similar to gelatin that hasn't hardened.

Next, the liquid is allowed to flow out of the agglomerator. As it leaves the machine, it collects on a drying belt where its own heat, exposure to air, and hot air blowers render it friable—easy to crush or crumble. The newly made detergent is then pulverized and pushed through sizing screens that ensure that no large lumps of unmixed product go out to the market. The result of this process is a dry detergent made up of granules of the mixed detergent.

c) The slurry method In this process, ingredients are dissolved in water to create a slurry. With a

Rev 1 (07/31/2014) Page 6 of 25 pump, the slurry is blown through nozzles inside the top of a cone shaped container as hot, dry air is simultaneously forced into the bottom of the cone. As the slurry dries, "beads" of dry detergent fall to the bottom of the cone, where they can be collected for packaging.

d) Liquid detergent If the detergent is to be liquid rather than powder, it is simply mixed back in— after all ingredients are blended—with a solution consisting of water and various chemicals known as solubilizers. The solubilizers help the water and detergent blend together more fully and evenly. 14. What are the GLYCEROL FROM FATS x manufacturing processes AND OILS of glycerol? FATS SPLITTING: From fat splitting or hydrolysis without added alkali, of fats and oils. This is a method for preparing fatty acids, which are then in some cases reduced to the corresponding fatty alcohols. The glycerin is then obtained in the sweet water. Crude glycerin recovered from this is termed as saponification crude. The main sources of natural glycerol are now high pressure splitting and transesterification. Glycerol from the neutral saponification of oils is encountered only in small quantities.

HIGH PRESSURE SPLITTING: Splitting under pressure has been known since 1845. Continuous process reactors are now

Rev 1 (07/31/2014) Page 7 of 25 used.water and fat are fed into a splitting column in countercurrent fashion at 5- 6 Mpa and 250ºC 260ºC, leading to a 15% solution of glycerol in water known as sweetwater. This glycerol is marketed as 88% saponification Crude or hydrolysis glycerol.

RANSESTERIFICATION: Natural crude glycerol of same quality can be obtained from the continuous transesterification of oils and fats to their methyl esters.

SAPONIFICATION: The splitting of fats by saponification of neutral oil is a traditional method: caustic alkali or alkali carbonates are used, as in the production of soap. The use of calcium hydroxide in the form of milk of lime is also possible.

GLYCEROL SYNTHESIS:

PRODUCTION FROM ALLYL CHLORIDE: The first synthetic glycerol was produced in 1943 by I.G.Farben in Oppau and Hydebreck and in 1948 by Shell in houston, Texas.The allyl chloride produced is oxidized with hypochlorite to dichlorohydrin, which is then converted without isolation to epichlorohydrin by ring closure with calcium or sodium hydroxide. Hydrolysis to glycerol is carried out with sodium hydroxide or sodium carbonate. Epichloro-hydrin is hydrolyzed at 80-200ºC with a 110-15% aqueous solution of sodium hydroxide or sodium

Rev 1 (07/31/2014) Page 8 of 25 carbonate at atmospheric or overpressure .The yield of dilute (10-25%) glycerol solution is >98%.The solution contains 5-10% sodium chloride and less than 2% of other impurities. Glycerol is finally treated further to remove colored impurities and odorous material,this can be performed for example with activated carbon.

PRODUCTION FROM PROPENE OXIDE: Preparation from propene oxide does not use chlorine. Propene is epoxidized to propene oxide, which is then isomerized to allyl alcohol by the progil process. A second epoxidization is carried out with peracetic acid, and the resulting glycidol is hydrolyzed to glycerol.

FERMENTATION FROM SUGAR The formation of glycerol by fermentation of alcohol was discovered in 1858 by pasture. Industrial use became possible once the mechanism was understood; the fermentation could be interrupted at the glyceraldehyde 3- phosphate stage with sodium carbonate or with alkali or alkaline earth sulfites. After reduction to glycerol phosphate, glycerol is obtained in yield upto 25% by hydrolysis. The process is economically unimportant.

HYDROGENATION OF CARBOHYDRATES Hydrogenation of natural polyalcohols such as cellulose, starch, or sugar

Rev 1 (07/31/2014) Page 9 of 25 leads to mixture of glycols, which can be separated by distillation. Catalyst used in high temperature includes nickel, cobalt, copper, chromium and tungsten as well as oxides of some of the lanthanides. The crude glycerin produced is poor in quality and requires drastic, expensive refining methods.

