Background Statement for SEMI Draft Document 5117A REVISION TO SEMI MS2-1109, TEST METHOD FOR STEP-HEIGHT MEASUREMENTS OF THIN FILMS

Note: This background statement is not part of the balloted item. It is provided solely to assist the recipient in reaching an informed decision based on the rationale of the activity that preceded the creation of this document.

Note: Recipients of this document are invited to submit, with their comments, notification of any relevant patented technology or copyrighted items of which they are aware and to provide supporting documentation. In this context, “patented technology” is defined as technology for which a patent has issued or has been applied for. In the latter case, only publicly available information on the contents of the patent application is to be provided.

Background SEMI MS2-1109 enables the determination of step height measurements of thin films. Step height measurements can be used to determine thin film thickness values. Thickness measurements are an aid in the design and fabrication of MEMS devices and can be used to obtain thin film material parameters, such as Young’s modulus.

SEMI MS2 became publicly available in March of 2007 without precision and bias data. The MEMS Young’s Modulus and Step Height Round Robin Experiment was held from December 2008 through April 2009. The SEMI MS2 standard was revised to include the round robin precision and bias data and was published in November 2009 after a successful reballot.

Standard reference materials (SRM 2494 and SRM 2495) are being developed to aid customer’s in their use of five documentary standard test methods (including SEMI MS2). During the review process of the standard reference materials, most sections of this test method were modified as reflected by the changes in this SEMI Document 5117, resulting in what can be considered a complete rewrite of this test method. Of particular note is the following: 1. Those definitions obtained from ASTM are modified, 2. The calibration procedure is updated and is similar to that used in draft Test Methods E 2244, E 2245, and E 2246 that are being balloted in ASTM, 3. Improved the round robin tables, and 4. The combined standard uncertainty equation is modified to include the incorporation of two additional uncertainty components in the combined standard uncertainty equation and added Table A1-1 to facilitate the understanding of this equation. This SEMI Document 5117A is now being balloted and the complete set of changes can be seen in the redlined version of this document. SEMI Document 5117A was approved for letter balloting in July 2011. Review and Adjudication Information Task Force Review Committee Adjudication Group: MEMS Materials Characterization TF NA MEMS / NEMS Committee Date: Monday, October 24, 2011 Monday, October 24, 2011 Time & Timezone: 1:30 PM to 2:30 PM, Pacific Time 3:00 PM to 5:00 PM, Pacific Time Location: SEMI Headquarters SEMI Headquarters 3081 Zanker Road 3081 Zanker Road City, State/Country: San Jose, CA San Jose, CA Leader(s): Janet Cassard (NIST, [email protected]) Mark Crocket (MEMSMART, [email protected]) Win Baylies (BayTech Group, [email protected]) Standards Staff: Paul Trio (SEMI NA) Paul Trio (SEMI NA) 408.943.7041 /[email protected] 408.943.7041 / [email protected] This meeting’s details are subject to change, and additional review sessions may be scheduled if necessary. Contact the task force leaders or Standards staff for confirmation.

Telephone and web information will be distributed to interested parties as the meeting date approaches. If you will not be able to attend these meetings in person but would like to participate by telephone/web, please contact Standards staff. Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and layers are assumed to have a uniform thickness across the chip and, as such, do not enter into the calculations. This post- This 4 calculations. the into enter not do such, as and, chip the across thickness is processing considered the of testoutside scope this method. uniform a have to assumed are layers additional These measurements. gold interferometric the accurate enabling for surface layer reflective smooth, adhesion a an provides coverage as gold serves the while chromium The surface. top the on deposited be can gold of nm 150 approximately by 1: NOTE 3.1 3 the determine and practices health and safety appropriate other ofprior limitations use.applicability regulatoryor to establish to standard this of users the of responsibility NOTICE: interferometer optical data 2-D traces. the capability with oftopographical instrument obtaining an be can using which materials, imaged (MEMS) system microelectromechanical accurately in found those as such films, to only applies It 2.1 2 measurements Thickness values. thickness film thin as parameters, Young’s canusedthin obtain such MEMSto material modulus. and be film fabrication of devices determine to used be can 1.1 1 NOTICE: THIN MEASUREMENTSFILMS OF SEMIMS2-1109, TESTFOR STEP-HEIGHT TO METHOD REVISION Draft Document SEMI 5117A emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This Fax: 610.832.9555; 610.832.9585; 3 Test MEMS Structures,” Processes using Beams,” 2 Polysilicon Processes,” MEMS in Micromechanical Thickness Systems Layer Measuring for of Technique Optomechanical “New Measurements C., J. Marshall, Property “Material D., in MEMS,” and Structure Nonidealities Test Properties S. Material Determine to Microcantilevers Actuated Senturia, of “Interferometry A., D. LaVan, and F., Bitsie, D., N. Masters, P., M. and Boer, de D., B. Jensen, M., P. Osterberg, in Micromachining II and Metrology Microlithography K., R. Gupta, J.NIST Res 1 an Using Films Reflecting Thin, of Measurements Strain Residual InterferometerOptical for Method Test Standard — E2245 ASTM an Using Films Reflecting Thin, of Measurements Length InterferometerOptical In-Plane for Method Test Standard — E2244 ASTM 4.2 Resonance Beamsin of Frequency the on Based Films Reflecting Thin, of Measurements Modulus Young’s for Method Test — MS4 SEMI 4.1

American Society for Testing and Materials,Drive, 100 Barr forHarbor West Society Pennsylvania and Conshohocken, Testing USA. Telephone: American 19428-2959, Vernier, J. L., C., D. P. in D. Standard Herman, Marshall, Gaitan, DeVoe, T., M.,Measurements ICCMOS “Young’s and L. Modulus Referenced Standards Referenced Documents and Limitations Scope Purpose Marshall, J. C., and Vernier, P. T., “Electro-Physical Technique for Post-Fabrication Measurements of CMOS Process Layer Thicknesses,” Layer Process CMOS of Measurements Post-Fabrication for Technique “Electro-Physical T., P. Vernier, and C., J. Marshall, For optical interferometry, all platforms involved in step height measurements mustreflective. platformsstepmeasurements all height in involved be For opticalinterferometry, structures. test height step using films thin of heights step measuring for procedure a presents method test This of stepmeasurements height thinmeasurements the height determination Step enables of method test films. This ASTM SEMI , Vol 10(March pp.153–157. 2001): ., Vol.5(2007): 112,No. pp.223–256.

Standard the is It use. its with associated any, if issues, safety address to purport not does standard This Standards This document was completely rewritten in 2009. completelyin rewritten documentThis was If in doubt as to whether or not the platforms are sufficiently reflective, approximately 8 nm of chromium followed chromium of nm 8 approximately reflective, sufficiently are platforms the not or whether to as doubt in If 3 http://www.astm.org IEEE Electron Device Letters IEEE Electron , SPIE,14-15, Volpp.39–45. 2880(October 1996): Journal of Microelectromechanical Systems ofJournal Microelectromechanical as ald a nefrmti microscope) interferometric an called (also Page , Vol. 28, No. 11 (2007): pp.960–963. , Vol.11(2007): 28,No. jn l jn 3 , Vol 10 (September 2001): pp.336–346. 2001): , Vol 10(September 1

are an aid in the design and design the in aid an are Journal of Microelectromechanical of Journal Document Document Number: Doc. r comparable or Date: SEMI 4/9/2018 DRAFT 2

