Electronic Supplementary Material

Parallel solid-phase isothermal amplification and detection of multiple DNA targets in microliter-sized wells of a digital versatile disc

Sara Santiago-Felipe, Luis Antonio Tortajada-Genaro, Rosa Puchades, Ángel Maquieira

Instituto interuniversitario de Reconocimiento Molecular y Desarrollo Tecnológico (IDM) - Departamento de Química, Universitat Politècnica de València, Camino de Vera s/n, E46022 Valencia, Spain

*Corresponding Author E-mail: [email protected].

Set-up of the microfluidic disc

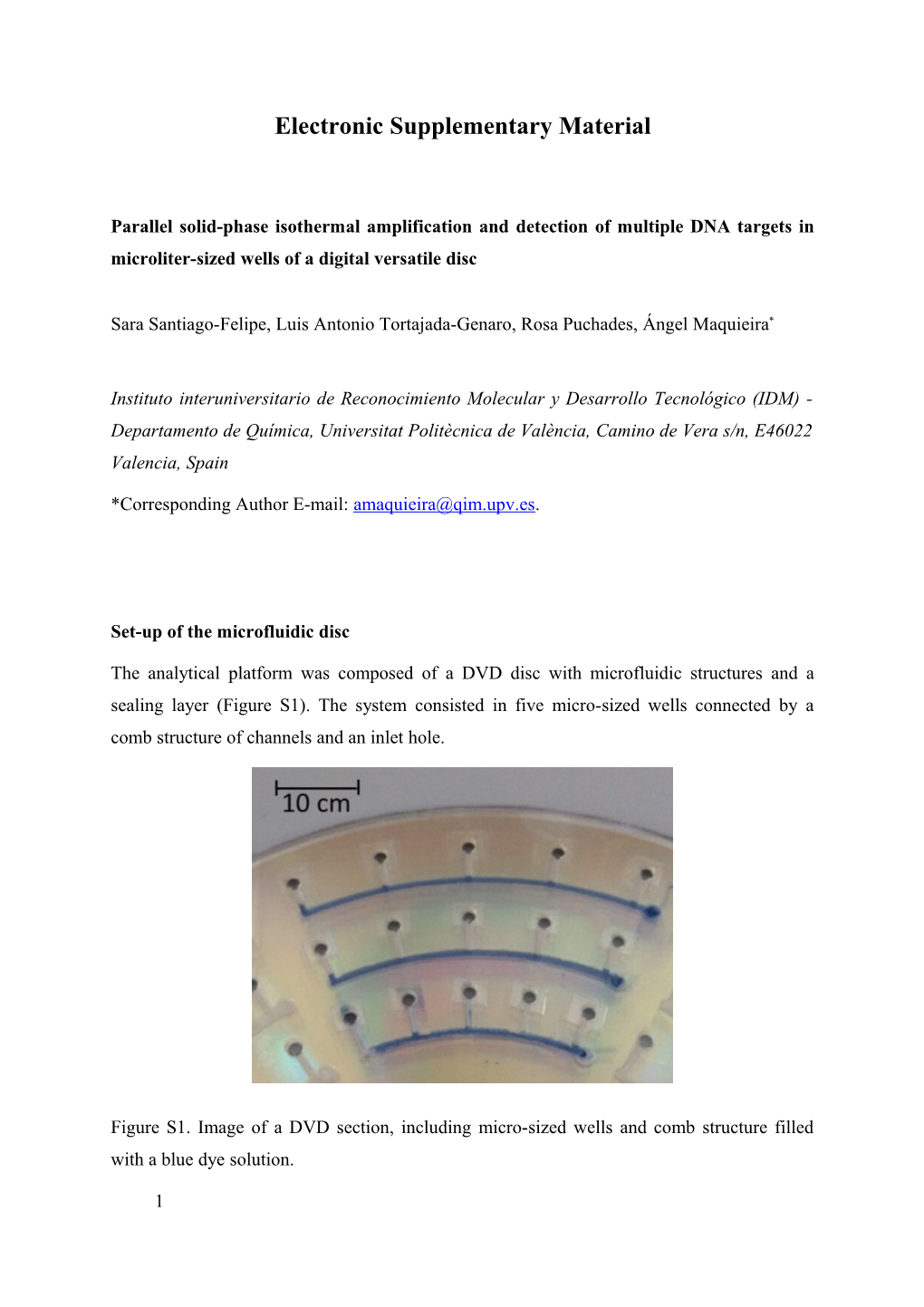

The analytical platform was composed of a DVD disc with microfluidic structures and a sealing layer (Figure S1). The system consisted in five micro-sized wells connected by a comb structure of channels and an inlet hole.

Figure S1. Image of a DVD section, including micro-sized wells and comb structure filled with a blue dye solution.

1 We first tested whether the disc with embedded structures can be managed and read by the disc drive. Mainly, scanning processes were completed without aborting and a good transmitted signal was recorded.

