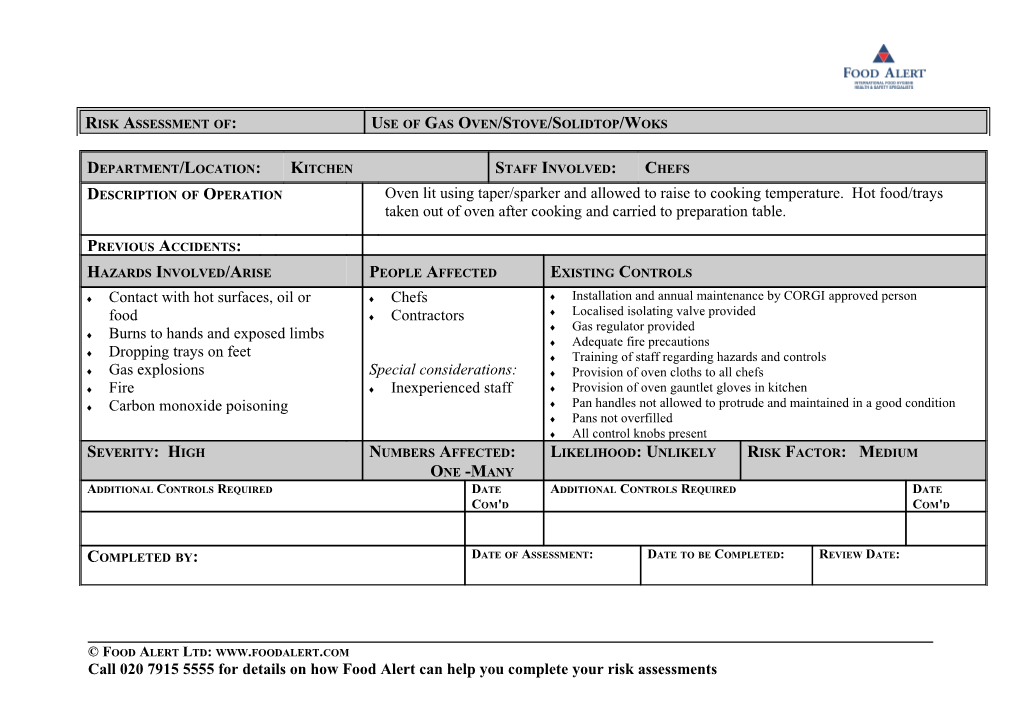

RISK ASSESSMENT OF: USE OF GAS OVEN/STOVE/SOLIDTOP/WOKS

DEPARTMENT/LOCATION: KITCHEN STAFF INVOLVED: CHEFS DESCRIPTION OF OPERATION Oven lit using taper/sparker and allowed to raise to cooking temperature. Hot food/trays taken out of oven after cooking and carried to preparation table.

PREVIOUS ACCIDENTS: HAZARDS INVOLVED/ARISE PEOPLE AFFECTED EXISTING CONTROLS

Contact with hot surfaces, oil or Chefs Installation and annual maintenance by CORGI approved person Localised isolating valve provided food Contractors Gas regulator provided Burns to hands and exposed limbs Adequate fire precautions Dropping trays on feet Training of staff regarding hazards and controls Gas explosions Special considerations: Provision of oven cloths to all chefs Fire Inexperienced staff Provision of oven gauntlet gloves in kitchen Carbon monoxide poisoning Pan handles not allowed to protrude and maintained in a good condition Pans not overfilled All control knobs present SEVERITY: HIGH NUMBERS AFFECTED: LIKELIHOOD: UNLIKELY RISK FACTOR: MEDIUM ONE -MANY ADDITIONAL CONTROLS REQUIRED DATE ADDITIONAL CONTROLS REQUIRED DATE COM'D COM'D

COMPLETED BY: DATE OF ASSESSMENT: DATE TO BE COMPLETED: REVIEW DATE:

© FOOD ALERT LTD: WWW.FOODALERT.COM Call 020 7915 5555 for details on how Food Alert can help you complete your risk assessments

RISK ASSESSMENT OF: USE OF ELECTRIC OVEN/STOVE

DEPARTMENT/LOCATION: KITCHEN STAFF INVOLVED: CHEFS DESCRIPTION OF OPERATION Oven switched on and allowed to reach cooking temperature. After cooking, hot food/trays taken out of the oven and carried to preparation tables.