OTHER NON- COMMERCIAL PROCESS Photo production of glycerol along with other biomass is possible by means of solar energy and algae. Another synthetic process involves the catalytic hydrogenation of carbon monoxide. A process based on the manufacture of synthetic glycerol from invert molasses via sorbitol has been suspended since 1969. 15. How do you • Shoe polish can be x manufacture shoe polish? manufactured using large vats, reasonably powerful heaters and air conditioners. There is no set method of manufacture, although most methods use pressures of two atmospheres to ensure the naphtha does not boil off, and temperatures of up to 85 °C. • The first step in the manufacture of a typical shoe polish is the melting of the wax with the highest melting point in an electric heater. Following this, all other waxes are added, usually by descending order of melting point. Whilst

Rev 1 (07/31/2014) Page 10 of 25 this wax is held at a constant temperature, the emulsion—a mixture of the various oils and, if used, fats, is then heated separately, at around 85 °C. The heated emulsion is then added to the waxes, along with distilled water. When the mixture reaches around 80 °C, turpentine oil is added. This mixture is then mixed and continually stirred for half an hour. Dyes are added and mixed in turpentine oil if it is not a neutral polish. The mixed mass is reduced slowly to 50 °C, and as its viscosity increases, it is poured through a closed funnel into a cooling chamber. The poured mass is allowed to settle slowly, providing uniform distribution. The process is considered straightforward and the required equipment is relatively easy to acquire. The cost of establishing shoe polish manufacturing facilities has been estimated at around $600,000 (as of 2005). • Shoe polish is traditionally packaged in flat, round, 60-gram (2-ounce) tins, usually with an easy-open facility. Because the amount of shoe polish that needs to be applied is small, and the shoe polish will desiccate due to volatile ingredients, such as naphtha, a large container would dry out before being fully used. The

Rev 1 (07/31/2014) Page 11 of 25 traditional flat, round tins have since become synonymous with shoe polishes. 16. What is man-made Fibre whose chemical x fibre? composition, structure, and properties are significantly modified during the manufacturing process. Man-made fibres are spun and woven into a huge number of consumer and industrial products, including garments such as shirts, scarves, and hosiery; home furnishings such as upholstery, carpets, and drapes; and industrial parts such as tire cord, flame-proof linings, and drive belts. The chemical compounds from which man-made fibres are produced are known as polymers, a class of compounds characterized by long, chainlike molecules of great size and molecular weight. 5.6 SNI ISO 5263-1:2014 - x Pulps – Laboratory wet 17. Are there any legal disintegration – Part 1: and other requirements Disintegration of related for chemicals, chemicals pulp chemical products and SNI ISO 20492-2:2014 fibres products? What are - Glass in buildings — they? Insulating glass — Part 2: Chemical Fogging Tests SNI 14-2163-1991 - Carbonless copy paper chemical transfer type SNI 15-2173-1991 - Silicate lime soda glass, Chemical analysis test method SNI 07-0308-1989 - Carbon steel, Test method for composition SNI 07-0812-1989 - Iron alloy metal, Sampling method for determination of chemical composition SNI 07-0826-1989 -

Rev 1 (07/31/2014) Page 12 of 25 Aluminium and aluminium alloys, Test method for chemical composition SNI 07-0958-1989 - Chemical test method for brase/ bronze SNI 07-1160-1989 - Aluminium and aluminium alloys, Chemical test methods for determination of bismuth contents SNI 07-1165-1989 - Aluminium and aluminium alloys, Chemical test method for determination of nickel contents SNI 07-1166-1989 - Aluminium and aluminium alloys, Chemical test method for determination of zinc contents SNI 07-1162-1989 - Aluminium and aluminium alloys, Chemical test method for determination of chromium contents SNI 07-1163-1989 - Alluminium and aluminium alloys, Chemical test method for determination of magnesium content SNI 07-1164-1989 - Aluminium and aluminium alloys, Chemical test method for determination of manganese contents SNI 07-1167-1989 - Aluminium and aluminium alloys, Chemical test method for determination of silicon contents SNI 07-1168-1989 - Aluminium and aluminium alloys, Chemical test methods for determination of copper contents

