ECE 477 Digital Systems Senior Design Project Rev 8/09

Homework 4: Packaging Specifications and Design

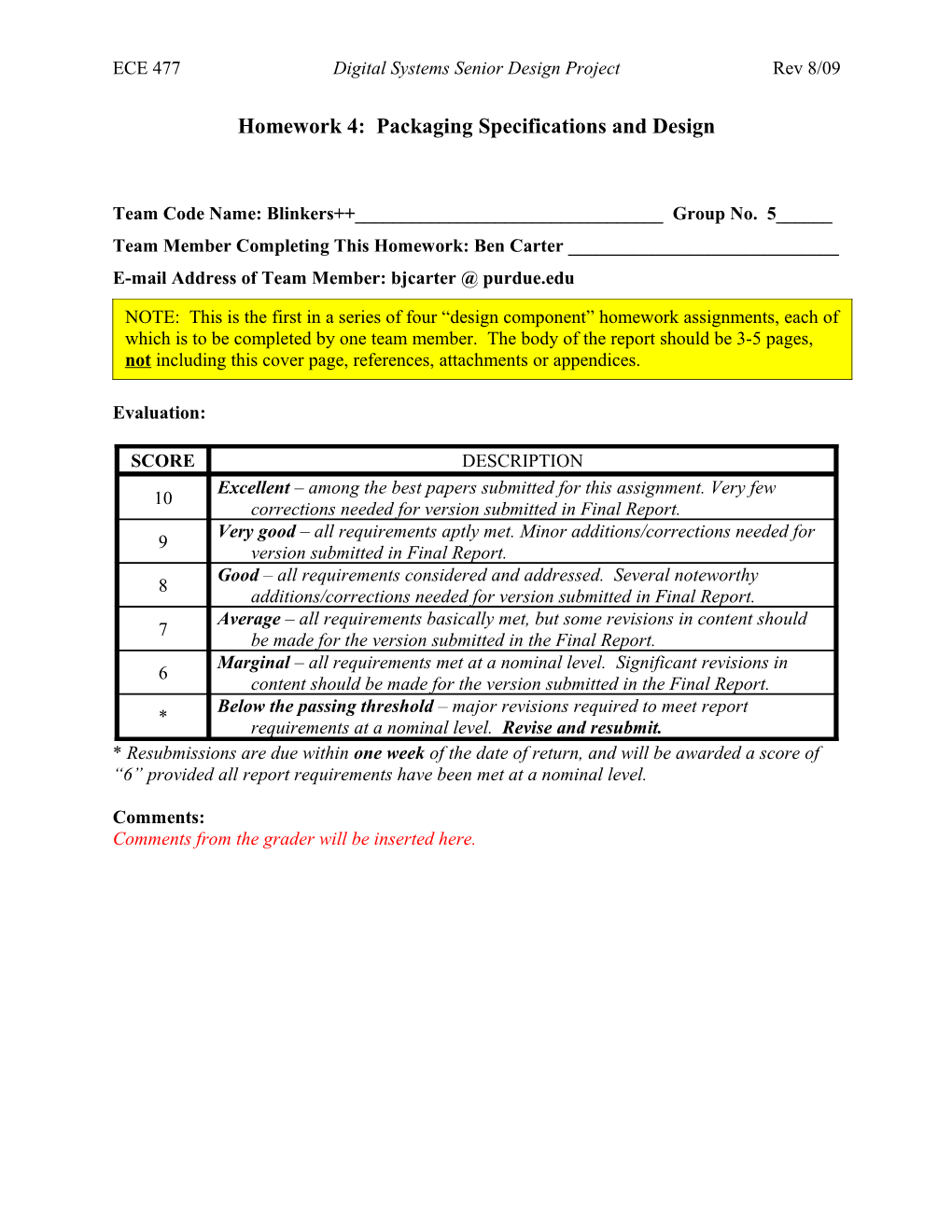

Team Code Name: Blinkers++______Group No. 5______Team Member Completing This Homework: Ben Carter ______E-mail Address of Team Member: bjcarter @ purdue.edu

NOTE: This is the first in a series of four “design component” homework assignments, each of which is to be completed by one team member. The body of the report should be 3-5 pages, not including this cover page, references, attachments or appendices.

Evaluation:

SCORE DESCRIPTION Excellent – among the best papers submitted for this assignment. Very few 10 corrections needed for version submitted in Final Report. Very good – all requirements aptly met. Minor additions/corrections needed for 9 version submitted in Final Report. Good – all requirements considered and addressed. Several noteworthy 8 additions/corrections needed for version submitted in Final Report. Average – all requirements basically met, but some revisions in content should 7 be made for the version submitted in the Final Report. Marginal – all requirements met at a nominal level. Significant revisions in 6 content should be made for the version submitted in the Final Report. Below the passing threshold – major revisions required to meet report * requirements at a nominal level. Revise and resubmit. * Resubmissions are due within one week of the date of return, and will be awarded a score of “6” provided all report requirements have been met at a nominal level.