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and NOTE 4: 4: NOTE sets 5.2.4 locations. specified 5.2.3 view the fieldof of within the instrument 5.2.2 3: NOTE 5.2.1 2: NOTE 5.2 5.1.3 5.1.2 5.1.1 5.1 5 Subnanometer at Microscope Force NOTICE: Atomic an of Z-Magnification the Calibrating UsingSi Monatomic Steps (111) Levels Displacement for Practice Standard — Films Reflecting Thin, on Taken Measurements to Relating Terminology Standard — E2444 ASTM E2444 ASTM an Using Films Reflecting Thin, of Measurements Gradient Strain InterferometerOptical for Method Test Standard — E2246 ASTM emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This Conshohocken,19428 Drive, West PA 4 5: NOTE (or processed surface platform).flat, 5.2.10 the during part) microstructuresallow freestanding in or whole (in removed then added) (or deposited 5.2.9 direction. 5.2.8 or processedsurface. reference flat, 5.2.7 interferometer 5.2.6 [ASTM E2444] technologies), and 5.2.5 edgestransitional sample

Referenced definitions reprinted, with permission, from the with permission, reprinted, from Referenced definitions Terminology and 2-Dtraces) data and Definitions Abbreviations and actuators interferometer micromachining bulk set data 3-D trace data 2-D MEMS FOV CMOS sacrificial layer sacrificial platform reference height platform height step physical systems microelectromechanical h The . step height step

Unless otherwise indicated, all documents cited shall be theversions. latest published otherwise documents all cited be shall Unless indicated, —field of view For instruments,the datamany 2-D trace extracted is from 3-D set. a data the Some terms definitionsof following and are to found ASTM similar those in E2444. It recommendedis that two of bethe platforms interest designed adjacent each to other. interferometer T — — microelectromechanical systems —microelectromechanical he height of the sample is measured along t along measured is sample the of height he — Standard Terminology Relating to Measurements Taken onThin, Films Taken to TerminologyRelating Reflecting Measurements —Standard , interferometric microscopeinterferometric to measured be n and c omplementary omplementary — the distance in the the in distance the — — a three-dimensional group of points with a topographical topographical a with points of group three-dimensional a — [ASTM E2444] — a non-contact optical instrument used to obtain topographical topographical obtain to used instrument optical non-contact a — — a two-dimensional group is that the of —a to points parallel r te the or — the distance in the the in distance the — — — Acronyms . [ASTM E2444] interferometric microscope interferometric —tefa,poesdsraeta sue olvladzr h esrmnsi h the in measurements the zero and level to used is that surface processed flat, the — to allow freestanding microstructures, microstructures, freestanding allow to a ES fbiain poes process fabrication MEMS a — .

. ehoois ue o hi their for used technologies m standard . etal [ASTM E2444] — — o xide . or comparable instrument in the out-of-plane comparablein instrument or z

-direction that an initial, flat, processed surface (or platform) is to a final, a to is platform) (or surface processed flat, initial, an that -direction a in general, this general, in h the — z s -direction that a flat, processed surface of interest is from a designated a from is interest of surface processed flat, a that -direction emiconductor Annual Book of ASTMStandards Annual Book s’s x ai stpclyaindprle rpredclrt h the to perpendicular or parallel aligned typically is -axis obntos thereof combinations he he Page artifact z -axis of the interferometer the of -axis term term jn l jn 4 tp hih height step manufacture is is ht eoe removes that a single thickness of material that is intentionally is that material of thickness single a used to describe micron-scale structures, sensors, structures, micron-scale describe to used micromachining manufacture , copyright ASTM International, 100Barr Harbor, copyrightInternational, ASTM

hr where z xz sd t airt h optical the calibrate to used -value for each ( each for -value is used to measure the height of the of height the measure to used is - or yz z substrate the sc s iio process silicon as, (such irmciigmicromachining -direction. 3-D 3-D -plane of-plane the instrument. both data data Document Document Number: . Doc. x (such as 3-D data 3-D as (such , , y ) pixel location pixel ) 4 Date: s rmvd removed is ASTM E2530 ASTM SEMI process measured 4/9/2018 DRAFT , to , z at -

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and 5.3.1.2 session. physicalafter the data takenstepstandard measurements height the six along the deviationof the standard measur height step six the 5.3.1.1 5.3.1 5.3 6: NOTE not does it that such enough small is strain the assuming the material. deform irreversibly tension, uniaxial in loaded is material the when strain 5.2.19 data a asin 2-D trace. seen displacement 5.2.18 5.2.17 about layer) a of gradient E2444] strain the or strain residual the as, (such information 5.2.16 [ASTM E2444] 5.2.15 and of (orremovalor part) sacrificiallayers. bythestructural deposition in (insubstrate addition)and whole 5.2.14 fabrication process 5.2.13 5.2.12 5.2.11 emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This height step physical the on location same the the data the taken minimum measurements session (at maximumof before calibration the six between and values 5.3.1.10 instruments. 5.3.1.9 3 (typically less than 5.3.1.8 height for used calibrationheight step physical the th (at session data on the after taken measurements location calibration six the of same average the (at session data the before 5.3.1.7 5.3.1.6 5.3.1.5 sample thatfabricate ato in similar process the used fabricated structures 5.3.1.4 5.3.1.3 session and measurem height step six the of Symbols For Young’s modulus Young’s edge transitional thickness structure test micromachining surface substrate layerstructural structure step test height z z cert cal perc drift cert z 6same 6ave repeat(samp)

repeat Calibration z

hs etis oms otcl nefrmtr adteeoetherefore and interferometers optical most to pertains This

σ It also is called elastic modulus elasticity,the modulus, the of the and tensile modulus. lin — —

— — same2 —

(shs) —

—

the the certified value of thethe certifiedvalue the the the the — the height in the —thein height —

is the standard deviation of standardmeasur isthe six deviation the

— the vrteisrmn’ oa cnrne h aiu maximum the range, scan total instrument’s the over

z that can be used to build to devices. be MEMS can used that certified maximum of two uncalibrated values ( values uncalibrated two of maximum un -calibration factor of the factor of -calibration —

— a a — in a fabrication process, process, fabrication a in maximum of two uncalibrated values ( values uncalibrated two of maximum h aiu ftotwo of maximum the %) calibrated positive difference between the average of the six calibration measurements taken measurements calibration six the of average the between difference positive calibrated

— a single thickness of material thickness single of material —a the , as quotedmanufacturer by the instrument , as — the side of a MEMS structure that is characterized by a distinctive out-of-plane vertical out-of-plane distinctive a by characterized is that structure MEMS a of side the — — a parameter indicative of material stiffness that is equal to the stress divided by the by divided stress the to equal is that stiffness material of indicative parameter a — ). e relative step height repeatability standard deviation as obtained from step height test height step from obtained as deviation standard repeatability height step relative fabricated fabricated men one sigma uncertaintythe sigma of one t where process fabrication MEMS a — — a test structure from which step height measurements are obtained. structure test which are stepmeasurements height —a from e s taken along the physical step height standard before the data session and and session data the before standard height step physical the along taken s nts taken at the same location o location same the at taken nts z component (such as, a fixed-fixed beam or cantilever) that is used to extract to used is that cantilever) or beam fixed-fixed a as, (such component -direction ofmorethin-direction onelayers. designated or film double-sided double-sided un standard interferometer the thick, starting material (often single crystal silicon or glass) glass) or silicon crystal single (often material starting thick, the calibrated values; one of which is the positive calibrated difference calibrated positive the is which of one values; calibrated used for calibration) and the other is the positive calibrated positive the is other the and calibration) for used physical step height Page that isthat certified jn l jn σ interferometric microscopeinterferometric e before 5 σ [ASTM E2444] men same1 present in the final MEMS device. [ASTM thedevice. E2444] final in MEMS present and n t physical step height

s taken at this same location after the data session. at this locationafter the data s taken same the physical step height standa height step physical the (typically less than 3%) and and

σ after σ same2 micron-scale micron-scale ) where where ) standard standard . z relative perc ) where where ) standard is may equal zero percent for other for percent zero equal may e same location same σ the percent used forused calibration. before σ a or comparable instrument. or comparable used for calibration for used standard standard same1 fbiainpoes process. fabrication components are formed on a on formed are components

is the standard deviation of deviation standard the is deviation from linearity from deviation . is the standard deviation standard the is Document Document Number: on the physical step physical the on used forused calibration. Doc. r d before the data the before d Date: SEMI ) and the and ) 4/9/2018 [ASTM σ DRAFT after in a in

is

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and indicators indicators and platform, reference a from is it indicates where structure, test height step one on traces data multiple 5.3.2.3 “ “ traces data from obtained values deviation standard the all of smallest the as measured is it then compositions, for 5.3.2.2 5.3.2.1 5.3.2 session datacalculate to andsession) after the used before 5.3.1.15 5.3.1.14 5.3.1.13 z 5.3.1.12 stepusedcalibration. height same for locationonthe physical at the 5.3.1.11 data the after taken measurements calibration six the thsession (at of values maximum and minimum the between difference emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This and traces data from obtained values deviation standard the all of smallest the as measured is it then compositions, for 5.3.2.11 5.3.2.10 5.3.2.9 5.3.2.8 5.3.2.7 examined. with starting ( number 5.3.2.6 “ and etc.) 5.3.2.5 and of closestthe top to the chip), designed indicators compass the (using platform reference ( number structure 5.3.2.4 z repeat b C same ,” and “ ,” and , ” c s etc.) as lettered starting with asstartingwith etc.) lettered (shs) along these platforms. along these platNXt platNXt For Step Height Measurements andCalculations For Step Height

— is found. is ( s s s platNXt platNX platNrDt platNrD

at the same locationonthe physicalat thestep same height platNXt platNXave platNrDt platNXt s s roughNX “ X the uncalibrated average of the twelve calibration measurements calibration twelve the of average uncalibrated the z z z z z c roughNX platNYt “ 1 oee, i h ufcs o h ltom icuig te rfrne pafr) al hv identical have all platform) reference the (including platforms the of surfaces the if however, ; 6 6 is the capital letter (or (or letter capital the is 6 ave ” along these platforms.” along these oee, i h ufcs o h ltom icuig te rfrne pafr) al hv identical have all platform) reference the (including platforms the of surfaces the if however, ; N — — , ave same ” — — is ,

“ ” — — the calibrated average of the twelve calibration measurements taken before and after the data session data the after and before taken measurements calibration twelve the of average calibrated the

“ e same location on the physical step height used for locationonthe physicale stepused calibration) height same A

— the uncalibrated standard deviation of the data from Trace on data t from deviationof— the uncalibratedstandard the — the calibrated platform height measurement, where where measurement, height platform calibrated the — —

— the “ 2

— a — — the uncalibrated standard deviation of the data from Trace t on t from deviationof standard the Trace data — the uncalibrated ” — the uncalibrated standard deviation of the data from Trace on data t from deviationof— the uncalibratedstandard the

— the the — the the

S — , — the average of the calibrated standard deviation values from the data traces on the data deviationvalues standard traces from of— the average the calibrated — a — — the uncalibrated surface roughness of of roughness surface uncalibrated — the for the platform closest to to closest platform the for h the — ” , the ”

“ the “

1 un “ the 3 n average of the twelve calibration measurements (taken along the physical step height standard height step physical the along (taken measurements calibration twelve the of average , E , ” n uncalibrated average of the six calibration measurements from which of calibration the average six from measurements uncalibrated un

” calibrated average of the six calibration measurements measurements calibration six the of average calibrated , un

un ” uncalibrated average of the six calibration measurements used to of calibration the average six used measurements determine uncalibrated t., etc.), “ un calibrated standard deviation of the data from deviationofcalibrated standard the data or or airtdcalibrated 2 calibrated platform height measurement from one data trace, where where trace, data one from measurement height platform calibrated calibrated surface roughness of of roughness surface calibrated , calibrated reference platform height measurement from one data trace, where where trace, data one from measurement height platform reference calibrated ” “

“ W 3 X ” , ” is the capital letter associated with the platform ( platform the with associated letter capital the is

where etc.), etc.), “ “ A r vrg ftethe of average ” ” for the platform for closest to the is used if it is the reference platform) associated with the platform ( platform the with associated platform) reference the is it if used is

“ r N indicates it is from a reference platform, platform, reference a from is it indicates ”

t refers to the reference to refers is the data trace ( the data is platNrW D directionally indicates which reference platform (using the compass the (using platform reference which indicates directionally “ cal N airtdcalibrated , ” z or or Page

“ standard S , platNX platNrS platNX ” jn l jn

“ 6 E “ N reference platform height measurements taken from taken measurements height platform reference , a ” is the test structure number ( number structure test the is , or or ) and that ) platNrW measured as the smallest of all the values obtained values the all of smallest the as measured ” measured as the smallest of all the values obtainedvalues theall ofsmallest the as measured , and and ,

platform designed of closestthe top platform to the chip). “ b “ , W ” t

race race N ” “ t is the data trace ( trace data the is

c is the test structure number ( number structure test the is or or where , that were that ” is etc.) being examined. etc.) “ , used to calculate to, used calculate platNrS t ” that was used to determine to used was that ) on .

“ platNX N platNrD platNY. platNX ” refers to the reference platform reference the to refers , taken before and after the data the after and before taken , . D “ A directionally indicates which indicates directionally , ” .

. “ . B “ σ a , ” 6ave , ”

Document Document Number: “ N cal

“ 1 “ C is the test structure test the is

, b is found. Doc. ” z , platNX , . ”

” etc.) as lettered as etc.) “ σ

2 “ 6same Date: c , ” “ , ”

1 N “ from which from etc.) being etc.) , SEMI . ” 3 is the test the is

“ , “ ” A 4/9/2018 2 etc.), etc.), , DRAFT , ” ”

a “ “ B , , 3 a b , , ,” ” ” r ,

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and 5.3.3.4 of the uncertaintythephysical tovalue step height of due the 5.3.3.3 the across physical stepstandard. height uncertaintythetaken tomeasurements of due the 5.3.3.2 5.3.3.1 5.3.3 final to platform. platform the platform), reference the is “ where 5.3.2.15 (or platform (or platform initial the with where structure, test height step 5.3.2.14 number structure number structure test where from and platform platform final the to platform initial the from is step and 5.3.2.13 and traces data from obtained values deviation standard the all of smallest the as measured is it then compositions, for 5.3.2.12 emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This one to being measuredsimilarly the to due is that measurements 5.3.3.11 for measurement height platNX platform the of uncertainty the to due is that structures test height step two from obtained 5.3.3.10 scan. linearityof the due data theis deviationfrom to 5.3.3.9 of the edge the to step. perpendicular measured is length the where step, the of length the across height step the of uncertainty measurement the to due is 5.3.3.8 of the edge the to step. perpendicular of length the across uncertainty measurement the to due is that measurements 5.3.3.7 is 5.3.3.6 a measurement of the uncertainty 5.3.3.5 r ” the uncertainty of a measurement due to the deviation from linearity of the data scan. linearity of the duedata measurement the deviationfrom to ofthe a uncertainty is used if it is the reference platform), platform), reference the is it if used is c M s along these platforms. along these platNYt For Combined Standard Uncertainty Calculations Uncertainty For CombinedStandard ) on the same test chip, which is equal to the final platform height minus the initial platform height, where the where height, platform initial the minus height platform final the to equal is which chip, test same the on ) N . u u u u u u u u u is the number associated with the test structure, structure, test the with associated number the is u u linear Lstep LplatNX linear drift cSH cert cal c stepN stepN stepN s — the combined standard uncertainty standard —the combined roughNY repeat(samp) platNX oee, i h ufcs o h ltom icuig te rfrne pafr) al hv identical have all platform) reference the (including platforms the of surfaces the if however, ;

— the combined standard uncertaintya standard stepmeasurement. height of —the combined — the component in the combined standard uncertainty calculation for step height measurements that is that measurements height step for calculation uncertainty standard combined the in component the —

“ — the component in the combined standard uncertainty calculation calculation uncertainty standardcombined the in component — the — — the component in the combined standard uncertainty calculation for step height measurements that measurements height step for calculation uncertainty standard combined the in component the —

r — the component in the combined standard uncertainty calculation for step height measurements that measurements height step for calculation uncertainty standard combined the in component the — — ” XYt XY X h opnn n te cmie tnad ucrany cluain fr pafr height platform for calculation uncertainty standard combined the in component the — — the component in the combined standard uncertainty calculation for step height measurements height step for calculation uncertainty standard combined the in component the — is used if it is the reference platform), and the step is from the initial platform the final platform), thefromto stepplatform. is the reference the usedis initial and is if it M the component in the combined standard uncertainty calculation for step height measurements that is calculationthat stepmeasurements height the combineduncertainty for in standard the component

— the average of the calibrated step height measurements taken from multiple data traces on one on traces data multiple from taken measurements height step calibrated the of average the — — the uncalibrated surface roughness of of roughness surface uncalibrated the — the component in the combined standard uncertainty calculation for step height measurements that measurements height step for calculation uncertainty standard combined the in component the — a calibrated step height measurement from one data trace on one step height test structure, test height step one on trace data one from measurement height step calibrated a — M Y

.

— the calibrated step height measurement taken from two different step height test structures ( structures test height step different two from taken measurement height step calibrated the — h opnn n te cmie tnad ucrany cluain fr se height step for calculation uncertainty standard combined the in component the — t “ is the data trace ( trace data the is r h eetblt fmaueet tkno on taken measurements of repeatability the ” is used if it is the reference platform), platform), reference the is it if used is N due to the amount of amount tosession. drift during the data due the is the number associated with the test structure, structure, test the with associated number the is . N n and , Y is the capital letter associated with the final platform (or (or platform final the with associated letter capital the is Y “ is the capital letter associated with the final platform from test from platform final the with associated letter capital the is a value (i.e., the estimated standard deviationof estimated standard the result) (i.e., the value , ”

“ b Page , ”

X “ platNY c is the capital letter associated with the initial platform (or platform initial the with associated letter capital the is jn l jn , ” 7 etc.) being examined, and the step is from the initial the from is step the and examined, being etc.) standard standard measured as the smallest of all the values obtained values the all of smallest the as measured X is the capital letter associated with the initial the with associated letter capital the is used forused calibration. Y is the capital letter associated with the final the with associated letter capital the is tpstep platNX for step height measurements measurements height step for height X , where the length is measured is length the where , is the capital letter associated letter capital the is

test structures processed structures test Document Document Number: Doc. “ Date: r ” is used if it if used is SEMI . 4/9/2018 DRAFT that is that a , , b N ,

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and instrument is used to obtain multiple 2-D data traces along the top of the test structure(s) involved in the step. A step. the in involved ex structure(s) test the of top the along traces data 2-D multiple obtain to used is instrument optical An values, uncertainty standard combined their and structures test height step two from or (recommended) structure test 6.1 the obtain required data. to appropriate, as made, be to need may modifications Therefore, instruments. all to pertain specifically not may and instrument 7: NOTE is width the 6 where step, the of width the across height step the of step. parallel of the edge the to measured uncertainty measurement the to due is that 5.3.3.17 of the edge the to ste parallel of width the across uncertainty measurement the to due is that measurements 5.3.3.16 of the edge the to step. perpendicular measured is length the where step, the of length the across height step the of uncertainty measurement the to due is 5.3.3.15 of the edge the to step. perpendicular of length the across uncertainty measurement the to due is that measurements 5.3.3.14 5.3.3.13 standardheight to due is that 5.3.3.12 emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This 6.4 measurement The chip.) test same the on are structures test layerstwo the design that same and the of comprised is structure test each in platform reference the that assumes (This structures. test that for height platform reference height, step The structure. calculated just the minus traces data the 2-D of the average the from is measurements measurement height platform platform a structure, test each For structure. test that on traces data 2-D the from taken measurements height platform reference the of average the as calculated is height platform reference 6.3 1 as determined givenAppendix is in measurement height, step The value 6.2 pertinent platform(s),arerecorded. platforms, the reference including along the s Summary ofMethod Summary ample ample This test method can be used to obtain the step height measurements measurements height step the obtain to used be can method test This Obtaining stepN Obtaining stepN Obtaining s for u for u u u u U u

of a a of Wstep WplatNX Lstep LplatNX repeat SH interferometer c SH hs et ehd i witn fr ue ih n pia optical an with use for written is method test This —the the uncertainty of a measurement due to to due measurement a of uncertainty the is determined as determined is — the component in the combined standard uncertainty calculation for step height measurements that measurements height step for calculation uncertainty standard combined the in component the — — the component in the combined standard uncertainty calculation for step height measurements height step for calculation uncertainty standard combined the in component the — ) 2-D data trace is shown in Figure 6. Data averages and standard deviations from the 2-D data traces data 2-D the from deviations standard and averages Data 6. Figure in shown is trace data 2-D (shs) .

— For each 2-D data trace, the difference in the platform heights involved in the step is calculated. is step the in involved heights platform the in difference the trace, data 2-D each For — h opnn n te cmie tnad ucrany cluain fr pafr height platform for calculation uncertainty standard combined the in component the — stepN

h opnn n te cmie tnad ucrany cluain fr pafr height platform for calculation uncertainty standard combined the in component the — — — expanded uncertainty of a stepmeasurement. height of expandeda uncertainty X XY M the component in the combined standard uncertainty calculation for step height measurements height step for calculation uncertainty standard combined the in component the XY rmOeSe egtTs tutr rcmedddet to due (recommended Structure Test Height Step One From Y , is the average of these values from the different 2-D data traces. The value for for value The traces. data 2-D different the from values these of average the is , From Two Step Height Test Structures on the Same Chip Same the on Structures Test Height Step Two From interferometric microscope interferometric stepN p . are X given in Appendix 1 givenAppendix in M Y , is the difference in height between the two platforms measured for the two test two the for measured platforms two the between height in difference the is , u c (specifically§A1-1) SH (a schematic of which is shown in Figure 5) or comparable or 5) Figure in shown is which of schematic (a . Sample step height test structures are shown in Figure in shown are structures test height step Sample . (specifically§A1-2) the repeatability of of repeatability the Page jn l jn 8 interferometer value for for value ,

respectively, respectively, . a a stepN equations used to determine determine to used equations . measurement interferometric microscope interferometric platNX platNX XY

or or on the same chip same the on — For each test structure, the structure, test each For — stepN , where the length is measured is length the where , , where the width is measured is width the where , a s taken on the physical step physical the on taken s the lower the X M Y Document Document Number:

from one step height step one from Doc.

