COMPETITION POOL The new competition pool at the facility is the first point of analysis in trying to verify if adequate air speeds and volumes can be realized to effectively ventilate the space and control humidity by coating interior surfaces with dry air.

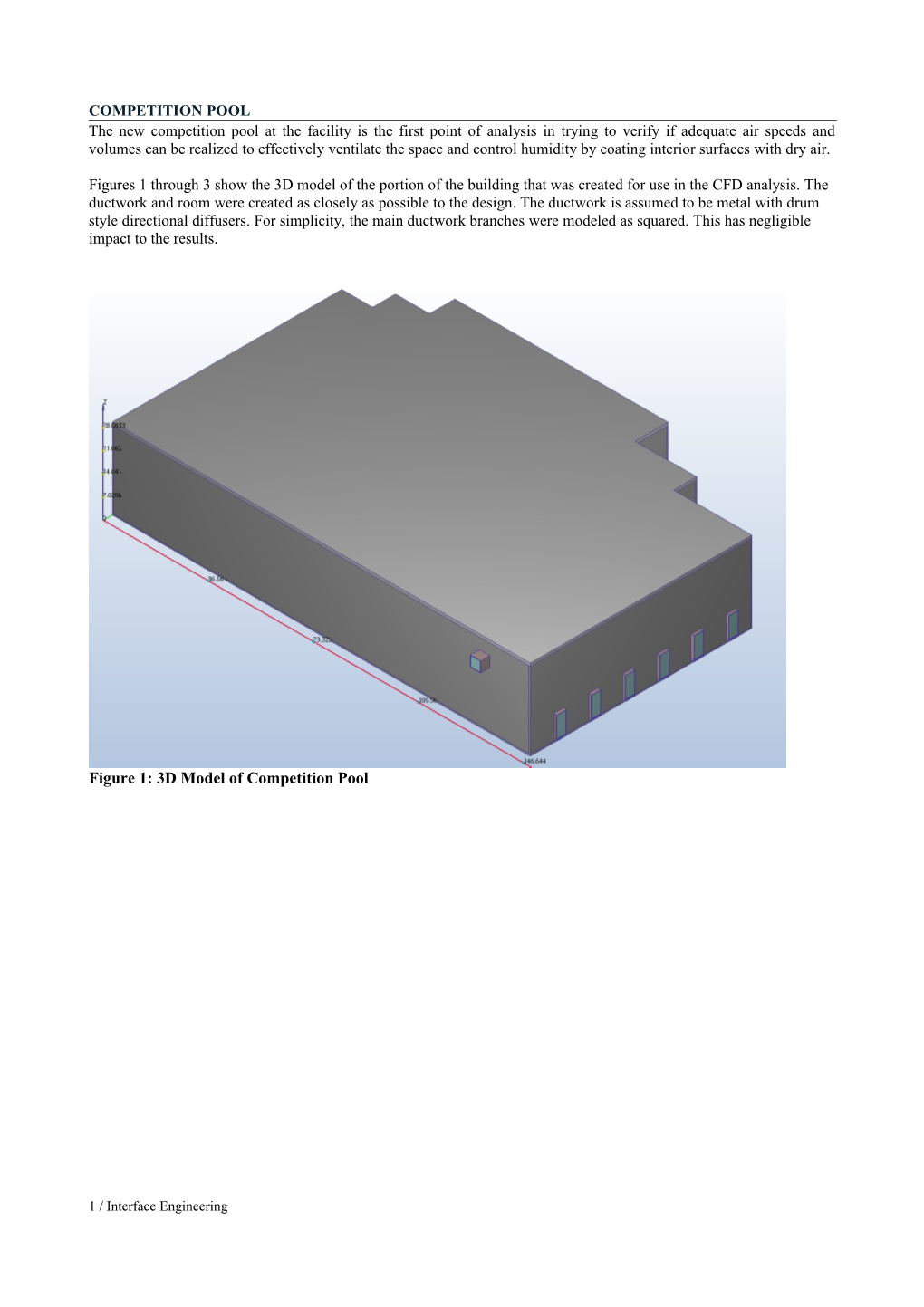

Figures 1 through 3 show the 3D model of the portion of the building that was created for use in the CFD analysis. The ductwork and room were created as closely as possible to the design. The ductwork is assumed to be metal with drum style directional diffusers. For simplicity, the main ductwork branches were modeled as squared. This has negligible impact to the results.

Figure 1: 3D Model of Competition Pool

1 / Interface Engineering Figure 2: 3D Model of Competition Pool

Figure 3: 3D Model of Competition Pool

Figure 4 and 5 show how the airflow was modeled and how the boundary conditions were set. Each nozzle was prescribed an air volume flowrate of 970 CFM to total 33,000 CFM. Exhaust grilles were defined an air volume flowrate of 500 CFM each to total 3000 CFM. Return grilles were defined an air volume flowrate of 4996 CFM in order to provide a net airflow of zero within the system. The supply airflow was set to a constant temperature 65degF and water surface was set to a constant temperature of 80degF.

2 / Interface Engineering

Exhaust sliver at bottom to exhaust heavy chloramines. Return grille at top.

Figure 4: Boundary Conditions and Airflow Direction

3 / Interface Engineering Figure 5: Boundary Conditions and Airflow Direction

Figure 6, 7, and 8 illustrate the results. As expected, we have a near horizontal airflow return near the surface of the water. However, it appears that some areas have elevated air flow magnitude.

Figure 6: Velocity Vector

4 / Interface Engineering Figure 7: Velocity Vector Near Bleachers

Figure 8: Velocity Vector near Pool Surface

5 / Interface Engineering