Section B Chapter 3 Page 1 Rev # ROUTED TYPE WING RIBS

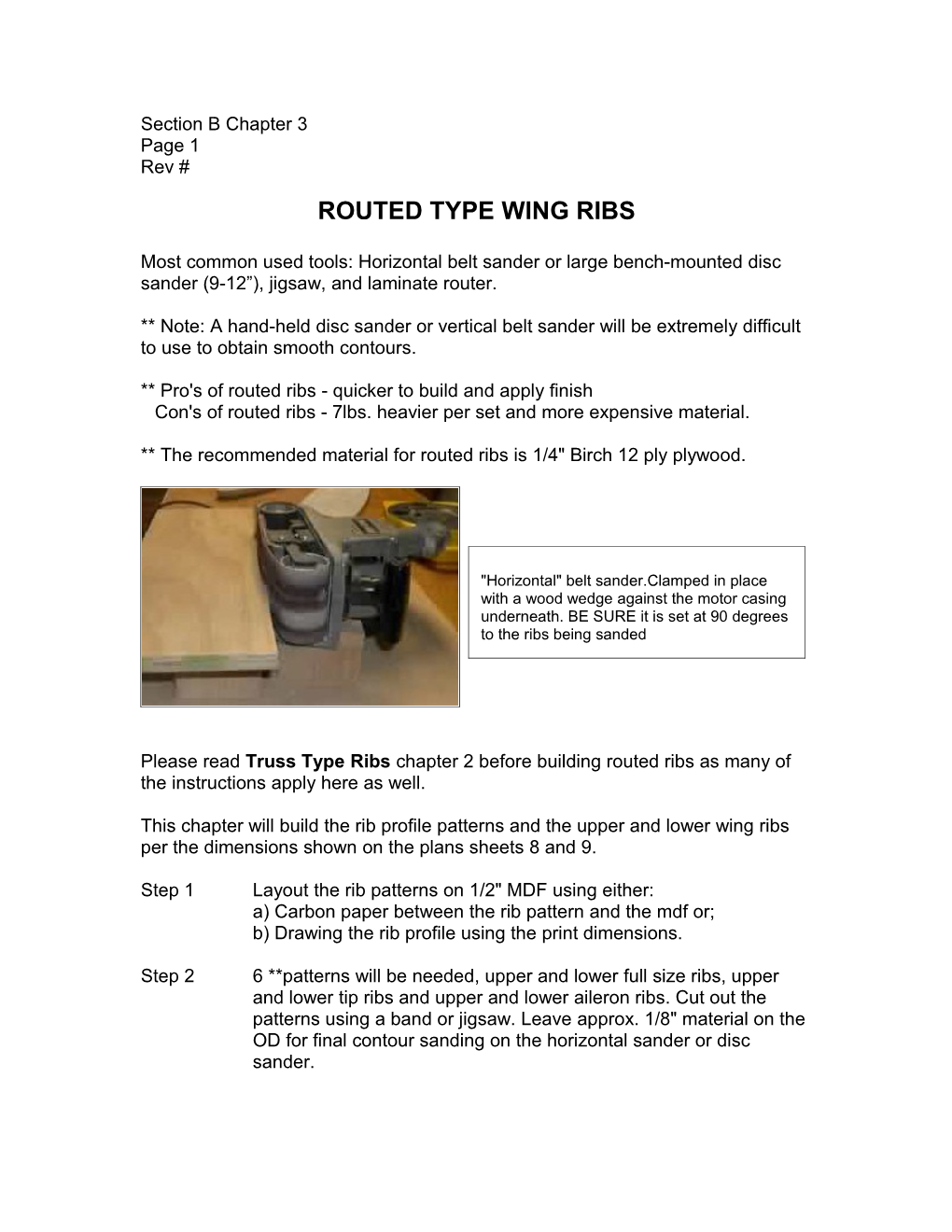

Most common used tools: Horizontal belt sander or large bench-mounted disc sander (9-12”), jigsaw, and laminate router.

** Note: A hand-held disc sander or vertical belt sander will be extremely difficult to use to obtain smooth contours.

** Pro's of routed ribs - quicker to build and apply finish Con's of routed ribs - 7lbs. heavier per set and more expensive material.