The microwells inside the DVD were designed with several diameters (up to 4 mm) and depths (600 to 1100 m). Shapes were tested using a blue dye solution. The optical signal recorded by the photodiode detector was similar for all the different diameters, but values higher than 2 mm led to a reading error caused by loss of the disc track during DVD reading. The measured signal increased in relation to microwell depth due to optical pathway variation (Figure S2).

Figure S2. (a) Scheme of micro-sized well. (b) Effect of microwell dimensions on the transmitted light intensity.

The best results were achieved by a compartment with a total volume of 3.2 µL (Figure S3). The micro-sized well had a conical-shaped bottom (diameter of 2 mm, height of 400 m), a cylinder on top (diameter of 2 mm, height of 700 m), and a cube-shaped hole on the sealing layer (width of 3.2 mm, length of 3.5 mm and height of 800 m). This design probably provided the best thermal transfer among the solution, support and environment. Regarding the recorded signal, the wells-based system showed relevant advantages compared to previous approaches based on assays performed on the surface of raw discs. (1),(2) The optical path length was longer, and the total laser intensity from the DVD pick up focused on the solution as the reflective metallic layer was crossed. 2 Figure S3. Scheme of the structures embedded in the multi-layer system of a standard DVD.

The distance between microwells was chosen after considering that the error correction system of a DVD can read up to a burst of defective 2900 bits. A simple platform was fabricated with 30 wells per radius (6 samples 5 genes), and the distances between wells were 7, 9 and 11 mm for the internal, middle and external radius, respectively. Under these conditions, appropriate tracking during DVD reading was achieved.

The comb structure (inlet hole, primary channel and distribution channels) was designed to hold the loading reagents, distribute the solution, and fill all the micro-sized wells. Regarding flow reagent movements, the condition for spontaneous filling or valving is highly sensitive to both materials and the aspect ratio of the structures.(3) The proposed channels were rectangular, composed of PC on three walls and acetate film at the top, and the contact angles were θPC ~ 90° (hydrophobic) and θacetate ~ 60° (hydrophilic), respectively. By assuming a constant cross-section, the dimension restrictions of the microchannel, height (H) and width (W) are expressed as:(2)

This equation revealed that wider and shallower channels were more favorable for liquid filling. The selected dimensions of the primary channel were 1.1 mm wide, 400 m high and 35-50 mm long, depending on the radius. Distribution channels were 5 mm long, 8 mm wide and 400 m high. Under these conditions, buffered solutions were loaded in the primary channel through the inlet, spontaneously moved forward along by capillary action, and stopped at the junctions of the narrower distribution channels (Figure 1b). At this point,

3 surface tension turned out to be a retarding force that stopped the fluid from moving forward by acting as a capillary valve. The flow rate through the structures, controlled by disc rotation, was modeled as described by Tortajada-Genaro et al.(4) Taking into account the characteristics of the centrifugal platform and the fluid, a rate of 500 rpm was chosen, and a flow rate of 1.00 ± 0.13 μL per second was achieved. DVD spinning allowed the liquid to overcome the capillary pressure barrier by pushing the fluid into the distribution channels. Samples were then completely transferred to microwells in less than 3 seconds, and the excess volume remained in the distribution channels. Compared to other microfluidic devices fabricated using hydrophobic substrates, no bubbles or other artifacts were observed.(5) No preferential distribution among channels or radiuses occurred since all the samples were uniformly and simultaneously dispensed to the microwells.

Assay format optimization a) Choice of solid-phase approach. Several reaction formats for solid-phase amplification are compatible with high-throughput screening, and use the developed platform. A first option was to attach one primer in the microwell and add the other to the reaction mixture. However, the non specific formation of primer dimers can take place which limits multiplexing capabilities. The attenuation of possible non specific by-products is a crucial factor for isothermal amplification reactions, particularly for those that work at lower temperatures, where mismatches are more likely to occur.(6) To this end, a bridge solid-phase approach was selected, where both primers were attached to the support (Figure S4). The same reaction mix (extracted DNA template, nucleotides, digoxigenin-labeled nucleotides, enzymes involved in the amplification reaction) was used for all the micro-sized wells. Only the presence of the targeted DNA region produced the formation of the anchored labeled product in a bridge format.

4 Figure S4. Scheme of the parallel bridge solid-phase approach performed in the micro-sized wells embedded in the DVD disc (physically isolated micro-reactors). FP: forward primer; RP: reverse primer; DIG-product: digoxigenin-labeled product.

b) Immobilization mode of primers. The amplification process on solid supports greatly depends on the immobilization density of the primer.(7)(8) An indirect adsorption mode was chosen based on streptavidin/biotin recognition with no previous surface treatment or blocking steps. Coating conditions were optimized by varying the streptavidin concentration from 5 to 20 ppm, and the biotinilated-primer concentration from 50 to 400 nM. The strongest signal was obtained for a primer concentration of 200 nM, which yielded a density of 1.2 fmol/mm2 (Figure S5).

5 Figure S5. Effect of coating conditions (streptavidin and primer concentration) on signal intensity. Results from the amplification of the p35S gene from Bt-11 maize at 1%.