Comments: Comments from the grader will be inserted here. ECE 477 Digital Systems Senior Design Project Rev 8/09

1.0 Introduction Blinkers++ is a device designed to increase the quality and quantity of inter-car communication. Because one of its intended qualities is being intuitive, the packaging for the device will need to be simple to understand as well as unobtrusive. The packaging for the device will consist in two main portions, the user interface and the LED output. The user interface for the device will be housed in a box containing the PCB with all of the capacitive touch inputs printed on it, an antenna for transmitting the output directions to the LED output module, and all the processing circuitry for the multiple touch signal processor. The LED output for Blinkers++ will be placed on a radio controlled car for demonstration purposes. There will be two types of PCBs for the LED output. The LED Controller PCB will receive the data from the user input module and instruct the LED drivers over an I2C interface. The LED Panel PCB will consist of 5 tri-color on perfboard. The plan is to mount the 14 LED Panel PCBs on the exterior of the RC car and keep the LED Controller PCB inside the body of the car. There will be wires from inside to out to connect the LED Panel PCBs with the controller, as well as supply the LED driver chips with power.

2.0 Commercial Product Packaging Because Blinkers++ is a relatively unexplored usage of multi-touch inputs for vehicle communication, there exist few products that significantly reflect all the major qualities of our design. However, there have been several practical attempts to address the issue of more dynamic inter-car communication. The Scrolling LED Panel and the Animated Driving LED Emoticon will be examined.

2.1 Product #1 One product that uses LEDs for inter-car communication is the StreetGlow Scrolling LED Panel [1]. This device can be mounted on the cars exterior on the license plate, or on any interior surface such as a car or window. The user can control the device with a wireless remote. The Scrolling LED Panel displays messages with obvious communicative value, but is not as universally beneficial as Blinkers++. The scrolling panel of English words precludes some observers from understanding what is being communicated. Furthermore, while up to five

-2- ECE 477 Digital Systems Senior Design Project Rev 8/09 messages can be programmed into the Streetglow Scrolling LED Panel, the panel cannot be quickly reprogrammed to accommodate new messages and cannot be directed towards a specific angle for targeted communication. The device is enclosed in molded plastic which is perhaps the most preferable type of enclosure for an inter-car communication system. Because we are prototyping our LED output on an RC car, we will be using the plastic body of our car to house the LEDs. While the StreetGlow will cost approximately $85, when comparing it to Blinkers++, one should remember that Blinkers++ offers multiple touch input, a technology that can cost up to $1000 for development kits.

2.2 Product #2 Another product that can be classified as an inter-car communication system is the Animated Driving LED Emoticon from ThinkGeek [2]. This device uses LEDs to create faces capable of expressing emotion through smiling, winking, etc. The packaging for this device is once again molded plastic, but is intended only for interior use. As such, the device is generally depicted hanging in a rear window. The device uses a simple wireless remote that can be used to select one of 5 different faces. The drawbacks to a device like this are that while expressing

-3- ECE 477 Digital Systems Senior Design Project Rev 8/09 emotions is useful, it cannot easily and clearly express intended directions to other drivers, a sector of inter-car communication that Blinkers++ hopes to augment.

3.0 Project Packaging Specifications The packaging for Blinkers++ will be comprised of a user input module, and an LED output module. The user input module will be housed in an 8”x8”x1” box. This box will be responsible for user input on the capacitive touch array, processing the input data, and then informing the LED cluster controller of the pattern it needs to output. The touch array will be printed on a PCB, of which a 6”x6” area designated for the capacitive touch array will be exposed to the user. The signal processer and other circuitry will be also on this PCB, although these portions will not be as easily accessible. Mounting the PCB to the box will require some support for the relatively large PCB as well as supporting the board at a few key touch pad contact points to aid in stability during use. Our device should be used intuitively, and it should offer a durable user interface module that can handle frantic swipes and gestures. Another design consideration that must be made is the need to denote the top of the touch array, since our Blinkers++ device will be calculating direction. One proposed solution for this is to print a black and white top-view sketch of a car on the touchpad to indicate which direction on the pad maps to specific areas of the car. For the LED output, we will be using an RC car for demonstration purposes. The RC car we will be using will be about 20”x11”x6” in size as to accommodate the LED cluster circuitry. Inside the body of the RC car, we will be housing our LED output PCB, as well as 70 tri-color LEDs. The LED output PCB will have header pins to connect to each of the LEDs with wire. The LEDs will be placed around the exterior of the car through holes we will need to drill in the

-4- ECE 477 Digital Systems Senior Design Project Rev 8/09 car’s exterior. As the design stands, the front and back will each have 13 LEDs while the sides will have 22 LEDs apiece.