PREVIOUS ACCIDENTS: HAZARDS INVOLVED/ARISE PEOPLE AFFECTED EXISTING CONTROLS

Contact with hot surfaces, oil or Chefs Equipment installed and subject to annual recorded maintenance by competent person food Contractors Equipment not used if defective Burns to hands and to exposed Maintenance Training of staff regarding hazards and controls limbs Personnel Adequate fire precautions Dropping trays on feet Provision of oven cloths to all chefs Electrical shock and burns Provision of oven gauntlet gloves in kitchen Fire Special considerations: Pan handles not allowed to protrude and maintained in a good condition Pans not overfilled Inexperienced staff See separate manual handling assessment

SEVERITY: SIGNIFICANT NUMBERS AFFECTED: LIKELIHOOD: POSSIBLE RISK FACTOR: MEDIUM ONE ADDITIONAL CONTROLS REQUIRED DATE ADDITIONAL CONTROLS REQUIRED DATE COM'D COM'D

COMPLETED BY: DATE OF ASSESSMENT: DATE TO BE COMPLETED: REVIEW DATE:

© FOOD ALERT LTD: WWW.FOODALERT.COM Call 020 7915 5555 for details on how Food Alert can help you complete your risk assessments

RISK ASSESSMENT OF: USE OF COMBINATION OVEN

DEPARTMENT/LOCATION: KITCHEN STAFF INVOLVED: CHEFS DESCRIPTION OF OPERATION Oven switched on and allowed to reach cooking temperature. Food cooked and removed from oven and carried to preparation table. Steam released when door opened.

PREVIOUS ACCIDENTS: HAZARDS INVOLVED/ARISE PEOPLE AFFECTED EXISTING CONTROLS

Contact with hot surfaces or food Chefs Installation and equipment subject to annual recorded maintenance by competent person Burns to hands and exposed limbs Contractors Defective equipment not used Scalds by steam when opening door Maintenance Staff Training of staff regarding hazards and controls when using the equipment Electrical shock Provision of oven cloths to all chefs Fire Provision of oven gauntlet gloves in kitchen Special considerations: Display of notice regarding steam emission when door opened Inexperienced staff Clearly identified electrical isolation switch

SEVERITY: SIGNIFICANT NUMBERS AFFECTED: LIKELIHOOD: POSSIBLE RISK FACTOR: MEDIUM ONE ADDITIONAL CONTROLS REQUIRED DATE ADDITIONAL CONTROLS REQUIRED DATE COM'D COM'D

COMPLETED BY: DATE OF ASSESSMENT: DATE TO BE COMPLETED: REVIEW DATE:

© FOOD ALERT LTD: WWW.FOODALERT.COM Call 020 7915 5555 for details on how Food Alert can help you complete your risk assessments

RISK ASSESSMENT OF: USE OF GAS GRILLERS/SALAMANDERS

DEPARTMENT/LOCATION: KITCHEN STAFF INVOLVED: CHEFS DESCRIPTION OF OPERATION Grill lit using sparker/taper and allowed to heat up, food cooked and removed for service

PREVIOUS ACCIDENTS: HAZARDS INVOLVED/ARISE PEOPLE AFFECTED EXISTING CONTROLS

Burns to hands and exposed limbs Chefs Installation and annual recorded maintenance by CORGI approved person Defective equipment not used Gas explosion Maintenance Wall mounted units not sited above cooking equipment Fire Personnel Fitting of gas regulator Trays falling out Identified main and localised cut off valve Carbon monoxide poisoning Handle on salamander in good condition Contact with hot surfaces Special considerations: Training regarding hazards and controls when using equipment Inexperienced staff Correct lighting procedure followed Provision of oven cloths to all chefs SEVERITY: HIGH NUMBERS AFFECTED: LIKELIHOOD: UNLIKELY RISK FACTOR: MEDIUM ONE-MANY ADDITIONAL CONTROLS REQUIRED DATE ADDITIONAL CONTROLS REQUIRED DATE COM'D COM'D