Rev 1 (07/31/2014) Page 13 of 25 SNI 07-1169-1989 - Aluminium and aluminium alloys, Chemical test method for determination of tin contents SNI 07-1170-1989 - Aluminium and aluminium alloys, Chemical test method for determination of lead contents SNI 07-1171-1989 - Aluminium and aluminium alloys, Chemical test methods for determination of titanium contents SNI 07-1159-1989 - Aluminium and aluminium alloys, Test method for determination of iron contents SNI 07-1159-1989 - Aluminium and aluminium alloys, Test method for determination of iron contents SNI 15-1320-1989 - Gypsum, Chemical analysis test method SNI 07-1174-1989 - Aluminium and aluminium alloys, Chemical composition test method by photometric emission spectrophotometer SNI 07-3119-1992 - Test method for determination of nickel content of steels by gravimetric methods SNI 07-1775-1990 - Ferrovanadium, Test method for chemical composition SNI 15-1854-1990 - Test method for activity of pozolan by chemical and physical method SNI 13-3488-1994 - Garnerite nickel ores,

Rev 1 (07/31/2014) Page 14 of 25 Sampling method for determination of water content and chemical composition SNI 13-3493-1994 - Tin ingots, Test methods for chemical composition by atomic absorption spectrophotometers SNI 13-3496-1994 - Mining goods, Preparation of sample for chemical analysis and physical characteristic test in laboratories SNI 13-3608-1994 - Test method for chemical composition main substance of xeolits SNI 07-3624-1994 - Convension which valid for electro chemical measuring in corrosion testing SNI 06-4376-1996 - Guidances for chemical testing methods SNI 06-6695-2002 - Test methods for chemical analysis of soda lime and borosilicate glass SNI 14-2162-2001 - NCR (no carbon required) paper base chemical transfer type SNI 13-6339.4.1-2001 - Terms of metals, minerals and coal testing - Part D: Chemical testing of minerals and metals - Section 1: Gravimetric methods SNI 13-6339.4.2-2001 - Terms of metal, minerals and coal testing - Part D: Chemical testing of minerals and metals - Section 2: Volumetric methods

Rev 1 (07/31/2014) Page 15 of 25 SNI 13-6230-2000 - Special purpose steam turbines for petroleum, chemical, and gas industry services SNI 03-6474-2000 - Test methods for determination of unconfined compressive strength index of chemical grouted soils SNI 07-6013-1999 - Chemical test method of stainless steel SNI 07-6003-1999 - Test method for chemical composition of ferrotitanium SNI 07-6004-1999 - Test methods for chemical composition of ferrochromium SNI 07-4616-1998 - Chemical test method for cast iron SNI 03-4819-1998 - Methods for making sediment extracts for chemical properties testing of sediment SNI 07-4905.1-1998 - Test method for chemical composition of ferrosilicon SNI 07-4905.2-1998 - Test method for chemical composition of ferromangan SNI 14-4935-1998 - Test method for bleaching chemicals of pulp (chlorine, chlorine oxide, sodium hypochlorite, sodium hydroxide and hydrogen peroxide) SNI 19-2743-1992 - Quantities and units of physical chemistry and molecular physics SNI 01-2354.2-2006 - Test methods of chemistry - Part 2: The determination of water

Rev 1 (07/31/2014) Page 16 of 25 content in fishery products SNI 01-2354.3-2006 - Test methods of chemistry - Part 3: The determination of total lipid content in fishery products SNI 01-2354.4-2006 - Test methods of chemistry - Part 4: The determination of protein content in fishery products by nitrogen total methods SNI 12-1547-2005 - PVC boots with chemical resistance SNI 19-0232-2005 - Threshold levels for chemical substances in the workplace atmosphere SNI 07-3016-1992 - Hot-rolled steel for welded structure, chemical composition and mechanical properties SNI 02-3126-1992 - Dust (D) pesticides, Physic-chemical test methods SNI 02-2722-1992 - Chemical physic test methods of emulsifable concentrate (EC) pesticides SNI 02-3124-1992 - Wettable powder (WP) pesticides, Physic- chemical test methods SNI 02-3127-1992 - Oil concentrate (OC) pesticides, Physic- chemical test methods SNI 02-3128-1992 - Water soluble concentrate (WSC) pesticides, Physic- chemical test methods SNI 07-1158-1989 - Chemical test methods for determination of berilium contents