4.0 PCB Footprint Layout Our main PCB will be housed in the user input module, which reads and interprets multiple touch inputs. The board will be two layer, with the top layer being exposed to the user. The user will have access to the capacitive touch array, and will be able to view the 20 surface mount LEDs intended for simple user feedback. The bottom of the board will have all the controllers and processers mounted as well as other circuitry. The selection of packaging for the dsPIC33 was made primarily due to Microchip only offering the DSP in TQFP packaging [3]. The CapSense controllers have been selected to be in SSOP packaging, since the other option was QFN, which lacks the leads for easy soldering [4]. TSSOP packaging was chosen for the LED drivers, since the other option was the QFN packaging, which we are avoiding. In laying out the preliminary PCB, two specifications guided the placement of parts on the user input PCB, which will contain the capacitive touch array and gesture recognition chip. The most significant PCB consideration made was the need for the CapSense controller chips to be close in proximity to the input pads they are controlling. By reducing the physical proximity, the traces will be shorter and noise on the lines will be reduced. Another consideration made was to place the LED drivers in close proximity to the LEDs they control on the other side of the board. The LED drivers are situated under the LEDs for simplicity of design and construction. With regards to the LED output PCB, we will be restricted by the 60in2 PCB allotment. As such, our LED output PCB will be limited to approximately 11in2. We designed a 70x100mm (2.8x3.9in) board that will contain 14 LED driver chips, a PIC18, a linear voltage regulator, and 224 header pins used to drive the LEDs [5, 6]. Additionally, the accelerometer chip will be included on the PCB [7]. The RF receiver will also be included [8]. The spacing is admittedly tight, so the team is exploring other avenues to handle issue of limited PCB space.

5.0 Summary

-5- ECE 477 Digital Systems Senior Design Project Rev 8/09

In this report, Blinkers++’s packaging design is laid in a series of scaled drawings, written descriptions, and a parts table. Because Blinkers++ is a proof of concept project, many of the packaging constraints present in a marketable product have not been addressed, including weatherproofing and full size car mounting. As such, the Blinkers++ design will mainly be composed of the user interface box containing the multiple-touch input system, and the RC car containing the LED output circuitry.

-6- ECE 477 Digital Systems Senior Design Project Rev 8/09

List of References

[1] StreetGlow, “SGLSCR - SCROLLING LED PANEL,” http://www.streetglow.com/SGLSCR#, [Accessed Sept. 23, 2009]

[2] ThinkGeek, “Animate Driving LED Emoticon,” http://www.thinkgeek.com/gadgets/car/aa16/, [Accessed Sept. 23, 2009]

[3] Microchip Inc. “High Performance, 16-bit Digital Signal Controllers,” dsPIC33FJXXXMCX06/X08/X10 datasheet, Jul 2007 [Revised Mar. 2009]

[4] Cypress Semiconductors. “CapSense Applications,” CY8C20x36/46/66/96 datasheet, Oct 2008 [Revised July 2009]

[5] Texas Instruments, “16-Channel Fm+ I2C-Bus Constant-Current LED Sink Driver,” TLC59116 datasheet, Feb. 2008 [Revised Jul. 2008]

[6] Microchip Inc. “20-Pin USB Flash Microcontrollers with nanoWatt XLP Technology,” PIC18F13K50/14K50 datasheet, May 2008 [Revised Apr. 2009]

[7] Freescale Semiconductor. “Low G Micromachined Accelerometer,” MMA1270EG datasheet, April 2007

[8] Holy Stone Enterprise Co., Ltd, “SAW Resonator Transmitter/Receiver Module,” MO- SAWR-AS315M datasheet, Jun. 2004

IMPORTANT: Use standard IEEE format for references, and CITE ALL REFERENCES listed in the body of your report.

-7- ECE 477 Digital Systems Senior Design Project Rev 8/09

Appendix A: Project Packaging Illustrations

Figure 1: User Input Module

Figure 2: LEDs on RC Car

-8- ECE 477 Digital Systems Senior Design Project Rev 8/09

Appendix B: Project Packaging Specifications Part Tool Weight Unit Cost Quantity Total cost Required Model Car Drill 10.4 ounces 16.37 1 16.37 dsPIC33FJ256GP710 Soldering Negligible 9.94 1 9.94 (DSP) tools PIC18F14K50 (LED Soldering Negligible 2.87 1 2.87 cluster controller) tools CY8C20566 Soldering Negligible 3.61 8 28.81 (Capacitive button tools controller) TLC59116 (LED Soldering Negligible 2.01 18 36.18 driver chip) tools MO-SAWR- Soldering Negligible 3.95 1 3.95 AS315M (RF tools transmitter) MO-RX3400- Soldering Negligible 4.95 1 4.95 A315M (RF tools receiver) ADXL325 Soldering Negligible 3.44 1 3.44 (accelerometer) tools SML- Soldering Negligible 0.93 70 65.10 H1505SIUBUBCTR tools (tri-color LEDs) Box(Metal) Saw 1 lb 0 1 0 Total ~1 lb 10.4oz 1 171.61

-9- ECE 477 Digital Systems Senior Design Project Rev 8/09

Appendix C: PCB Footprint Layout

Figure 3. Input touchpad PCB – user view

-10- ECE 477 Digital Systems Senior Design Project Rev 8/09

Figure 4. Input touchpad PCB – rear view

-11- ECE 477 Digital Systems Senior Design Project Rev 8/09

Figure 5. LED Driver PCB with accelerometer and receiver

-12-