Mechanical heterogeneity and geometry effects on yield load solutions

Dražan Kozak* Department of Mechanical Design, J. J. Strossmayer University of Osijek, Mechanical Engineering Faculty in Slavonski Brod, Croatia. E-mail: [email protected], Tel.: +38535446188, Fax: +38535446446

Nenad Gubeljak Institute for Engineering and Design , University of Maribor, Faculty of Mechanical Engineering, Slovenia. E-mail: [email protected], Tel.: +38622207661, Fax: +38622207990

Abstract: The paper deals with numerical solutions for the mismatch yield load of three points bend (3PB) fracture toughness specimen with the weld joint cracked in the middle. Effects of difference in yield strength of materials in the joint as well as geometrical influence parameters on the yield load value have been analyzed. The results for mismatch yield load are given in the form of diagrams depending on the crack depth ratio a/W and slenderness of the weld (W-a)/H. The magnitude and shape of the yielding zones have been compared for the specimens with the constant value of a/W=0,5, but with different weld root widths 2H.

Keywords: 3PB specimen, weld joint, strength mismatch, yield load solution, finite element analysis

Reference to this paper should be made as follows: KOZAK, D., GUBELJAK, N. Mechanical heterogeneity and geometry effects on yield load solutions. In. Bulletin of Technology Systems Operation. Vol. 1. pp. 2007. ISSN XXXX-XXXX.