resulting lower resulting Date: or comparable or , respectively, , u u SEMI c c SH SH for this for

4/9/2018 for this for DRAFT s 1–4. n

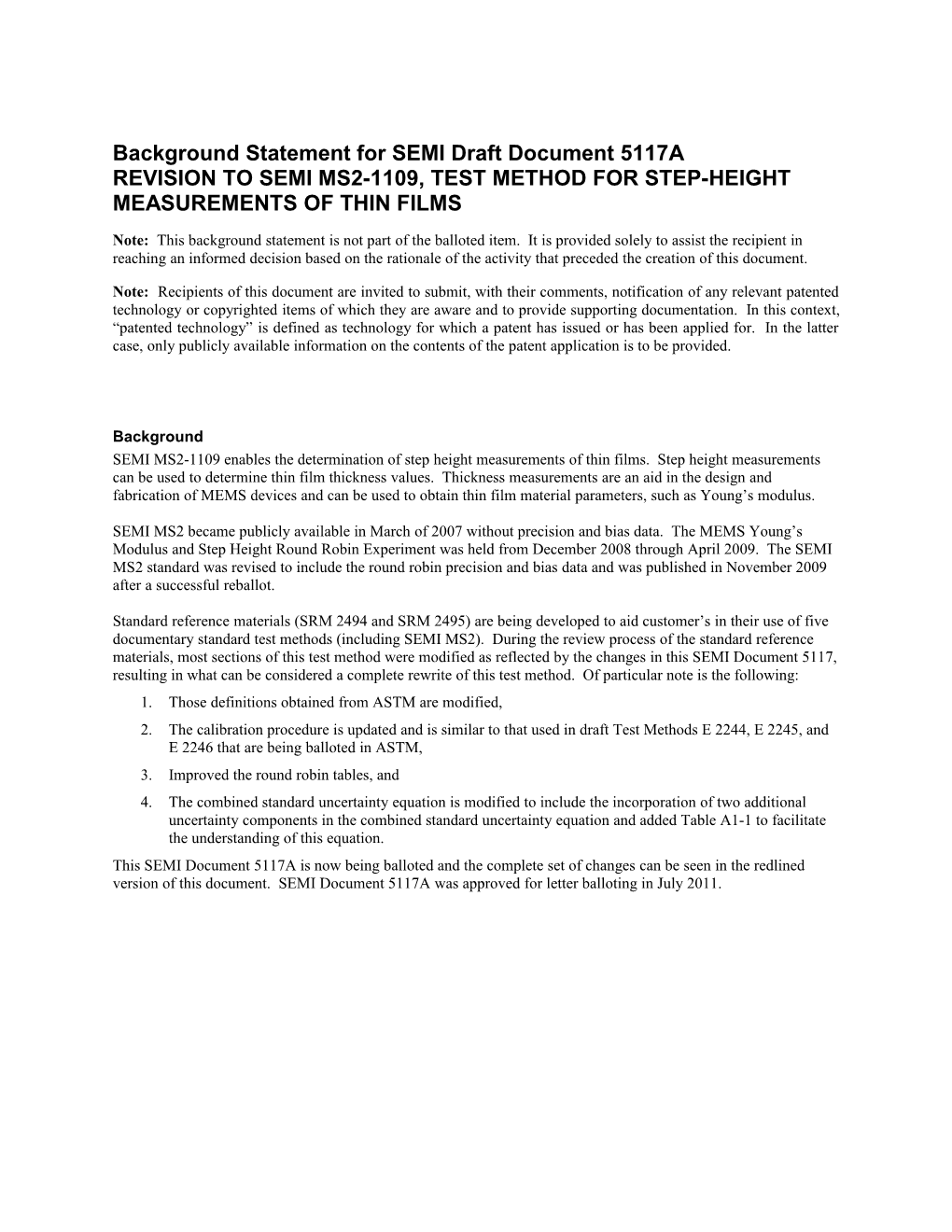

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This An Ideal StepHeightTest Ideal An StructureIndicating 2-D theTraces of Location Data Three Figure 1 Figure Page jn l jn 9 Document Document Number: Doc. Date: SEMI 4/9/2018 DRAFT

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This Dimensional in forIdeal Considerations Fig the Test StepHeight Structure A Step StructurewithMultipleA Test Steps Height Indicating the LocationData ThreeIndicating 2-D Traces the of Figure 3 Figure 2 Figure Page jn l jn 10

Document Document Number: ure Doc. 1 Date: SEMI 4/9/2018 DRAFT

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This b) a) For Fig Test StepHeight Structure1in

ure Figure 4 Figure Page 3 a) aDesignRendition and 3a) b)aCross Section jn l jn 11 Document Document Number: Doc. Date: SEMI

4/9/2018

DRAFT

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This optical deviations. capable must ofstandard extracting be and The 5 permitted. least at to heights step is measuring of capable be nm must instrument 1 than vertical less a with procedure test resolution the performing of capable is that and applicable, if 1, Table in specified as spacings optical any However, optical typical a of schematic a is 5 Figure traces. data 2-D topographical 7.1 7 Ex Apparatus S pia Optical ample of a of Interferometer 2-D Data Trace 2-D Trace Data Schematic ofSchematic Optical an interferometer nefrmti Microscope Interferometric along interferometric microscope interferometric Along Along step1 the the Fig Top StepHeight Test of Structurein AB Interferometer

Figure 5 Figure Figure 6 Figure Page step1 r Cmaal Instrument Comparable or 4 interferometer jn l jn 12 C Interferometric Microscope Interferometric D or comparable instrument that has pixel-to-pixel has that instrument comparable or

m higher than the step heights to be measured be to heights step the than higher m step1 nefrmti microscope interferometric interferometer E F

step1 aal f obtaining of Capable — interferometric microscope interferometric Gr Document Document Number:

Doc. ure

r comparable or 3and Date: SEMI 4/9/2018 Figure

DRAFT .

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and SM E25 n and beto measured. E2246. ASTM recommen still is height step physical 7.5 E2245, 7.4 7.3 be to measured. 11: NOTE 10: NOTE instrument the out-of-plane comparable in 7.2 E2246.ASTM ASTM 9: NOTE optical with used interferometry. be not shall 2.5× than less or at magnifications Therefore, data. the affect adversely can at magnifications set these data the in fringes interferometric of set second a of introduction possible the and work this for large too be will spacings 8: NOTE uh ta h ogs ieso f te etr et srcue cn sil ft wti h O f the of FOV (document committee Standards International the SEMI of scope the within within only part, in fit or whole in document, still Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an can reproduce as construed be to to is granted page this is on material structure No Permission program. Standards International SEMI the of Document Draft a test is This entire the of dimension longest the interferometer that such limited be platforms of number the that recommended is it 4), Figure and 3 Figure in shown (as structure test height 8.1.1.2 single is Eachfrom design a layers. platform. platform built set the of reference including 8.1.1.1 8.1.1 processes. for be process.Appropriate should changes made surface-micromachining bulk-micromachining 8.1 8 It is recommended that the certified value of the physical step height height step physical the of value certified the that recommended is It Test Specimen Test T Humidity Meter (optional) Humidity Meter (optional) Thermometer Double-sided Step Height Test Structures Test Height Step Although the double-sided feature of th of feature double-sided the Although Platforms If more than than more If not 2), Figure and 1 Figure in shown (as platforms distinct two of consists structure test height step ideal An