** The recommended material for routed ribs is 1/4" Birch 12 ply plywood.

"Horizontal" belt sander.Clamped in place with a wood wedge against the motor casing underneath. BE SURE it is set at 90 degrees to the ribs being sanded

Please read Truss Type Ribs chapter 2 before building routed ribs as many of the instructions apply here as well.

This chapter will build the rib profile patterns and the upper and lower wing ribs per the dimensions shown on the plans sheets 8 and 9.

Step 1 Layout the rib patterns on 1/2" MDF using either: a) Carbon paper between the rib pattern and the mdf or; b) Drawing the rib profile using the print dimensions.

Step 2 6 **patterns will be needed, upper and lower full size ribs, upper and lower tip ribs and upper and lower aileron ribs. Cut out the patterns using a band or jigsaw. Leave approx. 1/8" material on the OD for final contour sanding on the horizontal sander or disc sander. ** After the main ribs are completed [stations 2 ¼ thru 57 ¼] the patterns are modified to make the short ribs in front of the ailerons ribs [stations 68 ¼ thru 101 ¼] . Section B Chapter 3 Page 3 Rev #

** Double check the distance between spar centers shown on the plans. The main rib and tip rib distance must be the same!

** Figure A below shows the layout of the routed rib in comparison to the truss rib profile. The solid lines are the truss rib; the broken lines are the routed rib profile.

Figure A

Step 2 The upper and lower "cap strip" should be 1/2" thick. The vertical cap strip as shown on the plans should be 1" thick on your pattern. Measured 1/2" left and right from the cap strip center as shown on the plans. The necks adjacent to the spars are ½” (except the shorter wing ribs, which are ¼” aft of the rear spar as per rib outline on the plans ). There are no diagonals in the routed rib patterns. Drag wire clearance is already achieved with routered ribs.

Step 4 Drill starter holes in the corners on every section to be discarded. These will be the starter holes for the jigsaw. Section B Chapter 3 Page 4 Rev #

Step 5 With a jigsaw, cut out the sections to be discarded leaving approx. 1/8" of material past the pattern line to be routed out.

Step 6

½” mdf blocks are tacked/screwed to the bench, surrounding the template, effectively locking it in position. Temporarily tack/screw 1/2" mdf guide boards right on the pattern cutout lines as shown at the left, tack or screw the boards to the mdf bench blocks.

Using a router pattern bit similar to the one shown in section W, page 2, figure B, except with the guide bearing on the top of the bit, set the cutter depth so the bearing is riding against the mdf guide boards and the bit is cutting the template. Section B Chapter 3 Page 5 Rev #

Step 7 Repeat step 6 to clean up every cutout area on the pattern ribs.

All the pattern ribs are completed

Step 8 Using the templates, layout all the ribs needed on the 1/4" plywood (grain lengthways). Run a pencil line around the templates and in each aperture.

Step 9 Cutout the outline of all the ribs with a band or jigsaw leaving approx 1/8”. Drill starter holes in the apertures and remove with the jigsaw, again, leaving 1/8” for the router to clean up.

Step 10 Temporarily attach the ¼” ply to the template using finish nails, small screws, double sided tape, etc. Install the router pattern bit with the bottom mounted bearing, adjust the cutter height and proceed to cut completely around the ID and OD of the rib

Step 11 Repeat step 10 until all the ribs are finish profiled.

** The 6.5-degree sweepback in the upper rib spar openings will be filed in at wing assembly Section B Chapter 3 Page 6 Rev #

Step 12 With step 11 completed modify the upper and lower rib patterns at the rear spar location and build the short ribs following steps 8 thru 11 above.

Step 13

The spar opening corners are radiused due to the nature of routing. These need to be squared up using a sharp chisel. If your chisel is NOT sharp, you may crack the thin ¼” neck! You can also use a jigsaw with a fine metal cutting blade to achieve the same result

Aileron ribs at various stages of build.

Pattern matched to print and attached to table

Rib cutout attached to pattern with router bit starter holes drilled. Laminate trimmer router in the background. Section B Chapter 3 Page 7 Rev #

The end result: