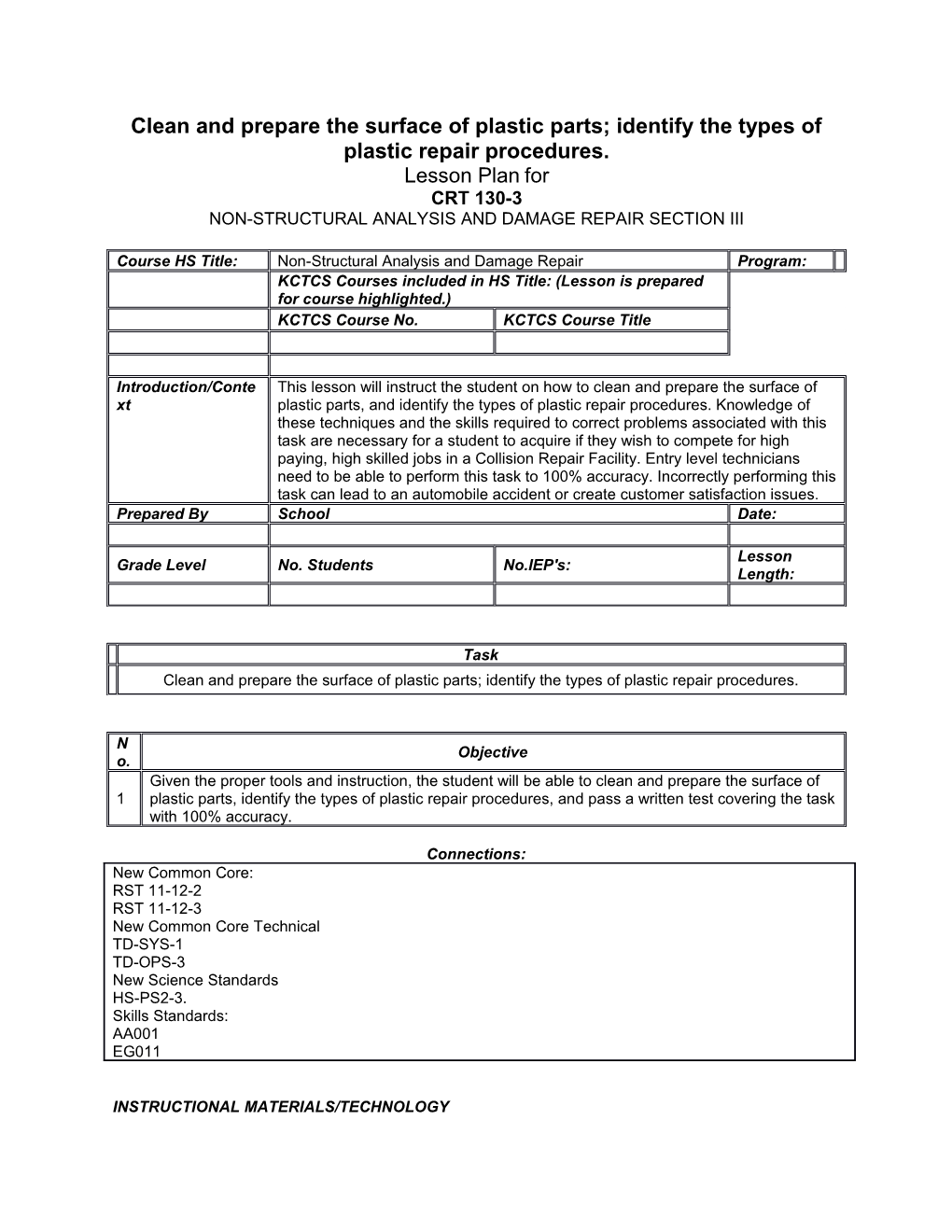

Clean and prepare the surface of plastic parts; identify the types of plastic repair procedures. Lesson Plan for CRT 130-3 NON-STRUCTURAL ANALYSIS AND DAMAGE REPAIR SECTION III

Course HS Title: Non-Structural Analysis and Damage Repair Program: KCTCS Courses included in HS Title: (Lesson is prepared for course highlighted.) KCTCS Course No. KCTCS Course Title

Introduction/Conte This lesson will instruct the student on how to clean and prepare the surface of xt plastic parts, and identify the types of plastic repair procedures. Knowledge of these techniques and the skills required to correct problems associated with this task are necessary for a student to acquire if they wish to compete for high paying, high skilled jobs in a Collision Repair Facility. Entry level technicians need to be able to perform this task to 100% accuracy. Incorrectly performing this task can lead to an automobile accident or create customer satisfaction issues. Prepared By School Date:

Lesson Grade Level No. Students No.IEP's: Length:

Task Clean and prepare the surface of plastic parts; identify the types of plastic repair procedures.

N Objective o. Given the proper tools and instruction, the student will be able to clean and prepare the surface of 1 plastic parts, identify the types of plastic repair procedures, and pass a written test covering the task with 100% accuracy.