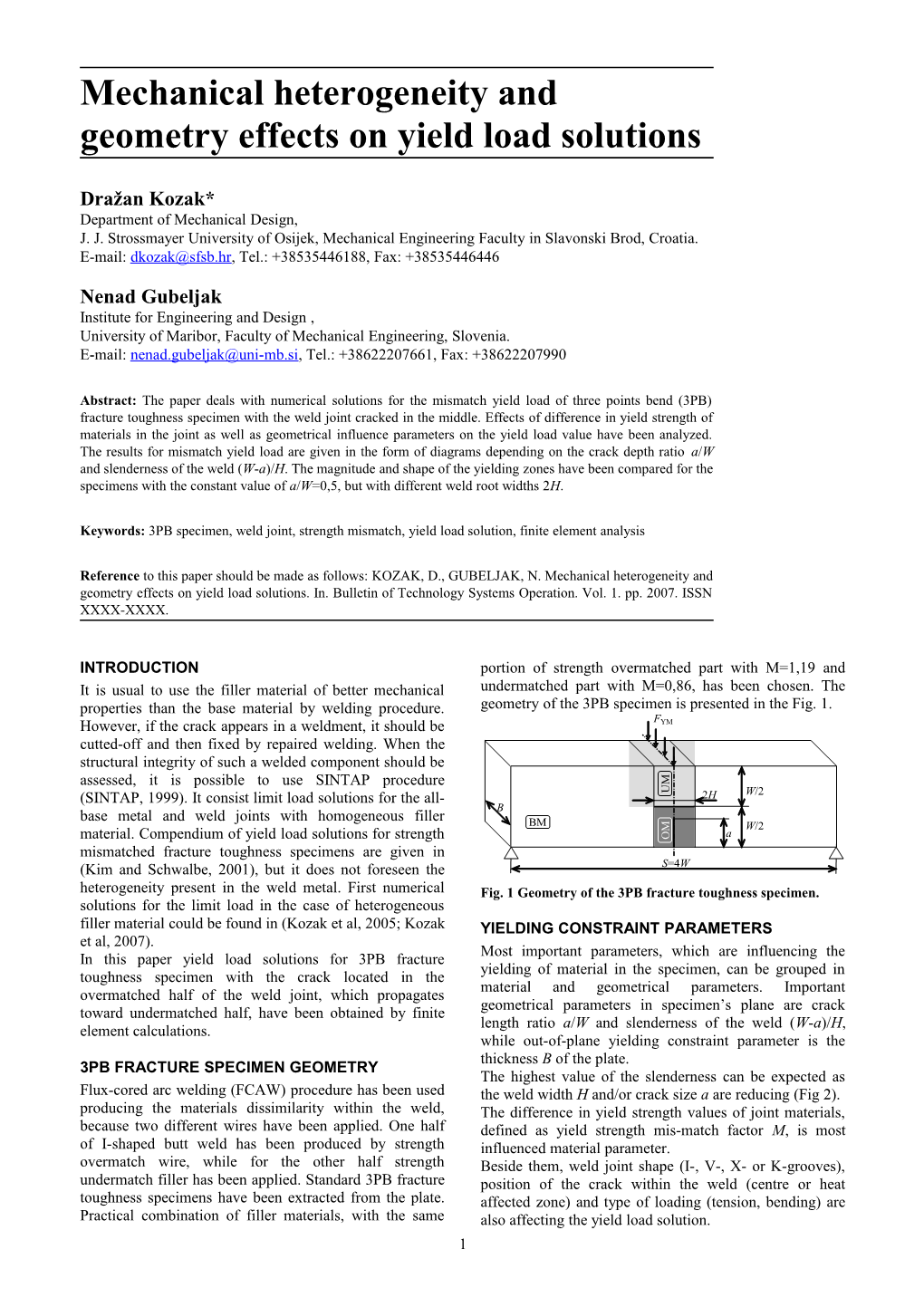

INTRODUCTION portion of strength overmatched part with M=1,19 and It is usual to use the filler material of better mechanical undermatched part with M=0,86, has been chosen. The properties than the base material by welding procedure. geometry of the 3PB specimen is presented in the Fig. 1. However, if the crack appears in a weldment, it should be FYM cutted-off and then fixed by repaired welding. When the structural integrity of such a welded component should be

assessed, it is possible to use SINTAP procedure M (SINTAP, 1999). It consist limit load solutions for the all- U 2H W/2 B base metal and weld joints with homogeneous filler BM

M W/2 a material. Compendium of yield load solutions for strength M O mismatched fracture toughness specimens are given in (Kim and Schwalbe, 2001), but it does not foreseen the S=4W heterogeneity present in the weld metal. First numerical Fig. 1 Geometry of the 3PB fracture toughness specimen. solutions for the limit load in the case of heterogeneous filler material could be found in (Kozak et al, 2005; Kozak YIELDING CONSTRAINT PARAMETERS et al, 2007). Most important parameters, which are influencing the In this paper yield load solutions for 3PB fracture yielding of material in the specimen, can be grouped in toughness specimen with the crack located in the material and geometrical parameters. Important overmatched half of the weld joint, which propagates geometrical parameters in specimen’s plane are crack toward undermatched half, have been obtained by finite length ratio a/W and slenderness of the weld (W-a)/H, element calculations. while out-of-plane yielding constraint parameter is the thickness B of the plate. 3PB FRACTURE SPECIMEN GEOMETRY The highest value of the slenderness can be expected as Flux-cored arc welding (FCAW) procedure has been used the weld width H and/or crack size a are reducing (Fig 2). producing the materials dissimilarity within the weld, The difference in yield strength values of joint materials, because two different wires have been applied. One half defined as yield strength mis-match factor M, is most of I-shaped butt weld has been produced by strength influenced material parameter. overmatch wire, while for the other half strength Beside them, weld joint shape (I-, V-, X- or K-grooves), undermatch filler has been applied. Standard 3PB fracture position of the crack within the weld (centre or heat toughness specimens have been extracted from the plate. affected zone) and type of loading (tension, bending) are Practical combination of filler materials, with the same also affecting the yield load solution. 1 M for 0 1 F YM M (3) 1 1 FYB A B C for H 1 / 2 0 ) a

- W (

1 5 s s e n r 1 0 e d n e l W a (M 1)/8 M 49 s 5 , 2e , A , d

l 1 e H 50 W 0 where: 49(M 1) 1 0 1 0 B C, C 0,3(M -1) M -1. 50 5 5 Equation (3) is valid in the case when the yielding zone W e l d h a l f w i d t h H , m m 0 0 C r a c k l e n g t h a , m m spreads through the cracked section of the weld metal.

Fig. 2 The slenderness variation with the H and a. Yield load for strength undermatched plate Analytical yield load solution for a strength undermatched ANALYTICAL SOLUTIONS FOR YIELD LOAD (UM) single-edged notch specimen subjected to bending When assess the crack-like defect in the dissimilar welded is given as: joint, the behaviour of the all base plate component is M for 0 2 taken as the starting point. The base material properties 2 are kept constant, while the weld metal properties vary. FYM (5,384 3 ) This variation is described by mis-match factor: M / for 2 12 FYB (2 3,384) 3 YW M (1) M 0,616 1,384/ for 12 YB where YW and YB present the yield strength of the weld 2 metal and the yield strength of base metal, respectively. It (4) where: is usual that weld metal is produced with a yield strength 10 greater than that of the base plate; this case is designated Equation (4) is the solution for the case when the plastic as overmatch (OM) with the mis-match factor M > 1. deformation is fully confined to the weaker weld metal, Today, an increasing use of high strength steels forces the determined from the slip line field analysis. fabricator to select a consumable with lower strength to comply with the toughness requirements, what is FINITE ELEMENT ANALYSIS designated as undermatch (UM), where M < 1. If the weld joint is composed from two or more materials, The mismatch yield load solutions for SE(B) specimen are analytical solutions given by Eqs. (3) and (4) can not be given in the Ref. 2 for all possible crack lengths and applied to calculate yield load. This was the reason why locations within the weld metal and for both plane strain finite element analysis has to be done to determine the and plane stress conditions. The basic equations for the influence of the geometrical and material parameters on yield load for all-base plate and for the cases of pure OM the yield load solution. Table 1 gives rang of the weld and pure UM weld, given in the following, are valid geometrical parameter values, which have been varied to for the crack in the centre line of the homogeneous OM or simulate different weld joint widths edged by crack with homogeneous UM weld metal assuming the plane strain different depths. The aim was to calculate the yield load state. solution generally, regardless the concrete values of some geometrical measures. The percent of the strength Yield load for all-base metal plate overmatch and undermatch part was constant. If the plate is produced as all-base metal, the yield load solution for the single-edged notch bend specimen is Tab. 1 Matrix rang of varied parameters used by finite element calculations. given as follows: 2 Crack depth ratio a/W YB BW a