Higher concentrations led a reduced signal, probably due to steric hindrance, which can reduce the hybridization of DNA in solution and/or the attachment of the DNA polymerase to tethered oligonucleotides.(8)(9) Immobilization density was higher than others reported for conventional solid-phase RPA performed on polycarbonate surfaces (0.3-0.6 fmol·mm-2).(4)(10) This can be explained by the higher bridge sp-RPA densities required to allow the formation of bridges between immobilized primers.(11) The streptavidin/biotin immobilized primers were resistant to the microfluidic flow achieved by disc rotation.

(c) Addition of blocking reagents. Non specific adsorptions were studied in relation to the wall effects of reaction vessels and the addition of blocking agents. Regarding the first factor, the developed microfluidic structure had a surface-to-volume ratio of 5 nm-1 and 7 nm-1 for channels and microwells, respectively. These values were the same order of magnitude as those obtained for a 10 µL reaction performed in a standard PCR tube (0.002 µm -1), and were significantly lower (~ 100 times) than those obtained in other microfluidic devices, in which considerable surface adsorption of reagents (DNA and proteins) has been reported.(12)

Addition of BSA (0.5%), PEG (1%) or Denhardt’s reagent (2.5×) was also studied to prevent non specific adsorptions. The presence of these additives in reaction mixtures did not increase the measured signal in any case (ANOVA, p-value>0.05). These results are in agreement with those obtained in other DNA assays on PC surfaces, where non specific adsorption was also negligible.(10)(13) Therefore, both microfluidic design and DVD composition minimizes the surface adsorption effect. d) Developing conditions. Different strategies were evaluated for developing the amplification products formed in the micro-sized wells and the latter detection by the DVD drive. The developed analytical platform enabled the laser beam transmitted through wells to be read. Therefore, the developing immunoenzymatic reaction was done in both homogeneous (liquid) and heterogeneous (solid) formats, and a detectable product formed in both cases. The signal variations in laser intensity (λ=650) during disc scanning were 2.36 ± 0.17 a.u. and 0.59 ± 0.05 a.u., respectively. The differences observed between formats (t-test: p- value<0.01) were probably caused by the precipitate of the heterogeneous format not being

6 absorbed enough to withstand washing flows. Therefore, the enzymatic reaction in the homogeneous format was selected for the proposed approach.

REFERENCES

[1] Morais S, Tamarit-López J, Carrascosa J, Puchades R, Maquieira A (2008) Analytical prospect of compact disk technology in immunosensing, Anal Bioanal Chem 391: 2837-2844 [2] Li G, Chen Q, Li J, Hu X, Zhao J (2010) A compact disk-like centrifugal microfluidic system for high-throughput nanoliter-scale protein crystallization screening, Anal Chem 82: 4362-4369 [3] Blanco-Gomez G, Glidle A, Flendrig LM, Cooper JM (2009) Integration of low- power microfluidic pumps with biosensors within a laboratory-on-a-chip device, Anal Chem 81: 1365-1370 [4] Tortajada-Genaro LA, Santiago-Felipe S, Amasia M, Russom A, Maquieira A (2015) Isothermal solid-phase recombinase polymerase amplification on microfluidic digital versatile discs (DVDs), RSC Adv 5: 29987-29995 [5] Liu Y, Ganser D, Schneider A, Liu R, Grodzinski P, Kroutchinina N (2001) Microfabricated polycarbonate CE devices for DNA analysis, Anal Chem 73: 4196-4201 [6] Kersting S, Rausch V, Bier FF, von Nickisch-Rosenegk M (2014) Multiplex isothermal solid-phase recombinase polymerase amplification for the specific and fast DNA- based detection of three bacterial pathogens, Microchim Acta 181: 1715-1723 [7] Tillib SV, Strizhkov BN, Mirzabekov AD (2001) Integration of multiple PCR amplifications and DNA mutation analyses by using oligonucleotide microchip, Anal Biochem 292: 155-160 [8] Palanisamy R, Connolly AR, Trau M (2010) Considerations of solid-phase DNA amplification, Bioconjugate Chem 21: 690-695 [9] Carmon A, Vision YJ, Mitchell SE, Thannhauser TW, Muller U, Kresovich S (2002) Solid-phase PCR in microwells: effects of linker length and composition on tethering, hybridization, and extension, BioTechniques 32: 410-421 [10] Santiago-Felipe S, Tortajada-Genaro LA, Morais S, Puchades R, Maquieira A (2014) One-pot isothermal DNA amplification–Hybridisation and detection by a disc-based method, Sensor Actuat B-Chem 204: 273-281 [11] Shapero MH, Leuther KK, Nguyen A, Scott M, Jones KW (2001) SNP genotyping by multiplexed solid-phase amplification and fluorescent minisequencing, Genome Res 11: 1926-1934

7 [12] Hoffmann J, Trotter M, von Stetten F, Zengerle R, Roth G (2012) Solid-phase PCR in a picowell array for immobilizing and arraying 100000 PCR products to a microscope slide, Lab Chip 12: 3049-3054 [13] Wang Z, Li RX (2007) Fabrication of DNA micropatterns on the polycarbonate surface of compact discs, Nanoscale Res Lett 2: 69-74

8