This optical optical This Table 1 does not include magnifications at or less than 2.5× for optical interferometry because the pixel-to-pixel the because interferometry optical for 2.5× than less or at magnifications include not does 1 Table This step physical height can bestandard also used ASTM E2245, withand E2244, E2246. ASTM ASTM It is recommended that the certified value of the physical step height standard be within 10 10 within be standard height step physical the of value certified the that recommended is It interferometric microscopeinterferometric Certified two Interferometric Microscope Table 1 interferometer 2 distinct platforms (not including the reference platform) are incorporated within the step the within incorporated are platform) reference the including (not platforms distinct

obesddDouble-sided — To record the temperature during measurement. the temperature —Torecord — To record the relative humidity during the measurement. relative —Torecord Interferometer

Magnification,× — The design of a representative step height test structure is specified below for a for below specified is structure test height step representative a of design The — interferometric microscope interferometric can also be used with with used be also can 5 40 20 10 10 20 40 80 80 5 or comparable instrument at a magnification of comparable at a 20×. instrument magnification or Physical Step Height Step Physical z -direction. is

Pixel-to-Pixel Spacing e physical step height height step physical e Requirements

Page jn l jn 13 can also be used for measurements taken with ASTM E2244, ASTM with taken measurements for used be also can ded due to its use in ASTM E2244, ASTM E2245, and E2245, ASTM E2244, ASTM in use its to due ded Pixel-to- Standard Requirements foran Requirements tnadstandard < 2.00 < P standard standard p < 1.00 < 0.50 < 0.40 < 0.20 < ixel Spacing, < < < < — For calibrating the interferometer or interferometer the calibrating For — 0.21 0.39 0.83 1.57 < 0.11 is not used in this test method, this method, test this in used not is be within 10 10 within be m Document Document Number: m of the step height step the of m Doc. m of the step height step the of m Date: SEMI 4/9/2018 DRAFT

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and sufficiently reflective for optical interferometry, a smooth reflective layer can be deposited on the test structure before the before 8.1.2 structure test the on deposited be can layer reflective smooth taken.measurements See are Note 1. a interferometry, optical for reflective sufficiently 12: NOTE layer. topmost the as m2) (or metal2 shows it and 4a Figure in shown structure test height step the of section cross a is 4b Figure reflective). is (which metal exposed be to designed typically is layer top the process, CMOS a For reflective. 8.1.1.7 edges.coincident platforms the between edge designated layers pertinent the designing consider rules, design no are there If rules. design the 8.1.1.6 be to doubled. may need dimensions these measurements, stylus For edges. transitional nearby from disturbances include not do that and height platform the of representative are that trace) data 2-D each (along obtained edges be can transitional points data of nearby number sufficient from a (b) and disturbances processing any without steps) multiple with structure test height step be can measurements height by given (as platform made representative for traces data 2-D sufficiently-separated three, (a) that such 50 and structure test height 8.1.1.5 directions.) testfrom a to these rotationof byinstance the structure 30degrees chip’s the in oriented are 1–4 Figures in shown structures test height step the in steps or step (The application. intended for the variations width and length the characterize with fully consistent more to chip order the in measurement, on this direction of results a the in of use structure intended test height step the in step the orient to step), the of width 8.1.1.4 nexteachother. right to designed 8.1.1.3 emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This as made, be to need may modifications obtainappropriate, to the data.Therefore, required instruments. all to pertain specifically not may and instrument comparable 15: NOTE 9 in chip case platform measurementa is height from different required two test structures. optical the for before layer), layer 14: reflective NOTE reflective smooth a a (or with metal covered not be is to need layer will of 1). taken.consideredthe outside scope this is This (seeNote method test are measurements top structure the test If height step 4b). the Figure interferometry (see between in oxide deposited 8.1.2.3 8.1.2.2 reference adjacentplatform to step used leveling. the is for the only used, is lens magnification higher a If leveling. for fourused are the platform reference of the of one areas extreme on two the eliminated only sides, is platform reference the If leveling. for used is platform reference entire the platform, reference the by surrounded is structure test the If platform. reference the of top the to respect with set) data 3-D the (or optics the leveling 13: NOTE is platform reference the leveling more provide theof twoextremes thestructure. test platforms onthe reference at data If to order in step 3). the of width Figure the doubling by and for compensated be 2 should actual it the and to Figure steps adjacent or side step a in on be shall shown it 4), Figure and (as 3 Figure in structure shown (as sides four test the of one the on eliminated of sides four the of three 8.1.2.1 Calibration Reference x -direction. This orientation is acceptable for the majority of applications as is a a is as applications of majority the for acceptable is orientation This -direction. The reference platform in a CMOS process typically consists of exposed metal over active area with area active over metal exposed of consists typically process CMOS a in platform reference The the design to platformrules. conform theshall reference at the layers outer of edge The least at on μm 100 by structure test the within platforms the beyond extend should platform reference The interferometry, optical For to conform shall platform) reference the (including platforms between boundary or region transitional The 50 (e.g., enough wide and long be shall platform Each and length the along taken be will measurements multiple (since mandatory not though recommended, is It be measurement height step a in involved platforms the that mandatory, not though recommended, is It

If in doubt as to whether or not the platforms (including the reference platform) in the step height test structure are structure test height step the in platform) reference the (including platforms the not or whether to as doubt in If It is important to have the same design layers in each reference platform for each step height test structure on the on structure test height step each for platform reference each in layers design same the have to important is It For instruments capable of obtaining 3-D data sets, any tilt in the sample (or the sample data) is eliminated by eliminated is data) sample the (or sample the in tilt any sets, data 3-D obtaining of capable instruments For h olwn airto s itne o s ih a pia optical an with use for intended is calibration following The

Platform . T t races races “ a , m × 100 100 × m ”

“ b , ” T and and t he top layer of each platform in the step height test structure is assumed to be to assumed is structure test height step the in platform each of layer top he m, as shown in Figure 3, for a step height test structure with multiple steps) multiple with structure test height step a for 3, Figure in shown as m, , keeping in mind that it is typically not a good design practice to have to practice design good a not typically is it that mind in keeping , “ c ” in Figure 1 for the ideal step height test structure and in Figure 3 for the for 3 Figure in and structure test height step ideal the for 1 Figure in Page jn l jn 14 m × 50 50 × m m, as shown in Figure 2, for an ideal step ideal an for 2, Figure in shown as m, interferometer to to y nefrmti microscope interferometric -orientation, as opposed for opposed as -orientation, less than less Document Document Number: Doc.

5 5 Date: m from m SEMI 4/9/2018 DRAFT to the or

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and

NOTE 17: 17: NOTE measurements six the of value mean the call these measurements deviation of but 9.1.1.2 ¶ in done as sets data 3-D 9.1.2.2 these measurements deviation of height 9.1.2.1 the minimumof measurements Call the six 9.1.2 these measurements deviationof standard physical standard. the height of step width) and length the along (both range certified the within taken be should measurements These measurements six Record 9.1.1.2 measurements deviationof the standard these and spe standard.step height physical the side of each along evenly out spread taken the along height 9.1.1.1 9.1.1 16: NOTE measurements. a of value certified the using 9.1 emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This http://www. C.D., 5 19: NOTE 9.1.3.1 taken 9.1.3.1 9.1.3 18: NOTE measurements location same the at taken measurements that assumed