Rev 1 (07/31/2014) Page 17 of 25 aluminium and aluminium alloys SNI 07-1161-1989 - Aluminium and aluminium alloys, Chemical test method for determination of boron contents SNI 07-1172-1989 - Aluminium and aluminium alloys, Chemical test method for determination of vanadium contents SNI 07-1173-1989 - Aluminium and aluminium alloys, Chemical test method for determination of zirconium contents SNI 07-1175-1989 - Aluminium and aluminium alloys, Chemical composition test method using atomic absorption spectrophotometer SNI 07-3114-1992 - Test method for determination of molybdem content of steels by photometric method SNI 07-3117-1992 - Test method for determination of chromic content of steels by molybdem austenitic stain titration methods SNI 07-3118-1992 - Test method for determination of titan content of steels by spectrophotometric methods SNI 07-3120-1992 - Steels, Test method for determination of cobalt content of steels by photometric method SNI 02-3125-1992 - Granule (G) pesticides, Physic-chemical test methods

Rev 1 (07/31/2014) Page 18 of 25 SNI 07-4604-1998 - Chemical test method of niobium in steel SNI 07-4619-1998 - Chemical test method for babbit metals SNI 03-1768-1990 - Aggregates for concrete, Test methods for reactive properties against alkalin by chemical method SNI 03-6791-2002 - Test method of cement content in soil-cement mixture by chemistry analysis SNI 03-6804-2002 - Manual for laboratory preparation of chemical-grouted soil test specimen for obtaining design strength parameter SNI 06-2862-1992 - Chemicals for fire extinguisher SNI 06-4571-1998 - Test methods for chemical oxygen demand (COD) of waste water in permaganometric manner SNI 2354.5:2011 - Chemical test methods - Part 5: Determination of heavy metal lead (Pb) and cadmium (Cd) in fishery products SNI ISO 1833-4:2011 - Textiles - Quantitative chemical analysis - Part 4: Mixtures of certain protein and certain other fibres (method using hypochlorite) SNI ISO 1833-20:2011 - Textiles - Quantitative chemical analysis - Part 20: Mixtures of elastane and certain other fibres (method using

Rev 1 (07/31/2014) Page 19 of 25 dimethylacetamide) SNI ISO 1833-5:2011 - Textiles - Quantitative chemical analysis - Part 5: Mixtures of viscose, cupro or modal, and cotton fibres (method using sodium zincate) SNI ISO 1833-3:2011 - Textiles - Quantitative chemical analysis - Part 3: Mixtures of acetate and certain other fibres (method using acetone) SNI ISO 1833-16:2011 - Textiles - Quantitative chemical analysis - Part 16: Mixtures of polypropylene fibres and certain other fibres (method using xylene) SNI ISO 1833-21:2011 - Textiles - Quantitative chemical analysis - Part 21: Mixtures of chlorofibres, certain modacrylics, certain elastanes, acetates, triacetates and certain other fibres (method using cyclohexanone) SNI ISO 1833-2:2011 - Textiles - Quantitative chemical analysis - Part 2: Ternary fibre mixtures SNI ISO 1833-10:2011 - Textiles - Quantitative chemical analysis - Part 10: Mixtures of triacetate or polylactide and certain other fibres (method using dichloromethane) SNI ISO 1833-17:2011 - Textiles - Quantitative chemical analysis - Part 17: Mixtures of chlorofibres (homopolymers of vinyl chloride) and certain other fibres (method using sulfuric acid)

Rev 1 (07/31/2014) Page 20 of 25 SNI ISO 1833-18:2011 - Textiles - Quantitative chemical analysis - Part 18: Mixtures of silk and wool or hair (method using sulfuric acid) SNI ISO 1833-19:2011 - Textiles - Quantitative chemical analysis - Part 19: Mixtures of cellulose fibres and asbestos (method by heating) SNI ISO 1833-12:2011 - Textiles - Quantitative chemical analysis - Part 12 : Mixtures of acrylic, certain modacrylics, certain chlorofibres, certain elastanes and certain other fibres (method using dimethylformamide) SNI ISO 1833-7:2011 - Textiles - Quantitative chemical analysis - Part 7: Mixtures of polyamide and certain other fibres (method using formic acid) SNI ISO 1833-9:2011 - Textiles - Quantitative chemical analysis - Part 9: Mixtures of acetate and triacetate fibres (method using benzyl alcohol) SNI ISO 1833-6:2011 - Textiles - Quantitative chemical analysis - Part 6: Mixtures of viscose or certain types of cupro or rayon modal or lyocell and cotton fibres (method using formic acid and zinc chloride) SNI ISO 1833-8:2011 - Textiles - Quantitative chemical analysis - Part 8: Mixtures of acetate and triacetate fibres (method using

