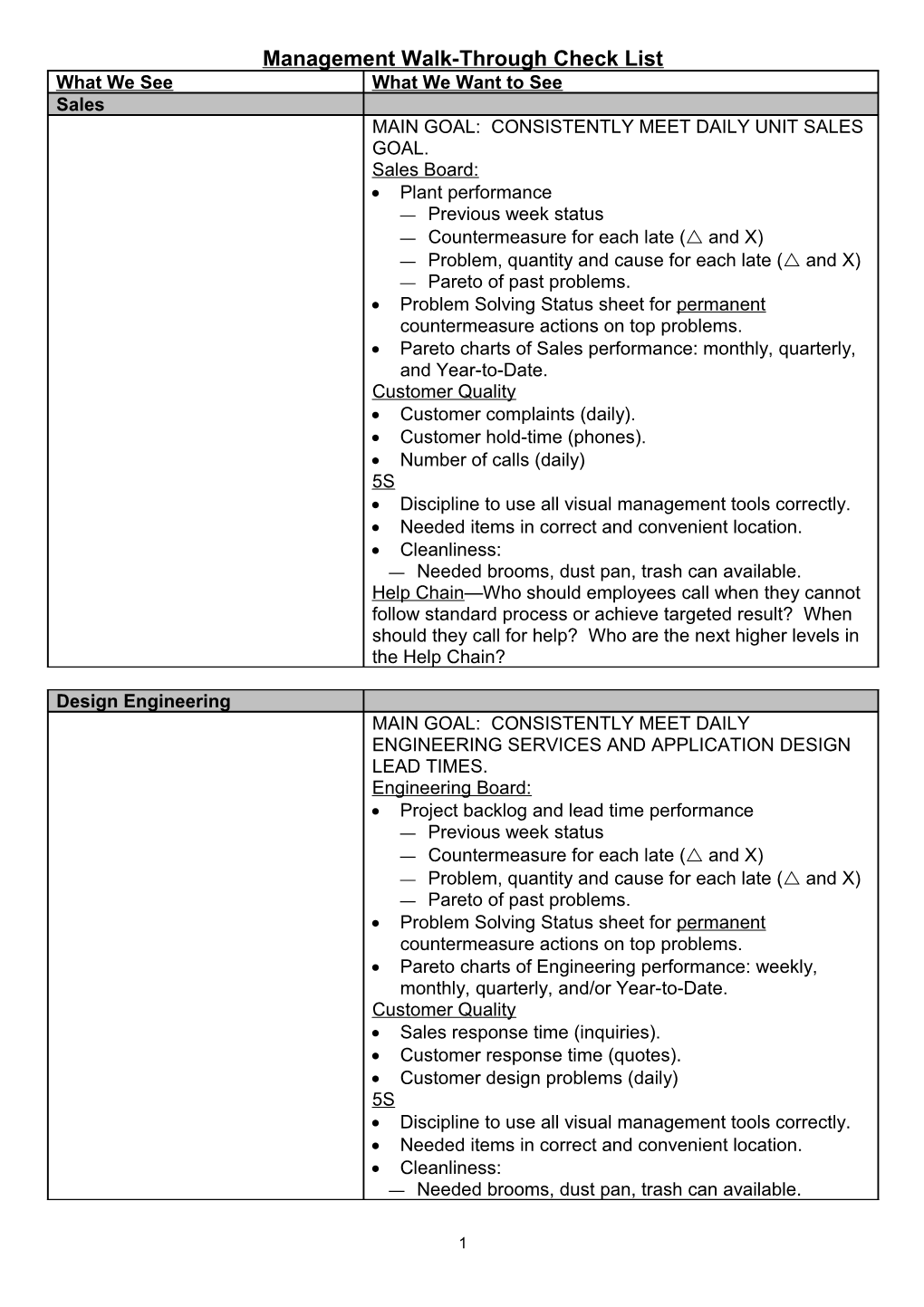

Management Walk-Through Check List What We See What We Want to See Sales MAIN GOAL: CONSISTENTLY MEET DAILY UNIT SALES GOAL. Sales Board: Plant performance — Previous week status — Countermeasure for each late (△ and X) — Problem, quantity and cause for each late (△ and X) — Pareto of past problems. Problem Solving Status sheet for permanent countermeasure actions on top problems. Pareto charts of Sales performance: monthly, quarterly, and Year-to-Date. Customer Quality Customer complaints (daily). Customer hold-time (phones). Number of calls (daily) 5S Discipline to use all visual management tools correctly. Needed items in correct and convenient location. Cleanliness: — Needed brooms, dust pan, trash can available. Help Chain—Who should employees call when they cannot follow standard process or achieve targeted result? When should they call for help? Who are the next higher levels in the Help Chain?

Design Engineering MAIN GOAL: CONSISTENTLY MEET DAILY ENGINEERING SERVICES AND APPLICATION DESIGN LEAD TIMES. Engineering Board: Project backlog and lead time performance — Previous week status — Countermeasure for each late (△ and X) — Problem, quantity and cause for each late (△ and X) — Pareto of past problems. Problem Solving Status sheet for permanent countermeasure actions on top problems. Pareto charts of Engineering performance: weekly, monthly, quarterly, and/or Year-to-Date. Customer Quality Sales response time (inquiries). Customer response time (quotes). Customer design problems (daily) 5S Discipline to use all visual management tools correctly. Needed items in correct and convenient location. Cleanliness: — Needed brooms, dust pan, trash can available.

1 Help Chain—Who should employees call when they cannot follow standard process or achieve targeted result? When should they call for help? Who are the next higher levels in the Help Chain?

