Fabrication Technique

Equipment To fabricate our samples in Qulab we use two main pieces of equipment – a FEI scanning electron microscope (SEM) and the PLASSY electron beam evaporator. The SEM has a writing resolution of about 20nm and viewing resolution of about 5nm. The PLASSY can evaporate thin films of Al, Cu, Nb, Au, Ta, and Cr with a base pressure of 1x10-8 mT. Its stage has two main axes of rotation and an Argon ion beam. Other equipment used in our fabrication processes include a PECVD for insulator deposition, an RIE for etching samples and spinners to put resist on silicon wafers.

Our main fabrication procedure is described below, using a josephson junction (a superconductor-insulator-superconductor sandwich) as an example.

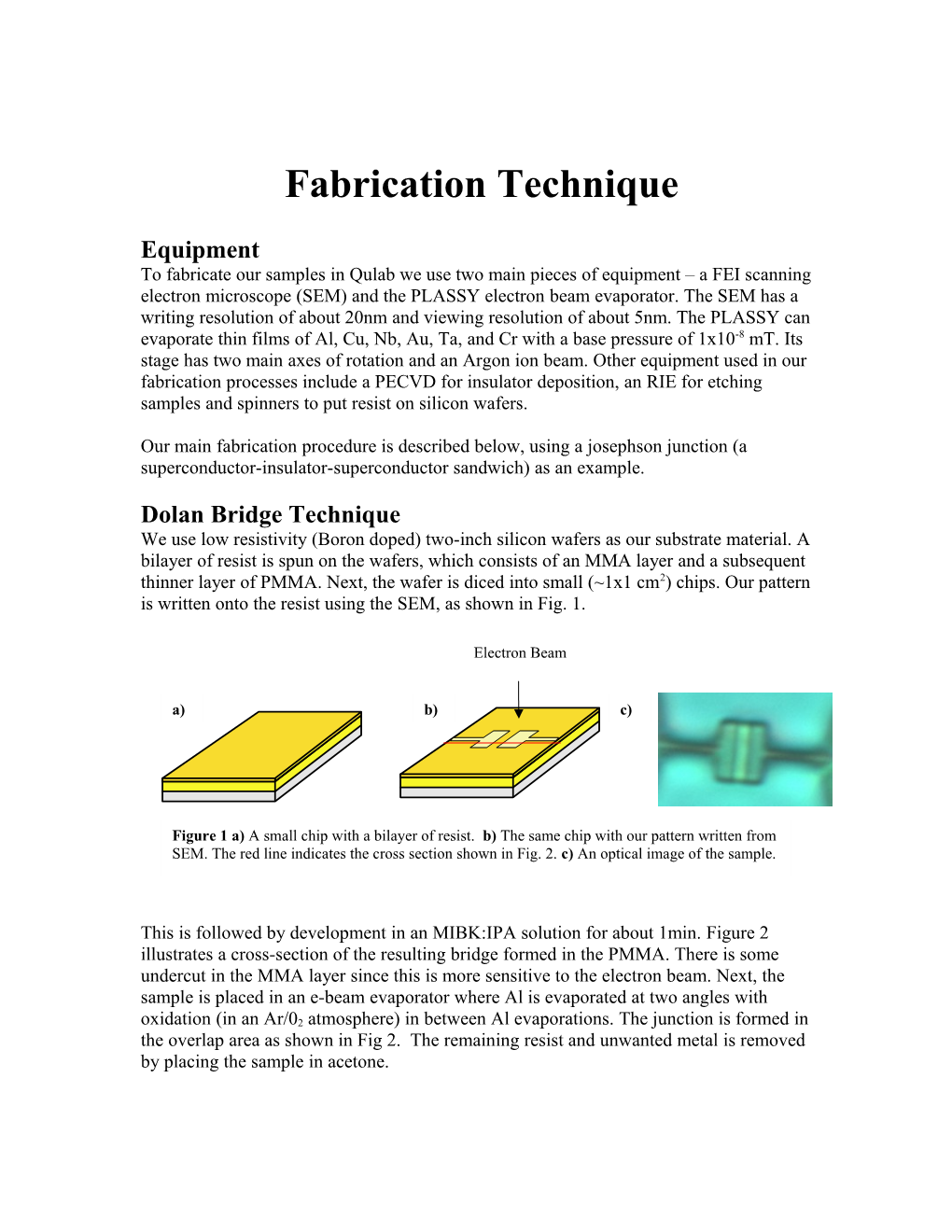

Dolan Bridge Technique We use low resistivity (Boron doped) two-inch silicon wafers as our substrate material. A bilayer of resist is spun on the wafers, which consists of an MMA layer and a subsequent thinner layer of PMMA. Next, the wafer is diced into small (~1x1 cm2) chips. Our pattern is written onto the resist using the SEM, as shown in Fig. 1.

Electron Beam

a) b) c)

Figure 1 a) A small chip with a bilayer of resist. b) The same chip with our pattern written from SEM. The red line indicates the cross section shown in Fig. 2. c) An optical image of the sample.

This is followed by development in an MIBK:IPA solution for about 1min. Figure 2 illustrates a cross-section of the resulting bridge formed in the PMMA. There is some undercut in the MMA layer since this is more sensitive to the electron beam. Next, the sample is placed in an e-beam evaporator where Al is evaporated at two angles with oxidation (in an Ar/02 atmosphere) in between Al evaporations. The junction is formed in the overlap area as shown in Fig 2. The remaining resist and unwanted metal is removed by placing the sample in acetone. Al Al

a) b)

c) d)

3.5m

Figure 2: a) A cross section of the chip from Fig. 1 after development. b) Two-angle Al evaporation with oxidation (red) in between is used to form the junction. c) The remaining resist is lifted off. d) SEM image of the resulting sample with the cross section illustrated in a) - c) in red.

Josephson Bifurcation Amplifier

The Josephson Bifurcation Amplifier (JBA) (described elsewhere: LINK to vijay/irfan??) is a current amplifier based on the non-linear inductance of the josephson junction. It was designed as a sensitive readout device for a qubit Bonding pads (quantum bit). A capacitor Ti a) b) Cr is placed in parallel with Cu Cr the junction to form a non- Si linear LC oscillator with two stable oscillating Al capacitor pads states. The capacitor is formed by depositing a copper ground plane c) followed by a silicon nitride insulating layer (in PECVD). Resist is then spun on. The junction with top capacitor electrodes is Figure 3: a) An optical image of the JBA. b) Schematic subsequently deposited of the copper ground plane structure. c) SEM image of the junction. using the procedure described above (see Fig. 3). The Cr layers sandwiching the Cu layer are used to protect the Cu during silicon nitride deposition while the Ti layer is utilized to promote adhesion of the silicon nitride layer. To measure out the state of the JBA, a microwave signal is sent into the device. The phase change of the reflected RF signal is then measured, as diagrammed in Fig 4. Figure 5 shows the resulting phase diagram with a linear resonance near 1.55GHz. For large powers, we clearly see the bistability of the non-linear LC oscillator. For more detail, please see (LINK).

Figure 4: Schematic of the measurement setup.

Figure 5: Phase change diagram of the reflected RF signal vs. power and frequency.