SPECIFICATION

PIPES AND FITTINGS MATERIAL

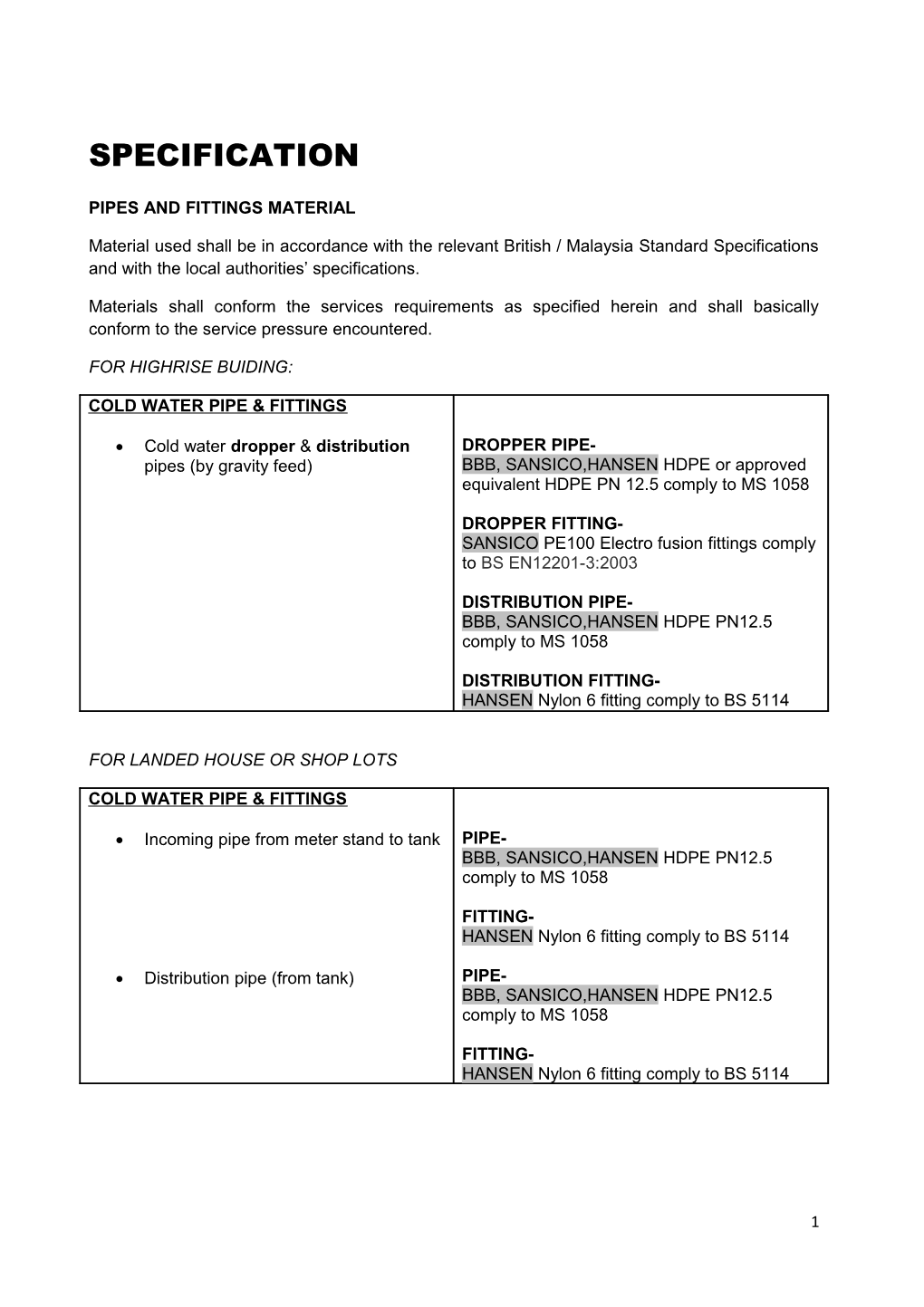

Material used shall be in accordance with the relevant British / Malaysia Standard Specifications and with the local authorities’ specifications.

Materials shall conform the services requirements as specified herein and shall basically conform to the service pressure encountered.

FOR HIGHRISE BUIDING:

COLD WATER PIPE & FITTINGS

Cold water dropper & distribution DROPPER PIPE- pipes (by gravity feed) BBB, SANSICO,HANSEN HDPE or approved equivalent HDPE PN 12.5 comply to MS 1058

DROPPER FITTING- SANSICO PE100 Electro fusion fittings comply to BS EN12201-3:2003

DISTRIBUTION PIPE- BBB, SANSICO,HANSEN HDPE PN12.5 comply to MS 1058

DISTRIBUTION FITTING- HANSEN Nylon 6 fitting comply to BS 5114

FOR LANDED HOUSE OR SHOP LOTS

COLD WATER PIPE & FITTINGS

Incoming pipe from meter stand to tank PIPE- BBB, SANSICO,HANSEN HDPE PN12.5 comply to MS 1058

FITTING- HANSEN Nylon 6 fitting comply to BS 5114

Distribution pipe (from tank) PIPE- BBB, SANSICO,HANSEN HDPE PN12.5 comply to MS 1058

FITTING- HANSEN Nylon 6 fitting comply to BS 5114

1 TYPES OF JOINTS

All fittings shall be those approved by the manufacturer. Properties of material shall be in accordance with the specifications in the above prescribed standards. Polyethylene (PE) pipes and fittings shall be firmly joined in accordance with manufacturer’s recommendation and practice for installation and commissioning.

HANSEN FITTINGS

The polyethylene (PE) pipes shall be firmly joined by winding the nut of the fitting onto the pipe forming a high pressure seal. Fittings used should not have rubber or acetal compression rings as a means of forming the seal.

Joining of Stainless Steel pipes, copper pipes and other approved pipe materials to Nylon 6 fitting shall be made with fittings having BSPT threads.

SANSICO ELECTRO FUSION FITTINGS

The polyethylene (PE) pipes shall be firmly jointed with electro fusion fittings by using electro fusion welding machine. The welding voltage, welding time and cooling time should comply with manufacturer’s technical specifications as shown on each fittings.

TESTING FOR PIPEWORKS AND FITTINGS (above ground)

COLD WATER

HDPE PIPES AND FITTINGS – 1.5 times working pressure or 100 psi whichever is higher for a period of minimum four (4) hours.

Testing method: Pump water to fill up the pipe until all the trapped air is fully released. Stop pumping when the pressure required (eg.100 psi) is reached. If the pressure drops once the stop cock is shutoff, pump back to 100 psi immediately, repeat until the pressure is stable/constant. Start to observe the reading when the pressure has stabilized. The test shall be considered to have passed if there is no reduction in pressure or a drop of not more than 10% within the observation time.

2