How to use the G-23 magnets with the Futaba GV-1 Governor

Rich Bono, 7 Redfield Circle, Derry, NH 03038 © Copyright 2003 (Version 1.1 6/26/2003)

The Futaba GV-1 (http://www.futaba-rc.com/radioaccys/futm1001.html) governor controls the engine speed in helicopters by having you install a magnet in the fan of the engine. This is a delicate procedure to perform. You must drill a hole in the fan, epoxy the magnet into the whole with the proper polarity. After doing this you must balance the fan to be sure that you do not induce too much vibration into your helicopter.

With the added magnet, there is the risk that a magnet will come loose during operation. This will cause the governor to fail to control the engine speed as well as present a physical danger to people if the magnet strikes someone. Even the Futaba instructions warn you to check the magnet after every 10 flights.

In the Gas X-Cell (or any Zenoah G-23 a.k.a. G230PUH powered helicopter) you can use the magnets in the engine flywheel as a trigger source for the Futaba GV-1 instead of mounting the magnets supplied by Futaba.

Some may ask why I didn’t simply mount the magnets in the fan as per the Futaba GV-1 instructions. The reasons are:

There is barely any free room to mount the sensor and its bracket under the fan in the Gas X-Cell. The G-23 takes up a lot of room in this X-cell!

There will be no added vibration issues to worry about!

There will be no need to try to balance anything as all moving parts in the helicopters are un-touched.

There is NO chance that a magnet will fall off in flight to cause a failure of the governor to control the engine/head speed!

There is NO chance that a magnet falling off while the engine is operating will injure someone or jam the gears of the head/tail mechanism!

This is easier to do than installing the magnet and aligning the sensor.

Note, there does appear to be three magnets in the G-23 flywheel, but only one of them seems to be the proper polarity to trigger the GV-1 sensor. How convenient!

