Information contained herein is based on careful investigation and is intended for information only. User is obliged to test the suitability of the products for their particular use. Supplier may change any specifications without notice.

2007 HS Compliant Scratch Resistant Clear – low solvent content Retaining an ability to re-flow, even after curing.

The EU Limit value for this product (product category IIB c) in ready for use form is max 540g/litre of VOC. The VOC content of this product in ready for use form is. 600g/l- 2004/42/IIB(c)(840)600

A) Product description – 2007 2-pack Compliant Clear – high solids, high functionality at low viscosity For application ranging from the repair of individual panels to overall re-sprays. Solid content 45.5% by weight (RFU) – Excellent flow, gloss and DOI NB Always check substrate before application

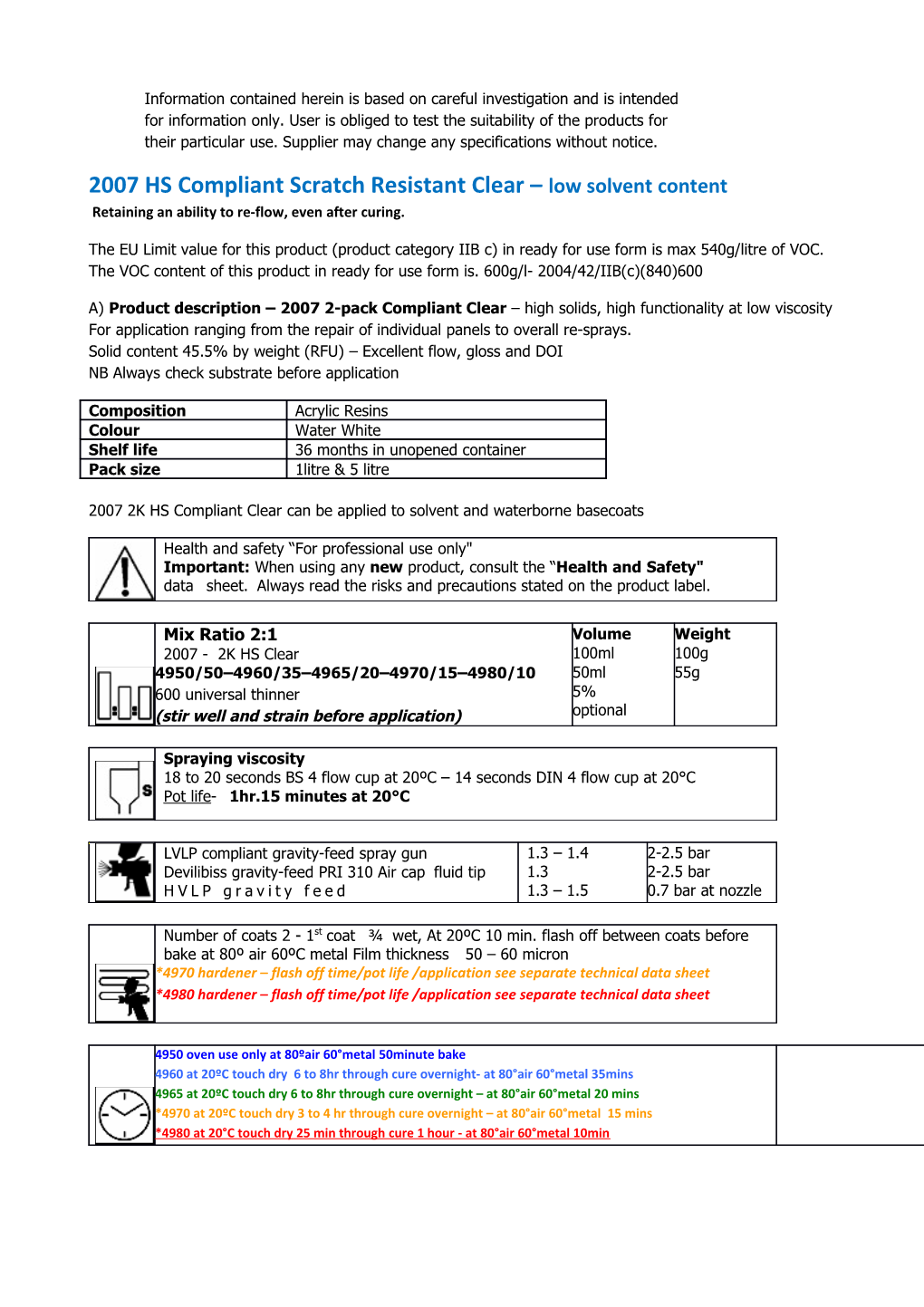

Composition Acrylic Resins Colour Water White Shelf life 36 months in unopened container Pack size 1litre & 5 litre

2007 2K HS Compliant Clear can be applied to solvent and waterborne basecoats

Health and safety “For professional use only" Important: When using any new product, consult the “Health and Safety" data sheet. Always read the risks and precautions stated on the product label.

Mix Ratio 2:1 Volume Weight 2007 - 2K HS Clear 100ml 100g 4950/50–4960/35–4965/20–4970/15–4980/10 50ml 55g 600 universal thinner 5% (stir well and strain before application) optional

Spraying viscosity 18 to 20 seconds BS 4 flow cup at 20ºC – 14 seconds DIN 4 flow cup at 20°C Pot lif e- 1hr.15 minutes at 20°C

9 LVLP compliant gravity-feed spray gun 1.3 – 1.4 2-2.5 bar Devilibiss gravity-feed PRI 310 Air cap fluid tip 1.3 2-2.5 bar H V L P g r a v i t y f e e d 1.3 – 1.5 0.7 bar at nozzle

Number of coats 2 - 1st coat ¾ wet, At 20ºC 10 min. flash off between coats before bake at 80º air 60ºC metal Film thickness 50 – 60 micron *4970 hardener – flash off time/pot life /application see separate technical data sheet *4980 hardener – flash off time/pot life /application see separate technical data sheet

4950 oven use only at 80ºair 60°metal 50minute bake 4960 at 20ºC touch dry 6 to 8hr through cure overnight- at 80°air 60°metal 35mins 4965 at 20ºC touch dry 6 to 8hr through cure overnight – at 80°air 60°metal 20 mins *4970 at 20ºC touch dry 3 to 4 hr through cure overnight – at 80°air 60°metal 15 mins *4980 at 20°C touch dry 25 min through cure 1 hour - at 80°air 60°metal 10min