Shipping MAIN GOAL: SHIP GOOD QUALITY PARTS ON TIME. Shipping Board: 5-day customer requirements (current week) — Ahead/behind: O, △, X by each entry — Recovery date for each late (△ and X) — Problem, quantity and cause for each late (△ and X) Confirm history of problems is being retained. Pareto of past problems. Problem Solving Status sheet for permanent countermeasure actions on top problems. Customer Quality Open customer quality issues, containment & recovery. 5S Discipline to use all visual management tools correctly. Needed items in correct and convenient location. Cleanliness: — Needed brooms, dust pan, trash can available.

Packing MAIN GOAL: SEE AT A GLANCE WHETHER NEEDED KITS FOR SCHEDULED DELIVERIES ARE IN STOCK. Staging Lanes/Boards Consistent with Shipping status. Due days clearly defined, with attention to “past-due” and “due today”. Material Storage—one part number per location; store by frequency. Stock moved in Staging Lanes and short lead- time to Shipping. 5S Part label matches parts. Discipline to use all visual management tools correctly. Needed items in correct and convenient location. Cleanliness: — Needed brooms, dust pan, trash can available. Productivity. Help Chain—Who should employees call when they cannot follow standard process or achieve targeted result? When should they call for help? Who are the next higher levels in the Help Chain?

Painting

2 MAIN GOALS: ZERO DEFECTS TO CUSTOMER AND EFFICIENCY. Painting Board Schedule/Progress Control Board: — Ahead/Behind with problems listed. — History of problems (check sheet or other) — Pareto and Problem Solving Status Quantity and FIFO of orders from Assembly. “What are the rules?” Are people following the rules? Process 5S Standardized Work posted and being followed. Rejects: — Appropriately identified and segregated. — Moved to repair area within one hour. — Scrap properly documented. Customer Quality Is data collected useful for problem solving? Maintenance: — Accurate records of all downtimes. — Maintenance work orders prepared as needed. — Operator maintenance performed. Help Chain—Who should employees call when they cannot follow standard process or achieve targeted result? When should they call for help? Who are the next higher levels in the Help Chain?