The physical step height step physical The c “ Calibrate the the Calibrate if i at the same locationontheat the same After the data session: After the data session: Before the Determine the the Determine ed certified area along the length and width of the step. the of width and length the along area certified ed

standard tnadstandard Before the data session, session, data the Before Determine the the Determine Determine Record six measurements measurements six Record After the data session, r session, data the After

nist.gov/pml/div681/grp13/upload/nist physical physical ITNIST

Calibrating physicalthe step height Multiply the z fagvnisrmn osntditsgiiatydrn aassin session, data a during significantly drift not does instrument given a If z max2 before . . sdn nin done as . If double-sided step height measurements are taken, are measurements height step double-sided If interferometer step z = ufc Surface ave z standard -calibration factor:-calibration z height standard height Call the mean value of these six measurements taken at the same location location same the at taken measurements six these of value mean the Call z -calibration factor using theequation: factor following using -calibration (the average of the twelve calibration measurements from ¶ 9.1.1 ¶ from measurements calibration twelve the of average (the after z -data values during data obtained the session by s are calibrated at NIST as specified in Vorburger, T.V., T.V., Vorburger, in specified as NIST at calibrated are s ¶ ,

double-sided double-sided ... u altema au ftesxmaueet measurements six the of value mean the call but 9.1.1.1 σ r R interferometric microscope interferometric before ogns n tp Hih Height Step and Roughness along the R σ σ ecord six measurements measurements six ecord ecord six measurements measurements six ecord (at the same location on the physical step height height step the physical on location the same (at same2 after (at the same location on the physical step height step physical the on location same the (at = . z . σ . same

If single-sided step height measurements are taken, three measurements are measurements three taken, are measurements height step single-sided If

mel.nist.gov/div821/webdocs-13/ after physical step height physical σ z z same1 ave , min1 physical step height step physical standard . . Call the minimum of the six measurements measurements six the of minimum the Call z . Call the maximum of the six measurements measurements the maximumsix . Call of cal same . . σ z before z before NISTat = Page z cert . z same ave 2 (using six 3-D data sets) sets) data 3-D six (using (using six 3-D data sets) data 3-D (using six jn l jn or comparable instrument in the out-of-plane out-of-plane the in instrument comparable or 15 z 5 . the uncertaintylowers total in certified the value. after standard n and , Call the mean value of the six measurements six the of value mean the Call

standard

surfcalib. . σ cal six measurements are taken spread out evenly out spread taken are measurements six same1 ) theformula: following using z

to obtain to calibrated =

pdf . Do this for each objective used for the for used objective each for this Do . σ Song, J.F., J.F., Song, Calibrations The measurement The htm same2 and outlined in ASTM E2530. outlined in ASTM and . ¶ 9.1.2 can be skipped and it can be can it and skipped be can 9.1.2 ¶ al te ma au f tee six these of value mean the Call . standard

standard standard of the height of the physical step physical the of height the of of the height of the physical step the physical of the height of Renegar, T.B., and and T.B., Renegar, n pca Tests Special and z

min2 . Call the maximum of the six the of maximum the Call . .1 z z ) -data values.-data as in ¶ 9.1.1 ¶ in as same z z using six 3-D data sets data 3-D six using and ¶ 9.1.2 ¶ and max1 after Document Document Number: s s . are t Doc. and the standard the and and the standard the and Zheng, A., Zheng, z ak Date: same en within thewithin en .2 .1 SEMI z ) that were that -direction using six using and the and 4/9/2018 Foreman, z (2) DRAFT before (1) ,” .

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and 9.1.0.1 found sourcenot Reference 9.1.6.1 9.1.6.1 9.1.6 step height) theformula: following using physical 9.1.5 calculations. 9.1.4 ASTM E2245, and E2246. 20: NOTE emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This September 2011Edition,” 2495: The 5-in-1, 2494 and MEMS Cassard, T. J. M., J., Geist, Vorburger, Also consult ( seconds. http://www.eeel.nist.gov/812/test-structures/MEMSCalculator.htm 6 ( inclusive): 10.3–10.8, §§ in (given steps six following the performing the by of step), edge the to parallel measured is width the (where structure test the of width the across traces data 2-D three 10.2 test in 10.2for structurethe steps¶ each given value lower 10.1 as made, be to need may modifications Therefore, obtainappropriate, to the data. required instruments. all to pertain specifically not may and instrument comparable 21: NOTE 10 9.1.0.1 z

http://srdata.nist.gov/gateway/ By inserting the inputs into the theappropriate inserting into on correctthe NIST locations inputs By 6 same Procedure Obtain Data From One Step Height Test Structure Test Height Step One From Data Obtain to due (recommended structure test height step one from obtained be can measurements height Step Obtain the additional parameters that will be used in Appendix 1 in the combined standard uncertainty standard Determine combined the in 1 Appendix in used be will that parameters additional the Obtain z The Calcu MEMS using theequations: following using Record Record Determine Determine

z 2011. repeat if

z for same

if h bv airto rcdr ofn find to procedure calibration above The h olwn tp r o esrmnstknwt notcloptical an with taken measurements for are steps following The ( s of s same shs ( cert ) cal z same

z σ (the calibrated average of the twelve calibration measurements taken at the same location on the on location same the at taken measurements calibration twelve the of average calibrated (the u and drift 6ave c SH z l ator Web Site (Stand ator WebSite )

z ) as detailed in ¶ 10.2 or from two step height test structures on the same chip by performing by chip same the on structures test height step two from or 10.2 ¶ in detailed as ) z using theequation: following using if if max ) z same repeat p with the keywordwith “MEMS Calculator.” lin cert

6 same before before erc (shs) , then

, as defined in 5.3.1, , as in defined

z

, then min and and

Error: Reference source Reference Error:foundnot source after

after z 6 ar same 6 d Reference Database 166) is accessible viad Reference N is Database the 166) accessible ave NIST Special Publication260 NIST Special z

6 V., V., , then , then repeat same

Read, D. Seiler, “Stand G., Read, and D. T.,

using the following equations: following the using z as specified in specified 10.9 ¶ as drift ( shs same z ) 6 6 ave repeat cal same ave for use in Appendixfor in 1. use 6 )

, the calculations in this teston-line methodcanbe matter in calculations this of in performed , the a Page and z z is s is z same ( — For a step height test structure, obtain data from at least at from data obtain structure, test height step a For —

shs max The inputs to thesevalues. are inputs data sheets to uncalibrated The and z mlrimilar jn l jn after ) before 16 6same MEMS Calculator WebPage MEMS

and and

z z z z 6same and -174 repeat ihl ifrn different lightly same min . z z , National Institute of, National Standa Institute 6ave same z

( 6ave shs

(3) . z ) same . a

and rd Reference Material rd Error: Reference source not found not source Reference Error: z interferometer

after z before and z IS to that found in ASTM E2244, ASTM E2244, ASTM in found that to

. 1

T DataGatewayT

if ) select two transitional edges for edges transitional two select ) and web page (accessible via web via page (accessible z

z repeat

same interferometric microscope interferometric

( ( r 5 shs ds and Technology, ds and Technology, 6) s : User’s for: SRM Guide )

Document Document Number: eemn Determine

Doc. z repeat Date:

SEMI ( a resulting a σ shs 6same

4/9/2018 )

DRAFT Error: , then

( ( ( ( and 7 6 4 3 ( ( or 8 7 5) 5 4 4 ) ) ) ) )