F (2) H YB 0,1 0,2 0,3 0,4 0,5 h

3 S / 2 t

d W/2 √ √ √ √ √ i

where: w W/4 √ √ √ √ √

f

2 l 1,125 0,892 2,238 for 0 a/W 0,172 a W/8 √ √ √ √ √ h

d W/16 √ √ √ √ √

1,199 0,096 for 0,172 1 l

e W/24 √ √ √ √ √ W

and S = 4 W.

Yield load for strength overmatched plate Commercial FEM programme ANSYS has been used to Analytical yield load solution for an strength overmatched calculate the mismatch yield loads for different (OM) single-edged notch bend specimen is given as: combinations of geometry. Detail of typical finite element mesh with weld joint width of H=W/8, where the crack tip is located on the 0,3W, is presented in the Fig. 3. The heat 2 affected zones were omitted. Due to symmetry, only one overmatched part of the weld, although in the case of half of the specimen was modelled. First fan of elements a/W=0,5; the crack tip was positioned on the interface was sized by about 100 m. Materials were considered as between OM and UM part. The a/W ratio and weld joint isotropic elastic-almost ideal plastic, with small hardening width 2H are varied similarly. It is evident from the Fig. 4 after yielding point. The magnitude of applied loading was that the yield load results are most influenced by weld half made large enough to bring the specimen to its limiting width H for the crack length ratio a/W=0,5. Increasing of load state. For mismatched specimens, plastic deformation the strength mismatched weld width by constant crack pattern is very complex, due to influence of not only (W- length causes the lower yield loads. It is worthy note that a)/H parameter, but also on value of mis-match factor M. yield load, for the component with shallow crack, is greater than the yield load for all-base metal, regardless

the weld width value. This fact may be of some help,

M shielding the welded components with shallow cracks of U unplanned failure. 1,08

e n

i 1,06 l

y r t

e 1,04 m m y s

1,02 n e m B i Y

c 1 e F / p s M W

Y 0,98 F W=2H 0,96 W=4H 0,94 W=8H W=16H 0,92

W W=24H 3 , 0 =

a 0,9

BM M 0 0,1 0,2 0,3 0,4 a/W 0,5 O Fig. 4 Mis-match yield load solutions for heterogeneous weld H obtained by plane strain finite element analysis. 2W The value of slenderness of the weld (W-a)/H is calculated Fig. 3 Typical detail of the finite element mesh. for the different values of a/W and H. Its magnitude drops with a/W increasing, by H=const. It also drops with H MISMATCH YIELD LOAD SOLUTIONS FOR THE value increasing, by a/W=const. In this investigation the 3PB SPECIMEN WITH HETEROGENEOUS WELD slenderness ranges from 1 (a/W=0,5 and H=W/2) to 21,6 (a/W=0,1 and H=W/24). Fig. 5 shows an example of effect In practice, inhomogeneous multipass weld joint with half of (W-a)/H on the weld mis-match yield load solutions OM and half UM weld metal is usually used for repair F , for different crack lengths. The transition from the welding of weld joints where possibly cold hydrogen YM undermatch to overmatch solution is obviously for the assisted cracking can appear (Gubeljak et al, 2003). deep cracked components. On the other hand, the yield Undermatched weld part satisfied high toughness solution for the components with shallow cracks is mainly requirements, while overmatched weld half has the crack dictated by overmatch region ahead the crack tip. The shielding effect. It is fairly questionable how accurately curve has very low slope and it seems almost horizontal. It may be used the yield load solutions, given earlier for the depends very few on the slenderness value. case of homogeneous weld, if the weld is heterogeneous? 1,08 The conservative approach means to calculate the yield load solution assuming the weld made wholly from UM. This approach is near reality for the specimen with 1,04 a/W=0,5, where the region ahead the crack is B Y F undermatched, but considering the shallow crack, it can / 1 M underestimate the yield load value. Such approach Y a/W=0,5 F becomes more incorrect with the weld width 2H 0,96 a/W=0,4 decreasing. Namely, as the weld is narrower, its influence a/W=0,3 on the complete fracture behaviour decreases. Therefore, 0,92 a/W=0,2 the yield load values converge to those obtained for all- a/W=0,1 base metal. In this work, a practical combination of the overmatched and undermatched weld halves with M=1,19 0,88 and M=0,86 (yield strength of base metal is considered as 0 4 8 12 16 20 24 (W -a)/H YB=545 MPa) with the same portion in the butt weld joint is considered. The weld centre crack was located in the