Connections: New Common Core: RST 11-12-2 RST 11-12-3 New Common Core Technical TD-SYS-1 TD-OPS-3 New Science Standards HS-PS2-3. Skills Standards: AA001 EG011

INSTRUCTIONAL MATERIALS/TECHNOLOGY Teacher Designed Materials and Other Handouts

Textbooks and Workbooks Autho Editio Publishe Page Title/ISBN No. r n r s Variou ASE Test Prep Non Structural Analysis and Damage Repair Third Delmar 35 s

Equipment Quantity Item Source As Needed Welder Various

Content/Presentation/Demonstration Outline Instruct students that Thermoplastic parts may be welded or bonded with adhesives, and Thermoset parts should be adhesive bonded. Before repair, tell students that the part should be cleaned with soap and water, followed with a plastic cleaner. Explain that soap and water will remove water-soluble contaminants. Other nonwater-soluble contamination present on the surface will be removed by the plastic cleaner. Teach students that plastic welding uses heat and sometimes a plastic filler rod to join or repair plastic parts. Let them know that the welding of plastic is not unlike the welding of metals. Both methods use a heat source, welding rod, and similar techniques, and joints are prepared in much the same manner and evaluated for strength. Instruct students that hot air plastic welding uses a tool with an electric element to produce hot air that blows through a nozzle and melts plastic. The air supply comes from either the air compressor or a self- contained portable compressor that comes with the welding unit. Tell students that the torch is used in conjunction with the welding rod, which is normally 3/16 inch (5 mm) in diameter. Let students know that the plastic welding rod must be made of the same material as the plastic being repaired. Inform students that one problem with hot air plastic welding is that the plastic welding rod is often thicker than the panel to be welded. Explain that this can cause the panel to overheat before the rod has melted. Let them know that using a smaller diameter rod with the hot air welder can often right such warpage problems. Tell them that some hot air welder manufacturers have developed specialized welding tips and rods to meet specific needs. Have them check the product catalog for more information. Instruct students that airless plastic welding, which has become very popular, uses an electric heating element to melt a smaller diameter rod with no external air supply. Let them know that airless welding with a smaller rod helps eliminate two troublesome problems: panel warpage and excess rod buildup. Tell students to make sure the rod is the same material as the damaged plastic, or the weld will be unsuccessful. Let them know that many airless welder manufacturers provide rod application charts. When the right rod has been chosen, inform them that it is good practice to run a small piece through the welder to clean out the tip before beginning. Tell students that ultrasonic plastic welding relies on high-frequency vibratory energy to produce plastic bonding without melting the base material. Explain that handheld systems, available in 20 and 40 kHz frequencies, are equally adept at welding large parts and tight, hard-to-reach areas. Tell them welding time is controlled by the power supply. Let them know that most commonly used injection-molded plastics can be ultrasonically welded without the use of solvents, heat, or adhesives. Tell students that ultrasonic weldability depends on the plastic’s melting temperature, elasticity, impact resistance, coefficient of friction, and thermal conductivity. Inform them that generally, the more rigid the plastic, the easier it is to weld ultrasonically. Let them know that thermoplastics are ideal for ultrasonic welding, provided the welder can be positioned close to the joint area. Instruct students that in a typical ultrasonic system, the vibration is generated in the transducer and then transmitted through the sonotrode, which is the equivalent of an electrode. Tell them the sonotrode tip directly contacts the workpiece. An anvil supports the assembly. Let them know that the best results are achieved when the sonotrode tip and anvil are contoured to accommodate the specific shape of the parts being joined. Tell students that when welding plastic, single or double V-butt welds produce the strongest joints. When using a round or V-shaped welding rod, instruct them to prepare the area by slowly grinding, sanding, or shaving the adjoining surfaces to produce a single or double V. Have them wipe any dust shavings from the joint with a clean, dry rag. Let them know to not use cleaning solvents because they can soften the plastic edges and cause poor welds.

Applications/Practice 1 Refer to content

Evaluation and feedback Prior to Testing or Lab Work Objective 1. / Formative assessment / Instructor will observe students as they practice the procedure to assure correct procedure and safety practices are being followed. A checklist will be utilized to chart 1 student progress on the task. Questioning techniques will be utilized as necessary to demonstrate student comprehension / Adaptations and/or accommodations for special needs students will be added if required.

STUDENT ASSESSMENT: (Assess student progress with performance criteria.) Objective 1 / Summative assessment / written test questions on stated objective / adaptation and / or 1 accommodations for special needs students will be added if required

IMPACT--Reflection/Analysis of Teaching and Learning: (How did students’ progress in relation to the state objectives? Was the instruction successful? Analyze samples of student work particularly that which is unsatisfactory, for the purpose of planning further instruction.)

REFINEMENT--Lesson Extension and Follow-up: (To be filled in as the lesson is modified during initial planning and/or during the teaching learning process.)