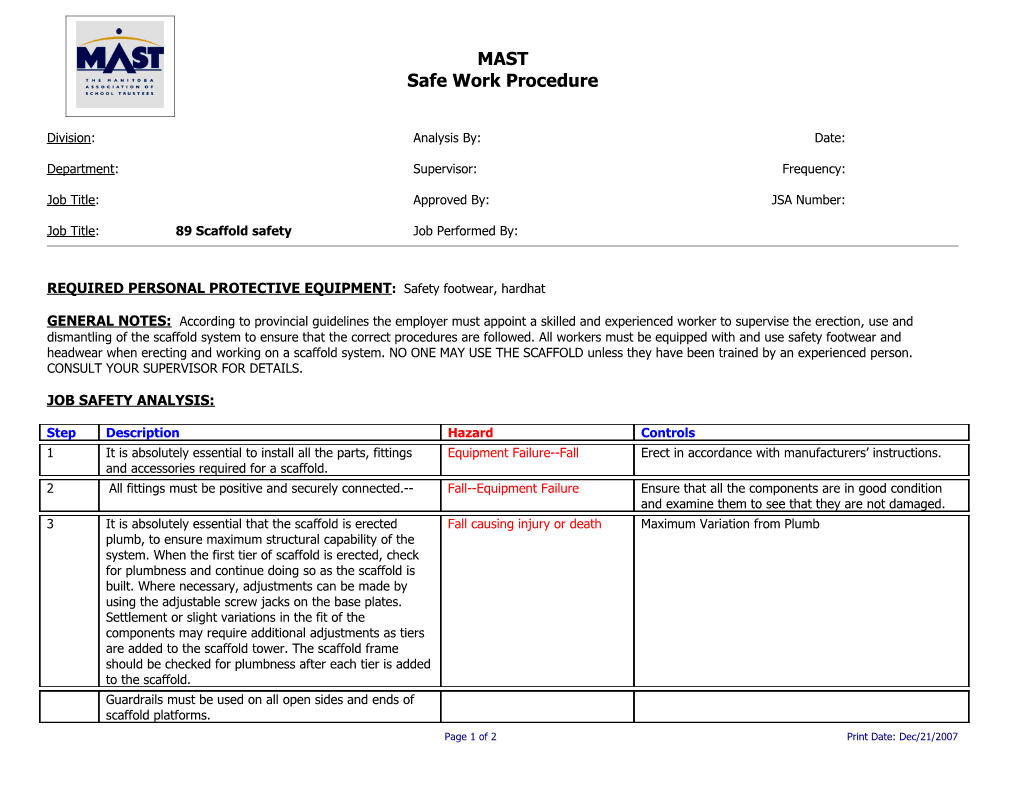

MAST Safe Work Procedure

Division: Analysis By: Date:

Department: Supervisor: Frequency:

Job Title: Approved By: JSA Number:

Job Title: 89 Scaffold safety Job Performed By:

REQUIRED PERSONAL PROTECTIVE EQUIPMENT: Safety footwear, hardhat

GENERAL NOTES: According to provincial guidelines the employer must appoint a skilled and experienced worker to supervise the erection, use and dismantling of the scaffold system to ensure that the correct procedures are followed. All workers must be equipped with and use safety footwear and headwear when erecting and working on a scaffold system. NO ONE MAY USE THE SCAFFOLD unless they have been trained by an experienced person. CONSULT YOUR SUPERVISOR FOR DETAILS.

JOB SAFETY ANALYSIS:

Step Description Hazard Controls 1 It is absolutely essential to install all the parts, fittings Equipment Failure--Fall Erect in accordance with manufacturers’ instructions. and accessories required for a scaffold. 2 All fittings must be positive and securely connected.-- Fall--Equipment Failure Ensure that all the components are in good condition and examine them to see that they are not damaged. 3 It is absolutely essential that the scaffold is erected Fall causing injury or death Maximum Variation from Plumb plumb, to ensure maximum structural capability of the system. When the first tier of scaffold is erected, check for plumbness and continue doing so as the scaffold is built. Where necessary, adjustments can be made by using the adjustable screw jacks on the base plates. Settlement or slight variations in the fit of the components may require additional adjustments as tiers are added to the scaffold tower. The scaffold frame should be checked for plumbness after each tier is added to the scaffold. Guardrails must be used on all open sides and ends of scaffold platforms. Page 1 of 2 Print Date: Dec/21/2007 When frames with built-in ladders are used, cleated plank or fabricated plank must be used at platform levels to minimize or eliminate platform overhang. Access ladders must extend at least three (3) feet above platforms. -- Side and end brackets are designed to support people Materials should never be placed on cantilevered only. platforms unless the assembly has been designed to support material loads by a qualified person. Check the erected assembly before use. Collapse A qualified person should thoroughly inspect the completed assembly to see that is complies with all safety codes, that nuts and bolts are tightened, that it is level and plumb, that work platforms are fully planked, that guardrails are in place and safe access is provided. 4 Dismantling 5 The dismantling of a scaffold proceeds in reverse order -- to its erection. Each tier should be completely dismantled and the material lowered to the ground before dismantling of the next tier begins. If platform sections or planks have been left at each level during erection, it is best to lower additional platform materials from above to the working deck being dismantled.

AUTHORIZED EMPLOYEE INFORMATION:

ID NUMBER: LAST NAME: FIRST NAME: REMARKS: JOB HISTORY INFORMATION:

DATE: REMARKS:

Approval Signature: Date:

Page 2 of 2 Print Date: Dec/21/2007