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and 10.4.1.7 p fringes if however, nulled; fringes bright.) appears FOV the within platform reference entire the until fringe brightest the out spreading by accomplished be can (This structure. test height step the surrounding partially 10.4.1.6 10.4.1.5 appropriate). 10.4.1.4 10.4.1.3 FOV lens, if applicable)appropriate 10.4.1.2 10.4.1.1 ¶in 10.3.1. 10.4.1 10.4 the in smaller is spacing pixel-to-pixel instrument’s the the than in direction if possible, if steps) or step the traverse will direction 10.3.2 interferometer “ 10.3.1 10.3 and ( platforms, un ( alignment, emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This dataanother trace,if possible. 25: NOTE trace “ as (such trace data 2-D a obtain taken, not was set data 3-D a If 6). Figure in shown trace data the obtain to 3, 10.5.1 10.5 24: NOTE not in FOV the referencedo fit the of instrument, the platform adjacent the is to step used level zero to and the data 3-D set. 23: NOTE referencethe platform used are to and the level zero 3-D set. data 22: NOTE without flaws. any debris including obvious and or if edges)structure, these test near variations the processing avoiding around (thus edges fashion transitional any symmetrical to close a too coming in without possible, and feasible and possible as platform reference the on data 10.4.1.9 set 10.4.1.8 FOV. 2 b erpendicular to the edge of the edge the to step erpendicular ” ” calibrated data from the reference platform, if needed, ( needed, if platform, reference the from data calibrated . as shown in Figure 3) and level and zero it (with respect to the top of the reference platform) to obtain obtain to platform) reference the of top the to respect (with it zero and level and 3) Figure in shown as the to perpendicular or parallel aligned be will edges transitional These 1). Figure in such as Obtain a 3-D DataSet, if a3-D Obtain Two Edges Alignment Transitional for Select Extract orObtain Data 2-D Extract aLeveled From the leveled 3-D data set in ¶ 10.4.1. ¶ in set data 3-D leveled the From selected edges transitional the to perpendicular or parallel traces data 2-D contains that set data 3-D a Obtain instrument’s in thestructure steptest height the Orient (e.g., alignment ensure to structure test height step the within edges transitional two Select Level and zero the 3-D data set with respect to the top of the reference platform. To do this, select as much as select this, do To platform. reference the of top the to respect with set data 3-D the zero and Level the using set data 3-D a Obtain the bring and alignment sample the Recheck or surrounding platform reference the of top the on fringes the nulling by sample the in tilt any Eliminate the intensityAdjust w and available (if crosshairs using FOV the in 10.3.1 ¶ in selected edges transitional the align Visually Choose u investigated, be to areas sample the Given r For informational purposes,

2 The shown Figure in 6. areas of extreme two sides,the four all on platform reference a by surrounded not testis height structure step the If ) obtain a 3-D data set, if applicable, ( applicable, if set, data 3-D a obtain ) If a higher magnification lens is used for the measurements such that the reference platforms at the extreme ends extreme the at platforms reference the that such measurements the for used is lens magnification higher a If In the 2-D data trace, if there are any anomalies along the platforms where measurements will be taken, obtain taken, be will measurements where platforms the along anomalies any are there if trace, data 2-D the In interferometric microscopeinterferometric 6 ) repeat for at least two other 2-Dtraces. at least repeatfor twoother data ) z Select Select values the of leveled points thedata along top the of reference are platform expected lie ±40to between nm. y -direction, if applicable. An the iforientation applicable. in -direction, the detector array size the array detector

hile viewinghile Applicable given the sample areas to be investigated sample areasbe to given the . r rsn,te hudb be should they present, are (The presence of fringes helps to account for systematic errors.) for account ofhelps to presence fringes (The ecord the room temperature and relative humidity. relative room temperature and ecord the or comparable instrument. or Take an an Take

Trace toith respect with 9 8 average of at least three measurements three least at of average that achievesthat , extract a 2-D data trace (such as as (such trace data 2-D a extract , 3 ) extract or obtain a leveled 2-D data trace, ( trace, data 2-D leveled a obtain or extract ) Page U se the most powerful objective possible (while choosing the choosing (while possible objective powerful most the se nulled nulled the brightest layer of interest.the brightestlayerof jn l jn 17 5 ) obtain the raw, raw, the obtain ) x -direction (i.e., such that any 2-D data traces in the in such data anythe that (i.e., 2-D traces -direction fringes to just past the topmost platform within the within platform topmost the past just to fringes the best lateral resolution. the best lateral y After nulling the fringes, create a few fringes few a create fringes, the nulling After -direction is-direction also acceptable.

The measurement is typically taken with the with taken typically is measurement The . un calibrated data from the pertinent the from data calibrated T t race race to comprise one 3-D data 3-D one comprise to “ b Document Document Number: x , o (or - ” as shown in Figure in shown as Doc. 4 ) obtain the raw, the obtain ) E y Date: e -) axis of the of axis -) dges dges SEMI a “ 4/9/2018 the 1 DRAFT T ” t data and race x x - -

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and 10.6.4 a value that high for the If procedure. the perform to platforms similar ¶ with in obtained height structure average test another for search (e) or applicable, if set, ¶ from repeat (d) set, data 3-D the level to which with platform reference the within data the of ¶ from repeat (b) selected), be ¶ from repeat (c) should trace, data 2-D the of data selection the in vigilant more less (perhaps platform reference the along data the of selection the in 0.000 is data leveled ¶ in obtained the of height average the obtained, was set data 3-D a if 2 28: NOTE 5.3.2) NrDt un cursors. 10.6.3 27: NOTE p 10.7.1 onthe pertinent 1 least 10.6.2 the moment. one for ofjust these with associated data the on concentrate structure, test the of extremes two the at platform reference a with associated 10.6.1 recorded used measurement. height step a obtain to used are structures test different two if only calculations 26: NOTE 10.6 emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This from structure. test ¶ the second 10.2for repeat 10.9 10.8.1 10.8 data2-D trace. 10.7.3 1. Appendix 5.3.2 ¶ in given are un cursors. 10.7.2 29: NOTE edge eachtransitional from perpend measured is a 10.7.1 10.7 available. and present 0 pproximately 1 calibrated average height height average calibrated calibrated average height height average calibrated , and Note 2 Note and , to obtain a step height measurement, skip to to skip measurement, height step a obtain to in in Obtain the Raw, the Raw, Obtain If two step height test structures on the chip are required for a step height measurement (not recommended), (not measurement height step a for required are chip the on structures test height step two If at for 2-D Two DataTracesRepeat Least Other the Raw, Obtain for use in Appendixfor in 1. use 0 Repeat from Repeat this along platform) reference the including (not interest of platforms other any for 10.7.1–10.7.2 ¶¶ Repeat the Record encompass cursors, the using interest, of platform a on data 2-D the Examining if structure, test the of side other the on platform reference the on data 2-D the for 10.6.2–10.6.3 ¶¶ Repeat the Record approximately encompass cursors, the Using Examining

platNrDt in ¶ 10.6.3in ¶

Calibrate these values by multiplying them by by them multiplying by values these Calibrate by them multiplying by values these Calibrate m from each transitional edge transitional each from m

10.6.3 should be within within be should 10.6.3 Avoid Avoid The data was leveled and zeroed with respect to the top of the reference platform as specified in ¶ in specified as platform reference the of top the to respect with zeroed and leveled was data The t least t 1 h The 2 for a 3-D data set and as specified in ¶ 10.5.1 for a 2-D data trace data 2-D a for 10.5.1 ¶ in specified as and set data 3-D a for are given in 5.3.2 ¶ aregiven for Appendix calculations.for 1 u un or eliminate eliminate or eliminate or .6 T c nairtduncalibrated uncalibrated 17 17 SH ¶ ¶ icu t calibrated average height values obtained below in ¶ 10.6.3 on the reference platform are used in used are platform reference the on 10.6.3 ¶ in below obtained values height average calibrated . Call the resulting resulting the Call . aerace 10.4 or ¶

Un Un is expectedis if different structures two test are to a heightused obtain step measurement. lar to the edge of the step) of step) of the of edge the to lar la C C m (that is, approximately one-third the length of the 50 50 the of length the one-third approximately is, (that m