3 Fig. 5 Mis-match yield load variation for the heterogeneous have been used for welding. It is assumed that the material weld with different slenderness. yields when von Mises equivalent stress overcomes An approximated 3-D area of yield load solutions over corresponding yield strength of particular material in the considered range of a/W and (W-a)/H parameters is joint. At the moment when all materials in front of the depicted on the Fig. 6. Of course, this solutions field is crack front yield and yield region spread from the crack valid only for aforementioned combination of welded tip to the other side of the specimen, it can be read yield metals and for the crack located in the centre of load value for considered configuration. Such analysis has overmatched weld. to be very precise with small increment of the loading increase to be able to observe the first moment of the yield zone spreading through the ligament.

Acknowledgements The authors wish to thank the Ministries of Science, Education and Sports of the Republic of Croatia and Slovenia for the support of their work through the international bilateral project: ’Application of fracture mechanics by revitalisation of energetic components’.

CONCLUSIONS This paper compiles yield load solutions for the SE(B) fracture toughness specimen with the crack in the centre of heterogeneous weld, obtained by 2-D plane strain finite element analysis. Most influenced geometrical parameters on the yielding constraint as a/W and (W-a)/H were varied systematically in practical range of values. In the case of Fig. 6 3-D surface of mismatch yield load solutions obtained highly constrained heterogeneous weld (a/W=0,5) filled by finite element analysis. with M=1,19 in overmatched half and M=0,86 in undermatched half, the yield load solutions transits from Yield zones of particular materials in the joint can be near undermatch solutions to near overmatch solutions extracted from the finite element analysis, as is presented with increasing of (W-a)/H values. On the other hand, the in Fig. 7. The crack depth ratio a/W was kept as constant single edged notch bend specimen with shallow crack is with amount 0.5, while weld root width was varied from less affected by (W-a)/H value. In order to be able to find H=W/2 to H=W/24. the yield load solution for each combination of parameters a/W and (W-a)/H, an approximated 3-D yield solutions surface is given, which is valid for considered combination and portion of the materials in the joint. A view of the yield zone spreading through the ligament and forming of the yielding pattern has been shown in the case of the specimen with different weld widths by keeping W a/W ratio as constant. Existing solutions given in literature for homogeneous a H weld could underestimate or overestimate the limit load solution for about 15%, when the heterogeneity in the H=W/24 H=W/16 H=W/8 weld is not taken into account. Therefore, it can be recommended to calculate a real yield/limit load for any other geometry, if the materials dissimilarity is present within the weld by using finite element method.

UM REFERENCES [1] SINTAP: Structural INTegrity Assessment Procedures for European Industry, Final Revision, EU-Project BE 95-1462, BM < 468 MPa Brite Euram Programme, 1999. OM [2] Kim, Y.-J., Schwalbe, K.-H., Compendium of yield load H 468…545 MPa solutions for strength mis-matched DE(T), SE(B) and C(T) 545…648 MPa specimens, Engineering Fracture Mechanics, Vol. 68, 2001, pp. 1137-1151. H=W/4 H=W/2 > 648 MPa [3] Kozak, D., Vojvodič-Tuma, J., Gubeljak, N., Semenski, D., Factors influencing the yielding constraint for cracked welded Fig. 7 Yield zones shape for different weld root widths by the components, Materials and Technology, Vol. 39 (1-2), 2005, pp. constant value of a/W=0,5. 29-36. [4] Kozak, D., Gubeljak, N., Vojvodič-Tuma, J., The effect of a In this paper, the base metal has the yield strength of 545 material's heterogeneity on the stress and strain distribution in MPa and as the mis-match factor M is 0,86 and 1,19 for the vicinity of a crack front, Materials and Technology, Vol. 41 strength overmatch and undermatch material, respectively, (1), 2007, pp. 41-46. electrodes with 468 MPa and 648 MPa of yield strength 4 [5] Gubeljak, N., Kolednik, O., Predan, J. and Oblak, M., Effect of Strength of Mismatch Interface on Crack Driving Force, Key Engineering Materials Vols. 251-252, 2003, pp. 235-244

5