Pre-Assembly/Assembly MAIN GOAL: RELIABLY, WITH HIGH QUALITY & PRODUCTIVITY, PRODUCE PARTS PER SCHEDULE. Assembly Board — Ahead/Behind with problems listed. — History of problems (check sheet or other) — Pareto and Problem Solving Status Customer Quality Are QC checks made in a timely and effective manner? Is data recorded useful for problem solving? Tool/Fixture life: — Visual control of tooling. — Proper use of replenishment form. Maintenance: — Accurate records of all downtimes. — Maintenance work orders prepared as needed. — Operator maintenance performed. Productivity—labor constraints. Rework Rework schedule meets shipping schedule. Rework process and handling do not cause new defects. Process 5S Standardized Work posted and being followed. Rejects: — Appropriately identified and segregated. — Moved to repair area within one hour. Scrap properly documented.

3 Forklift Route (bus driver) Progress Control Board—ahead/behind, problems recorded. — Check Sheet, Pareto, Problem Solving Status. Help Chain—Who should employees call when they cannot follow standard process or achieve targeted result? When should they call for help? Who are the next higher levels in the Help Chain?

Supermarkets MAIN GOAL: STORE TO BUFFER MACHINING OUTPUT VARIATION AND ENABLE SHIPMENT OF CUSTOMER ORDERS WITHIN REQUIRED DAYS. Store Inventory: Inventory on hand within min/max of store. Overstock clearly identified (possibly in “Overflow Area”). Only correct reference number stored under each sign.

Machining MAIN GOAL: RELIABLY, WITH HIGH QUALITY & PRODUCTIVITY, PRODUCE PARTS PER SCHEDULE. Machining Board — Ahead/Behind with problems listed. — History of problems (check sheet or other) — Pareto and Problem Solving Status Customer Quality Are QC checks made in a timely and effective manner? Is data recorded useful for problem solving? Tool/Fixture life: — Visual control of tooling. — Proper use of replenishment form. Maintenance: — Accurate records of all downtimes. — Maintenance work orders prepared as needed. — Operator maintenance performed. Productivity—labor constraints. Process 5S Standardized Work posted and being followed. Rejects: — Appropriately identified and segregated. — Moved to repair area within one hour. — Scrap properly documented. Help Chain—Who should employees call when they cannot follow standard process or achieve targeted result? When should they call for help? Who are the next higher levels in the Help Chain?

Planning MAIN GOAL: CONSISTENTLY BALANCE DAILY PROCESS SCHEDULING TO CUSTOMER REQUIREMENTS. Planning Board: Planning performance

4 — Orders scheduled/held — Inventory Turns — Countermeasure for each late (△ and X) — Problem, quantity and cause for each late (△ and X) — Pareto of past problems. Problem Solving Status sheet for permanent countermeasure actions on top problems. Pareto charts of historical Inventory Turns and Dollars. Customer Quality Proactive due-date communication (daily). Planning constraints (material, labor shortages, etc). Customers affected by held orders. 5S Discipline to use all visual management tools correctly. Needed items in correct and convenient location. Cleanliness: — Needed brooms, dust pan, trash can available. Help Chain—Who should employees call when they cannot follow standard process or achieve targeted result? When should they call for help? Who are the next higher levels in the Help Chain?

Purchasing MAIN GOAL: CONSISTENTLY SUPPLY MATERIALS TO MEET CUSTOMER REQUIREMENTS. Purchasing Board: Purchasing performance — Supplier orders late — Raw Material Inventory levels — Countermeasure for each late (△ and X) — Problem, quantity and cause for each late (△ and X) — Pareto of vendor performance Problem Solving Status sheet for permanent countermeasure actions on top problems. Pareto charts of historical vendor performance. Customer Quality Proactive due-date communication (daily). Material shortages. Customers affected by shortages. 5S Discipline to use all visual management tools correctly. Needed items in correct and convenient location. Cleanliness: — Needed brooms, dust pan, trash can available. Help Chain—Who should employees call when they cannot follow standard process or achieve targeted result? When should they call for help? Who are the next higher levels in the Help Chain?

5