Rev 1 (07/31/2014) Page 21 of 25 acetone) SNI ISO 1833-24:2011 - Textiles - Quantitative chemical analysis - Part 24: Mixtures of polyester and certain other fibres (method using phenol and tetrachloroethane) SNI ISO 1833-13:2011 - Textiles - Quantitative chemical analysis - Part 13: Mixtures of certain chlorofibres and certain other fibres (method using carbon disulfide/acetone) SNI ISO 1833-14:2011 - Textiles - Quantitative chemical analysis - Part 14: Mixtures of acetate and certain chlorofibres (method using acetic acid) SNI ISO 1833-15:2011 - Textiles - Quantitative chemical analysis - Part 15: Mixtures of jute and certain animal fibres (method by determining nitrogen content) SNI ISO 1833-1:2011 - Textiles - Quantitative chemical analysis - Part 1: General principles of testing SNI ISO 1833-11:2011 - Textiles - Quantitative chemical analysis - Part 11: Mixtures of cellulose and polyester fibres (method using sulfuric acid) SNI 0449:2010 - Clay and feldspar, Test method for wet chemical method SNI ISO 10545- 13:2010 - Ceramic tiles-Part 13: Determination of chemical resistance SNI 7575:2010 - Chemical analysis of

Rev 1 (07/31/2014) Page 22 of 25 gypsum samples SNI 6527.4:2012 - Safety of toys - Part 4: Chemical toys set as the chemistry trial SNI ISO 9184-7:2014 - Paper, board and pulps – Fiber furnish analysis Part 7: Determination of weight factor SNI ISO 9184-6:2014 - Paper, board and pulps – Fiber furnish analysis Part 6: Determination of fiber coarseness SNI ISO 9184-5:2014 - Paper, board and pulps – Fiber furnish analysis Part 5: Lofton-Merritt staining test (modification of wisbar) SNI ISO 9184-4:2014 - Paper, board and pulps – Fiber furnish analysis Part 4: Graff “C” staining test SNI 13-6794-2002 - Test methods for determination of fiber content on peat sample by drainage in the laboratory SNI 13-6622-2001 - Determination for fiber content of peat or dried non-peat organic soils SNI 08-4643-1998 - Test methods for overlength fiber content of man - made staple fibres SNI 7615.3:2010 - Optical fiber cables - Part 3: Single mode loose tube constructed for the application of aerial cable SNI 7615.2:2010 - Optical fiber cables - Part 2: Single mode loose tube constructed for duct applications SNI 7615.1:2010 - Optical fiber cables - Part 1: Single mode

Rev 1 (07/31/2014) Page 23 of 25 loose tube constructed for the application of direct planting 18. How do you assess • Review and have x legal and other access applicable legal requirements that are and other requirements applicable for chemicals, for mining and chemical products and quarrying business. fibres business? • Check how they determine the application of such applicable legal and other requirements. • Do they update the applicable legal and other requirements regularly? • Evaluate the compliances to the applicable legal and other requirements 19. What is outsourcing? In business, outsourcing is x How do you assess this? the contracting out of a business process to a third- party. Outsourcing sometimes involves transferring employees and assets from one firm to another, but not always. Outsourcing is also used to describe the practice of handing over control of public services to for-profit corporations.

Outsourcing includes both foreign and domestic contracting, and sometimes includes offshoring or relocating a business function to another country. Financial savings from lower international labor rates is a big motivation for outsourcing/ offshoring.

I will assess the mechanism: • Check how they selected thru purchasing mechanism • Check whether they evaluated regularly 20. How do you assess The impact of organization x the impact of organization type, size, governance,

Rev 1 (07/31/2014) Page 24 of 25 type, size, governance, structure, functions and structure, functions and relationships on relationships on development and development and implementation of the implementation of the quality management quality management system and certification system and certification activities more to their activities? commitment, how they plan, implement, manage, control, improve the implemented system, including the documented scope, I will assess: • Scope of application • Documented system • Management, including commitment, policy, objective • Provision of resources, including human resources • Process, including material, machine, method, control, inspection • Improvement mechanism, audit, inspection, process control, control of nonconformance, corrective and preventive action, management review

Rev 1 (07/31/2014) Page 25 of 25