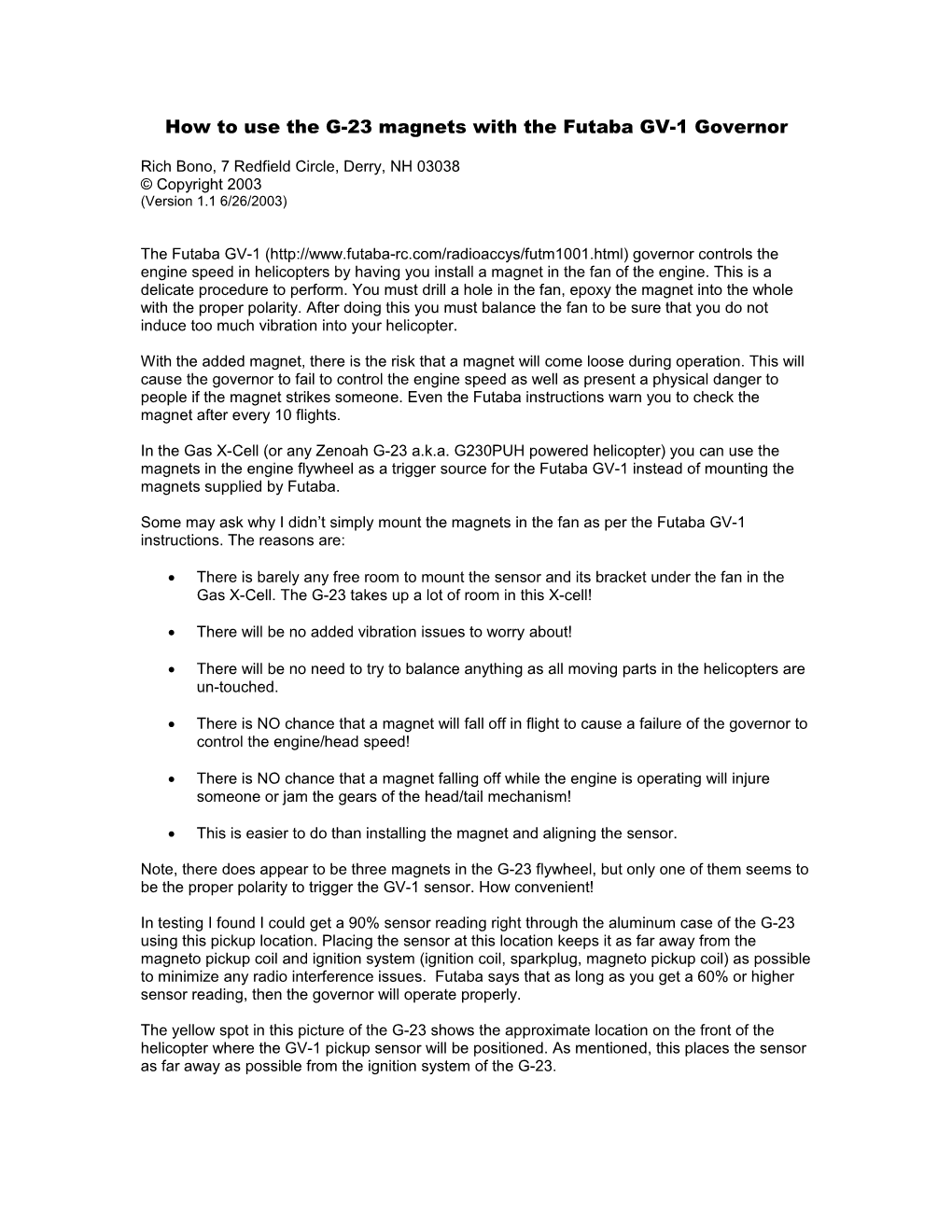

In testing I found I could get a 90% sensor reading right through the aluminum case of the G-23 using this pickup location. Placing the sensor at this location keeps it as far away from the magneto pickup coil and ignition system (ignition coil, sparkplug, magneto pickup coil) as possible to minimize any radio interference issues. Futaba says that as long as you get a 60% or higher sensor reading, then the governor will operate properly.

The yellow spot in this picture of the G-23 shows the approximate location on the front of the helicopter where the GV-1 pickup sensor will be positioned. As mentioned, this places the sensor as far away as possible from the ignition system of the G-23. You will need to build a bracket and a standoff block to mount the GV-1 sensor in the position shown by the yellow spot.

First, build a bracket for the GV-1 sensor. You can use a Miniature Aircraft part number 106-66 to do this, or build it from either some aluminum or 3/16 or ¼ inch thick aircraft plywood.

Do not use anything too flexible as you don't want it to flex or vibrate during operation. If you use plywood, paint it black to protect it and make it look better. Whichever you use, you need two of them. One will mount between the front landing gear bolts and the other between the rear landing gear bolts so that the frame of the X-Cell will not be tilted to the rear when on its skids. If you choose to use the ¼ inch think aircraft plywood, you can omit the stand-offs (3923-1) between the frame and the landing gear.

The bracket will be mounted between the landing gear and the bottom for the frame rails (105- 86). The landing gear stand-offs (3923-1) will be between the bracket and the landing gear (3923), not between the bracket and the frame rails (105-86).

Use the bracket (106-66) as a mounting point for the GV-1 sensor. You will need to drill two 2mm holes in the bracket at the appropriate point. To determine the proper place to mount the GV-1 sensor, remove your landing gear from the X-Cell. Then place the bracket in position and slide some bolts through it and the frame rails (105-86). Place the sensor on top of a 6mm thick standoff block. Position the sensor so that it will be in the position as shown in the pictures. Mark this spot so that you can drill the two 2mm holes for the mounting hardware. Use the GV-1 sensor as a guide to drilling the two 2mm holes. Elongate the holes to allow for some adjustment of the GV-1 sensor. The bracket is part "A" as identified in the included picture. Note that my mounting bracket was made from some scrap frame material; the 106-66 part will not look anything like this!

The standoff block (“B” in this photo) was made from some 6mm thick piece of plastic cut from an old anti-rotation arm (Miniature Aircraft part number 0247). This is part "B" as identified in the included picture. You can use some 6mm thick aircraft plywood and paint it black (do not use ‘light-ply’). You need to raise the sensor 6mm off the surface of the bracket so that it will be in the correct position on the G-23 case as seen in the first picture. Use the GV-1 sensor as a guide to drilling two 2mm holes in the standoff block.

When you mount it, you do not want the sensor to come in contact with the G-23!! You do want a very small gap between the sensor and the engine case so that any engine vibration is not transmitted directly to the pickup sensor. Note that in this picture, "A" is pointing to the mounting bracket, and "B" is pointing to the offset block. For your information, the offset block "B" is about 6mm thick made from a piece cut from a salvaged anti-rotation arm (Miniature Aircraft part number 0247). The mounting plate is 2mm thick Miniature Aircraft part number 106-66.

I used two of these brackets, one under the front landing gear mounts as shown and another between the rear landing gear mounts so that the helicopter would still sit level. Here is a view showing how the bracket is mounted between the frame rails and the landing gear stand-offs (3923-1). Plus is shows a clearer view of the standoff to raise the sensor into the correct position on the G-23. Here is a full view of how the sensor, bracket and offset block are mounted.