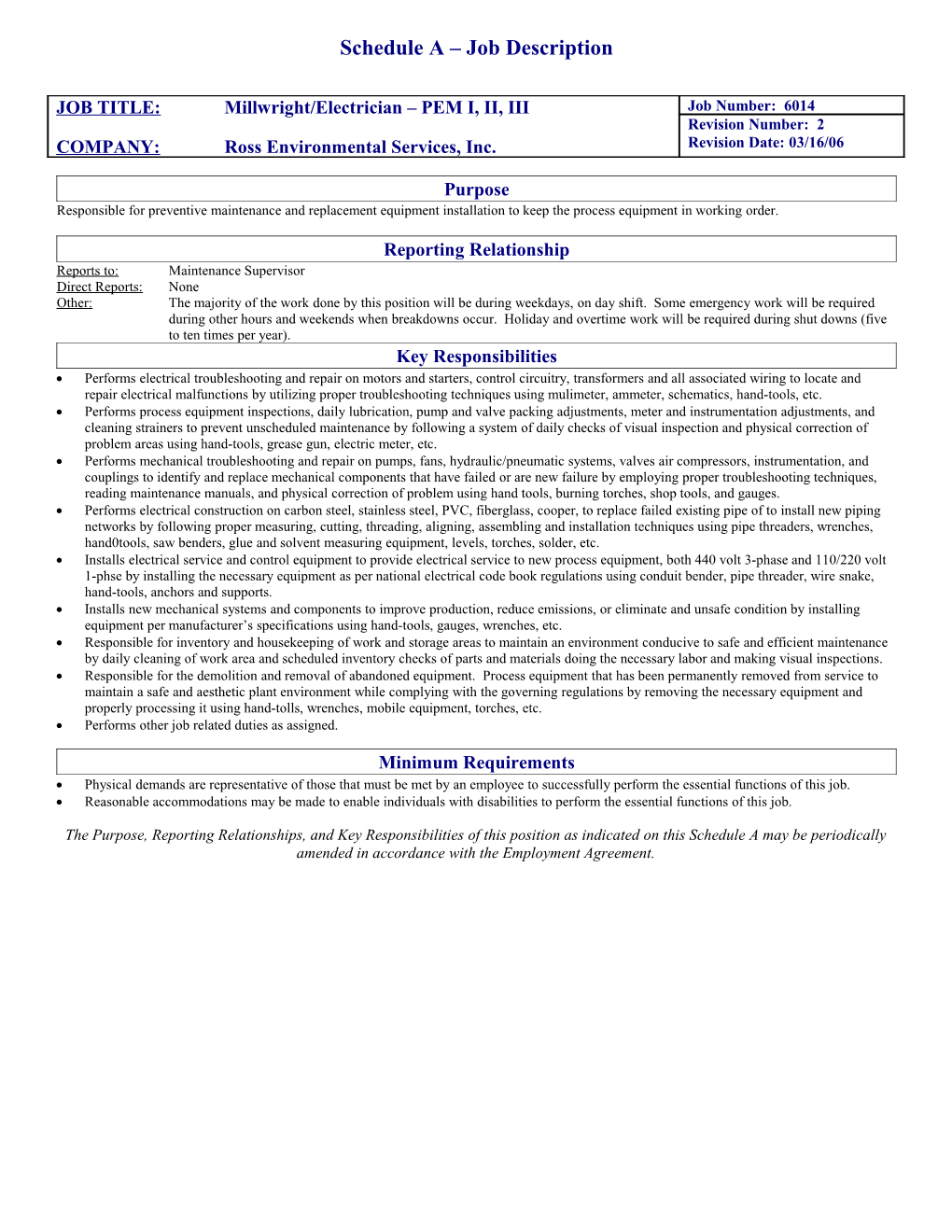

Schedule A – Job Description

JOB TITLE: Millwright/Electrician – PEM I, II, III Job Number: 6014 Revision Number: 2 COMPANY: Ross Environmental Services, Inc. Revision Date: 03/16/06

Purpose Responsible for preventive maintenance and replacement equipment installation to keep the process equipment in working order.

Reporting Relationship Reports to: Maintenance Supervisor Direct Reports: None Other: The majority of the work done by this position will be during weekdays, on day shift. Some emergency work will be required during other hours and weekends when breakdowns occur. Holiday and overtime work will be required during shut downs (five to ten times per year). Key Responsibilities Performs electrical troubleshooting and repair on motors and starters, control circuitry, transformers and all associated wiring to locate and repair electrical malfunctions by utilizing proper troubleshooting techniques using mulimeter, ammeter, schematics, hand-tools, etc. Performs process equipment inspections, daily lubrication, pump and valve packing adjustments, meter and instrumentation adjustments, and cleaning strainers to prevent unscheduled maintenance by following a system of daily checks of visual inspection and physical correction of problem areas using hand-tools, grease gun, electric meter, etc. Performs mechanical troubleshooting and repair on pumps, fans, hydraulic/pneumatic systems, valves air compressors, instrumentation, and couplings to identify and replace mechanical components that have failed or are new failure by employing proper troubleshooting techniques, reading maintenance manuals, and physical correction of problem using hand tools, burning torches, shop tools, and gauges. Performs electrical construction on carbon steel, stainless steel, PVC, fiberglass, cooper, to replace failed existing pipe of to install new piping networks by following proper measuring, cutting, threading, aligning, assembling and installation techniques using pipe threaders, wrenches, hand0tools, saw benders, glue and solvent measuring equipment, levels, torches, solder, etc. Installs electrical service and control equipment to provide electrical service to new process equipment, both 440 volt 3-phase and 110/220 volt 1-phse by installing the necessary equipment as per national electrical code book regulations using conduit bender, pipe threader, wire snake, hand-tools, anchors and supports. Installs new mechanical systems and components to improve production, reduce emissions, or eliminate and unsafe condition by installing equipment per manufacturer’s specifications using hand-tools, gauges, wrenches, etc. Responsible for inventory and housekeeping of work and storage areas to maintain an environment conducive to safe and efficient maintenance by daily cleaning of work area and scheduled inventory checks of parts and materials doing the necessary labor and making visual inspections. Responsible for the demolition and removal of abandoned equipment. Process equipment that has been permanently removed from service to maintain a safe and aesthetic plant environment while complying with the governing regulations by removing the necessary equipment and properly processing it using hand-tolls, wrenches, mobile equipment, torches, etc. Performs other job related duties as assigned.

Minimum Requirements Physical demands are representative of those that must be met by an employee to successfully perform the essential functions of this job. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions of this job.

The Purpose, Reporting Relationships, and Key Responsibilities of this position as indicated on this Schedule A may be periodically amended in accordance with the Employment Agreement.