CE 300 AY 07-1 (Distance Education Pilot Project) 17 October 2006

PROBLEM SET #7 (50 points)

Due on the scheduled date for Lesson 26

1. (25 Points) Tributary Area and Frame Analysis

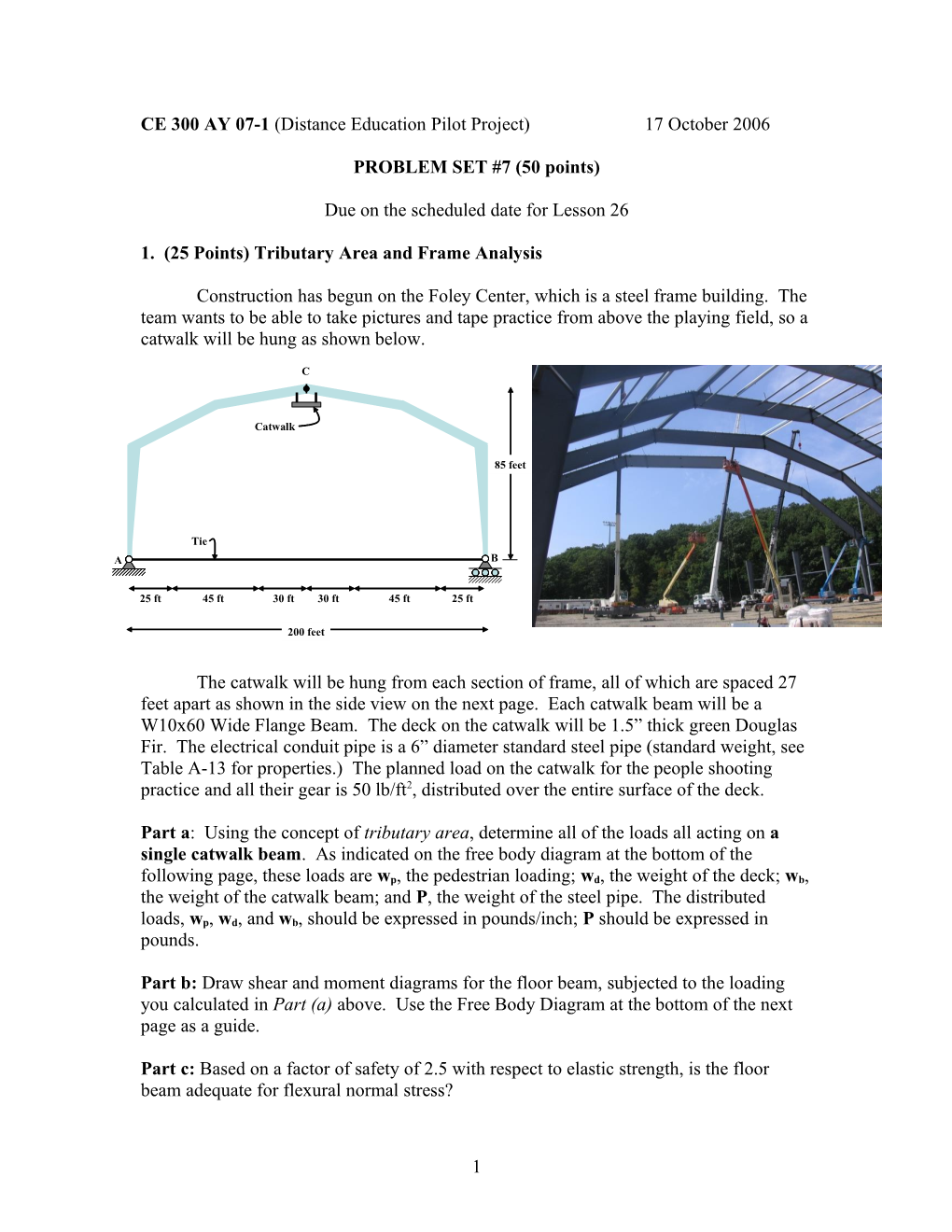

Construction has begun on the Foley Center, which is a steel frame building. The team wants to be able to take pictures and tape practice from above the playing field, so a catwalk will be hung as shown below.

C

Catwalk

85 feet

Tie A B

25 ft 45 ft 30 ft 30 ft 45 ft 25 ft

200 feet

The catwalk will be hung from each section of frame, all of which are spaced 27 feet apart as shown in the side view on the next page. Each catwalk beam will be a W10x60 Wide Flange Beam. The deck on the catwalk will be 1.5” thick green Douglas Fir. The electrical conduit pipe is a 6” diameter standard steel pipe (standard weight, see Table A-13 for properties.) The planned load on the catwalk for the people shooting practice and all their gear is 50 lb/ft2, distributed over the entire surface of the deck.

Part a: Using the concept of tributary area, determine all of the loads all acting on a single catwalk beam. As indicated on the free body diagram at the bottom of the following page, these loads are wp, the pedestrian loading; wd, the weight of the deck; wb, the weight of the catwalk beam; and P, the weight of the steel pipe. The distributed loads, wp, wd, and wb, should be expressed in pounds/inch; P should be expressed in pounds.

Part b: Draw shear and moment diagrams for the floor beam, subjected to the loading you calculated in Part (a) above. Use the Free Body Diagram at the bottom of the next page as a guide.

Part c: Based on a factor of safety of 2.5 with respect to elastic strength, is the floor beam adequate for flexural normal stress?

1 Hangers A

Catwalk

A

27’ 27’ 27’ 27’ 27’ 27’ 27’ 27’ Side View

T1 T2

Catwalk Beam Hanger

Deck

6” 6” 24” 6” 6”

Section A-A Electrical Conduit Pipe

2 wp= pedestrian Loading

wd= self-weight of deck

wb= self-weight of catwalk beam

P = weight of electrical T1 P T2 conduit pipe

24” 6” 6” 6” 6” Free Body Diagram of Catwalk Beam

3 2. (25 Points) Beam Analysis and Design

You have been asked to help with the design of the latest air support jet fighter. The loads due to lift (a uniform load from A to B and a triangular load from B to C) and the weight of the engine have already been determined as shown in the figure below.

300 lb/ft

A B

C

12 ft 24 ft

3000 lb

The engineers you are working with have told you to model all the loads on the wing as being carried by one T beam.

Wing Cross Section

Part a. Draw the shear and moment diagrams for the loading on the wing.

Part b. One of the planners suggests using the Tee Beam shown to the 8” right for the wing. Based on a Factor of Safety of 3 with respect to the elastic strength, will the section below be adequate for flexural normal 1” stress if the beam will be made out of 2024-T4 Aluminum?

Part c. The budget folks say that to manufacture these beams will add excessive cost to the project. Design the least expensive Structural Steel 9” (A36) Structural Tee Beam (see Table A-11). Use a Factor of Safety of 3 with respect to the elastic strength.

0.5” 4