COMPLETED BY: DATE OF ASSESSMENT: DATE TO BE COMPLETED: REVIEW DATE:

© FOOD ALERT LTD: WWW.FOODALERT.COM Call 020 7915 5555 for details on how Food Alert can help you complete your risk assessments

RISK ASSESSMENT OF: USE OF DEEP FAT FRYER (ELECTRIC)

DEPARTMENT/LOCATION: KITCHEN STAFF INVOLVED: CHEFS DESCRIPTION OF OPERATION Unit switched on and oil heated to cooking temperature. Basket filled and lowered into hot oil. Once cooked, food removed and excess oil allowed to drain off.

PREVIOUS ACCIDENTS: HAZARDS INVOLVED/ARISE PEOPLE AFFECTED EXISTING CONTROLS

Burns to all unprotected parts of the Chefs Thermostat control must be serviced regularly to ensure the oil cannot overheat. Installation and equipment subject to annual recorded maintenance by competent body from fat/oil by contact Contractors person Electrical shock Maintenance Personnel Defective equipment isolated and not used Fire due to overheating of oil Fire blanket or lid in close proximity Slippery floors due to spilled fat Identified electrical isolating switch Burns whilst emptying oil Special considerations: Training of staff regarding hazards and controls when using equipment Inexperienced staff Only emptied when oil is cooled - below +40C. Display of notice inside door re: only empty when oil is cooled Cold oil never put into hot oil Fire suppression system installed SEVERITY: SIGNIFICANT NUMBERS AFFECTED: LIKELIHOOD: POSSIBLE RISK FACTOR: MEDIUM ONE ADDITIONAL CONTROLS REQUIRED DATE ADDITIONAL CONTROLS REQUIRED DATE COM'D COM'D

COMPLETED BY: DATE OF ASSESSMENT: DATE TO BE COMPLETED: REVIEW DATE:

© FOOD ALERT LTD: WWW.FOODALERT.COM Call 020 7915 5555 for details on how Food Alert can help you complete your risk assessments

RISK ASSESSMENT OF: USE OF DEEP FAT FRYER (GAS)

DEPARTMENT/LOCATION: KITCHEN STAFF INVOLVED: CHEFS DESCRIPTION OF OPERATION Unit lit using taper/sparker and oil heated to cooking temperature. Basket filled and lowered into hot oil, once cooked, food is removed and excess oil allowed to drain off.

PREVIOUS ACCIDENTS: HAZARDS INVOLVED/ARISE PEOPLE AFFECTED EXISTING CONTROLS

Burns to all unprotected parts of the Chefs Thermostat control must be serviced regularly to ensure the oil cannot overheat. Installation and annual recorded maintenance by Corgi approved person body by contact Maintenance Personnel Defective equipment isolated and not used Gas explosion Contractors Identification of main and localised gas cut off valve Fire due to overheating of oil Provision of gas regulator to equipment Slippery floor due to spilt oil/fat Fire blanket and or lid provided in close proximity Carbon monoxide poisoning Only emptied when oil is cooled - below +40C. Special considerations: Training of chefs regarding hazards and controls when using equipment Notice displayed inside door stating not to be emptied whilst the oil is hot Inexperienced staff Cold oil never put into hot oil Fire suppression system installed SEVERITY: HIGH NUMBERS AFFECTED: LIKELIHOOD: POSSIBLE RISK FACTOR: MEDIUM FEW-MANY ADDITIONAL CONTROLS REQUIRED DATE ADDITIONAL CONTROLS REQUIRED DATE COM'D COM'D

COMPLETED BY: DATE OF ASSESSMENT: DATE TO BE COMPLETED: REVIEW DATE:

© FOOD ALERT LTD: WWW.FOODALERT.COM Call 020 7915 5555 for details on how Food Alert can help you complete your risk assessments

RISK ASSESSMENT OF: KNIFE AND CLEAVER USE

DEPARTMENT/LOCATION: KITCHEN STAFF INVOLVED: CHEFS DESCRIPTION OF OPERATION Appropriate sharp knife and appropriate cutting surface utilised for cutting/slicing food stuffs.

PREVIOUS ACCIDENTS: HAZARDS INVOLVED/ARISE PEOPLE AFFECTED EXISTING CONTROLS

Cuts to hands Chefs/KP’s Use of correct knife Stabs to body Cleaners Knives are sharp Contact with blade Arrangements for knife sharpening in place Safe storage provided (blades flat and pointing away) Special considerations: Training of staff regarding safe use of knives Inexperienced staff Knives carried flat at the persons side Dropped knives not caught Knives not left in sinks SEVERITY: MEDIUM NUMBERS AFFECTED: LIKELIHOOD: LIKELY RISK FACTOR: MEDIUM ONE ADDITIONAL CONTROLS REQUIRED DATE ADDITIONAL CONTROLS REQUIRED DATE COM'D COM'D

COMPLETED BY: DATE OF ASSESSMENT: DATE TO BE COMPLETED: REVIEW DATE:

© FOOD ALERT LTD: WWW.FOODALERT.COM Call 020 7915 5555 for details on how Food Alert can help you complete your risk assessments

RISK ASSESSMENT OF: USE OF FOOD MIXER

DEPARTMENT/LOCATION: KITCHEN STAFF INVOLVED: CHEFS DESCRIPTION OF OPERATION Ingredients placed into food mixer and guard put in place. Machine operated and once mixing completed, ingredients then removed PREVIOUS ACCIDENTS: HAZARDS INVOLVED/ARISE PEOPLE AFFECTED EXISTING CONTROLS

Limbs being trapped in the machine Chefs Appropriate guard put in place and locked before use. Safe equipment purchased and subject to annual recorded maintenance by Clothing, hair, etc., becoming Maintenance competent person entangled Personnel Defective equipment not used Manual handling Contractors Electrical isolating switch clearly identified and labelled Training of staff regarding hazards and controls when using the equipment Electrical shock Training in manual handling provided No person under 18 allowed to operate or clean machine Special considerations: Display of dangerous machines notice Inexperienced staff Use of castor framed trolleys to move large mixing bowls Portable appliance testing User checks; Visual Inspection by Competent Person SEVERITY: SIGNIFICANT NUMBERS AFFECTED: LIKELIHOOD: UNLIKELY RISK FACTOR: LOW ONE ADDITIONAL CONTROLS REQUIRED DATE ADDITIONAL CONTROLS REQUIRED DATE COM'D COM'D

COMPLETED BY: DATE OF ASSESSMENT: DATE TO BE COMPLETED: REVIEW DATE:

© FOOD ALERT LTD: WWW.FOODALERT.COM Call 020 7915 5555 for details on how Food Alert can help you complete your risk assessments

RISK ASSESSMENT OF:

DEPARTMENT/LOCATION: STAFF INVOLVED: DESCRIPTION OF OPERATION

PREVIOUS ACCIDENTS: HAZARDS INVOLVED/ARISE PEOPLE AFFECTED EXISTING CONTROLS

Chefs Maintenance Personnel Contractors

Special considerations: Inexperienced staff

SEVERITY: NUMBERS AFFECTED: LIKELIHOOD: RISK FACTOR:

ADDITIONAL CONTROLS REQUIRED DATE ADDITIONAL CONTROLS REQUIRED DATE COM'D COM'D

COMPLETED BY: DATE OF ASSESSMENT: DATE TO BE COMPLETED: REVIEW DATE:

© FOOD ALERT LTD: WWW.FOODALERT.COM Call 020 7915 5555 for details on how Food Alert can help you complete your risk assessments